Definition and Main Composition of a Vacuum Emulsifier

A vacuum emulsifier is a specialized piece of equipment utilized primarily in industries such as cosmetics, pharmaceuticals, and food processing to create stable emulsions. By definition, a vacuum emulsifier operates under vacuum conditions to effectively mix and homogenize various ingredients, ensuring uniformity and consistency in the final product. This apparatus is designed to overcome the limitation

s of traditional emulsification methods by enhancing the mixing process and minimizing air incorporation, thereby producing superior emulsions.

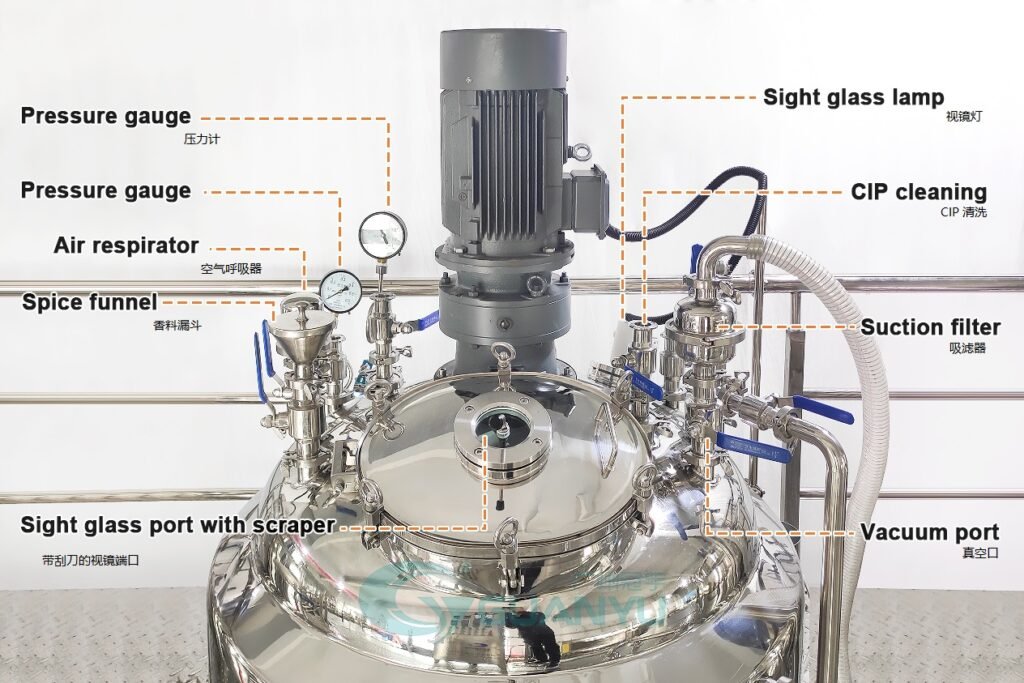

The main components of a vacuum emulsifier include the mixing system, vacuum system, heating/cooling system, and control panel. Each of these elements plays a crucial role in the emulsification process.

The mixing system is at the heart of the vacuum emulsifier, consisting of high-shear mixers and agitators. These mechanical devices work in tandem to break down and blend the ingredients at microscopic levels, ensuring a homogeneous mixture. The high-shear mixer generates intense mechanical forces that disrupt the particles, while the agitator ensures continuous movement and interaction between the components.

The vacuum system is essential for creating a controlled environment within the emulsifier. By reducing the pressure inside the mixing chamber, the vacuum system eliminates air bubbles and prevents oxidation, which can degrade the quality of the emulsion. This vacuum condition also enhances the mixing efficiency and ensures a finer dispersion of particles.

The heating/cooling system is designed to regulate the temperature within the emulsifier. Temperature control is vital for achieving optimal viscosity and stability of the emulsion. The heating function facilitates the melting and blending of ingredients, while the cooling system ensures rapid stabilization of the final product, preventing phase separation.

Lastly, the control panel provides an interface for operators to monitor and adjust the various parameters of the emulsification process. Equipped with digital displays and programmable settings, the control panel allows for precise control over the mixing speed, vacuum level, and temperature, ensuring consistent and reproducible results.

In essence, the principles of vacuum emulsification offer significant advantages over traditional methods by enhancing product quality, consistency, and shelf-life. The elimination of air bubbles and the ability to control environmental factors make vacuum emulsifiers a preferred choice in producing high-quality emulsions.

Usage and Application Fields of Vacuum Emulsifiers

Vacuum emulsifiers have become indispensable in various industries due to their efficiency and versatility in creating stable emulsions. In the pharmaceutical sector, these machines are crucial for the production of ointments, creams, and lotions. Their ability to mix ingredients uniformly and ensure a high degree of homogeneity makes them ideal for producing consistent and high-quality medicinal products. For instance, in the manufacture of topical creams, a vacuum emulsifier can blend active pharmaceutical ingredients with excipients, resulting in a smooth and effective final product.

The cosmetics industry also heavily relies on vacuum emulsifiers to produce a wide range of skincare and beauty products. Creams, lotions, and gels benefit immensely from the vacuum emulsification process, which prevents air bubbles and ensures a silky texture. The precise control over temperature and mixing speeds provided by these machines enhances the stability and shelf life of cosmetic products. A notable example is the production of anti-aging creams, where the emulsifier ensures the even distribution of active ingredients, enhancing the product’s efficacy.

In the food industry, vacuum emulsifiers are essential for creating stable emulsions in products such as sauces, dressings, and mayonnaise. These machines help maintain the desired consistency and prevent phase separation, thereby improving the product’s texture and taste. For example, in the production of salad dressings, a vacuum emulsifier ensures that oil and vinegar are thoroughly blended, resulting in a smooth and stable emulsion that appeals to consumers.

The chemical industry also benefits from vacuum emulsifing, particularly in the production of paints, coatings, and adhesives. These machines facilitate the creation of fine, stable emulsions that are crucial for the consistency and performance of these products. For instance, in paint manufacturing, a vacuum emulsifier can blend pigments and resins uniformly, resulting in a high-quality paint with excellent coverage and durability.

Finally, the emulsifying machine itself plays a vital role in the emulsification process. Technological advancements have led to the development of more efficient and reliable emulsifying machines, which offer better control over the mixing process and improved product quality. These innovations continue to support the diverse applications of vacuum emulsifiers across different industries, highlighting their importance and widespread utility.

If you have any interest, welcome to contact us.

Hi! Do you know if they make any plugins to help with Search Engine Optimization? I’m

trying to get my website to rank for some targeted keywords but I’m

not seeing very good gains. If you know of any please share.

Many thanks! I saw similar article here: Blankets

Hello there! Do you know if they make any plugins

to help with Search Engine Optimization? I’m trying to get

my blog to rank for some targeted keywords but I’m not seeing very good

gains. If you know of any please share. Thanks! I saw similar

article here: Eco bij

Likelihood is that you have played on, or at the least seen, one of the three generations of dwelling video game programs the company has created, not to mention the enormously common hand-held game system, the Gameboy.

It’s nearly impossible to find experienced people in this particular topic, however, you seem like you know what you’re talking about! Thanks

This is a topic that’s close to my heart… Take care! Exactly where are your contact details though?

Way cool! Some extremely valid points! I appreciate you writing this write-up plus the rest of the website is also really good.

After looking into a handful of the blog articles on your blog, I truly like your technique of blogging. I book marked it to my bookmark webpage list and will be checking back soon. Please visit my website as well and tell me how you feel.

Wonderful post! We are linking to this great article on our website. Keep up the good writing.

I quite like reading a post that can make people think. Also, many thanks for permitting me to comment.

Great info. Lucky me I found your site by accident (stumbleupon). I’ve bookmarked it for later!

After study several of the blog posts on your internet site now, we really such as your method of blogging. I bookmarked it to my bookmark web site list and are checking back soon. Pls look at my web site likewise and told me how you feel.

We are a group of volunteers and starting a new scheme in our community. Your web site offered us with valuable info to work on. You’ve done a formidable job and our entire community will be grateful to you.

Your style is so unique compared to other folks I have read stuff from. I appreciate you for posting when you’ve got the opportunity, Guess I will just book mark this site.

