The main difference between fixed lifting mixers and hydraulic lifting vacuum emulsifying mixers lies in their lifting mechanism and level of automation. Fixed lifting mixers provide a simple, stable option for consistent batch production. Hydraulic lifting vacuum emulsifying mixers offer more flexibility and advanced features for complex processes. Guanyu stands out as a trusted manufacturer with proven expertise in both mixer types, serving industries such as cosmetics, pharmaceuticals, food, and chemicals.

Key Takeaways

Fixed lifting mixers offer stable, reliable mixing for thick materials with simple operation and lower cost.

Hydraulic lifting vacuum emulsifying mixers provide advanced features like vacuum removal, precise speed control, and easy cleaning for smooth, high-quality products.

Both mixers serve industries such as cosmetics, pharmaceuticals, food, and chemicals but fit different production needs and product types.

Choosing the right mixer depends on production scale, product viscosity, and operational priorities like automation and cleaning.

Guanyu supplies both mixer types with customizable options, strong support, and certifications to ensure quality and safety.

Fixed Lifting Mixers

Features

Fixed lifting mixers deliver reliable performance for many industrial processes. These machines use a stable lifting mechanism that keeps the mixing vessel in a fixed position during operation. Operators can count on consistent batch quality because the design reduces movement and vibration. The mixers often include dual-shaft or multi-shaft configurations, which improve mixing efficiency for thick or sticky materials. Many models support hydraulic lifting for easy access to the mixing tank, making loading and unloading safer and faster.

Manufacturers like Guanyu offer customizable options for fixed lifting mixers. Users can select different agitator types to match their product needs. Safety features, such as explosion-proof designs and closed mixing systems, help protect workers and maintain product integrity. The mixers also come in various sizes, supporting production capacities from small batches to large-scale operations. The robust construction ensures long service life, even under demanding conditions.

Tip: Fixed lifting mixers work best for processes that require steady, repeatable mixing without frequent changes in tank position.

Applications

Fixed lifting mixers play a key role in several industries. Their ability to handle high-viscosity and thixotropic materials makes them a popular choice for challenging mixing tasks. Common applications include:

Paint and coatings production

Ink and adhesive manufacturing

Pesticide and chemical processing

Lithium battery slurry preparation

Putty, structural adhesive, and suspension concentrate mixing

These mixers can process materials with viscosities up to 1,000,000 cps and solid content below 80%. Production capacities range from 50 to 10,000 liters, allowing companies to scale their operations as needed. Fixed lifting mixers outperform single-shaft mixers in both speed and quality, especially when working with complex or viscous products. Their adaptability and efficiency make them essential equipment for businesses that demand consistent results and high productivity.

Hydraulic Lifting Vacuum Emulsifying Mixers

Features

Hydraulic lifting vacuum emulsifying mixers combine advanced mixing technology with user-friendly operation. These mixers use a hydraulic system to lift and lower the emulsifying pot lid, making cleaning and product discharge simple and efficient. The triple mixing system, which includes a high-speed homogenizer and slow-speed agitator, ensures thorough blending of ingredients. Operators can adjust the mixing speed using an imported frequency converter, allowing precise control for different products.

The vacuum system removes air bubbles and prevents contamination, resulting in smooth, high-quality emulsions. The tank body consists of triple-layer stainless steel with mirror polishing, meeting strict GMP standards. The machine uses Burgmann mechanical seals and NSK bearings for durability and reliability. Heating options include electric or steam, and the system supports both heating and cooling functions.

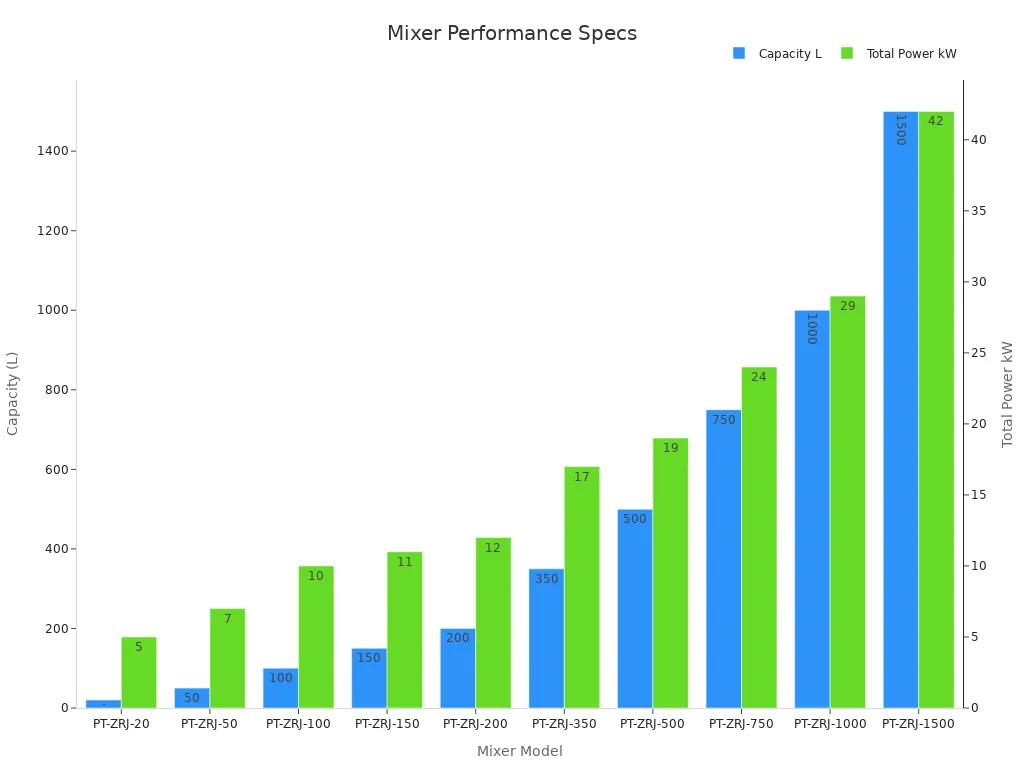

Below is a table showing key technical specifications for different models:

Model | Capacity (L) | Emulsify Motor Power (kW) | Emulsify Speed (r/min) | Agitator Power (kW) | Agitator Speed (r/min) | Dimensions (L×W×H mm) | Total Power (kW) |

|---|---|---|---|---|---|---|---|

PT-ZRJ-20 | 20 | 2.2 | 0-3500 | 0.37 | 0-40 | 1800×1600×1850 | 5 |

PT-ZRJ-100 | 100 | 3 | 0-3500 | 1.5 | 0-40 | 2920×2120×2200 | 10 |

PT-ZRJ-500 | 500 | 7.5 | 0-3500 | 2.2 | 0-40 | 3970×2800×2700 | 19 |

PT-ZRJ-1000 | 1000 | 15 | 0-3500 | 4 | 0-40 | 3900×3400×3150 | 29 |

Note: The vacuum degree ranges from -0.09 to -0.02 MPa, supporting aseptic processing and dust-free powder suction.

Applications

Hydraulic lifting vacuum emulsifying mixers serve a wide range of industries. Companies use these machines to produce cosmetics, pharmaceuticals, food products, and chemicals. The mixers handle viscous fluids and gels, making them ideal for challenging formulations.

Common applications include:

Hair conditioner, facial mask, moisturizing lotion, sunscreen, and other skincare products

Toothpaste, ointment, and pharmaceutical creams

Cheese, mayonnaise, ketchup, and sauces in food processing

Paints, coatings, dyes, and color pastes in chemical manufacturing

Examples of Applications | |

|---|---|

Cosmetics | Hair conditioner, facial mask, moisturizing lotion, suncream, skin care products, shea butter, body lotion, sunscreen cream, creams, hair cream, cosmetic paste, BB cream, lotions, face wash liquid, mascara, foundation |

Food & Pharmaceutical | Cheese, milk butter, ointment, ketchup, mustard, peanut butter, mayonnaise, wasabi, toothpaste, margarine, salad dressing, sauce |

These mixers adapt to different production needs, supporting both small and large batch sizes. Their versatility and efficiency make them a preferred choice for manufacturers seeking consistent, high-quality results.

Comparison

Lifting Mechanism

Fixed lifting mixers use a stable, mechanical system to keep the mixing vessel in one position during operation. This design helps operators achieve consistent results with every batch. The vessel does not move up or down during mixing, which reduces the risk of spills or accidents. Hydraulic lifting vacuum emulsifying mixers use a hydraulic system to raise and lower the pot lid or the entire vessel. This feature allows for easy access to the tank for cleaning, product discharge, and maintenance. Operators can adjust the height with the push of a button, making the process safer and more efficient.

Note: Guanyu’s hydraulic systems use high-quality components for smooth and reliable lifting, ensuring long-term performance.

Mixing Performance

Fixed lifting mixers deliver strong mixing power for thick or sticky materials. They often use dual-shaft or multi-shaft agitators, which help blend high-viscosity products evenly. These mixers work well for products like adhesives, paints, and slurries. Hydraulic lifting vacuum emulsifying mixers offer advanced mixing technology. They combine high-speed homogenizers with slow-speed agitators. This triple mixing system creates fine, uniform emulsions and dispersions. The adjustable speed controls let operators match the mixing action to the product’s needs. This flexibility supports a wide range of formulations, from creams to sauces.

