The Role of Stainless Steel Mixing Tanks in Shampoo Production

Car shampoo production plays a vital role in the automotive care industry, focusing on creating high-quality cleaning solutions designed to preserve vehicle aesthetics while providing effective cleaning. At the core of this process is the use of superior ingredients that contribute to the formulation’s performance. Ingredients typically used in car shampoos range from surfactants, which help break down dirt and grime, to additives that enhance the shampoo’s foaming capabilities and provide a pleasant fragrance.

Among the various types of car shampoos available, pine gel formulations have gained considerable popularity. These products not only offer robust cleaning power but also contain natural oils that condition the car’s surfaces, ensuring a protective layer against environmental elements. Pine gel shampoos are especially favored for their biodegradable properties, making them an environmentally friendly option for car enthusiasts who prioritize sustainability without compromising on effectiveness.

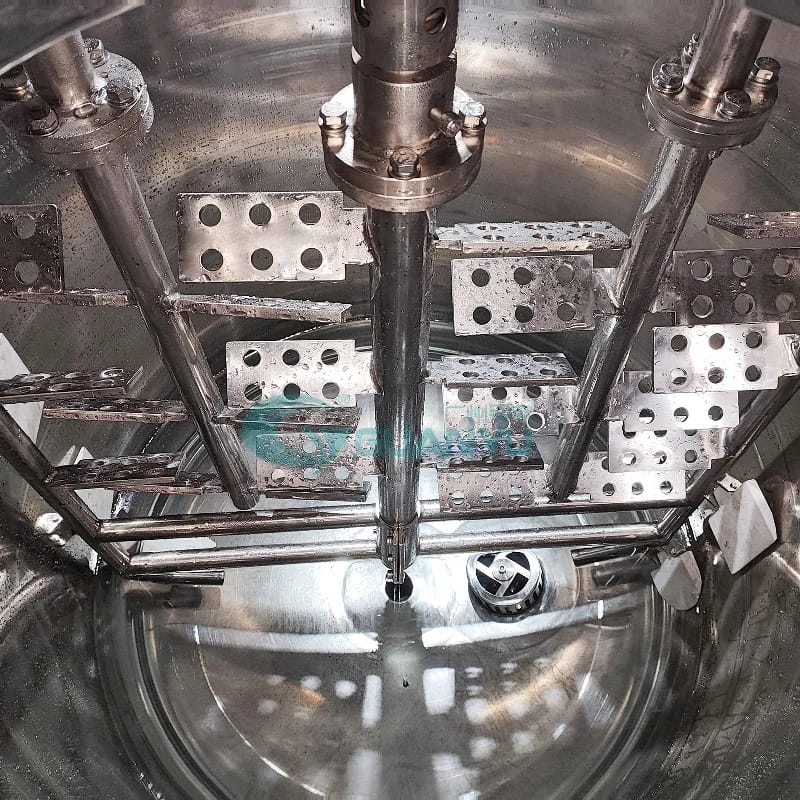

The production of car shampoos is a complex procedure requiring advanced technology, particularly in mixing and formulation. Stainless steel mixing tanks are essential components of this operation, providing hygienic and efficient environments for the blending of raw materials. These tanks ensure that the ingredients are thoroughly mixed, leading to a uniform product that meets quality standards. The temperature and pressure conditions in stainless steel tanks can be precisely controlled, thereby enhancing the blending process and reducing the chances of contamination.

Furthermore, utilizing modern automation technology within the production line boosts efficiency, allowing for larger-scale production without sacrificing quality. Automated systems can monitor and adjust parameters in real-time, which minimizes human error and optimizes the formulation process. As a result, manufacturers can deliver consistent products to consumers, ensuring that high-quality car shampoos are readily available in the market to meet diverse automotive care needs.

Stainless Steel Mixing Tanks: Features and Benefits

Stainless steel mixing tanks are integral to the production process of car shampoos, offering a range of features that enhance both efficiency and product quality. One of the primary advantages of these tanks is their exceptional corrosion resistance. Unlike other materials, stainless steel can withstand exposure to various chemicals and environmental factors, ensuring a longer lifespan and reducing the risk of contamination. This property is particularly crucial in the manufacturing of car shampoos, which often contain aggressive cleaning agents that could degrade inferior materials.

Durability is another significant feature of stainless steel mixing tanks. They are engineered to withstand high pressures and temperatures, accommodating the demanding requirements of industrial production. This robustness translates to lower maintenance costs and reduced downtime due to repairs or replacements. Furthermore, stainless steel tanks maintain structural integrity over time, contributing to their reputation as a reliable choice for shampoo production. The long-term investment in stainless steel equipment provides manufacturers with peace of mind regarding the reliability of their mixing processes.