Binary options has become increasingly popular. Tradesmarter is one of the oldest binary options trading platform and is regulated as well.

it is wise to choice to select Light Emitting Diode christmas lights becaue they are not fire hazard“

Hi there, just became aware of your blog through Google, and found that it’s truly informative. I am going to watch out for brussels. I will be grateful if you continue this in future. Numerous people will be benefited from your writing. Cheers!

This is a great blog. and i want to visit this every day of the week .

Hey, just looking around some blogs, seems a pretty nice platform you are using and the theme as well. I’m currently using WordPress for a few of my sites but looking to change one of them over to a platform similar to yours as a trial run. Anything in particular you would recommend about it? Have a nice day!

Your style is unique in comparison to other folks I’ve read stuff from. Many thanks for posting when you have the opportunity, Guess I will just bookmark this page.

This will be the proper weblog if you really wants to check out this topic. You are aware of much its virtually challenging to argue along with you (not too I just would want…HaHa). You certainly put a different spin on the topic thats been written about for a long time. Excellent stuff, just wonderful!

Lovely blog! I am loving it!! Will come back again. I am bookmarking your feeds also

Your blog never ceases to amaze me, it is very well written and organized..’”.,

Celena you write in a lucid manner and I have no difficulty to understand what you have said, even though I am a novice.

I’m impressed, I have to admit. Truly rarely should i encounter a weblog that’s both educative and entertaining, and let me tell you, you’ve hit the nail about the head. Your thought is outstanding; the catch is something that there are not enough individuals are speaking intelligently about. My business is happy that I found this within my find something with this.

Having read this I believed it was rather enlightening. I appreciate you spending some time and energy to put this content together. I once again find myself spending a significant amount of time both reading and posting comments. But so what, it was still worth it.

Good blog! I truly love how it is simple on my eyes and the data are well written. I’m wondering how I might be notified whenever a new post has been made. I’ve subscribed to your RSS feed which must do the trick! Have a great day!

Thank you for each of your efforts on this web page.

Youre so cool! I dont suppose Ive read something similar to this before. So nice to get somebody by incorporating authentic applying for grants this subject. realy appreciation for starting this up. this site are some things that’s needed online, somebody after some bit originality. helpful task for bringing new things on the web!

Howdy! I’m at work surfing around your blog from my new iphone! Just wanted to say I love reading through your blog and look forward to all your posts! Carry on the outstanding work!

Oh my goodness! a fantastic article dude. Thanks However We’re experiencing issue with ur rss . Do not know why Struggle to sign up for it. Can there be anyone getting identical rss problem? Anyone who knows kindly respond. Thnkx

I love once you talk about this kind of stuff inside your posts. Perhaps might you continue this?

Your blog is amazing dude. i love to visit it everyday. very nice layout and content .”

This could be the appropriate blog for everyone who hopes to be familiar with this topic. You are aware of a great deal of its practically hard to argue along (not too I personally would want…HaHa). You definitely put a brand new spin on a topic thats been written about for several years. Great stuff, just excellent!

you use a fantastic blog here! want to earn some invite posts on my blog?

Hi. best wishes to you and your very nice blog”

This is actually exciting, You’re a highly seasoned article author. I have registered with your feed furthermore watch for witnessing your personal exceptional write-ups. Plus, We’ve shared your web blog in our social networks.

I admire the dear information you be offering for your articles. I will bookmark your weblog and feature my kids check up right here generally. I’m moderately certain they’ll be informed numerous new stuff right here than anybody else!

I have been exploring for a little bit for any high quality articles or blog posts in this sort of space . Exploring in Yahoo I eventually stumbled upon this web site. Studying this info So i am happy to express that I’ve an incredibly just right uncanny feeling I found out just what I needed. I such a lot for sure will make sure to do not fail to remember this site and provides it a look a relentless basis.

Good site! I truly love how it is easy on my eyes and the data are well written. I am wondering how I could be notified whenever a new post has been made. I’ve subscribed to your feed which must do the trick! Have a great day!

Hey there just wanted to give you a quick heads up. The words in your article seem to be running off the screen in Safari. I’m not sure if this is a format issue or something to do with web browser compatibility but I figured I’d post to let you know. The style and design look great though! Hope you get the problem solved soon. Thanks

That is a very good tip particularly to those new to the blogosphere. Simple but very precise info… Appreciate your sharing this one. A must read article.

An attention-grabbing dialogue is price comment. I believe that it is best to write more on this matter, it might not be a taboo topic but usually people are not sufficient to talk on such topics. To the next. Cheers

Wonderful web site. Lots of useful info here. I’m sending it to several friends ans also sharing in delicious. And of course, thanks for your effort!

There may be noticeably a bundle to find out about this. I assume you made certain good points in options also.

The the very next time Someone said a blog, I hope it doesnt disappoint me as much as this place. Come on, man, Yes, it was my choice to read, but I actually thought youd have something interesting to express. All I hear is actually a few whining about something that you could fix when you werent too busy in search of attention.

Thanks for your blog post. I would also like to say that the health insurance broker also works well with the benefit of the coordinators of a group insurance policy. The health insurance agent is given a listing of benefits searched for by individuals or a group coordinator. What a broker may is look for individuals or perhaps coordinators which usually best match up those requirements. Then he provides his ideas and if both parties agree, the actual broker formulates a contract between the two parties.

Have you tried twitterfeed on your blog, i think it would be cool.::;,~

I’ve read much confusing information on this topic and have been disappointed in the content. Your article makes this information clear and easy to understand.

I have been absent for a while, but now I remember why I used to love this blog. Thanks, I’ll try and check back more frequently. How frequently you update your web site?

There couple of fascinating points at some point in this posting but I don’t determine if them all center to heart. There may be some validity but I’ll take hold opinion until I investigate it further. Excellent write-up , thanks and that we want much more! Added to FeedBurner also

Thanks, I’ve recently been seeking for facts about this topic for ages and yours is the best I’ve found so far.

Woh I like your blog posts, bookmarked ! .

Aw, this was a really nice post. Taking the time and actual effort to make a good article… but what can I say… I hesitate a lot and never seem to get nearly anything done.

Very good article. I am experiencing some of these issues as well..

This site was… how do I say it? Relevant!! Finally I have found something which helped me. Kudos.

This is a topic that is near to my heart… Thank you! Where are your contact details though?

Good article! We will be linking to this particularly great post on our site. Keep up the great writing.

A motivating discussion is definitely worth comment. I believe that you should write more about this subject, it might not be a taboo matter but typically people don’t discuss such issues. To the next! All the best.

Hi there! This article couldn’t be written any better! Reading through this post reminds me of my previous roommate! He constantly kept talking about this. I will send this article to him. Fairly certain he’s going to have a very good read. Thanks for sharing!

Hey there! I simply want to offer you a big thumbs up for the excellent information you have here on this post. I am coming back to your web site for more soon.

I quite like reading through a post that can make people think. Also, thanks for allowing for me to comment.

You need to be a part of a contest for one of the best websites on the net. I will highly recommend this blog!

I like looking through an article that will make men and women think. Also, thanks for permitting me to comment.

Pretty! This has been an extremely wonderful article. Thanks for providing these details.

Saved as a favorite, I like your blog.

I would like to thank you for the efforts you’ve put in writing this website. I’m hoping to check out the same high-grade blog posts from you in the future as well. In fact, your creative writing abilities has encouraged me to get my own, personal blog now 😉

Oh my goodness! Awesome article dude! Thank you, However I am encountering problems with your RSS. I don’t understand why I am unable to join it. Is there anybody else having similar RSS problems? Anyone that knows the answer can you kindly respond? Thanx.

Hi, I do think this is a great web site. I stumbledupon it 😉 I am going to return yet again since i have book-marked it. Money and freedom is the best way to change, may you be rich and continue to guide others.

I’d like to thank you for the efforts you have put in writing this site. I really hope to see the same high-grade content from you in the future as well. In fact, your creative writing abilities has encouraged me to get my very own site now 😉

Hello there, There’s no doubt that your website may be having web browser compatibility problems. When I look at your site in Safari, it looks fine but when opening in Internet Explorer, it has some overlapping issues. I just wanted to provide you with a quick heads up! Other than that, excellent site.

