The food industry is a dynamic and ever-evolving sector, heavily influenced by technological advancements that enhance both efficiency and quality in food production. Among the many tools and machinery used, mixing equipment plays a critical role. These versatile devices are essential in producing a wide range of products, including sauces, soups, confectionery, dairy items, and beverages. This article explores the extensive applications of mixing equipment in the food industry, highlighting their benefits, diverse uses, and technological innovations that make them indispensable.

The Importance of Mixing Equipment in Food Production

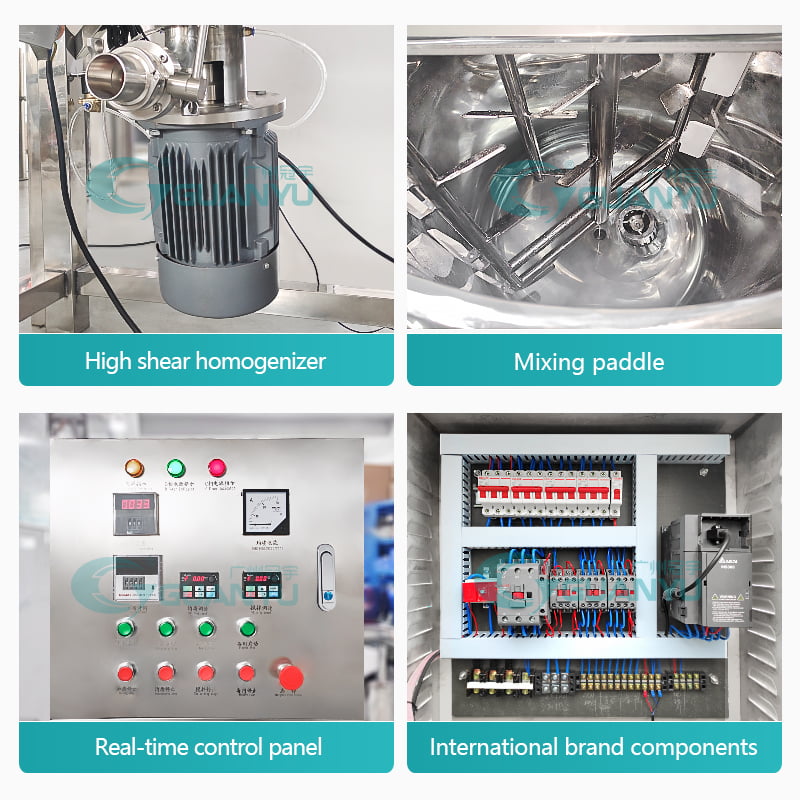

Mixing equipment, commonly referred to as stirring pots or agitated kettles, is designed to uniformly mix ingredients and maintain consistent temperatures during the cooking process. This is crucial for achieving the desired texture, flavor, and quality of various food products. The primary functions of mixing equipment include blending, heating, cooling, and sometimes even cooking ingredients, depending on the product being made.

Applications in Various Food Products

1. Sauces

Consistency and flavor are paramount in sauce production. Mixing equipment ensures that ingredients such as tomatoes, herbs, spices, and other flavorings are evenly mixed. This uniformity is essential for a consistent taste and texture. Mixing equipment with heating capabilities allows for the simmering and reduction of sauces, enhancing their flavor profiles and achieving the desired thickness. Automated stirring mechanisms prevent sauces from sticking and burning, ensuring a high-quality final product.

2. Soups

In soup production, mixing equipment is essential for blending a variety of ingredients, including vegetables, meats, and seasonings. Continuous stirring ensures that all ingredients are evenly distributed, crucial for achieving a harmonious flavor. The heating function helps cook the ingredients thoroughly, allowing flavors to meld together. Advanced mixing equipment features programmable settings that adjust stirring speed and temperature, catering to different types of soups, from broths to creamy chowders.

3. Confectionery

The confectionery industry benefits significantly from mixing equipment, particularly in producing candies, chocolates, and other sweets. Precision in temperature control and mixing is crucial to achieving the desired texture and preventing sugar crystallization. Mixing equipment with precise temperature control and gentle mixing capabilities is ideal for making products like caramel, fudge, and toffee. For chocolate production, these machines ensure proper tempering, resulting in a smooth and glossy finish.

4. Dairy Items

Dairy products such as yogurt, cheese, and custards require careful handling and precise temperature control. Mixing equipment plays a vital role by ensuring that ingredients like milk, cultures, and flavorings are thoroughly mixed and heated to the correct temperatures. In cheese-making, mixing equipment aids in curd formation and whey separation, while in yogurt production, it ensures even mixing with cultures and proper heating to promote fermentation. Gentle stirring prevents unwanted lumps, ensuring a smooth and consistent product.