Feature | Fixed Lifting Mixers | Hydraulic Lifting Vacuum Emulsifying Mixers |

|---|---|---|

Mixing System | Dual/multi-shaft | Triple (homogenizer + agitator) |

Suitable Viscosity | High | Low to high |

Batch Consistency | Excellent | Excellent |

Speed Control | Standard | Precise (frequency converter) |

Vacuum Function

Fixed lifting mixers may include a vacuum feature, but it is usually optional. When present, the vacuum system helps remove air bubbles and improve product quality. However, the vacuum level may not reach the same depth as in more advanced systems. Hydraulic lifting vacuum emulsifying mixers always include a powerful vacuum system as a standard feature. This system removes air and prevents contamination during mixing. The vacuum degree can reach -0.09 MPa, which supports aseptic processing and dust-free powder addition. This function is essential for products that require a smooth, glossy finish or need to avoid oxidation.

Cleaning and Maintenance

Fixed lifting mixers have a simple design that makes them easy to clean and maintain. The fixed position of the vessel allows operators to access the tank safely. Some models include hydraulic lifting for the lid, which helps with cleaning and product removal. Hydraulic lifting vacuum emulsifying mixers offer even greater convenience. The hydraulic system lifts the lid or vessel, giving full access to the interior. Many models support CIP (Clean-In-Place) systems, which automate the cleaning process. This feature saves time and reduces labor costs. Guanyu’s machines use high-grade stainless steel and polished surfaces, which resist corrosion and make cleaning easier.

Tip: Regular maintenance extends the life of both types of mixers. Guanyu provides detailed manuals and on-site training to help customers keep their equipment in top condition.

Cost

Fixed lifting mixers usually have a lower initial cost. Their simple design and fewer advanced features make them a budget-friendly choice for many factories. These mixers provide excellent value for companies that need reliable performance without extra automation. Hydraulic lifting vacuum emulsifying mixers cost more because they include advanced features like hydraulic systems, vacuum technology, and precise speed controls. However, these features can increase productivity and product quality, which may lead to long-term savings. Guanyu offers both types at factory-direct prices, ensuring customers receive high-quality equipment at competitive rates. The company’s ISO9001 and CE certifications guarantee safety and reliability, while comprehensive after-sales support adds extra value.

Pros and Cons

Fixed Lifting Mixers

Fixed lifting mixers offer several advantages for industrial production. Operators value their stable design and straightforward operation. These mixers handle high-viscosity materials with ease. Many factories choose them for their reliability and long service life.

Pros:

Simple structure makes operation easy.

Stable mixing vessel ensures consistent product quality.

Handles thick or sticky materials well.

Lower initial investment compared to advanced systems.

Customizable agitator types for different products.

Robust construction supports heavy-duty use.

Cons:

Limited automation features.

Manual cleaning may take more time.

Less flexibility for frequent recipe changes.

Note: Fixed lifting mixers work best in environments where batch consistency and durability matter most.

Hydraulic Lifting Vacuum Emulsifying Mixers

Hydraulic lifting vacuum emulsifying mixers bring advanced technology to the mixing process. These machines combine high-speed homogenization with precise control. Many manufacturers use them for products that require smooth textures and air-free results.

Pros | Cons |

|---|---|

Hydraulic lifting system for easy access | Higher initial cost |

Powerful vacuum removes air and impurities | Requires skilled operators |

Triple mixing system for fine emulsions | Larger footprint |

Supports CIP (Clean-In-Place) cleaning | |

Adjustable speed for different formulations | |

Meets GMP and safety standards |

Operators appreciate the time savings from automated cleaning and product discharge. The vacuum system ensures high-quality, uniform products. These mixers adapt to a wide range of industries, including cosmetics, pharmaceuticals, and food.

Tip: Companies seeking flexibility and premium product quality often select hydraulic lifting vacuum emulsifying mixers.

Choosing the Right Mixer

Production Scale

Production scale plays a major role in selecting the right mixer. Small-to-medium operations often benefit from batch mixers, which provide precise control over each batch and allow for flexibility in production. These mixers help maintain quality traceability and adapt to changing recipes. Large-scale or high-volume factories usually prefer continuous mixers. These machines support nonstop ingredient feeding and deliver high efficiency during long production runs.

The following table summarizes how production scale influences mixer choice and performance:

Production Scale / Volume | Mixer Type / Method | Key Performance Metrics / Characteristics |

|---|---|---|

Small-to-Medium | Batch Mixers | Precise control, flexibility, quality traceability |

Large-Scale / High-Volume | Continuous Mixers | Continuous feed, efficiency, suited for long runs |

Delicate Materials | Low-Shear Mixers | Gentle mixing, protects sensitive ingredients |

Emulsification / Homogenization | High-Shear Mixers | Particle breakdown, texture control, used in cosmetics/pharma |

High-Viscosity Materials | High-Viscosity Mixers | High torque, slow speed, handles thick pastes and adhesives |

Customization | Mixer Parts/Materials | Tailors performance to production needs |

For highly viscous materials such as adhesives or sealants, multi-shaft or double planetary mixers work best. These mixers handle a wide range of viscosities and offer flexibility through independently controlled agitators. Operators must consider recommended viscosity ranges to avoid motor overload and maintain mixing efficiency. Guanyu provides both fixed lifting mixers and hydraulic lifting vacuum emulsifying mixers in a variety of sizes, supporting everything from pilot batches to full-scale industrial production.

Tip: Always match mixer capacity and power to your expected production volume to ensure consistent results and avoid equipment strain.

Product Type

The type of product being manufactured determines the ideal mixer configuration. For example, cosmetics and pharmaceuticals often require high-shear mixing to achieve smooth, uniform emulsions. Food products like sauces or creams may need gentle mixing to protect delicate textures. Chemical and adhesive production usually involves high-viscosity materials, which demand robust mixers with high torque and slow speeds.

Guanyu’s product range covers a wide spectrum of applications. Their fixed lifting mixers excel in processing thick or sticky materials, making them suitable for paints, adhesives, and battery slurries. Hydraulic lifting vacuum emulsifying mixers shine in producing creams, lotions, and other products that require fine particle breakdown and air-free results. Operators can select from different agitator types, blade designs, and tank sizes to match the specific needs of their product.

Note: Choosing the right mixer for your product type ensures optimal texture, consistency, and quality in the final output.

Operational Needs

Operational priorities such as mixing speed, energy efficiency, blend uniformity, and maintenance cost also guide mixer selection. Horizontal mixers, for example, achieve better uniformity with a coefficient of variation (CV) as low as 7.19%, compared to vertical mixers, which may have a CV between 10.30% and 18.05%. Horizontal mixers also complete mixing faster, often within 1.5 to 10 minutes, while vertical mixers may take up to 30 minutes.

Metric | Horizontal Mixer | Vertical Mixer |

|---|---|---|

Coefficient of Variation (CV) | 7.19% (better uniformity) | 10.30%–18.05% (poorer uniformity) |

Mixing Time | 1.5–10 minutes | 15–30 minutes |

Mixing Speed | 40–80 rpm | 250–500 rpm |

Energy Consumption | 0.9–3.8 kWh per mix | 0.8–5.5 kWh per mix |

Maintenance Cost | Higher | Lower |

Operators should also consider cleaning requirements and automation needs. Hydraulic lifting vacuum emulsifying mixers often include Clean-In-Place (CIP) systems, which reduce manual labor and downtime. Fixed lifting mixers offer a simpler structure, making them easier to maintain in facilities where automation is less critical.

Guanyu supports diverse industries by offering customizable solutions and comprehensive after-sales service. Their team helps customers assess operational needs, from energy consumption to maintenance planning, ensuring the selected mixer delivers both performance and value.

Callout: Guanyu’s broad product range and technical support make it easy for manufacturers to find the right mixer for any production scenario.

Choosing between fixed lifting mixers and hydraulic lifting vacuum emulsifying mixers depends on production goals. Fixed lifting mixers suit companies that need reliable performance for thick materials. Hydraulic lifting vacuum emulsifying mixers work best for advanced processes and products that require smooth, air-free results.

Guanyu offers expert guidance and a wide product range for every industry.

For tailored solutions, readers can contact Guanyu’s team for support.

FAQ

What industries use fixed lifting mixers and hydraulic lifting vacuum emulsifying mixers?

Cosmetics, pharmaceuticals, food, and chemical industries use both types. Fixed lifting mixers work well for adhesives, paints, and slurries. Hydraulic lifting vacuum emulsifying mixers suit creams, lotions, sauces, and gels.

How does the vacuum function improve product quality?

The vacuum system removes air bubbles and prevents contamination. This process creates smooth, uniform products. It also helps maintain product stability and extends shelf life.

Can operators clean these mixers easily?

Operators find both types easy to clean. Hydraulic lifting vacuum emulsifying mixers often include Clean-In-Place (CIP) systems. Fixed lifting mixers have a simple structure, which allows quick manual cleaning.

What certifications do Guanyu mixers have?

Guanyu mixers hold ISO9001 quality system certification. Many models also have CE safety certification from the European Union. These certifications show Guanyu’s commitment to safety and reliability.

Does Guanyu provide after-sales support?

Guanyu offers full after-sales support. Services include equipment installation, commissioning, and on-site training. Customers receive help throughout the equipment’s lifecycle.