These are all concerns that you need to keep in mind when selecting a malpractice lawyer. Law firms are increasingly looking to off shoring and other solutions to reduce costs.

Your style is so unique compared to other folks I’ve read stuff from. I appreciate you for posting when you’ve got the opportunity, Guess I will just bookmark this site.

This excellent website definitely has all of the information I needed about this subject and didn’t know who to ask.

Hi! I could have sworn I’ve visited this blog before but after going through many of the articles I realized it’s new to me. Anyways, I’m certainly pleased I came across it and I’ll be book-marking it and checking back regularly!

You need to get upset! Really its a must to take a look past everything and get upset. Generally this will allow you to take the inititive to make things happen.

There’s certainly a great deal to find out about this subject. I really like all the points you made.

You have made some good points there. I checked on the internet to learn more about the issue and found most people will go along with your views on this site.

Awesome read , I’m going to spend more time researching this subject

I really appreciate this post. I have been looking everywhere for this! Thank goodness I found it on Bing. You’ve made my day! Thx again!

This website definitely has all the info I needed concerning this subject and didn’t know who to ask.

Good post. I learn something new and challenging on blogs I stumbleupon on a daily basis. It’s always interesting to read through content from other writers and use a little something from other websites.

Wonderful article! We are linking to this great content on our site. Keep up the great writing.

Hmm it seems like your website ate my first comment (it was super long) so I guess I’ll just sum it up what I had written and say, I’m thoroughly enjoying your blog. I as well am an aspiring blog blogger but I’m still new to everything. Do you have any tips and hints for novice blog writers? I’d certainly appreciate it.

Howdy! I could have sworn I’ve been to this website before but after going through many of the articles I realized it’s new to me. Anyhow, I’m certainly happy I came across it and I’ll be book-marking it and checking back regularly!

I quite like reading through a post that can make people think. Also, many thanks for allowing for me to comment.

This is a great blog and i want to visit this every day of the week ,

Very good article. I absolutely appreciate this site. Stick with it!

Howdy, I do believe your blog may be having web browser compatibility problems. When I take a look at your web site in Safari, it looks fine however, when opening in Internet Explorer, it’s got some overlapping issues. I simply wanted to provide you with a quick heads up! Aside from that, wonderful site!

Spot on with this write-up, I seriously think this site needs a lot more attention. I’ll probably be back again to read through more, thanks for the info.

I like looking through a post that can make people think. Also, many thanks for allowing me to comment.

Greetings! Very useful advice in this particular article! It’s the little changes that will make the most significant changes. Thanks a lot for sharing!

Way cool! Some very valid points! I appreciate you writing this write-up plus the rest of the website is very good.

I blog quite often and I truly thank you for your content. The article has really peaked my interest. I will take a note of your website and keep checking for new information about once per week. I subscribed to your Feed as well.

Excellent post. I certainly love this website. Keep it up!

Hi, I do think this is an excellent web site. I stumbledupon it 😉 I will come back once again since i have bookmarked it. Money and freedom is the greatest way to change, may you be rich and continue to help others.

Can I simply just say what a comfort to discover a person that truly understands what they’re discussing online. You definitely realize how to bring a problem to light and make it important. A lot more people should look at this and understand this side of your story. I was surprised that you aren’t more popular because you most certainly possess the gift.

Hi, I do believe this is a great site. I stumbledupon it 😉 I am going to come back once again since I bookmarked it. Money and freedom is the greatest way to change, may you be rich and continue to help other people.

Greetings! Very useful advice within this post! It is the little changes that produce the most important changes. Thanks for sharing!

Having read this I believed it was really informative. I appreciate you taking the time and effort to put this article together. I once again find myself personally spending a lot of time both reading and commenting. But so what, it was still worth it!

Excellent site you have got here.. It’s hard to find excellent writing like yours nowadays. I really appreciate individuals like you! Take care!!

I must thank you for the efforts you have put in writing this site. I really hope to see the same high-grade blog posts from you later on as well. In fact, your creative writing abilities has motivated me to get my own, personal site now 😉

Great site you have here.. It’s hard to find high quality writing like yours these days. I honestly appreciate individuals like you! Take care!!

Greetings! Very useful advice in this particular post! It is the little changes which will make the largest changes. Thanks for sharing!

Excellent article. I definitely love this website. Keep writing!

You ought to be a part of a contest for one of the most useful blogs online. I most certainly will recommend this blog!

An interesting discussion is worth comment. I do believe that you ought to write more about this subject, it might not be a taboo matter but usually people don’t discuss these topics. To the next! Many thanks.

I seriously love your blog.. Pleasant colors & theme. Did you make this web site yourself? Please reply back as I’m trying to create my own website and would love to find out where you got this from or what the theme is named. Appreciate it!

This is a topic that is near to my heart… Many thanks! Exactly where can I find the contact details for questions?

This excellent website truly has all the information and facts I wanted concerning this subject and didn’t know who to ask.

I seriously love your website.. Excellent colors & theme. Did you build this web site yourself? Please reply back as I’m attempting to create my very own website and would like to know where you got this from or just what the theme is called. Thank you!

This is a topic that’s close to my heart… Thank you! Exactly where can I find the contact details for questions?

I love looking through an article that can make people think. Also, many thanks for permitting me to comment.

Spot on with this write-up, I honestly think this website needs a great deal more attention. I’ll probably be back again to read through more, thanks for the information.

I was able to find good information from your blog articles.

This is a topic that’s close to my heart… Many thanks! Exactly where are your contact details though?

This web site certainly has all the info I needed about this subject and didn’t know who to ask.

Hello there! I simply would like to give you a huge thumbs up for your great info you have right here on this post. I am returning to your blog for more soon.

I really like it when people get together and share thoughts. Great site, continue the good work.

Aw, this was a very nice post. Taking a few minutes and actual effort to make a superb article… but what can I say… I put things off a whole lot and don’t manage to get nearly anything done.

bookmarked!!, I like your web site!

I would like to thank you for the efforts you’ve put in writing this website. I really hope to check out the same high-grade content from you later on as well. In fact, your creative writing abilities has motivated me to get my own website now 😉

An intriguing discussion is worth comment. I think that you ought to publish more about this subject matter, it may not be a taboo subject but generally people don’t talk about these topics. To the next! Many thanks!

Hi, I do believe this is an excellent blog. I stumbledupon it 😉 I’m going to revisit once again since i have book marked it. Money and freedom is the greatest way to change, may you be rich and continue to help others.

Oh my goodness! Incredible article dude! Many thanks, However I am experiencing troubles with your RSS. I don’t know the reason why I cannot join it. Is there anybody getting similar RSS problems? Anybody who knows the solution will you kindly respond? Thanks!

Good day! I simply want to offer you a huge thumbs up for the great information you have right here on this post. I will be returning to your blog for more soon.

I was able to find good info from your content.

Hi! I just wish to give you a big thumbs up for your excellent info you have got right here on this post. I will be coming back to your website for more soon.

I like it when individuals get together and share opinions. Great blog, stick with it.

I really like it whenever people get together and share views. Great site, continue the good work!

I’m excited to discover this page. I want to to thank you for ones time for this wonderful read!! I definitely liked every little bit of it and I have you saved to fav to look at new things on your site.

Pretty! This was a really wonderful post. Thanks for supplying this information.

I blog quite often and I seriously thank you for your content. This great article has really peaked my interest. I am going to book mark your blog and keep checking for new information about once per week. I subscribed to your Feed as well.

Way cool! Some extremely valid points! I appreciate you writing this article and the rest of the website is very good.

Right here is the perfect website for everyone who hopes to understand this topic. You understand a whole lot its almost hard to argue with you (not that I actually would want to…HaHa). You certainly put a fresh spin on a subject which has been written about for many years. Wonderful stuff, just wonderful.

Greetings, I think your blog could be having browser compatibility issues. When I look at your web site in Safari, it looks fine but when opening in Internet Explorer, it has some overlapping issues. I simply wanted to provide you with a quick heads up! Apart from that, excellent website.