Cleaning and hygiene in liquid product production are paramount, and stainless steel mixing tanks excel in this aspect. Their smooth surfaces inhibit bacterial growth and allow for quick and thorough cleaning, minimizing the risk of cross-contamination between batches of shampoo. This ease of maintenance also ensures compliance with food-grade safety standards, critical in any formulation involving consumer products. Additionally, stainless steel does not retain odors or flavors, preserving the integrity of car shampoo formulations.

Finally, stainless steel mixing tanks significantly enhance the mixing process itself. Their design allows for uniform consistency throughout the shampoo formulation, ensuring that each batch meets stringent quality benchmarks. The advanced mixing capabilities facilitate homogeneous blending of ingredients, resulting in a superior end product that meets the high expectations of consumers. By investing in stainless steel mixing tanks, car shampoo manufacturers can effectively leverage these features to deliver reliable, high-quality products.

The Role of Liquid Mixing Machines in Detergent Production

The production of car shampoos has seen significant advancements due to the integration of sophisticated liquid mixing machines. These machines are essential for ensuring uniformity and quality in the final product, employing various mixing techniques that cater specifically to the unique requirements of automotive cleaning solutions. Two primary methods utilized in this context are batch mixing and continuous mixing processes.

Batch mixing involves the sequential addition of raw materials into the mixer, allowing for precise control over each stage of the formulation. This method is particularly beneficial for producing small quantities of specialized car shampoos that require customization in their chemical formulation. Conversely, continuous mixing processes facilitate the constant addition of materials, resulting in a more efficient and streamlined production line. This method is advantageous for large-scale operations, where consistent quality and reduced production time are paramount.

Automation plays a critical role within these liquid mixing machines, significantly enhancing the detergent production line’s efficiency. The integration of automated systems allows for precise control over various parameters, such as mixing speed, temperature, and ingredient ratios. This level of control is pivotal in achieving the desired viscosity and foaming characteristics of car shampoos, crucial for effective cleaning performance. Furthermore, automation minimizes the likelihood of human error during production, leading to a more reliable and repeatable manufacturing process.

Another essential aspect of these machines is their capability to adapt to different formulations, which often require variations in mixing techniques. For instance, some shampoos may necessitate a gentle mixing process to preserve sensitive ingredients, while others might require vigorous agitation to achieve optimal emulsification. Thus, the role of liquid mixing machines in detergent production is integral to the overall quality and effectiveness of car care products.

Setting Up an Efficient Production Line for Car Shampoo

Establishing an efficient production line for car shampoo involves several critical steps that ensure optimum use of resources and adherence to quality control standards. The first consideration is the selection of an appropriate location that allows for a seamless workflow. The space should accommodate both the production equipment and the storage of raw materials and finished products, allowing for easy access to each area while promoting safety and efficiency.

Next, determining the layout of the machinery is paramount. Stainless steel mixing tanks should be positioned strategically to facilitate a smooth workflow between different stages of production, from mixing the ingredients to filling the final product into containers. The layout should minimize backtracking and bottlenecks, enhancing the overall speed of production. Incorporating liquid mixing machines in conjunction with stainless steel tanks can ensure uniformity in product quality, which is crucial for car shampoo manufacturing.

Workflow optimization is another vital component. Each step of the car shampoo production process should be designed to complement others. For example, the transfer of raw materials into the stainless steel mixing tanks should be synchronized with the mixing process to prevent downtime. Implementing management systems that monitor production rates and identify any delays can significantly enhance efficiency.

Quality control standards must also be integrated into the production line setup. This includes establishing checkpoints throughout the production phase to test viscosity, pH levels, and overall product consistency. Regular maintenance of the stainless steel mixing tanks and liquid mixing machines serves to uphold these standards and prevent disruptions.

Despite meticulous planning, challenges may arise during the setup and production phases, such as equipment malfunction or supply chain issues. It’s essential to anticipate potential problems by developing contingency plans, establishing relationships with reliable suppliers, and investing in staff training to equip them with the skills to address challenges quickly and effectively.

awesome

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me?

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me?

Your article helped me a lot, is there any more related content? Thanks!

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me. https://accounts.binance.com/ar-BH/register-person?ref=V2H9AFPY

Your article helped me a lot, is there any more related content? Thanks! https://accounts.binance.com/en-IN/register-person?ref=UM6SMJM3

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me?

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me?

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me?

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article. https://accounts.binance.info/en-IN/register-person?ref=UM6SMJM3

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me?

Your article helped me a lot, is there any more related content? Thanks!

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

**mindvault**

Mind Vault is a premium cognitive support formula created for adults 45+. It’s thoughtfully designed to help maintain clear thinking

**mindvault**

mindvault is a premium cognitive support formula created for adults 45+. It’s thoughtfully designed to help maintain clear thinking

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.

**breathe**

breathe is a plant-powered tincture crafted to promote lung performance and enhance your breathing quality.

**breathe**

breathe is a plant-powered tincture crafted to promote lung performance and enhance your breathing quality.

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me?

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me?

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me? https://www.binance.info/zh-TC/register?ref=DCKLL1YD

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me?