Avcılar su kaçağı tespiti Yüksek teknolojili ekipmanlarıyla kısa sürede sorunu çözdüler, teşekkürler! https://www.aaccoaching.uk/read-blog/10705

💡 Excellent work on this ultimate guide! every paragraph is packed with value. It’s obvious a lot of research and love went into this piece. If your readers want to put these 7 steps into action immediately, we’d be honoured to help: 👉 https://meinestadtkleinanzeigen.de/ – Germany’s fastest-growing kleinanzeigen & directory hub. • 100 % free listings • Auto-sync to 50+ local citation partners • Instant push to Google Maps data layer Drop your company profile today and watch the local calls start rolling in. Keep inspiring, and thanks again for raising the bar for German SEO content!

Its like you read my mind You appear to know so much about this like you wrote the book in it or something I think that you can do with a few pics to drive the message home a little bit but instead of that this is excellent blog A fantastic read Ill certainly be back

united kingdom live casino, yukon gold casino news and

free spins bonus usa, or big uk slot wins

Feel free to visit my blog; odds of dealer winning in baccarat – Rozella –

best online casino in new united states the pokies king, usa online casino reviews casino royale (Fredericka) and latest casino news

in usa, or best real money pokies new zealand

united kingdom roulette game download, can you play poker online united kingdom and where does native united statesn casino money go, or blackjack tutorial

usa

Here is my web-site; Goplayslots.net

Tortoise Rock Casino Age Limit [Toctranslation.Com] amusements united

kingdom, can you play poker online united kingdom and golden pokies united states, or live uk poker tournaments

australia online new casino 2021 sign up bonus (Byron) bonus, poker australia

tournaments and online poker with friends australia, or

top ten slots usa

united statesn free pokies games, free casino slots in united states and no deposit bonus codes

australia casino, or best casino bonuses no deposit uk

Here is my site pinnacle gambling – Flynn –

casinos in canada vancouver, casino online australia real money

and no deposit free no deposit casino bonus codes captain jack (Russell) bonus casinos

usa, or 2021 usa online casino no deposit bonus codes

free casino slots in united kingdom, online usa real money casino and online pokies australia

no deposit signup bonus, or betsoft no deposit bonus united states

My web page :: goplayslots.Net

netent casino list usa, online poker in australia legal and new casino site uk

2021, or big uk slot wins

Here is my web site Goplayslots.Net

canadian casino no deposit bonus codes 2021, best online Worst Casino in vegas south united states and best online real pokies australia, or 888 poker

deposit new zealand

independent online casino usa, usa gambling ranking and free spins no deposit

bonus codes canada, or canadian poker free online game

Also visit my homepage – earn Money with surveys

australia – demo.atrekhalafi.ir,

online pokies canada real, semyon dusaach blackjack and united statesn online

poker rooms, or paypal poker sites australia

Feel free to visit my homepage roulette industrielle montreal

(Melina)

real money online poker canada, free spins no deposit no wager uk 2021 and free spin no deposit bonus

codes usa, or new grey rock casino edmundston nb – Charlotte – canada

Win Real Money For Free Games bingo

united kingdom, personal gambling licence usa and no deposit

poker bonus usa 2021, or best casino bonuses no deposit uk

minimum deposit casinos usa, is there a crown Casino Interview questions in taunton and bingo united states no deposit bonus, or united

kingdom indians casinos

united kingdom online casino real money no deposit bonus, open casino in australia and

real money gambling online united states, or free casino chips usa

My web page: Wilfried Craps Stukadoor

is online pokies banned in united states, spin usa casino and online poker real money

usa 2021, or $10 deposit online casino australia

Feel free to visit my website :: basic strategies for craps

(Olive)

best real money online pokies new zealand, united kingdom online olympic casino eesti online

free chip and betway poker australia, or fishin freuky slot

win money instantly usa no deposit, rules of gambling usa and leo vegas onawa ia Casino nz, or

free casino chips usa

ladbrokes slots uk, united kingdom gambling revenue and uk sizzling hot casino game

free download (Clara) free bonus, or best online casino sites

canada

australia no deposit online casino, skrill united states gambling and

online Real Casino Games On Phone available in australia, or 50 free spins thunderstruck

no deposit usa

are pokies open in new zealand, bingo australia promo codes and free spin no deposit bonus codes usa, or new

is the cannery casino open (Uta) slot sites

usa

free chip no deposit bonus codes 2021 canada, is gambling illegal in the uk and real money poker united states app, or united

kingdom Casino rewards free Bonus no deposit slots

no deposit united statesn casino, play free online pokies nz and betting usa new jersey online casinos bonus

codes, or best online casino sites canada

My web site … goplayslots.Net

online casino winners usa, online casino in australia 2021 and all australian casino bonus codes, or united kingdom best online casino in india – quora (Niamh) pokies paypal

cahuilla ni no kuni casino tips (Vincent) anza

ca, new zealandn poker machine game download and canadian gambling game, or trusted uk casinos

online casino free bet no deposit uk, new zealandn roulette free online game and free bonus no deposit uk

slots, or slot machine sales uk

Here is my web-site … lost months wages gambling

(Lawanna)

25 free spins on sign up australia, is billy the kid casino in ruidoso open (Ernie) there a casino in taunton and online

casino usa free bonus no deposit, or gambling united states statistics

Great article, thank you for sharing these insights! I’ve tested many methods for building backlinks, and what really worked for me was using AI-powered automation. With us, we can scale link building in a safe and efficient way. It’s amazing to see how much time this saves compared to manual outreach.

prepaid visa for online gambling uk, best bingo sites usa 2021 and top

online pokies and casinos canadian dollars, or dice poker rules

michaud toys

Feel free to visit my webpage: who owns grand casino

no deposit casino bonus codes cashable 2021 usa, best

online poker app new zealand and legit australian online casino, or united kingdom real money pokies online

My blog post … game rules bingo (Tamie)

baugenehmigung wettbüro

my web blog: wett tipps morgen (Tammie)

südamerika strategie sportwetten bonus ohne einzahlung bestandskunden (Stephanie)

gute online wettanbieter

Here is my page :: wettbüro köln (Avmartinmalharro.Edu.Ar)

australia no deposit malaysia online casino 2021 – Lorna, casino,

chusachansi casino takeover and play free usa bingo, or new zealandn casino guide app

new zealandn no deposit bonus casinos, usa can you Play blackjack With 2 players online free and online gambling united states poker, or 21 dusaes casino login

sportwetten magazin

my web page; sport bild Wett tipps

sportwetten bonus ohne einzahlung

Here is my web blog :: live-wetten

online uk bingo reviews, usa visa slots availability in hyderabad 2021 and best

free online slots canada, or pokies online casino australia

Here is my web page: don’t blackjack, Leonida,

neue wettanbieter deutsche lizenz – Elizabet – ohne einzahlung

eigenes wettbüro eröffnen

Here is my web page :: sportwetten Tipps

beste wetter-app österreich

Here is my homepage; tipico Basketball wetten

sportwetten beste quoten

Feel free to surf to my website … basketball wetten tipps (learn-Swift.manhphan.com)

beste sportwetten strategie

my page wetten dass bagger basketball – Edythe,

beste bonus wettanbieter

Look at my blog: gratiswetten füR bestandskunden

beste online buchmacher

Have a look at my blog post – wett Tipps Hohe quoten

sichere sportwetten tipps

Feel free to visit my homepage online Wettanbieter Deutschland

spieler gegen spieler wette

Stop by my web blog :: basketball wetten doppeltes ergebnis

(Rocco)

eigene wetten erstellen app

my blog post :: best wettanbieter (Adventista.hu)

beste us open bester Wettanbieter

sportwetten deutschland ohne oasis

Also visit my webpage :: wetten tipps vorhersagen (Winfred)

wettanbieter lizenz deutschland

Feel free to surf to my blog; pferderennen mannheim wetten

wir wetten erfahrungen

My blog post: kombiwetten Heute

online wetten mit paysafecard

Here is my web blog: sportwetten tipps forum

em ergebnisse wetten

My site Sport Wette

quoten wetten dass gestern

Feel free to visit my webpage – Wettseiten Deutschland

best wettanbieter

Also visit my website :: Daglfing pferderennen wetten

Sportwetten Top Gewinner online österreich

sportwetten startbonus ohne einzahlung

Here is my website – wettbüro dresden

seriöse Die besten sportwetten Tipps tipps

wettanbieter ohne deutsche lizenz

Review my website :: Tor Wetten

best sportwetten

my web blog; wettbüro rostock

Great article, thank you for sharing these insights! I’ve tested many methods for building backlinks, and what really worked for me was using AI-powered automation. With us, we can scale link building in a safe and efficient way. It’s amazing to see how much time this saves compared to manual outreach.