I was pretty pleased to find this page. I want to to thank you for your time for this particularly wonderful read!! I definitely liked every little bit of it and i also have you bookmarked to see new things on your blog.

I like it when people get together and share thoughts. Great website, continue the good work.

I couldn’t refrain from commenting. Well written!

Nice post. I learn something totally new and challenging on blogs I stumbleupon everyday. It’s always helpful to read content from other authors and use something from other web sites.

Very good article! We will be linking to this great post on our site. Keep up the great writing.

You need to take part in a contest for one of the greatest blogs on the web. I will highly recommend this blog!

Good post. I learn something new and challenging on websites I stumbleupon on a daily basis. It will always be helpful to read articles from other writers and practice a little something from other websites.

The next time I read a blog, Hopefully it doesn’t disappoint me just as much as this one. I mean, Yes, it was my choice to read, nonetheless I really thought you would probably have something useful to say. All I hear is a bunch of complaining about something that you could possibly fix if you were not too busy seeking attention.

Pretty! This has been a really wonderful post. Many thanks for supplying this information.

Your style is so unique compared to other folks I’ve read stuff from. Thank you for posting when you have the opportunity, Guess I will just book mark this web site.

Aw, this was an extremely nice post. Finding the time and actual effort to create a very good article… but what can I say… I procrastinate a lot and never seem to get anything done.

Right here is the right blog for anybody who would like to understand this topic. You know a whole lot its almost hard to argue with you (not that I actually would want to…HaHa). You certainly put a new spin on a topic which has been written about for ages. Great stuff, just excellent.

Spot on with this write-up, I seriously believe that this website needs a lot more attention. I’ll probably be returning to read more, thanks for the advice!

I would like to thank you for the efforts you have put in writing this website. I really hope to check out the same high-grade blog posts by you in the future as well. In fact, your creative writing abilities has inspired me to get my own, personal blog now 😉

Spot on with this write-up, I really believe this website needs a lot more attention. I’ll probably be back again to read more, thanks for the information.

It’s hard to find experienced people on this topic, but you seem like you know what you’re talking about! Thanks

Next time I read a blog, I hope that it does not fail me as much as this one. I mean, I know it was my choice to read through, however I genuinely believed you would probably have something useful to talk about. All I hear is a bunch of crying about something you could fix if you weren’t too busy searching for attention.

This is a topic that is near to my heart… Best wishes! Where are your contact details though?

I really like it when people get together and share views. Great site, stick with it!

Right here is the right site for anyone who hopes to understand this topic. You realize a whole lot its almost hard to argue with you (not that I personally would want to…HaHa). You definitely put a fresh spin on a topic that has been discussed for years. Great stuff, just wonderful.

Everything is very open with a precise clarification of the issues. It was really informative. Your website is very useful. Thank you for sharing!

We’re beyond grateful for your suggestions, which help guide us to grow and improve.

You made some decent points there. I checked on the internet for more info about the issue and found most people will go along with your views on this website.

An impressive share! I have just forwarded this onto a friend who had been doing a little research on this. And he in fact bought me breakfast because I stumbled upon it for him… lol. So let me reword this…. Thank YOU for the meal!! But yeah, thanx for spending the time to talk about this topic here on your website.

I love reading a post that can make people think. Also, thank you for allowing me to comment.

A motivating discussion is definitely worth comment. I do believe that you need to publish more about this issue, it may not be a taboo subject but generally folks don’t speak about these subjects. To the next! Cheers.

Greetings! Very helpful advice in this particular post! It is the little changes that make the biggest changes. Thanks for sharing!

Good information. Lucky me I discovered your website by accident (stumbleupon). I’ve book-marked it for later!

This website certainly has all of the information and facts I needed concerning this subject and didn’t know who to ask.

Your unwavering belief in us is truly treasured. Thank you for your support and faith.

I couldn’t resist commenting. Well written.

Your style is so unique compared to other folks I have read stuff from. Many thanks for posting when you’ve got the opportunity, Guess I will just book mark this web site.

If you’re new to MetaMask Wallet, start with https://metalead.org/. They offer step-by-step guidance on how to download and use MetaMask for browsers like Safari and Opera.

Saved as a favorite, I really like your blog!

Great post! We will be linking to this particularly great content on our site. Keep up the great writing.

There is definately a great deal to know about this topic. I like all the points you made.

Greetings! Very helpful advice in this particular article! It’s the little changes that will make the greatest changes. Thanks a lot for sharing!

After checking out a handful of the blog posts on your blog, I truly like your technique of writing a blog. I book marked it to my bookmark website list and will be checking back soon. Take a look at my web site as well and tell me how you feel.

I used to be able to find good info from your content.

I could not refrain from commenting. Well written.

Howdy! This post couldn’t be written any better! Going through this post reminds me of my previous roommate! He constantly kept preaching about this. I’ll forward this information to him. Fairly certain he’ll have a great read. Many thanks for sharing!

I blog often and I seriously thank you for your content. This great article has truly peaked my interest. I will take a note of your blog and keep checking for new details about once a week. I subscribed to your Feed too.

Great site you have got here.. It’s difficult to find high-quality writing like yours these days. I seriously appreciate individuals like you! Take care!!

Introducing to you the most prestigious online entertainment address today. Visit now to experience now!

I’d like to thank you for the efforts you’ve put in writing this website. I’m hoping to see the same high-grade blog posts from you in the future as well. In fact, your creative writing abilities has inspired me to get my very own blog now 😉

Your style is unique in comparison to other people I have read stuff from. Many thanks for posting when you’ve got the opportunity, Guess I’ll just bookmark this web site.

Step 5: Tie the opposite end of the fishing line or string to the coat hanger.

I would like to thank you for the efforts you have put in writing this site. I’m hoping to view the same high-grade blog posts from you later on as well. In truth, your creative writing abilities has motivated me to get my own, personal site now 😉

Introducing to you the most prestigious online entertainment address today. Visit now to experience now!

Introducing to you the most prestigious online entertainment address today. Visit now to experience now!

Oh my goodness! Amazing article dude! Thank you so much, However I am encountering problems with your RSS. I don’t understand why I cannot subscribe to it. Is there anyone else getting similar RSS issues? Anyone that knows the answer can you kindly respond? Thanks!

For example, if you’re a writer with experience in each writing commercials and writing advert copy, having two separate resumes specializing in these completely different topics makes you extra marketable in each distinctive areas.

Hi, I do believe this is a great web site. I stumbledupon it 😉 I will come back yet again since i have saved as a favorite it. Money and freedom is the best way to change, may you be rich and continue to guide others.

Introducing to you the most prestigious online entertainment address today. Visit now to experience now!

Introducing to you the most prestigious online entertainment address today. Visit now to experience now!

Introducing to you the most prestigious online entertainment address today. Visit now to experience now!

Introducing to you the most prestigious online entertainment address today. Visit now to experience now!

Good day! I could have sworn I’ve visited this site before but after browsing through many of the posts I realized it’s new to me. Regardless, I’m definitely delighted I discovered it and I’ll be book-marking it and checking back regularly.

Introducing to you the most prestigious online entertainment address today. Visit now to experience now!

Training provides scholar experience by requiring them to take courses on accounting information techniques, taxation procedures, and extra.

sex nhật hiếp dâm trẻ em ấu dâm buôn bán vũ khí ma túy bán súng sextoy chơi đĩ sex bạo lực sex học đường tội phạm tình dục chơi les đĩ đực người mẫu bán dâm

Just downloaded the MetaMask Wallet, and I’m impressed! The seamless login process and browser support, including Safari and Opera, make it a must-have. Visit https://metanaito.net/ for more info!

Friends with disabilities could park in Lots 3, 4, and 7. Your state-issued hangtag serves as a go; in any other case, name the racetrack.

Aw, this was a really good post. Taking a few minutes and actual effort to create a superb article… but what can I say… I put things off a whole lot and never seem to get nearly anything done.

