Specification | Working Volume(L) | Heating Method(optional) | Dimension(L*W*H)(m) | Weight(kg) |

GYE-50 | 50 | Electric heating or steam heating | 2.6*2.4*2 | 650 |

GYE-100 | 100 | 2.8*2.5*2.2 | 850 | |

GYE-200 | 200 | 3*2.8*2.3 | 1100 | |

GYE-500 | 500 | 3.3*3*2.5 | 1500 | |

GYE-1000 | 1000 | 4.2*3.5*3.8 | 2500 |

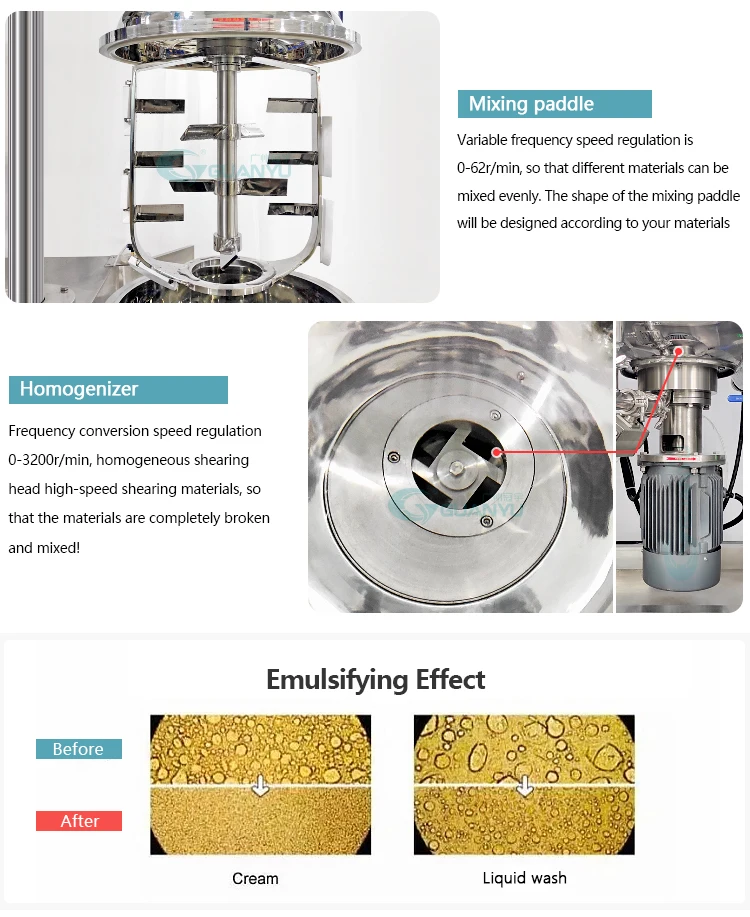

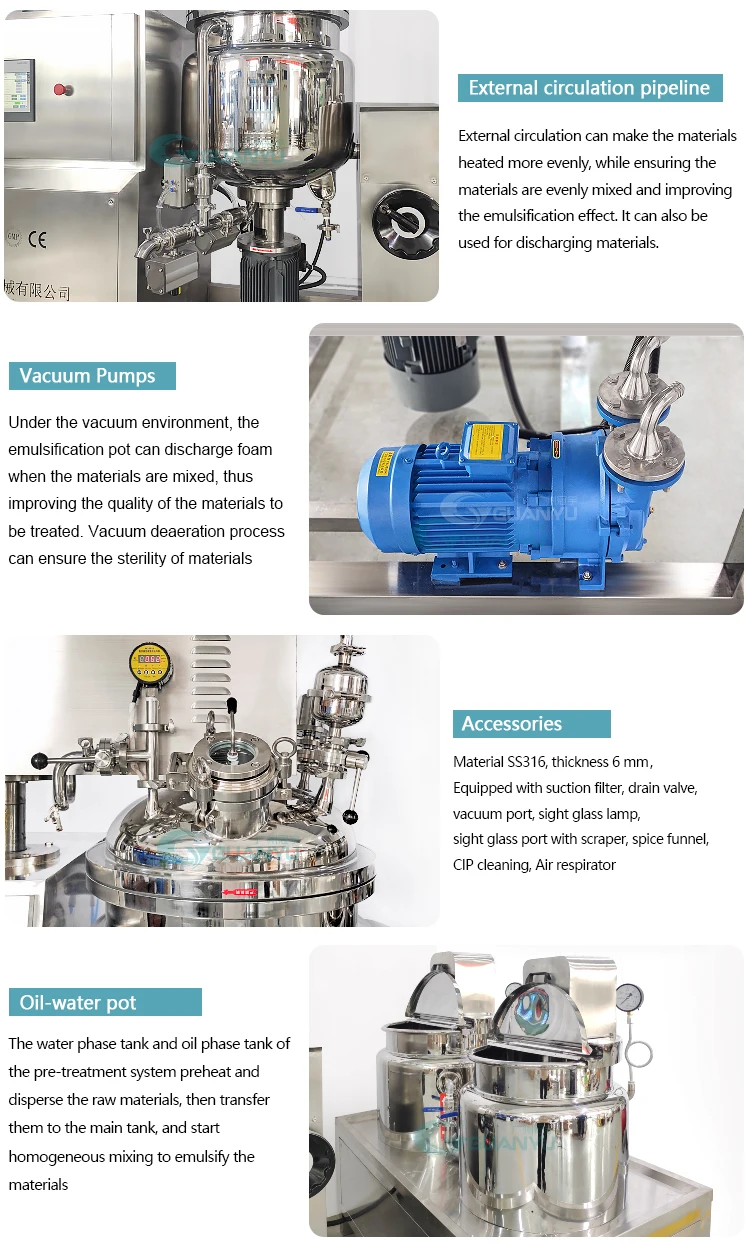

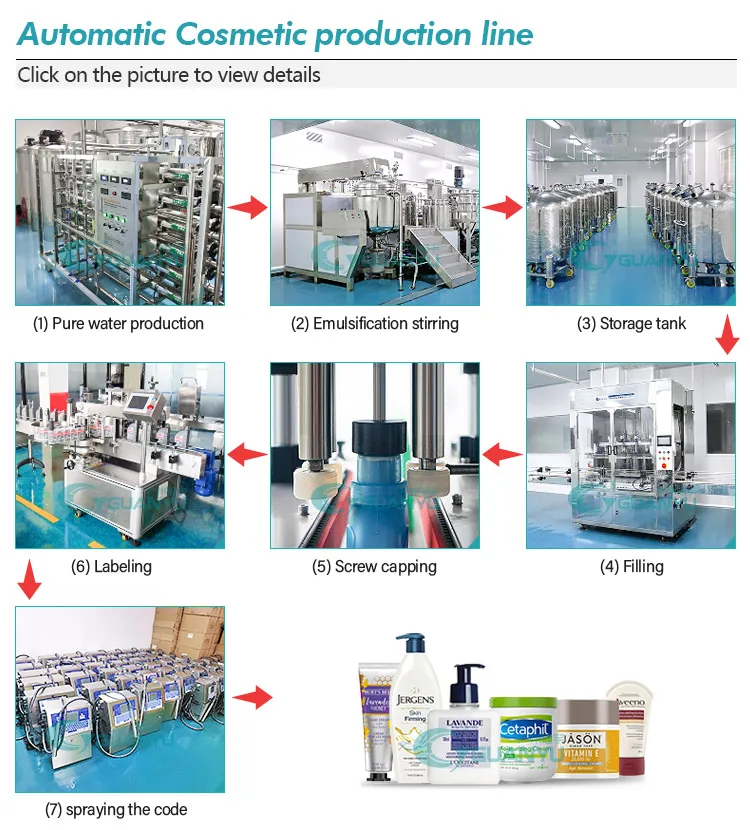

Feature1. This machine is suitable for different viscosity materials, the material viscosity range is 0~100,000 cps. 2. The main pot of the machine can be directly sucked into the material with the vacuum pump. 3. This machine can be equipped with heating function,cooling function, sealing function, online cleaning (connected to CIP cleaning system). 4. Particle grinding, emulsification,stirring, homogenization and dispersion processes can be completed in a very short time. 5. Homogenization and mixing can be operated independently. The speed can be adjusted according to the frequency converter. 6. With PLC touch screen and button control, it can be automated or semi-automated.Application industry1) Cosmetics industry: face cream, lotion, lipstick, health care products, gels, etc.

◭ Customized Machinery: Our main products include fixed vacuum emulsifying machines, mobile homogenizers, all kinds of reaction agitator kettles.

1. who are we?We are based in Jiangsu, China, start from 1997,sell to South America(20.00%),North America(15.00%),Domestic Market(15.00%),Eastern Europe(8.00%),Mid East(8.00%),Western Europe(6.00%),Central America(5.00%),Africa(5.00%),Southeast Asia(5.00%),Eastern Asia(3.00%),Oceania(3.00%),Southern Europe(3.00%),South Asia(2.00%),Northern Europe(2.00%). There are total about20-50 people in our office.2. how can we guarantee quality? First, our component/spare parts providers test their products before they offer com-ponents to us.Besides, our quality control team will test machines performance or running speed before shipment.We would like to invite you come to our factory to verify machines yourself, lf your schedule is busy,we will take a video to record the testing procedure and send the video to you.

Our warranty is one year, After warranty we still offer you lifetime after-sales service, anytime you need we are there to help. lf the problem is easily to solve, we will shoot a solution video for you. lf video doesn’t work out, we will send engineer to your factory.

Reviews

There are no reviews yet.