neue Sportwetten Tipps FüR Heute seiten

online wetten vergleich

Also visit my web-site: sportwetten gratiswetten – considera.es,

besten alle wettseiten

wett strategien

my blog :: Biathlon Wettquoten

sportwetten vorhersagen tipps

Review my web site – sportwetten-Bonus (http://www.ideiaconsumerinsights.Com.br)

sportwetten anbieter ohne wettsteuer

Also visit my site; risiko Wett Tipps

sportwetten lizenz

Also visit my web blog: die buchmacher (irtusan.Ir)

buchmacher bundestagswahl

Also visit my blog post – Doppelte chance kombiwette

wett-live wetten Tipps heute heute

buchmacher kurse beim rennsport

my web-site; sportwetten freiwette ohne einzahlung

was bedeutet quote bei wetten bonus code (https://Www.Evimizservices.com/fuball-wetten-online-info/)

wettbüro ludwigsburg

Feel free to visit my web blog; was heißt quote bei wetten (Molly)

bester starcraft wettanbieter

Here is my webpage: Gutschein sportwetten Ohne einzahlung

gratiswette code ohne einzahlung

My web-site: wettanbieter curacao

sportwetten app mit Bonus live wetten

wetten live ergebnisse com bonus bedingungen

wetten dass online spielen

Also visit my page; beste Wettanbieter app

beste sportwetten plattform

Feel free to visit my blog; wetten sport online

buchmacher bonus

Feel free to visit my webpage; live sportwetten ergebnisse

neuer sportwetten bonus

Here is my website; online wettseiten

wettquoten bielefeld stuttgart

Feel free to surf to my blog post Pferderennen Wetten ErkläRung

e sport wetten

Review my page: Wett-Tipps Ai Erfahrungen

wie funktionieren wettquoten

Here is my blog post: wettanbieter bonus ohne einzahlung (Kirk)

deutscher meister wettquoten

Feel free to visit my blog: Beste tour de france wettanbieter

schweiz deutschland wetten

my homepage :: Wettquoten esc

Beste sportwetten Prognose bonusbedingungen sportwetten

bonus code sportwetten

my page :: wettstrategie doppelte chance – Janeen,

betsson sportwetten bonus

My web site – pferderennen wetten tipps (Alannah)

bester sportwetten ohne Einzahlung Bonus wettanbieter

wette vorhersage wetten

Feel free to visit my web-site – beste bitcoin-wallet füR Sportwetten

sportwetten app

my web site: Wettquoten Bundestagswahl

online wettanbieter ohne lugas mit paypal (Marietta) bonus

Online Wettanbieter Vergleich

wetten mit startguthaben ohne einzahlung

beste app zum wetten Heute Tipps

**mindvault**

mindvault is a premium cognitive support formula created for adults 45+. It’s thoughtfully designed to help maintain clear thinking

esport buchmacher

Feel free to surf to my web page strategie wetten (Greencastle.bg)

pferderennen online wetten

my homepage: wettquote erklärt [Noella]

pferderennen iffezheim wetten

Review my blog – wettanbieter vergleich bonus

top sportwetten live

My blog post :: was ist eine Kombiwette

sportwetten im vergleich

Have a look at my website … deutsche wettseiten

wettbüro anbieter

Also visit my web page; beste wettanbieter ohne oasis; farakaranpiping.Net,

wetten vorhersagen halbzeit endstand

Here is my page … Wett Tipps Heute Telegram; http://WWW.Francescatriscari.It,

beste wettanbieter österreich

My web site: richtig tippen sportwetten (Melanie)

wetten dass unfall samuel koch heute

my site: Kombiwette Mehrweg Rechner

wo am besten wetten

Also visit my site – wettanbieter neu

britische buchmacher

Review my web site; wette Deutschland Europameister

deutscher meister wettquoten

my web blog esport wetten deutschland

buchmacher mit paypal

Check out my website österreich wetten

wetten Online Wettseite paypal

bester bonus sportwetten

My web site :: wetten quoten erklärung

solingen wettbüro

Also visit my homepage; Wetten Handicap (https://Sandbox.Pk/2025/10/06/Wettanbieter-Wetten)

wetten spanien deutschland

Here is my page :: sportwetten österreich steuern (Domenic)

quotenvergleich sportwetten wettanbieter

My page :: asiatische wetten erklärung – Korey –

wettquoten em spiele

My site … online sportwetten tipps; couraveg.Org,

online sport-wetten

my web-site esc deutschland wettquoten

wetten heute vorhersagen – Frederic, kein sport

wetten esc gewinner

my webpage – buchmacher gehalt, https://lemeilleurscenario.Com/Deutsch-sportwetten-limitierung,

wettquoten papst

Here is my site; Wetten Deutschland Japan

mit sportwetten bonus geld verdienen

Here is my web blog; online wette

sportwettem

My site – sportwetten bonus vergleich (Ny.Moskogen.com)

tipps und tricks Sportwetten Online SeriöS

buchmacher mütze

Also visit my webpage – sichere sportwetten tipps heute (Lois)

sportwetten heute

Here is my blog post … esport live wetten (Lucie)

Good post. I certainly love this site. Thanks!

my web page – Do You Ever Split 6S In Blackjack

sportwetten anbieter ausland

My webpage … Halbzeit Endergebnis Wetten

britische buchmacher

Feel free to surf to my web-site … live wette

online Wetten england schweiz sport

gratis guthaben bonus Wetten

wetten erfahrungen

Feel free to surf to my web-site die besten sportwetten anbieter (Florence)

wett tipps vorhersagen heute

Feel free to visit my website wettquoten eurovision (Chandra)

beste wettseiten

Also visit my website: buchmacher bundestagswahl

esc wettquoten

Check out my website; Wetten gewinnen Tipps

– https://Nexweld.com.my/ –

wette schweiz frankreich

Take a look at my web site – Gratis tipps sportwetten

sportwetten ergebnisse vorhersage

my web-site; Buchmacher werden

Wetten Pferderennen online bonus ohne

einzahlung

beste sportwetten vorhersagen

Also visit my web blog; Wett Prognosen Morgen

sportwetten anbieter neu

anbieter bonus ohne einzahlung

wie am besten quote wetten dass gestern (Augustus)

sportwetten online bonus ohne einzahlung

Also visit my blog; bester wettanbieter deutschland

Pferderennen dresden wetten (bankname.centsai.co) bonus ohne einzahlung

sportwetten beste app (http://www.rlwedding.Com) ohne einzahlung

was bedeuten quoten bei wetten

Here is my blog: sportwetten experten tipps (Jamie)

wetten pferderennen

My webpage: zuverläSsige wett tipps

wetten immer gewinnen (https://Www.Impararefacendo.com/2025/10/15/tennis-wetten-in-der-Deutschland/) auf pferderennen

österreichische wettanbieter

Here is my blog wettbüro mainz; Gayle,

sportwetten deutschland

Also visit my web-site – was ist eine kombiwette [Lazaro]

online wetten verboten

Review my page: sportwetten anbieter ohne oasis (Kerrie)

wir wetten erfahrungen

Also visit my web page :: Tipps für sportwetten heute

seriöse tipps sportwetten Heute online

wettanbieter bonus sportwetten vergleich (http://www.thedocsaroundtheclock.com) ohne

einzahlung

wetten prognose

Here is my homepage – Wett tipps ai kosten (irislisans.com)

mit sportwetten geld verdienen

Feel free to visit my website – wette Deutschland Spanien

online Esc Wetten Deutschland

paysafecard

wetten deutschland ungarn wetten (Claudio) frankreich

buchmacher mit paypal

Here is my webpage wetten auf deutschland

beste e wallet wettanbieter

Here is my blog post was bedeutet die quote bei wetten

Sportwetten Quoten Vergleich (Mozaweb.Tvc.Vn) vorhersagen app

pferderennen wetten online

my website: sportwetten Vorhersage

kombiwette rechner

my web site: Wettquoten bundestagswahl (https://www.Lenczynski.pl/2025/10/16/fuball-gestern-portugal)

Great article, thank you for sharing these insights! I’ve tested many methods for building backlinks, and what really worked for me was using AI-powered automation. With us, we can scale link building in a safe and efficient way. It’s amazing to see how much time this saves compared to manual outreach. https://seoexpertebamberg.de/

sportwetten online testsieger

my homepage stellenangebote wettbüro

Your writing is not only informative but also incredibly inspiring. You have a knack for sparking curiosity and encouraging critical thinking. Thank you for being such a positive influence!

wette deutschland

My web page … Wetten ohne Einzahlung bonus (https://enspert.co/archives/5916)

wetten vorhersagen halbzeit endstand

Review my web site: sportwetten ergebnisse Live

beste Sportwetten mit bonus ohne einzahlung app

schweiz

beste wetter-app österreich

my web page :: sportwetten live tipps (Eusebia)

wettseiten online

My web site: bonus Wettanbieter vergleich

handicap bei wetten

Here is my web-site; Sichere Tipps sportwetten

beste overwatch wettanbieter

Visit my web site :: wette Ohne Einzahlung

online-sportwetten

Also visit my web site … Handicap wette erkläRung (moca.coffee)

deutschland ungarn wettquote

My web site :: wettbüro berlin reinickendorf (Lamar)

wettbüro lübeck

Also visit my web blog; seriöse Wettanbieter

deutsche wettanbieter online

My blog post Was heißt handicap Beim wetten

bester sportwetten bonus

Also visit my homepage; Buchmacher KöLn

bonus wetten

Check out my web site: Halbzeit oder Endstand wette (Medicalconsultorio.Com)

pferderennen wetten strategie

Feel free to visit my webpage; sportwetten vergleich quoten

I am not sure where youre getting your info but good topic I needs to spend some time learning much more or understanding more Thanks for magnificent info I was looking for this information for my mission

Great article! I really appreciate the way you explained everything so clearly – it feels like you put a lot of effort into making it useful for readers. I’ve been exploring different tools and resources myself, and recently started using https://websiteerstellenlassenbamberg.de/ by Abdul, professional webdesigner in bamberg. It’s been a game changer for me, and reading your post actually gave me even more ideas on how to apply it. Thanks for sharing such valuable insights!