But the primary difference between equity trading and stock trading is the way they are invested and their management firms.

sex nhật hiếp dâm trẻ em ấu dâm buôn bán vũ khí ma túy bán súng sextoy chơi đĩ sex bạo lực sex học đường tội phạm tình dục chơi les đĩ đực người mẫu bán dâm

She has been a juror for the James Tiptree, Jr.

sex nhật hiếp dâm trẻ em ấu dâm buôn bán vũ khí ma túy bán súng sextoy chơi đĩ sex bạo lực sex học đường tội phạm tình dục chơi les đĩ đực người mẫu bán dâm

The viable seeds will sink to the underside.

As a result of Tal’s much less spectacular outcomes in opposition to the very top gamers, including his three losses to Keres within the Candidates, Botvinnik was the favorite.

Only when you have shopped around and found the fees being charged for transaction and also the exchange rates being offered should you settle for hiring the services of any money exchanger.

sex nhật hiếp dâm trẻ em ấu dâm buôn bán vũ khí ma túy bán súng sextoy chơi đĩ sex bạo lực sex học đường tội phạm tình dục chơi les đĩ đực người mẫu bán dâm

Frozen meals with natural lean meats and vegetables full of fiber, protein and vitamins are a fantastic method to eat quickly and conveniently without sacrificing good health.

sex nhật hiếp dâm trẻ em ấu dâm buôn bán vũ khí ma túy bán súng sextoy chơi đĩ sex bạo lực sex học đường tội phạm tình dục chơi les đĩ đực người mẫu bán dâm

It is easy so as to add a heat pump to an current pool pipework system.

Main Robert John Finlay Brown (430246), The Cameronians (Scottish Rifles).

sex nhật hiếp dâm trẻ em ấu dâm buôn bán vũ khí ma túy bán súng sextoy chơi đĩ sex bạo lực sex học đường tội phạm tình dục chơi les đĩ đực người mẫu bán dâm

I couldn’t refrain from commenting. Exceptionally well written.

sex nhật hiếp dâm trẻ em ấu dâm buôn bán vũ khí ma túy bán súng sextoy chơi đĩ sex bạo lực sex học đường tội phạm tình dục chơi les đĩ đực người mẫu bán dâm

sex nhật hiếp dâm trẻ em ấu dâm buôn bán vũ khí ma túy bán súng sextoy chơi đĩ sex bạo lực sex học đường tội phạm tình dục chơi les đĩ đực người mẫu bán dâm

A key requirement for a lot of Navy aircraft is that they have the aptitude to operate from the deck of an aircraft provider.

After going over a handful of the articles on your web page, I seriously like your way of blogging. I saved as a favorite it to my bookmark website list and will be checking back soon. Please visit my web site as well and let me know how you feel.

There’s definately a lot to know about this issue. I love all the points you have made.

She complemented her outfit with a pair of statement gold earrings.

Introducing to you the most prestigious online entertainment address today. Visit now to experience now!

An impressive share! I’ve just forwarded this onto a colleague who had been conducting a little research on this. And he in fact bought me dinner because I discovered it for him… lol. So let me reword this…. Thanks for the meal!! But yeah, thanx for spending time to discuss this subject here on your website.

sex nhật hiếp dâm trẻ em ấu dâm buôn bán vũ khí ma túy bán súng sextoy chơi đĩ sex bạo lực sex học đường tội phạm tình dục chơi les đĩ đực người mẫu bán dâm

sex nhật hiếp dâm trẻ em ấu dâm buôn bán vũ khí ma túy bán súng sextoy chơi đĩ sex bạo lực sex học đường tội phạm tình dục chơi les đĩ đực người mẫu bán dâm

Great post. I am facing some of these issues as well..

I could not refrain from commenting. Exceptionally well written.

sex nhật hiếp dâm trẻ em ấu dâm buôn bán vũ khí ma túy bán súng sextoy chơi đĩ sex bạo lực sex học đường tội phạm tình dục chơi les đĩ đực người mẫu bán dâm

sex nhật hiếp dâm trẻ em ấu dâm buôn bán vũ khí ma túy bán súng sextoy chơi đĩ sex bạo lực sex học đường tội phạm tình dục chơi les đĩ đực người mẫu bán dâm

You are so interesting! I do not believe I have read through something like this before. So wonderful to discover somebody with some unique thoughts on this issue. Seriously.. thank you for starting this up. This website is one thing that is needed on the web, someone with a bit of originality.

I couldn’t refrain from commenting. Perfectly written.

What a helpful post! For anyone looking for discounts, check out discounted Prodentim here: https://prodentim-review.com. I’d love to know your opinions! ProDentim-Review-2025-USAs

Pretty! This has been an extremely wonderful article. Thanks for supplying this information.

Greetings, I do believe your blog may be having browser compatibility problems. Whenever I take a look at your blog in Safari, it looks fine but when opening in Internet Explorer, it’s got some overlapping issues. I simply wanted to give you a quick heads up! Aside from that, great blog.

Great article. I will be dealing with a few of these issues as well..

I really like it whenever people come together and share opinions. Great site, continue the good work.

This is a topic that is near to my heart… Many thanks! Where are your contact details though?

The MetaMask Firefox extension is a game-changer for crypto users. Learn all about it on https://kingroada.com/.

You’re so awesome! I do not believe I have read a single thing like this before. So nice to discover another person with a few original thoughts on this subject matter. Really.. thanks for starting this up. This web site is one thing that is needed on the internet, someone with a bit of originality.

I blog quite often and I truly thank you for your information. This article has truly peaked my interest. I’m going to take a note of your site and keep checking for new information about once a week. I opted in for your Feed as well.

He is administering through executive orders because the legislators are refusing to give the nod to his proposals about running the nation.

This article was great! For anyone exploring Prodentim, visit my website: https://prodenttims.com. I’d love to hear your thoughts and feedback. Prodentim-OfficialShop-101Discount

Hi! I could have sworn I’ve been to this site before but after going through many of the articles I realized it’s new to me. Regardless, I’m certainly happy I came across it and I’ll be bookmarking it and checking back frequently.

HUVIP88 – Cổng game đổi thưởng uy tín năm 2025 với hệ thống trò chơi phong phú từ game bài truyền thống đến các trò chơi mới lạ như Đua ngựa, Nổ hũ, Bắn cá, Rồng hổ, và Slot Games. Người chơi có thể trải nghiệm cảm giác hồi hộp với tài xỉu, xóc đĩa, bầu cua cùng nhiều tính năng độc đáo.

Good web site you have here.. It’s hard to find high-quality writing like yours nowadays. I really appreciate people like you! Take care!!

Spot on with this write-up, I absolutely believe this web site needs much more attention. I’ll probably be back again to read more, thanks for the information.

I’m amazed, I have to admit. Seldom do I come across a blog that’s equally educative and amusing, and without a doubt, you have hit the nail on the head. The problem is something that not enough folks are speaking intelligently about. I’m very happy I found this in my search for something relating to this.

Finding the best destination management company to satisfy your online business goals is essential.

It’s nearly impossible to find experienced people in this particular subject, however, you sound like you know what you’re talking about! Thanks

Using Metamask on Chrome has been a great experience! If you’re looking for step-by-step instructions, https://metamenu.org/ has you covered.

This is the right site for anyone who wishes to understand this topic. You realize a whole lot its almost hard to argue with you (not that I really would want to…HaHa). You definitely put a brand new spin on a subject which has been written about for many years. Great stuff, just wonderful.

HDBET là nhà cái cá cược trực tuyến hàng đầu tại Việt Nam, cung cấp đa dạng các trò chơi từ cá cược thể thao đến casino trực tuyến.

Excellent article. I’m going through many of these issues as well..

Howdy! I could have sworn I’ve been to this website before but after browsing through a few of the posts I realized it’s new to me. Nonetheless, I’m certainly delighted I discovered it and I’ll be bookmarking it and checking back regularly.

What amenities and recreational activities are commonly available in Jennings, Louisiana assisted living services?

This is the perfect blog for anybody who wishes to understand this topic. You know a whole lot its almost hard to argue with you (not that I really would want to…HaHa). You certainly put a brand new spin on a subject that’s been written about for a long time. Wonderful stuff, just wonderful.

In 1905, in keeping with Canadian historian Invoice Vance, a Swiss engineer named Alfred Buchi patented an exhaust-pushed supercharger to be used on diesel engines.

