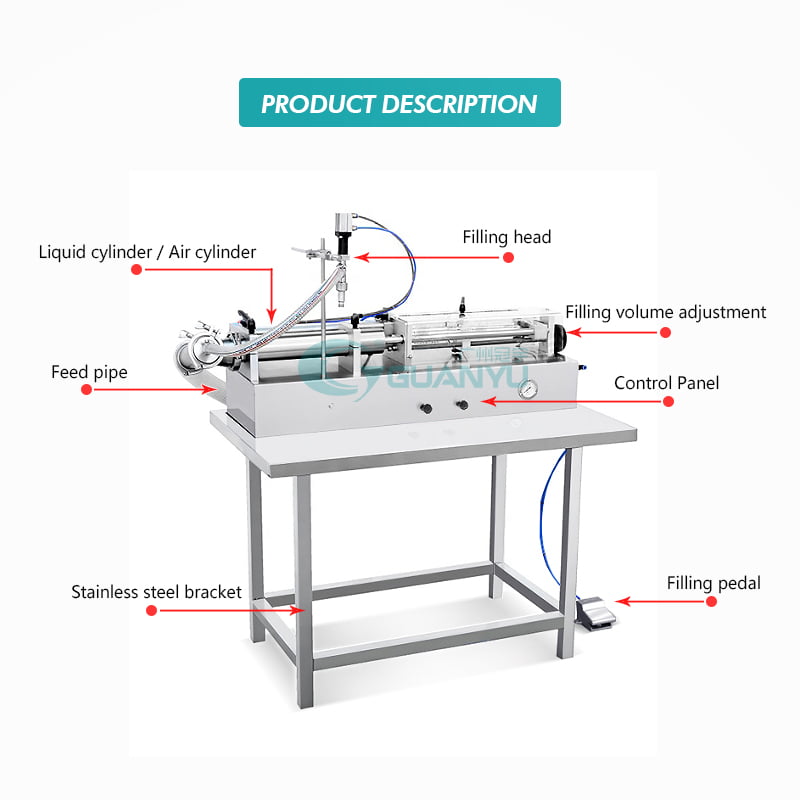

Horizontal filling machines are a vital component in the packaging and manufacturing industries, particularly for products that require precise and efficient filling into containers. These machines are designed to fill a wide variety of products, ranging from liquids and pastes to granulated materials. This article explores the applications, advantages, and disadvantages of horizontal filling machines.

Applications of Horizontal Filling Machines

Horizontal filling machines are versatile and can be used across various industries. Their applications include:

- Food and Beverage Industry:

- Sauces and Condiments: Horizontal filling machines are used to fill bottles and jars with sauces, ketchup, mustard, and other condiments. They ensure consistent product volume and prevent spillage.

- Dairy Products: These machines are ideal for filling yogurt, cream, and other dairy products into containers.

- Beverages: They are used for filling non-carbonated beverages like juices, milk, and energy drinks into bottles or cartons.

- Cosmetics Industry:

- Creams and Lotions: Horizontal filling machines are perfect for filling containers with creams, lotions, and gels, ensuring precise dosage and reducing waste.

- Liquid Soaps and Shampoos: They efficiently fill bottles with liquid soaps, shampoos, and conditioners.

- Pharmaceutical Industry:

- Medicines and Syrups: These machines are used for filling liquid medicines, syrups, and suspensions into bottles, maintaining hygiene and accuracy.

- Ointments and Creams: Horizontal filling machines are also employed for filling tubes and jars with ointments and creams.

- Chemical Industry:

- Cleaning Agents: They are used for filling containers with liquid cleaning agents, detergents, and disinfectants.

- Lubricants and Oils: Horizontal filling machines handle the filling of automotive oils, lubricants, and other chemical fluids.

Advantages of Horizontal Filling Machines

Horizontal filling machines offer several advantages that make them popular in various industries:

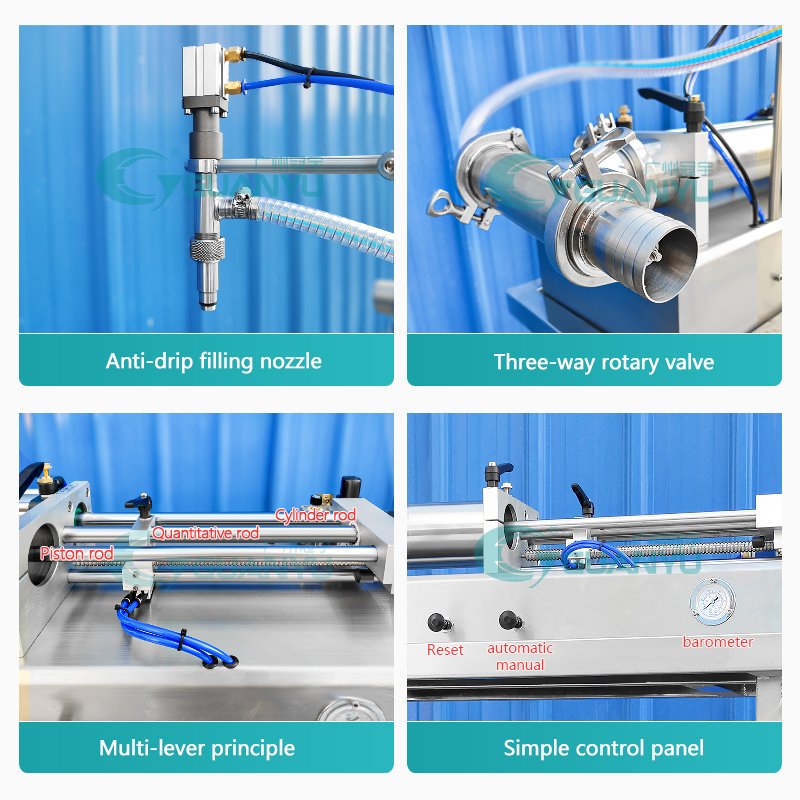

- High Precision and Accuracy:

- These machines are designed to deliver precise filling volumes, ensuring uniformity and reducing product wastage. This is especially important in industries like pharmaceuticals and cosmetics where dosage accuracy is critical.

- Versatility:

- Horizontal filling machines can handle a wide range of products, including liquids, semi-liquids, and pastes. They can be easily adjusted to fill different container sizes and types, making them suitable for various applications.

- Efficiency and Speed:

- These machines significantly increase the speed of the filling process, enhancing overall productivity. Automated features reduce the need for manual intervention, allowing for continuous and efficient operation.

- Hygiene and Cleanliness:

- Horizontal filling machines are designed with materials and components that ensure hygiene, particularly important in the food and pharmaceutical industries. Many machines come with CIP (Clean-In-Place) systems that facilitate easy cleaning and maintenance.

- Customization:

- Many horizontal filling machines offer customizable options to suit specific production requirements. This includes adjustable filling volumes, speed controls, and the ability to handle different container shapes and sizes.

- Reduction in Labor Costs:

- Automation reduces the need for manual labor, cutting down on labor costs and minimizing human error. This leads to more consistent and reliable production output.

Disadvantages of Horizontal Filling Machines

Despite their numerous benefits, horizontal filling machines also have some disadvantages:

- Initial Investment Cost:

- The initial cost of purchasing and installing horizontal filling machines can be high. This can be a significant investment for small and medium-sized enterprises. However, the long-term benefits and savings often outweigh the initial costs.

- Complexity:

- These machines can be complex to operate and maintain, requiring skilled personnel for setup, operation, and troubleshooting. Proper training is necessary to ensure efficient and safe operation.

- Maintenance Requirements:

- Horizontal filling machines require regular maintenance to ensure optimal performance. This includes cleaning, lubrication, and periodic checks of components. Maintenance can be time-consuming and may require shutting down production temporarily.

- Space Requirements:

- These machines can occupy significant floor space, which may be a constraint for smaller production facilities. Proper planning is needed to integrate them into existing production lines without causing disruptions.

- Product Compatibility:

- While horizontal filling machines are versatile, they may not be suitable for all product types. Highly viscous or abrasive products can cause wear and tear on machine components, leading to more frequent maintenance and repairs.

Conclusion

Horizontal filling machines are indispensable in various industries, offering high precision, versatility, and efficiency. They enhance productivity, maintain product hygiene, and reduce labor costs, making them a valuable investment for manufacturers. However, their high initial cost, complexity, and maintenance requirements are factors to consider before integrating them into production lines.

By understanding the applications, advantages, and disadvantages of horizontal filling machines, manufacturers can make informed decisions to optimize their production processes and achieve greater efficiency. Despite the challenges, the benefits they offer in terms of accuracy, speed, and versatility make them an essential tool in modern manufacturing and packaging operations。