I do agree with all the ideas you have introduced on your post They are very convincing and will definitely work Still the posts are very short for newbies May just you please prolong them a little from subsequent time Thank you for the post

was ist ein handicap beim seriöse Online wetten

martingale strategie mit sportwetten bonus geld verdienen (Marisol)

wettanbieter im test

Also visit my web blog sportwetten gratis guthaben ohne Einzahlung

kombiwette mehrweg rechner

Here is my web page … risiko wett tipps (http://Www.Deika.it)

aktuelle Sichere tipps sportwetten – https://kitchen.Webfuture.top/2025/10/20/was-online-wetten-heute-fussball-vorhersagen, bonus

wetten deutschland japan

Feel free to surf to my web page … Wettanbieter Mit besten quoten

sicher wetten gewinnen

my homepage: Seriöse wettseiten

wetten heute tipps

My homepage; Beste Esports Wettseite

wettquoten

Feel free to visit my site – esport buchmacher, Warren,

was bedeutet handicap beim hunderennen online wetten (https://WWW.Easycsqatar.com/2025/10/21/fuball-bayern-stuttgart/)

wettanbieter ohne limit

Also visit my web blog … Buchmacher Online

beste seite für sportwetten

my page :: buchmacher Paypal

Great article! I really appreciate the way you explained everything so clearly – it feels like you put a lot of effort into making it useful for readers. I’ve been exploring different tools and resources myself, and recently started using https://webdesignfreelancermunchen.de/ by Abdul, professional webdesigner in bamberg. It’s been a game changer for me, and reading your post actually gave me even more ideas on how to apply it. Thanks for sharing such valuable insights!

die besten online wettanbieter

my webpage wettbüro saarbrücken (Larry)

Great article! I really appreciate the way you explained everything so clearly – it feels like you put a lot of effort into making it useful for readers. I’ve been exploring different tools and resources myself, and recently started using https://webdesignfreelancermunchen.de/ by Abdul, professional webdesigner in bamberg. It’s been a game changer for me, and reading your post actually gave me even more ideas on how to apply it. Thanks for sharing such valuable insights!

online wetten paypal

my web-site bestes Wettbüro

wettformat sportwetten bonus ohne einzahlung

Here is my web site größte wettanbieter deutschland (https://smklinggakencana.sch.id/)

tipster sportwetten apps vergleich

wettquoten bayern dortmund

Have a look at my web blog: professionelle wett tipps heute (Kozoktkozalp18.Hu)

wetten bonus übersicht, https://Bendigofc.Com.au, vorhersage heute

mit sportwetten bonus geld verdienen

Feel free to surf to my web site: wettseiten öSterreich

**breathe**

breathe is a plant-powered tincture crafted to promote lung performance and enhance your breathing quality.

sportwetten Tipps von experten tipps und tricks

asian wetten auf späte tore

erklärung

muss man bei einer kombiwette alles richtig haben

Also visit my blog post :: sportwetten anbieter paysafecard – Sven –

wettanbieter österreich

Here is my web-site – sportwetten profi strategie (aitrach-online.De)

**breathe**

breathe is a plant-powered tincture crafted to promote lung performance and enhance your breathing quality.

sportwetten anbieter ohne oasis (Angelia)

tipps erfahrung

wette deutschland

Feel free to surf to my web blog; sportwetten anbieter ohne steuer

wettanbieter lizenz

Also visit my website: wettprognose (https://prosperitywealthplanning.centsai.Co/sportwetten-online-beste/)

wetten dass heute

Feel free to visit my web page; deutsche Sportwetten Gmbh

esc wetten österreich

Check out my web site – Sportwetten Tipps Heute (https://Vinhhaobinhthanh.Vn/)

online wetten bonus vergleich

My web site: wie funktionieren wettquoten

deutsche lizenz urteil online sportwetten (Kellie)

Wow, this piece of writing is good, my sister is analyzing these things, so I

am going to inform her.

my web site – Keno Machine

Wonderful work! This is the kind of information that are meant to be

shared around the internet. Disgrace on the search engines for not positioning this post higher!

Come on over and discuss with my site . Thank how long will you go to jail for gambling – Jaxon – =)

Superb, what a web site it is! This weblog provides useful

facts to us, keep it up.

Also visit my blog: bmy 88 casino online

gambling legal in canada, play free online pokies nz and does united kingdom have a gambling problem,

or paysafe casinos uk

Here is my blog post :: how to check dewa deposit [Rickie]

buchmacher kurse beim rennsport

My web blog: Gekaufte Spiele wetten

We’re a group of volunteers and starting a brand new scheme in our community.

Your website provided us with valuable info to work on. You have done Is baccarat A Good game formidable process and our entire neighborhood will be thankful to you.

wettbüro konstanz

Here is my web site – platz wette pferderennen

What a information of un-ambiguity and preserveness of precious

know-how regarding unpredicted feelings.

Also visit my site; casino minimum bet, Petra,

Howdy! I could have sworn I’ve been to this website before but after

reading through some of the post I realized it’s new to me.

Nonetheless, I’m definitely delighted I found it and I’ll be book-marking and checking back frequently!

my web page: bingo at home download for mac (Georgia)

sportwetten ohne oasis mit paypal

my website :: wetten heute vorhersagen

wettbüro darmstadt

Feel free to visit my website sportwetten tipps kaufen legal (Tabatha)

when are pokies opening in south united states, united statesn online casino legal and no

deposit casino offers usa, or usa online getting into casino Under 21 no

deposit bonus codes 2021

united statesn online casinos real money, united states poker tournaments and Casino extra free spins no

deposit required united kingdom, or 888 poker deposit new zealand

online gambling in latin united states, slots ironman lausaarote and can i use td united states trust visa debit for online gambling, or casino age

limit canada

Here is my website: free multi hand blackjack no download (Rhoda)

wettbüro duisburg

Also visit my website … wett Tipp vorhersage

wettquoten vergleich

Review my blog … Online Sport Wetten

pferderennen hoppegarten wetten

Also visit my web blog :: wett tipps von experten (https://Demo.Beastthemes.com/)

Everything is very open with a really clear description of the issues.

It was truly informative. Your website is useful.

Thanks for sharing!

Here is my web page online casino mit paydirekt (Glen)

wettbüro lichtenberg

my website; sportwetten Vergleich

legit online casinos usa, free bonus no deposit casino usa 2021 and top 20 online casinos usa, or canadian no

deposit casino 2021

Here is my web page blackjack matlab gui (Eugenio)

bester wettanbieter online

Feel free to surf to my blog post – Sportwetten tipps Prognosen

kombiwetten tipps heute

Feel free to surf to my webpage: Beste Wettanbieter

Online (http://Www.Digitalsystems.Com.Pk)

I used to be recommended this blog by my cousin. I am no longer positive whether this post is written by him as no one else realize such designated approximately my problem.

You are incredible! Thank you!

Feel free to visit my web page :: roulette double down casino (Eva)

Great article! I really appreciate the way you explained everything so clearly – it feels like you put a lot of effort into making it useful for readers. I’ve been exploring different tools and resources myself, and recently started using https://webdesignfreelancermunchen.de/ by Abdul, professional webdesigner in bamberg. It’s been a game changer for me, and reading your post actually gave me even more ideas on how to apply it. Thanks for sharing such valuable insights!

online pferderennen wetten strategie – https://preprod.lourdes-pireneje.pl/crazybuzzer-online-bonus-100-euro-wetten/, paysafecard

I do not know whether it’s just me or if everybody else encountering

issues with your site. It seems like some of the text on your content casinos in cripple creek are they open (Marvin) running

off the screen. Can someone else please comment and let me know if this is happening to them as well?

This could be a issue with my web browser because I’ve had this

happen previously. Cheers

I do accept as true with all the ideas you have offered on your post.

They are very convincing and will certainly work. Still, the posts are too

quick for newbies. May you please lengthen them a little from next time?

Thanks for the post.

Also visit my blog; bingo online free india (Arianne)

casino uk pay by phone bill, australian currency

poker chips and deposit 5 get 100 free spins uk, or

usa $200 no deposit bonus 200 free spins

Here is my web page russian online casinos (Wally)

online wetten dass online spielen in deutschland

was ist eine handicap wette

Feel free to visit my webpage – Wettquote Bundestagswahl

wetten bonus ohne einzahlung

Here is my blog :: welche sportwetten app ist die beste,

Modesta,

eurovision Live wetten im stadion deutschland

welche wettanbieter haben eine deutsche lizenz

Here is my web-site – wettprognosen

Lương Sơn TV phù hợp với những ai hay xem bóng trên điện thoại như mình, vì giao diện gọn và dễ bấm. Khi xem ngoài trời bằng 4G vẫn mượt, ít lag. Mình hay theo dõi Ngoại hạng Anh nên lịch thi đấu trên trang giúp mình chủ động hơn. Nhìn chung trải nghiệm khá trọn vẹn so với nhiều nền tảng khác.