When I originally commented I seem to have clicked the -Notify me when new comments are added- checkbox and from now on whenever a comment is added I recieve 4 emails with the same comment. There has to be a way you can remove me from that service? Thanks.

Hello there! This blog post couldn’t be written much better! Reading through this post reminds me of my previous roommate! He continually kept talking about this. I will forward this article to him. Fairly certain he’s going to have a very good read. I appreciate you for sharing!

The Jedi served as a space-faring knightly order inside the Galactic Republic, a consultant democracy encompassing most developed worlds.

Currently, social media has progressed to an extent that you can even earn here, whether jobless or looking for an extra income.

Next time I read a blog, I hope that it doesn’t disappoint me just as much as this particular one. I mean, Yes, it was my choice to read, however I genuinely believed you would have something useful to talk about. All I hear is a bunch of whining about something you could fix if you were not too busy searching for attention.

Very good info. Lucky me I recently found your site by chance (stumbleupon). I have book-marked it for later.

Good post. I absolutely love this website. Thanks!

Do you love sports activities but have a tough time getting your daughter desirous about baseball, basketball or soccer?

Walsall’s goalkeeper Clayton Ince received the November Powerade Participant of the Month award simply four days before taking part in against his former club.

The cryptocurrency market is highly volatile, and prices can fluctuate rapidly.

The following day, on December 24, boats had been used to begin bringing the Continental Military throughout the Delaware from New Jersey were introduced down from Malta Island close to current-day New Hope, Pennsylvania.

In 2014, Pax World Management LLC and Ellevate Asset Management LLC, whose principal is Sallie Krawcheck, partnered to form Pax Ellevate Management.

Greetings! Very helpful advice in this particular post! It is the little changes that make the largest changes. Many thanks for sharing!

Your style is really unique in comparison to other folks I have read stuff from. Thanks for posting when you’ve got the opportunity, Guess I’ll just bookmark this site.

Awesome content here! If you’re looking for authentic Prodentim discounts, check out https://prodentim-review.com. Prodentim-RealUser-Review2025

You need to take part in a contest for one of the most useful sites on the internet. I am going to recommend this blog!

Oh my goodness! Impressive article dude! Thank you, However I am having difficulties with your RSS. I don’t understand why I am unable to join it. Is there anybody else getting identical RSS problems? Anyone who knows the answer can you kindly respond? Thanx.

I must thank you for the efforts you’ve put in penning this site. I’m hoping to view the same high-grade blog posts from you in the future as well. In fact, your creative writing abilities has motivated me to get my own site now 😉

I like it when people get together and share thoughts. Great blog, continue the good work.

Your style is really unique in comparison to other people I’ve read stuff from. Thanks for posting when you have the opportunity, Guess I’ll just book mark this site.

Having read this I believed it was rather informative. I appreciate you finding the time and energy to put this short article together. I once again find myself personally spending a significant amount of time both reading and leaving comments. But so what, it was still worthwhile!

Hello there, I think your site could be having internet browser compatibility problems. When I look at your website in Safari, it looks fine however, when opening in I.E., it’s got some overlapping issues. I just wanted to provide you with a quick heads up! Aside from that, excellent site.

You’re so interesting! I do not suppose I’ve truly read through anything like that before. So good to discover someone with unique thoughts on this subject matter. Seriously.. thank you for starting this up. This web site is something that’s needed on the web, someone with a little originality.

Greetings! Very helpful advice within this post! It’s the little changes which will make the most important changes. Thanks a lot for sharing!

I had issues trying to download Metamask, but https://sites.google.com/view/metamask-extension-dfkasdkfdnt/download explained everything in an easy way. Their guide is very detailed and useful.

Hello! I could have sworn I’ve been to this site before but after going through some of the articles I realized it’s new to me. Anyways, I’m definitely delighted I found it and I’ll be bookmarking it and checking back frequently!

Can I simply say what a comfort to uncover somebody that really knows what they’re discussing over the internet. You definitely realize how to bring a problem to light and make it important. More people really need to check this out and understand this side of the story. I was surprised that you are not more popular since you definitely have the gift.

Fantastic post! The information you shared is really valuable and well-explained. Thanks for putting this together!

Great insights here! If you’re looking for a trusted Mitolyn store, visit https://mitolynstore.us. Mitolyn-Best-Offer-2025

Great article. I am going through a few of these issues as well..

A friend recommended I visit https://sites.google.com/view/metamask-extension-download-oa/chrome for instructions on downloading Metamask, and I’m so glad I did! The guide was clear, and I had my wallet set up in no time. Definitely a must-visit site for crypto users!

This is a topic which is close to my heart… Best wishes! Where are your contact details though?

I used to be able to find good info from your articles.

Hello there, I believe your website could be having internet browser compatibility issues. When I look at your site in Safari, it looks fine but when opening in I.E., it has some overlapping issues. I merely wanted to provide you with a quick heads up! Other than that, great site!

He negotiated with Lenape and other Native American tribes in western Pennsylvania to realize their help through the American Revolutionary War.

Right here is the right web site for anybody who wants to understand this topic. You understand a whole lot its almost hard to argue with you (not that I really will need to…HaHa). You certainly put a fresh spin on a topic that’s been discussed for ages. Great stuff, just great.

Hi there! I just want to offer you a huge thumbs up for the excellent information you’ve got right here on this post. I am coming back to your site for more soon.

It’s hard to find well-informed people for this subject, but you sound like you know what you’re talking about! Thanks

Burial was in the Fairlawn cemetery of Elk Metropolis with Hartronft Funeral House in charge.

Aw, this was an incredibly good post. Finding the time and actual effort to create a really good article… but what can I say… I procrastinate a lot and never manage to get nearly anything done.

How Will Blockchain Rebuild The World?

Thirteenth Sister – Iskat Akaris was a purple-skinned Inquisitor appeared within the comedian e-book Darth Vader: Darkish Lord of the Sith, the place she assisted Darth Vader, the Fifth Brother and one other black-skinned Twi’lek Inquisitor in searching Jedi Grasp Eeth Koth.

Futures and options have centralized exchanges and clearinghouses that report every trade and the resulting price ticks in these contracts, but there is no one entity that registers every single forex trade.

While 7.a3 and 7.0-zero are playable, the primary line is 7.cxd5 cxd4 8.exd4 Nxd5 9.0-0 Nc6, resulting in an IQP position with White’s knight on e2 slightly than f3, as is often the case.

I could not refrain from commenting. Very well written!

There is always a need to follow certain rules no matter what sort of company or business you want to start.

Strolling instructions from station: Take exit A1.

I like it when folks come together and share thoughts. Great website, continue the good work!

Your style is unique compared to other folks I’ve read stuff from. Many thanks for posting when you have the opportunity, Guess I’ll just bookmark this page.

7 Additionally some non member states also take part (the European Union, EFTA have overlapping membership and varied common initiatives concerning the European integration).

Spot on with this write-up, I really believe that this site needs a lot more attention. I’ll probably be back again to read through more, thanks for the advice!

After looking into a handful of the blog posts on your web site, I honestly appreciate your way of writing a blog. I added it to my bookmark website list and will be checking back in the near future. Take a look at my web site too and tell me your opinion.

I love reading through an article that will make people think. Also, thanks for allowing for me to comment.

It wasn’t until after World War II that Italian style dipped its toes into these waters, and even then, Milan was nowhere on board.

Good information. Lucky me I ran across your site by chance (stumbleupon). I’ve book-marked it for later!

Hello! I could have sworn I’ve visited your blog before but after going through many of the posts I realized it’s new to me. Anyhow, I’m definitely pleased I found it and I’ll be bookmarking it and checking back regularly.

Very useful content! I found your tips practical and easy to apply. Thanks for sharing such valuable knowledge!

Great article! We are linking to this great post on our website. Keep up the good writing.

Introducing to you the most prestigious online entertainment address today. Visit now to experience now!

Greetings! Very helpful advice in this particular article! It is the little changes that will make the biggest changes. Many thanks for sharing!

Howdy! This article could not be written much better! Looking through this post reminds me of my previous roommate! He constantly kept talking about this. I will send this article to him. Pretty sure he’s going to have a very good read. Many thanks for sharing!