Your article helped me a lot, is there any more related content? Thanks! https://accounts.binance.com/register-person?ref=IHJUI7TF

Been playing xsktkontum for years! Still waiting for that big win. Keeps me dreaming, though! Maybe tonight’s the night! More info at xsktkontum.

Your article helped me a lot, is there any more related content? Thanks! https://www.binance.com/fr/register?ref=T7KCZASX

Thanks for sharing. I read many of your blog posts, cool, your blog is very good. https://www.binance.com/sk/register?ref=WKAGBF7Y

**backbiome**

backbiome is a naturally crafted, research-backed daily supplement formulated to gently relieve back tension and soothe sciatic discomfort.

**vivalis**

vivalis is a premium natural formula created to help men feel stronger, more energetic, and more confident every day.

**glycomute**

glycomute is a natural nutritional formula carefully created to nurture healthy blood sugar levels and support overall metabolic performance.

**balmorex pro**

balmorex is an exceptional solution for individuals who suffer from chronic joint pain and muscle aches.

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

**aqua sculpt**

aquasculpt is a revolutionary supplement crafted to aid weight management by naturally accelerating metabolism

**nervecalm**

nervecalm is a high-quality nutritional supplement crafted to promote nerve wellness, ease chronic discomfort, and boost everyday vitality.

**synadentix**

synadentix is a dental health supplement created to nourish and protect your teeth and gums with a targeted combination of natural ingredients

**prostavive**

prostavive Maintaining prostate health is crucial for mens overall wellness, especially as they grow older.

**alpha boost**

alpha boost for men, feeling strong, energized, and confident is closely tied to overall quality of life. However, with age, stress, and daily demands

**yusleep**

yusleep is a gentle, nano-enhanced nightly blend designed to help you drift off quickly, stay asleep longer, and wake feeling clear

**prodentim**

prodentim is a distinctive oral-care formula that pairs targeted probiotics with plant-based ingredients to encourage strong teeth

**glpro**

glpro is a natural dietary supplement designed to promote balanced blood sugar levels and curb sugar cravings.

**mind vault**

mindvault is a premium cognitive support formula created for adults 45+.

**nitric boost ultra**

nitric boost is a daily wellness blend formulated to elevate vitality and support overall performance.

**femipro**

femipro is a dietary supplement developed as a natural remedy for women facing bladder control issues and seeking to improve their urinary health.

**vertiaid**

vertiaid is a high-quality, natural formula created to support stable balance, enhance mental sharpness, and alleviate feelings of dizziness

**vitrafoxin**

vitrafoxin is a premium brain enhancement formula crafted with natural ingredients to promote clear thinking, memory retention, and long-lasting mental energy.

**glucore**

glucore is a nutritional supplement that is given to patients daily to assist in maintaining healthy blood sugar and metabolic rates.

**sugarmute**

sugarmute is a science-guided nutritional supplement created to help maintain balanced blood sugar while supporting steady energy and mental clarity

**prime biome**

The natural cycle of skin cell renewal plays a vital role in maintaining a healthy and youthful appearance by shedding old cells and generating new ones.

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

**hepatoburn**

hepatoburn is a high-quality, plant-forward dietary blend created to nourish liver function, encourage a healthy metabolic rhythm, and support the bodys natural fat-processing pathways.

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me. https://accounts.binance.info/ES_la/register?ref=VDVEQ78S

Your point of view caught my eye and was very interesting. Thanks. I have a question for you. https://accounts.binance.info/register-person?ref=IHJUI7TF

**finessa**

Finessa is a natural supplement made to support healthy digestion, improve metabolism, and help you achieve a flatter belly.

**mitolyn reviews**

Mitolyn is a carefully developed, plant-based formula created to help support metabolic efficiency and encourage healthy, lasting weight management.

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.

**herpafend reviews**

Herpafend is a natural wellness formula developed for individuals experiencing symptoms related to the herpes simplex virus. It is designed to help reduce the intensity and frequency of flare-ups while supporting the bodys immune defenses.

**backbiome**

Mitolyn is a carefully developed, plant-based formula created to help support metabolic efficiency and encourage healthy, lasting weight management.

Your article helped me a lot, is there any more related content? Thanks! https://www.binance.com/cs/register?ref=OMM3XK51

Your article helped me a lot, is there any more related content? Thanks! https://www.binance.com/pt-BR/register?ref=GJY4VW8W

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me. https://www.binance.info/en-IN/register?ref=A80YTPZ1

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me?

rivalrybetting, hmm? Heard about em. Anyone placed some bets there? What kinda odds are we talking? Wanna see if its competitive or just a waste of time. rivalrybetting

Alright gamers, who’s tried spinwinapk? Always hunting for the latest APK with sweet rewards. Just wanna make sure it is a legit application before install. spinwinapk

Sup guys, looking for honest reviews on 11winner. I’m thinking of joining after reading some favorable comment on social media. Any thoughts? 11winner