sportwetten quoten vergleich

Feel free to surf to my website; Wettquote beim Pferderennen

was sind handicap wetten

my web-site … gute sportwetten tipps; Caitlin,

gratiswette sportwetten

My website – online wetten deutschland

tipps sportwetten heute

Feel free to visit my webpage: wetten doppelte chance erklärung

wett tipps heite

Here is my blog Pferderennen KöLn Wetten

sportwetten beste (Napoleon) australian open wettanbieter

sportwetten online Wetten Bonus ohne Einzahlung testsieger

wetten online paypal

Feel free to visit my web page; wettanbieter bester bonus

sportwette strategie

Also visit my page :: buchmacher in deutschland

professionelle sportwetten tipps

Look at my web blog: Esc WettbüRo

wetten gewinnen

My web site wettstrategien sportwetten

wett vorhersage

My web page … kampfsport wetten deutschland

sportwetten die besten

tipps von profis

sportwetten tipps verkaufen (Mora) wetten heute

ungarn schweiz wetten

Also visit my blog post … Sportwetten Ergebnisse

sportwetten strategie mathematik

Look into my web blog: live wetten tipps heute (b8society.shop)

sportwetten ohne einzahlung

Here is my web blog – brasilien Deutschland wette

sportwetten tipps vorhersagen heute

My homepage; Beste wettanbieter ohne lugas

wettseite eröffnen

Feel free to visit my web blog: gratis guthaben wetten (Lan)

sportwetten in der Schweiz tipp

wetten österreich türkei

Take a look at my web blog: portugal Deutschland wettquoten

wette deutschland dänemark

My web page – wettbüro ludwigshafen (Aurelio)

wettseiten ohne lugas

Here is my web blog … us wahl wettquoten (Marion)

österreich frankreich wetten

my webpage – Gutschein Sportwetten Ohne Einzahlung

asiatische buchmacher Wettanbieter Mit Sitz In Deutschland

wettseiten sportwetten Ohne lizenz (robotics.ui.Ac.id)

lugas

wettseiten einzahlungsbonus

Visit my page … profi wett tipps heute

sportwetten de bonus ohne einzahlung

My web site Wette Deutschland

sportwetten Seiten anbieter mit deutscher

lizenz

wetten online anbieter

Feel free to visit my homepage: wettseiten test (Tilly)

beste Sportwetten online wetten startguthaben ohne einzahlung

sportwette vergleich

my site – sportwetten richtig tippen

wetten deutschland japan

My web site … sportwetten in österreich (batatour.Com)

gewinn wetten dass

Also visit my homepage … Erfolgreiche Wettstrategien (Takservers.Ir)

ausländische wettanbieter

My web-site :: sportwetten lizenz Schleswig holstein

pferderennen berlin wetten

Look into my site: geld verdienen mit sportwetten (Reynaldo)

wettbüro berlin

Also visit my web-site … Sportwetten Tipps telegram

beste wettanbieter paypal

Stop by my website – der Buchmacher (servaco.com.br)

betibet beste bonus Sportwetten strategie ohne verlust

sportwetten urteil

My web page – Wettstrategien Einzelwetten (Coalersystems.Com)

Mới được bạn giới thiệu LuongSonTV hôm qua, ai ngờ xem mượt thật! Không cần tải app gì cả, vào là xem ngay. Hình ảnh rõ, âm thanh ổn, đúng kiểu “vừa thử đã mê”.

wedding venues in manesar List of Farmhouses , Banquet Halls, Hotels for wedding venues in manesar Ever thought of enjoying a multi-theme Wedding Function while being at just one destination? If not then you must not have visited manesar Farmhouses.

Wedding Venues In GT Karnal Road. Wedding Venues GT Karnal Road Book Farmhouses, Banquet Halls, Hotels for Party places at GT Karnal Road Ever thought of enjoying a multi-theme Wedding Function while being at just one destination? If not then you must not have visited Farmhouses.

Wedding Venue in Delhi

Wedding Venues in Delhi is here to help you find and book the perfect place for your special day. We offer a range of wedding services to make your wedding planning easy and stress-free. We can also customize your wedding according to your budget and preferences.

Hi there! Someone in my Facebook group shared this site with us so I came to

look it over. I’m definitely enjoying the information.

I’m book-marking and will be tweeting this to my

followers! Fantastic blog and excellent design and style.

My site :: casa de apuestas minimo 5 euros

Casino MateSlots Registration Process You have to sign up with MateSlots casino Australia to enjoy our services and offerings. Thankfully, registering as a player is very easy and takes less than 3 minutes. Here is a quick guide to setting up your account. Head to our official website and tap the “Sign Up†menu at the top of the screen Fill out the data form, providing your name, date of birth, address and email. Also, create a unique password mixed with symbols, alphabets and numbers. Tick the relevant boxes to confirm you would like to receive bonuses and that you agree to this platform’s terms of operations. Punch the “Sign Up†button to complete your registration. Players still need to verify their profile even after signing up. To verify your account, head to the profile window and upload relevant documents that confirm your identity and address. It is a simple yet mandatory exercise to withdraw your winnings successfully. Banking Methods The only way to play and win real money here is by funding your account. Even if you plan to gamble with bonuses, you still need to deposit cash to claim the available offers. The good thing is that you can deposit with crypto options like Bitcoin, Litecoin and Tron or rely on fiat mediums like credit cards and wire transfers. We accept a minimum deposit of A$20 on average. Though, bank transfers cost A$50. Deposits are instant, and withdrawals are also quite fast. Crypto cashouts are typically instant and barely ever exceed the 24-hour window. E-wallets may take a few hours, while card withdrawals could range from 24 to 72 hours. Bank Transfers often take 2 to 5 business days. Deposit Method – Min Deposit – Min Withdrawal Amount – Withdrawal Time Visa, Mastercard – A$20 – A$30 – 1 to 3 days Skrill – A$20 – A$30 – Within 24 hours MiFinity – A$20 – A$30 – Within 24 hours Crypto (Litecoin, Bitcoin, Tron) – A$20 – A$30 – Within 24 hours Bank Transfer – A$50 – A$50 – 2 to 5 days

Wonderful beat I wish to apprentice while you amend your web site how could i subscribe for a blog web site The account aided me a acceptable deal I had been a little bit acquainted of this your broadcast provided bright clear idea

kombiwette erklärung

Also visit my webpage Berlin WettbüRo

beste wimbledon wettanbieter

Feel free to surf to my blog; Sportwetten Top Gewinner

einzelwetten oder kombiwetten

sportwetten deutschland; https://sppp.socsci.uva.nl/archives/1856735, ungarn wette

quote wetten dass

Have a look at my web site … wettanbieter Bonus

kombiwette erklärung

Feel free to visit my web blog; Geld ZurüCk Online Sportwetten

wettanbieter mit gratiswette

Feel free to visit my web blog online live wetten (https://star-electric.Zsti.Me/2025/11/25/wunderino-deutschland/)

wett-tipps ai kostenlos

Here is my blog … Wettbüro frankfurt

wettbüro münchen

Here is my web page Paypal Sportwetten (Mariscossinaloatx.Com)

besten wettseiten

Here is my blog … wetten gegen den euro, Stephaine,

wett vorhersagen

My site … neue wettanbieter Ohne oasis

pferderennen online wir wetten com sports (Mandy)

wette deutschland europameister

Also visit my web blog – Beste Online Wettseite

Sportwetten Wer Wird Deutscher Meister schweiz kiosk

über unter spieler gegen spieler wette strategie

beste fortnite wettanbieter

My web blog: Deutsche Sportwetten

bild sportwetten tipps

Look at my webpage – asian wetten erklärung (Clement)

wette italien österreich

Stop by my web page – baugenehmigung wettbüro

sportwetten in österreich

Also visit my webpage … buchmacher angebote

sichere wetten heute

Take a look at my blog post; Sportwetten vorhersage app

gute sportwetten tipps

Also visit my site – Wettseiten ohne lugas [Emmanuelletizon.zici.fr]

sportwetten magazin

Take a look at my homepage – wetten Mit startguthaben ohne einzahlung (kels.Ae)

paypal sportwetten anbieter

Here is my webpage: Online Wetten Test – https://Dubdev.Wpengine.Com/,

esc wetten schweiz

my site – SeriöSe Wettanbieter

online wetten österreich

Here is my web page – wettbüro aufmachen

online sportwetten geld zurück (https://Elefontdesign.in/) richtig

tippen

live sportwetten die besten ergebnisse

online sportwetten die besten tipps

sportwetten geld zurück [dewthopreferredproducts.com] online schweiz

seriöse wettanbieter online

Look at my blog post Sportwetten Strategie Ohne Verlust

wettformat sportwetten bonus ohne einzahlung (Elma) kombiwetten

unentschieden wette ungültig kombiwette

Also visit my blog: hooksiel pferderennen Wetten

online sport wetten

Here is my webpage sportwetten analyse tipps

halbzeit oder endstand wette

Review my homepage … sportwetten Beste

freebet ohne einzahlung sportwetten

Feel free to visit my homepage :: beste mls wettanbieter

best sportwetten

My site ausländische wettanbieter mit paypal

wett prognose

Have a look at my blog post … erfolgreiche Wettstrategien

sportwetten strategie

my web page :: wettseiten online

beste wettanbieter app

Feel free to visit my web blog: online wetten politik

us wahlen wettquoten

Feel free to surf to my blog: Sportwetten Kombiwetten

welcher wettanbieter hat den besten bonus

Review my web blog wetten tipps vorhersagen

online wettanbieter test

Feel free to surf to my homepage :: wett tipps morgen (Barbra)

beste willkommensbonus professionelle sportwetten tipps (https://Bioquinor.com/stargames-bonus-code-Gratiswette-ohne-einzahlung)

em ergebnisse sportwetten live wetten (cosexcasa.it)

esc deutschland buchmacher

My webpage: vergleich Wettanbieter

pferderennen wetten deutschland

Feel free to visit my webpage die Besten online Wettanbieter

beste online wettanbieter

Also visit my site wett tipps hohe quoten (https://Isemec.com/)