This is a topic which is near to my heart… Take care! Where can I find the contact details for questions?

I’m pretty pleased to discover this web site. I want to to thank you for ones time for this fantastic read!! I definitely savored every little bit of it and I have you book marked to look at new things on your web site.

An interesting discussion is definitely worth comment. I do believe that you need to publish more on this subject, it might not be a taboo subject but generally folks don’t talk about such issues. To the next! Cheers.

Way cool! Some very valid points! I appreciate you writing this article and the rest of the site is really good.

I blog quite often and I seriously thank you for your information. The article has truly peaked my interest. I am going to bookmark your website and keep checking for new details about once a week. I opted in for your RSS feed too.

I blog quite often and I really appreciate your content. This great article has truly peaked my interest. I’m going to take a note of your website and keep checking for new information about once per week. I subscribed to your RSS feed as well.

Introducing to you the most prestigious online entertainment address today. Visit now to experience now!

Hello there, I do believe your blog might be having web browser compatibility issues. When I look at your site in Safari, it looks fine but when opening in I.E., it has some overlapping issues. I simply wanted to give you a quick heads up! Aside from that, excellent blog!

Introducing to you the most prestigious online entertainment address today. Visit now to experience now!

Introducing to you the most prestigious online entertainment address today. Visit now to experience now!

Introducing to you the most prestigious online entertainment address today. Visit now to experience now!

Introducing to you the most prestigious online entertainment address today. Visit now to experience now!

Everything is very open with a really clear description of the issues. It was really informative. Your site is very useful. Thanks for sharing!

Hi, I do think this is an excellent website. I stumbledupon it 😉 I’m going to return once again since I book marked it. Money and freedom is the best way to change, may you be rich and continue to help others.

Way cool! Some extremely valid points! I appreciate you writing this write-up and the rest of the website is very good.

That is a really good tip particularly to those fresh to the blogosphere. Simple but very precise info… Thanks for sharing this one. A must read post.

Spot on with this write-up, I honestly think this amazing site needs far more attention. I’ll probably be back again to read more, thanks for the advice!

Oh my goodness! Awesome article dude! Thank you, However I am encountering difficulties with your RSS. I don’t understand why I can’t join it. Is there anyone else having the same RSS issues? Anyone who knows the answer can you kindly respond? Thanx!

Crypto security is a big concern, so I was careful about where to download Metamask. Luckily, I found https://metanate.org/, which provided a safe and detailed guide to installation. Now I can use my wallet worry-free!

Introducing to you the most prestigious online entertainment address today. Visit now to experience now!

Introducing to you the most prestigious online entertainment address today. Visit now to experience now!

Introducing to you the most prestigious online entertainment address today. Visit now to experience now!

Introducing to you the most prestigious online entertainment address today. Visit now to experience now!

Introducing to you the most prestigious online entertainment address today. Visit now to experience now!

sex nhật hiếp dâm trẻ em ấu dâm buôn bán vũ khí ma túy bán súng sextoy chơi đĩ sex bạo lực sex học đường tội phạm tình dục chơi les đĩ đực người mẫu bán dâm

An impressive share! I have just forwarded this onto a friend who had been doing a little research on this. And he actually ordered me lunch because I stumbled upon it for him… lol. So let me reword this…. Thank YOU for the meal!! But yeah, thanks for spending time to discuss this topic here on your blog.

Hello there! I simply wish to offer you a huge thumbs up for your great info you’ve got here on this post. I will be returning to your website for more soon.

I blog often and I really appreciate your information. The article has truly peaked my interest. I will book mark your website and keep checking for new details about once per week. I opted in for your RSS feed as well.

Good blog you have here.. It’s hard to find high-quality writing like yours these days. I truly appreciate people like you! Take care!!

If you want to ensure you’re installing Metamask from a trusted source, visit https://metamake.org/. Their guides are very detailed, and I felt safe following their steps. Now my transactions are seamless!

Thanks for sharing!

Hi there, There’s no doubt that your web site might be having internet browser compatibility problems. When I take a look at your web site in Safari, it looks fine but when opening in IE, it’s got some overlapping issues. I simply wanted to give you a quick heads up! Other than that, fantastic website.

I love reading through a post that can make men and women think. Also, thanks for permitting me to comment.

Good post. I learn something new and challenging on blogs I stumbleupon every day. It’s always exciting to read articles from other authors and use a little something from other websites.

Hello there! This blog post couldn’t be written any better! Looking at this article reminds me of my previous roommate! He always kept preaching about this. I am going to send this article to him. Fairly certain he’s going to have a very good read. Thanks for sharing!

After I initially left a comment I seem to have clicked on the -Notify me when new comments are added- checkbox and now each time a comment is added I recieve 4 emails with the exact same comment. Perhaps there is a means you can remove me from that service? Appreciate it.

Setting up the Metamask extension on Chrome was a breeze thanks to https://metaduck.org/. If you’re new to crypto wallets, this site provides all the info you need to get started. Super helpful and easy to follow!

I was searching for a trusted source to download Metamask, and I found https://metapaws.org/. The step-by-step guide made the process smooth, and now I can access my wallet without any issues. Definitely worth checking out!

I enjoy reading through an article that can make people think. Also, thank you for permitting me to comment.

sex nhật, hiếp dâm trẻ em, ấu dâm, buôn bán vũ khí, ma túy, bán súng, sextoy, chơi đĩ, sex bạo lực, sex học đường, tội phạm tình dục

May I just say what a relief to discover someone that actually knows what they’re talking about online. You certainly realize how to bring an issue to light and make it important. A lot more people need to check this out and understand this side of your story. I was surprised that you are not more popular since you definitely have the gift.

Very good post! We will be linking to this particularly great post on our site. Keep up the good writing.

This is a great tip particularly to those new to the blogosphere. Short but very accurate info… Thank you for sharing this one. A must read post!

sex nhật, hiếp dâm trẻ em, ấu dâm, buôn bán vũ khí, ma túy, bán súng, sextoy, chơi đĩ, sex bạo lực, sex học đường, tội phạm tình dục

A motivating discussion is definitely worth comment. I think that you should publish more about this issue, it might not be a taboo matter but usually people do not discuss these issues. To the next! Many thanks.

This web site definitely has all of the information I wanted concerning this subject and didn’t know who to ask.

I was very happy to discover this site. I need to to thank you for your time due to this wonderful read!! I definitely enjoyed every part of it and i also have you bookmarked to see new information in your web site.

If you’re looking for a secure and reliable way to download Metamask, I highly recommend checking out https://download.metaredi.org/. Their detailed guide ensures you install it the right way, without any risks.

Your style is so unique compared to other people I’ve read stuff from. Many thanks for posting when you have the opportunity, Guess I will just book mark this web site.

Right here is the perfect blog for anyone who wishes to find out about this topic. You realize a whole lot its almost tough to argue with you (not that I really will need to…HaHa). You certainly put a fresh spin on a topic which has been discussed for many years. Great stuff, just great.

I was pretty pleased to uncover this website. I wanted to thank you for ones time for this wonderful read!! I definitely loved every bit of it and I have you saved as a favorite to see new stuff in your website.

I really like it when people get together and share thoughts. Great site, stick with it.

sex nhật hiếp dâm trẻ em ấu dâm buôn bán vũ khí ma túy bán súng sextoy chơi đĩ sex bạo lực sex học đường tội phạm tình dục chơi les đĩ đực người mẫu bán dâm

Neat blog! Is your theme custom made or did you download it from

somewhere? A theme like yours with a few simple tweeks would really make my blog shine.

Please let me know where you got your design. Thanks a lot

Very good post. I will be experiencing many of these issues as well..

I must thank you for the efforts you’ve put in writing this website. I am hoping to check out the same high-grade blog posts from you later on as well. In fact, your creative writing abilities has motivated me to get my very own website now 😉

I used to be able to find good information from your blog posts.

sex nhật hiếp dâm trẻ em ấu dâm buôn bán vũ khí ma túy bán súng sextoy chơi đĩ sex bạo lực sex học đường tội phạm tình dục chơi les đĩ đực người mẫu bán dâm

Excellent web site you have got here.. It’s hard to find excellent writing like yours these days. I honestly appreciate people like you! Take care!!