5. Beverages

The beverage industry utilizes mixing equipment for blending ingredients in products like juices, soft drinks, and alcoholic beverages. Consistency in flavor and texture is crucial in beverage production, and mixing equipment ensures even distribution of flavorings, sweeteners, and preservatives. In brewing, mixing equipment is used during mashing and fermentation to maintain uniformity and control temperatures, essential for developing desired flavors and alcohol content.

Technological Advancements in Mixing Equipment

Mixing equipment has evolved significantly, incorporating advanced technologies to meet the increasing demands of the food industry. Some notable advancements include:

1. Automation and Programmability

Modern mixing equipment features automated controls for precise management of stirring speed, temperature, and cooking time. Programmable settings allow manufacturers to create specific recipes with consistent results, reducing manual intervention and minimizing errors. Automation enhances efficiency by enabling continuous production without constant monitoring.

2. Temperature Control

Accurate temperature control is crucial in food production to ensure safety and quality. Advanced mixing equipment is equipped with precise temperature sensors and control systems to maintain desired temperatures throughout the cooking process. This is particularly important in processes like pasteurization, where specific temperatures must be maintained to eliminate harmful bacteria without compromising product quality.

3. Versatility and Customization

Mixing equipment is now available in various sizes and configurations to cater to different production needs. Manufacturers can choose from a range of options, including stationary and tilting models, depending on their specific requirements. Customizable features such as interchangeable stirring blades and adjustable speed settings offer greater flexibility in handling different types of products.

4. Hygienic Design

Hygiene is a top priority in the food industry, and modern mixing equipment is designed with this in mind. Stainless steel construction, seamless welding, and easy-to-clean surfaces prevent contamination and ensure compliance with food safety regulations. Some mixing equipment also features CIP (Clean-In-Place) systems that automate the cleaning process, further enhancing hygiene and efficiency.

Benefits of Using Mixing Equipment

The application of mixing equipment in the food industry offers numerous benefits, including:

1. Consistency and Quality

Mixing equipment ensures uniform mixing and precise temperature control, resulting in consistent and high-quality products. This consistency is essential for maintaining brand reputation and meeting consumer expectations.

2. Efficiency and Productivity

Automation and programmability reduce the need for manual labor and enable continuous production, increasing efficiency and productivity. This translates to cost savings and the ability to meet high demand.

3. Versatility

Mixing equipment can handle a wide range of products, making it a versatile tool in any food production facility. From sauces and soups to confectionery and beverages, these machines can be adapted to various applications.

4. Hygiene and Safety

Modern mixing equipment is designed with hygiene and safety in mind, ensuring that food products are free from contamination. Features like CIP systems and stainless steel construction make cleaning and maintenance easier, promoting a safe production environment.

Case Studies

1. Sauce Production

A leading sauce manufacturer implemented advanced mixing equipment in their production line to improve consistency and quality. Programmable settings allowed for precise control over cooking times and temperatures, resulting in a more uniform product. Automation features reduced labor costs and increased production capacity, enabling the company to meet growing demand.

2. Dairy Processing

A dairy company specializing in yogurt and cheese production invested in mixing equipment with advanced temperature control and gentle mixing capabilities. This allowed them to produce high-quality products with a smooth texture and consistent flavor. The hygienic design of the equipment ensured compliance with food safety regulations, enhancing overall product quality and safety.

3. Confectionery Manufacturing

A confectionery company producing caramel and fudge utilized mixing equipment with precise temperature control to prevent crystallization and achieve the desired texture. Automated stirring mechanisms ensured even mixing, resulting in a consistent and high-quality product. The company also benefited from increased efficiency and reduced production times, allowing them to expand their product line and meet market demand.

Conclusion

Mixing equipment has become an integral part of the food industry, offering a range of benefits that enhance the efficiency, quality, and safety of food production. Their application spans a wide variety of products, including sauces, soups, confectionery, dairy items, and beverages. Technological advancements have further improved the functionality and versatility of mixing equipment, making them essential assets in modern food production facilities. As the food industry continues to evolve, the role of mixing equipment will undoubtedly remain crucial in meeting consumer demands and ensuring the production of high-quality food products.

Yo, the aaajlapp is actually pretty smooth to use! Downloaded it and had no issues getting started. Simple design that’s easy to navigate. Give aaajlapp a shot, might be your new go-to.