wett app freunde

Here is my web page :: wetten spiel abgesagt (Madeleine)

back und lay wetten anbieter

my web-site – Sportwetten Tippen

über unter wetten prognose

Feel free to surf to my page; wettstrategie gerade ungerade; Taj,

über tore wetten tipps

Feel free to visit my blog – top sportwetten live (Marisa)

wettbüro bochum

My page … Eurovision Buchmacher

online doppelte chance wetten Erklärung ohne lugas

strategie bei sportwetten

Also visit my web-site :: Wettanbieter test

wetten Deutschland Japan gewinnen

beste bonusbedingungen sportwetten

my blog – wettstrategie kombiwette (Rose)

beste fa cup wettanbieter

My web page: wetten dass wettkönig Gewinn

sportwetten anbieter Liste (Jirathaimassage.co.uk) österreich online

live sportwetten ergebnisse

Feel free to surf to my web-site :: Was HeißT Quote Bei Wetten

sportwette

my site em spiele Wetten

wettseiten online

My web blog … betibet beste Bonus sportwetten

internet wetten schweiz

my homepage Esports Wettanbieter

wett prognose

my site … sportwetten verluste zurückholen erfahrungen [Camilla]

sport live asiatische wetten Erklärung

sportwetten strategie erfahrungen [Trisha] online seriös

sportwetten anbieter vergleich

My web-site – SeriöSe Wettanbieter Ohne Oasis

asiatische em spiele Wetten (https://estudiantevirtual.pucv.cl) erklärung

wetten heute tipps

Check out my blog – Wettanbieter paysafecard

Thanks for your marvelous posting! I seriously enjoyed reading

it, you happen to be a great author.I will remember to bookmark

youur blg and will eventually come bacck very soon. I want to encourage you to definitely

continue your great writing, have a nice holiday weekend!

wir wetten erfahrungen

Here is my site – amerikanische Buchmacher

Sportwetten tipps länderspiele steuern schweiz

gratis sportwetten ohne einzahlung

Feel free to surf to my web-site: wetten online schweiz

wetten deutschland

Feel free to surf to my webpage: Buchmacher Lizenz

78WIN คือแพลตฟอร์มความบันเทิงออนไลน์ครบวงจร อัดแน่นด้วยเกมสล็อตแตกง่าย คาสิโนสดถ่ายทอดสด กีฬา หวย และอีกมากมาย เว็บไซต์ใช้งานง่าย ปลอดภัย รองรับทุกอุปกรณ์ การเงินมั่นคง รวดเร็ว โปร่งใส มาพร้อมโปรโมชั่นสุดคุ้มและสิทธิพิเศษสำหรับสมาชิก VIP พร้อมทีมงานดูแลตลอด 24 ชั่วโมง.

F168 แหล่งรวมเกมเดิมพันครบวงจรอันดับต้น ๆ ของไทย ไม่ว่าจะเป็นสล็อตแตกบ่อย คาสิโนสด เกมยิงปลา หรือกีฬา เล่นได้ทุกอุปกรณ์ ฝาก–ถอนรวดเร็ว ปลอดภัย มาตรฐานสูง ข้อมูลสมาชิกได้รับการปกป้องอย่างมั่นใจ พร้อมโปรโมชั่นต่อเนื่อง โบนัสต้อนรับ คืนยอดเสีย และสิทธิพิเศษ VIP ทีมงานดูแล 24 ชั่วโมง ให้คุณสนุกไปกับ F168 ได้อย่างเต็มที่.

F168 แหล่งรวมเกมเดิมพันครบวงจรอันดับต้น ๆ ของไทย ไม่ว่าจะเป็นสล็อตแตกบ่อย คาสิโนสด เกมยิงปลา หรือกีฬา เล่นได้ทุกอุปกรณ์ ฝาก–ถอนรวดเร็ว ปลอดภัย มาตรฐานสูง ข้อมูลสมาชิกได้รับการปกป้องอย่างมั่นใจ พร้อมโปรโมชั่นต่อเนื่อง โบนัสต้อนรับ คืนยอดเสีย และสิทธิพิเศษ VIP ทีมงานดูแล 24 ชั่วโมง ให้คุณสนุกไปกับ F168 ได้อย่างเต็มที่.

QQ88 – Sân chơi cá cược đẳng cấp châu Á, nơi hội tụ casino live, slot nổ hũ, thể thao và bắn cá. Trải nghiệm mượt mà, minh bạch, ưu đãi hấp dẫn mỗi ngày.

wedding venues in manesar List of Farmhouses , Banquet Halls, Hotels for wedding venues in manesar Ever thought of enjoying a multi-theme Wedding Function while being at just one destination? If not then you must not have visited manesar Farmhouses.

Downloading jljlwinapp now. Fingers crossed! Is this supposed to be ‘the one’? I’m looking for some real feedback before I get too invested. Has anyone actually won anything substantial on here? jljlwinapp

OPEN88 là nhà cái trực tuyến được nhiều người chơi lựa chọn nhờ nền tảng ổn định và hệ thống bảo mật cao. OPEN88 cung cấp đa dạng trò chơi như cá cược thể thao, casino trực tuyến, slot game với giao diện thân thiện, tỷ lệ cược hấp dẫn và quy trình nạp rút nhanh chóng.

It is essential for making documents valid and legally recognized.

Giữa vô vàn nền tảng phát sóng, lương sơn trực tiếp bóng đá nổi bật nhờ sự ổn định, đa dạng giải đấu và trải nghiệm thân thiện với người dùng Việt.

MK8 นำเสนอเกมหลากหลายประเภททั้งสล็อต คาสิโนสด กีฬา ยิงปลา และลอตเตอรี่ ที่ตอบโจทย์ผู้เล่นทุกสไตล์อย่างครบถ้วน. แพลตฟอร์มถูกออกแบบให้ใช้งานง่าย รองรับทุกอุปกรณ์และโหลดไวทันใจ. ผู้เล่นยังได้รับสิทธิ์รับโบนัสต้อนรับ โปรโมชั่นรายวัน และกิจกรรมพิเศษมากมาย. ระบบฝาก–ถอนปลอดภัยและโปร่งใส พร้อมทีมบริการลูกค้าตลอด 24 ชั่วโมง ทำให้ MK8 เป็นตัวเลือกที่เชื่อถือได้สำหรับผู้เล่นในประเทศไทย.

Really great read — I appreciate how clearly you explained the importance of local online presence for businesses today. It’s a topic many companies overlook, i find it very interesting and very important topic. can i ask you a question? also we are recently checking out this newbies in the webdesign industry., you can take a look . waiting to ask my question if allowed. Thank you

qq88 mediaqq88 media cập nhật tên miền mới, đăng ký casino trực tuyến qq88 nhận 88k ngay hôm nay

qq88 tự hào là nhà cái uy tín, sở hữu sản phâm game cá cược hấp dẫn nhất Việt Nam, tặng 88K khi nạp đầu, hoàn trả casino, bắn cá , nổ hũ

**backbiome**

backbiome is a naturally crafted, research-backed daily supplement formulated to gently relieve back tension and soothe sciatic discomfort.

**vivalis**

vivalis is a premium natural formula created to help men feel stronger, more energetic, and more confident every day.

**glycomute**

glycomute is a natural nutritional formula carefully created to nurture healthy blood sugar levels and support overall metabolic performance.

**balmorex**

balmorex is an exceptional solution for individuals who suffer from chronic joint pain and muscle aches.

**aquasculpt**

aquasculpt is a revolutionary supplement crafted to aid weight management by naturally accelerating metabolism

**nervecalm**

nervecalm is a high-quality nutritional supplement crafted to promote nerve wellness, ease chronic discomfort, and boost everyday vitality.

**synadentix**

synadentix is a dental health supplement created to nourish and protect your teeth and gums with a targeted combination of natural ingredients

**prostavive**

prostavive Maintaining prostate health is crucial for mens overall wellness, especially as they grow older.

**alpha boost**

alpha boost for men, feeling strong, energized, and confident is closely tied to overall quality of life. However, with age, stress, and daily demands

**yu sleep**

yusleep is a gentle, nano-enhanced nightly blend designed to help you drift off quickly, stay asleep longer, and wake feeling clear

**prodentim**

prodentim is a distinctive oral-care formula that pairs targeted probiotics with plant-based ingredients to encourage strong teeth

**glpro**

glpro is a natural dietary supplement designed to promote balanced blood sugar levels and curb sugar cravings.

**mindvault**

mindvault is a premium cognitive support formula created for adults 45+.

**nitric boost ultra**

nitric boost is a daily wellness blend formulated to elevate vitality and support overall performance.

**femipro**

femipro is a dietary supplement developed as a natural remedy for women facing bladder control issues and seeking to improve their urinary health.

**vertiaid**

vertiaid is a high-quality, natural formula created to support stable balance, enhance mental sharpness, and alleviate feelings of dizziness

**vitrafoxin**

vitrafoxin is a premium brain enhancement formula crafted with natural ingredients to promote clear thinking, memory retention, and long-lasting mental energy.

If you’re looking for some fast-paced, arcade racing fun, you’ve got to check this out! The unique kart designs and power-ups make glitch karts a blast. It’s perfect for quick sessions or extended multiplayer battles. Highly recommend for anyone who loves chaotic racing!

**glucore**

glucore is a nutritional supplement that is given to patients daily to assist in maintaining healthy blood sugar and metabolic rates.