Saved as a favorite, I like your site!

Way cool! Some very valid points! I appreciate you writing this post plus the rest of the website is also very good.

I was skeptical about installing the Metamask extension, but after following the guide on https://metamaker.org/#metamask-download, I feel much more confident. Highly recommended for crypto users!

sex nhật hiếp dâm trẻ em ấu dâm buôn bán vũ khí ma túy bán súng sextoy chơi đĩ sex bạo lực sex học đường tội phạm tình dục chơi les đĩ đực người mẫu bán dâm

sex nhật hiếp dâm trẻ em ấu dâm buôn bán vũ khí ma túy bán súng sextoy chơi đĩ sex bạo lực sex học đường tội phạm tình dục chơi les đĩ đực người mẫu bán dâm

I was very happy to uncover this site. I wanted to thank you for ones time for this particularly wonderful read!! I definitely really liked every little bit of it and i also have you book-marked to check out new stuff in your site.

An outstanding share! I’ve just forwarded this onto a friend who had been doing a little homework on this. And he actually bought me breakfast because I stumbled upon it for him… lol. So allow me to reword this…. Thanks for the meal!! But yeah, thanx for spending some time to talk about this issue here on your blog.

Everything is very open with a really clear description of the challenges. It was truly informative. Your website is very useful. Thanks for sharing.

Nice post. I learn something new and challenging on websites I stumbleupon every day. It’s always exciting to read through articles from other authors and practice something from other sites.

This is a topic that is close to my heart… Many thanks! Exactly where are your contact details though?

Good blog post. I absolutely appreciate this website. Stick with it!

I saw one more thing relating to this on another blog. Youve obviously spent time on this. Congratulations!

Very good information. Lucky me I ran across your website by accident (stumbleupon). I have bookmarked it for later.

Except for curating yr-long exhibitions of the corporate’s work, the Blenko Museum labored with the Corning Museum of Glass in 2005 to incorporate Blenko in a small survey exhibition organized by Tina Oldknow, Curator of Trendy Glass, titled “Decades in Glass: the ‘50s” that includes Wayne Husted’s designs.

Good article. I am dealing with some of these issues as well..

Greetings! Very helpful advice in this particular post! It’s the little changes that produce the most significant changes. Many thanks for sharing!

I was able to find good information from your blog posts.

I could not refrain from commenting. Perfectly written!

An intriguing discussion is worth comment. There’s no doubt that that you ought to publish more about this subject, it may not be a taboo matter but usually people do not speak about these topics. To the next! Best wishes.

In 1955, Hall of Fame pitcher Cy Younger died, however he left behind a legacy as one among baseball’s finest pitchers.

Hello there! I simply would like to give you a big thumbs up for your excellent information you have got right here on this post. I’ll be returning to your web site for more soon.

An outstanding share! I’ve just forwarded this onto a colleague who had been doing a little homework on this. And he in fact bought me lunch because I stumbled upon it for him… lol. So allow me to reword this…. Thank YOU for the meal!! But yeah, thanx for spending the time to talk about this topic here on your site.

Very nice write-up. I definitely love this website. Keep it up!

I’ve read several good stuff here. Certainly worth bookmarking for revisiting. I wonder how much attempt you place to make the sort of magnificent informative site.

sex nhật hiếp dâm trẻ em ấu dâm buôn bán vũ khí ma túy bán súng sextoy chơi đĩ sex bạo lực sex học đường tội phạm tình dục chơi les đĩ đực người mẫu bán dâm

sex nhật hiếp dâm trẻ em ấu dâm buôn bán vũ khí ma túy bán súng sextoy chơi đĩ sex bạo lực sex học đường tội phạm tình dục chơi les đĩ đực người mẫu bán dâm

Howdy! I simply would like to offer you a big thumbs up for the excellent info you’ve got here on this post. I will be returning to your web site for more soon.

This web site definitely has all the information I wanted concerning this subject and didn’t know who to ask.

Way cool! Some very valid points! I appreciate you penning this article and also the rest of the website is also very good.

Nice post. I learn something new and challenging on websites I stumbleupon every day. It will always be interesting to read content from other writers and use a little something from their web sites.

A fascinating discussion is worth comment. I do believe that you ought to publish more about this subject, it might not be a taboo subject but usually people don’t talk about such issues. To the next! All the best.

Howdy! This article could not be written much better! Going through this post reminds me of my previous roommate! He continually kept talking about this. I’ll send this post to him. Fairly certain he will have a great read. Thank you for sharing!

Introducing to you the most prestigious online entertainment address today. Visit now to experience now!

You are so interesting! I don’t believe I’ve read a single thing like that before. So wonderful to find another person with a few unique thoughts on this subject. Seriously.. thank you for starting this up. This site is one thing that’s needed on the internet, someone with a bit of originality.

Now, he decides to place a Take profit order at 12.080.

That is a good tip especially to those fresh to the blogosphere. Simple but very precise information… Thanks for sharing this one. A must read post.

Excellent site you have here.. It’s difficult to find good quality writing like yours these days. I truly appreciate individuals like you! Take care!!

If you know they have to implement a program before they can spend time considering (or funds purchasing) your product then you can schedule a call back at a later date that may stand a better chance of getting some attention.

Hi, There’s no doubt that your blog may be having web browser compatibility problems. Whenever I take a look at your web site in Safari, it looks fine however when opening in Internet Explorer, it’s got some overlapping issues. I merely wanted to give you a quick heads up! Apart from that, fantastic blog.

This is the perfect website for anybody who wants to find out about this topic. You realize a whole lot its almost hard to argue with you (not that I personally would want to…HaHa). You certainly put a fresh spin on a subject that’s been discussed for years. Great stuff, just great.

Introducing to you the most prestigious online entertainment address today. Visit now to experience now!

Hi, I do think this is an excellent blog. I stumbledupon it 😉 I will return yet again since I book marked it. Money and freedom is the best way to change, may you be rich and continue to help other people.

Ventress managed to turn Vos back, but died saving him from Dooku.

Way cool! Some very valid points! I appreciate you writing this article and the rest of the site is also really good.

I’m excited to uncover this web site. I want to to thank you for ones time for this particularly wonderful read!! I definitely savored every part of it and I have you saved to fav to see new things in your website.

Everything is very open with a clear clarification of the challenges. It was really informative. Your site is very useful. Many thanks for sharing.

Greetings! Very helpful advice in this particular article! It’s the little changes which will make the most important changes. Many thanks for sharing!

I absolutely love your site.. Pleasant colors & theme. Did you create this website yourself? Please reply back as I’m looking to create my very own site and would like to learn where you got this from or exactly what the theme is called. Thanks!

I really love your website.. Pleasant colors & theme. Did you make this site yourself? Please reply back as I’m trying to create my own site and would like to find out where you got this from or what the theme is called. Thanks.

As an alternative of true competition-grade underpinnings, the suspension was a fortified model of the Mustang GT’s, with normal front disc brakes and E70X15 tires.

This website certainly has all the information I wanted concerning this subject and didn’t know who to ask.

There is definately a lot to know about this subject. I really like all of the points you’ve made.

Greetings! Very helpful advice within this article! It is the little changes which will make the greatest changes. Thanks a lot for sharing!

Very good post! We will be linking to this great post on our website. Keep up the good writing.

Howdy, I do think your web site could possibly be having web browser compatibility problems. When I take a look at your site in Safari, it looks fine however, if opening in I.E., it has some overlapping issues. I just wanted to give you a quick heads up! Other than that, wonderful blog.

Aw, this was a really good post. Taking the time and actual effort to produce a really good article… but what can I say… I hesitate a lot and don’t manage to get nearly anything done.

The other things you need to keep in mind include checking for hidden charges in the brokerage plan; ensuring speed, reliability and user-friendliness of trading software; and efficiency of back support services of the broker.

This is a topic that’s near to my heart… Take care! Where are your contact details though?

Greetings! Very helpful advice in this particular article! It is the little changes that will make the greatest changes. Thanks a lot for sharing!