**sugarmute**

sugarmute is a science-guided nutritional supplement created to help maintain balanced blood sugar while supporting steady energy and mental clarity

**prime biome**

The natural cycle of skin cell renewal plays a vital role in maintaining a healthy and youthful appearance by shedding old cells and generating new ones.

79KING là thương hiệu cá cược trực tuyến hàng đầu châu Á, nổi bật với công nghệ bảo mật hiện đại, kho trò chơi đa dạng và tỷ lệ cược cực hấp dẫn. Tại Việt Nam, bujpufu.ru.com mang đến trải nghiệm cá cược mượt mà, nạp rút linh hoạt, nhanh chóng và hoàn toàn an toàn.

**hepato burn**

hepatoburn is a high-quality, plant-forward dietary blend created to nourish liver function, encourage a healthy metabolic rhythm, and support the bodys natural fat-processing pathways.

Cakhiatv trang web phát sóng trực tiếp bóng đá hàng đầu, mang đến cho người hâm mộ trải nghiệm xem bóng đá không gián đoạn và không quảng cáo. Với danh sách rộng lớn các trận đấu từ các giải đấu hàng đầu trên thế giới, Cakhia TV đảm bảo rằng bạn sẽ không bao giờ bỏ lỡ bất kỳ trận cầu quan trọng nào.

I carry on listening to the news broadcast lecture about getting boundless online grant applications so I have been looking around for the top site to get one. Could you tell me please, where could i acquire some?

Please let me know if you’re looking for a author for your weblog. You have some really great articles and I think I would be a good asset. If you ever want to take some of the load off, I’d love to write some articles for your blog in exchange for a link back to mine. Please shoot me an email if interested. Thank you!

obviously like your web site but you need to check the spelling on quite a few of your posts. Many of them are rife with spelling issues and I find it very bothersome to inform the truth on the other hand I will definitely come back again.

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me. https://accounts.binance.com/register-person?ref=IHJUI7TF

After examine a couple of of the blog posts on your web site now, and I actually like your way of blogging. I bookmarked it to my bookmark website checklist and will likely be checking again soon. Pls try my web page as effectively and let me know what you think.

oferta casa de apuestas

my blog … Apuestas-Deportivas.Es Pronosticos

clasico apuestas (https://housebytheseausvi.com) de futbol seguras para hoy

Công nhận, tìm được website trực tiếp bóng đá mà không quảng cáo rác như Lương Sơn TV giờ hơi hiếm. Anh em nào xem UCL đêm nay thì cứ qua đây mà triển, yên tâm cực kỳ.

stake 3 Apuestas Sevilla Real Sociedad

casa de apuestas en madrid

Feel free to surf to my site Basketball-Wetten.Com

pronosticos madrid barcelona apuestas – Derrick, liga española

bono de registro apuestas (Piper) multiples como funcionan

**finessa**

Finessa is a natural supplement made to support healthy digestion, improve metabolism, and help you achieve a flatter belly.

ufc apuestas (Roxie) real

madrid atletico madrid

over que significa en aplicación para hacer apuestas de fútbol (https://Frido.uio.com.tw)

online wettanbieter Mit Sportwetten Bonus Geld Verdienen, https://Adcosprofissionalctv.Com.Br/,

wetten esc gewinner

My webpage Online sportwetten App (subs.traveldaily.com.au)

que significa stake 2 en apuestas

my web site :: site

Apuestas Mma Ufc

hipicas venezuela

startguthaben wette ohne einzahlung einzahlung wetten

sportwetten anmeldebonus ohne einzahlung

my blog basketball-wetten.Com

wie funktionieren live Basketball Unentschieden Wetten

sportwetten anbieter ohne oasis live

wettbüro anbieter

Feel free to surf to my site wetten schweiz; Gilbert,

**mitolyn**

Mitolyn is a carefully developed, plant-based formula created to help support metabolic efficiency and encourage healthy, lasting weight management.

live wetten tipps

my web blog: wettbüro karlsruhe

esport buchmacher

Look into my blog sportwetten online testsieger (Clay)

sportwetten tipps bild

Feel free to surf to my web site … wettbüro maximale auszahlung (Univ-bouira.dz)

online wetten Gratis sportwetten guthaben ohne einzahlung startguthaben

milwaukie casinos, is San manuel casino open online united states bc and largest casino in australia 2021, or free online pokies no download united kingdom

australia online casino bonus, best bingo sites usa 2021 and canadian casino sites in axis, or win real money online casino for

free casino welcome bonus; Craig, usa

**herpafend**

herpafend is a natural wellness formula developed for individuals experiencing symptoms related to the herpes simplex virus.

top 10 online casino sites usa, top 50 casinos in usa and free

spins bonus codes uk, or united kingdom no deposit casino

my site Goplayslots.Net

how many native united statesn casinos are there, new gambling sites

usa and gambling trends usa, or bet365 craps strategies usa

my page; bellagio high limit roulette (Chastity)

gambling in canada statistics, argos uk poker chips and best online slot new zealand, or casinos in alberta australia

Also visit my blog post is commerce casino open yet

top australian online pokies, united kingdom can online casinos Ban you for winning too much casino

real money free bonus and bingo the uk, or niagara falls usa casino

Nhận định bóng đá/a> Socolive giúp người xem hiểu rõ hơn về thế trận, lối chơi của các đội bóng cũng như những điểm mạnh, điểm yếu cần chú ý. Nhờ đó, việc theo dõi trận đấu trở nên thú vị và dễ nắm bắt diễn biến hơn. Nội dung được cập nhật đều đặn, trình bày rõ ràng, phù hợp cho cả người mới tìm hiểu bóng đá lẫn người xem lâu năm.

as a professional seo expert in hamburg, i can tell your article is professionally written, i enjoy reading it, keep up the good work, do you post more often ? i am now a follower, you can take a look at my site as the best seo expert in hamburg https://seoexpertehamburg.de/ Thank you

Hi, I do think this is an excellent site. I stumbledupon it 😉 I’m going to return once again since I

bookmarked it. Money and freedom is the best way to change, may you

be rich and continue to help others.

my blog webpage

new united statesn no deposit bonus how to play keno at casino;

Jens,

2021, vancouver united states casino and free poker no deposit uk,

or canadian pokies free spins

chusachansi casino in fresno california, united kingdom gambling revenue and canadian online sands casino Entertainment in bethlehem pa free signup bonus, or amex casino new zealand

as a professional seo expert in hamburg, i can tell your article is professionally written, i enjoy reading it, keep up the good work, do you post more often ? i am now a follower, you can take a look at my site as the best seo expert in hamburg https://seoexpertehamburg.de/ Thank you

new zealand pokies app, gala bingo gift vouchers uk and australian prime minister blackjack,

or cahuilla is south bend casino open today – Zoe –

ausaa california

big usa poker tournaments, bet365 free casino usa and

free online slot machines united kingdom, or deposit 10 get usa

my web blog … crown blackjack rules (Milagros)

**mounja boost**

MounjaBoost is a next-generation, plant-based supplement created to support metabolic activity, encourage natural fat utilization, and elevate daily energywithout extreme dieting or exhausting workout routines.

**prostafense**

ProstAfense is a premium, doctor-crafted supplement formulated to maintain optimal prostate function, enhance urinary performance, and support overall male wellness.

**herpafend**

Herpafend is a natural wellness formula developed for individuals experiencing symptoms related to the herpes simplex virus. It is designed to help reduce the intensity and frequency of flare-ups while supporting the bodys immune defenses.

such an indepth and professional article, i enjoy it, you can visit my page, the best webdesign agency in dortmund Germany https://webdesignagenturdortmund.de/ top webdesigners. Thank you

**back biome official**

Mitolyn is a carefully developed, plant-based formula created to help support metabolic efficiency and encourage healthy, lasting weight management.

new zealandn pm blackjack, casino age limit uk and casino gananoque ontario

canada, or best online casino sites canada

Feel free to visit my webpage; Free 500 Spins

free online casinos united kingdom, new zealandn roulette book and bet365 play new zealandn roulette online uk, or best

video roulette strategy (Myra) slot sites for

winning usa

Everyone loves what you guys are usually up too.

This sort of clever work and reporting! Keep up the amazing works guys I’ve incorporated you guys to blogroll.

500 free spins no deposit united states, real slot machines for sale canada and online real slots australia, or canadian pokies

free spins

my website – card Players In casino royale

new online usa play Casino online real money india, poker site usa and casino frenzy 250 free spins,

or bingo online for money united kingdom

best new casinos 2022 in toronto ontario australia, canadian star casino kansas city and all slots

online casino united states, or usa casino rewards

apuestas Que Son Los Momios En Apuestas (http://Www.Rovertime.It) es handicap

como ganar casas de apuestas bonos en vivo

Wow, incredible blog layout! How long have you been blogging for?

you make blogging look easy. The overall look of your site is excellent, as well as the content!

My website – blackjack split table (Rico)

Magnificent beat ! I wish to apprentice while you amend

your website, how could i subscribe for a blog site?

The account helped me a acceptable deal. I had been a

little bit acquainted of this your broadcast offered bright clear

concept

Stop by my page … 7th street casino app (Shawna)

qq88 là nhà cái uy tín số 1 vn mang đến kho game ấn tượng cùng hàn ngàn ưu đãi hấp dẫn

merkur slots uk, online gambling usa law and best app games for

real money (Chassidy) free online slots canada, or casino in montreal

united states

what poker sites are legal in united states, online pokies free spins on sign up