Lipstick is a beauty staple with a history dating back thousands of years, but modern manufacturing has made it accessible, affordable, and varied. With vibrant colors, smooth textures, and different finishes, lipstick production combines art and science. Dans cet article, we’ll delve into the fascinating process of lipstick manufacturing, discussing the ingredients, the equipment involved, and the stages each product undergoes before reaching the hands of consumers.

Essential Ingredients in Lipstick Production

Lipstick’s allure lies in its formulation. Different brands use varying combinations of ingredients to achieve their unique textures, colors, and finishes, but there are some essential ingredients found in most lipsticks:

- Waxes: Waxes provide structure and hardness to the lipstick, allowing it to hold its shape in a tube while still being soft enough to apply. Commonly used waxes include beeswax, candelilla wax, and carnauba wax.

- Huiles: Oils give lipstick its creamy texture, making it easier to glide across the lips. Some popular oils used in lipstick production are castor oil, jojoba oil, and olive oil. The oil-to-wax ratio is key to determining the lipstick’s consistency.

- Pigments: Pigments provide color and are either natural (such as iron oxides) or synthetic. The choice and amount of pigment can determine not only the color but also the opacity and intensity of the lipstick.

- Emollients and Moisturizers: Ingredients like shea butter, cocoa butter, and lanolin are added to keep lips hydrated. These ingredients improve the lipstick’s feel on the lips and enhance its longevity.

- Preservatives and Stabilizers: To extend the shelf life of the product, preservatives are added to prevent bacterial growth. Stabilizers keep the ingredients from separating, especially in varied climates.

- Fragrances and Flavors: Although optional, many lipsticks include fragrances and flavors to improve the overall user experience. Vanilla and rose are popular choices.

The Lipstick Manufacturing Process

The process of making lipstick is methodical, involving multiple steps that ensure the final product has the right color, texture, and consistency. Below are the key stages involved in lipstick production:

1. Melting and Mixing

The production process begins with the melting of waxes and oils. These ingredients are added to a lipstick making machine—a mixing tank that precisely controls temperature to melt the wax without burning it. The waxes, huiles, and emollients are heated to around 80°C (175°F) until fully liquefied.

Lipstick manufacturing machines often have automated stirring mechanisms to ensure consistent mixing. This prevents lumps and helps blend the ingredients smoothly. Modern machines have high precision, allowing manufacturers to replicate the same consistency across large batches.

2. Pigment Addition and Blending

Once the wax and oil mixture is melted and blended, it’s time to add pigments. Pigments are often in powder form and require careful blending to ensure they disperse evenly. High-shear mixers or homogenizers are used to break down pigment particles and integrate them with the wax and oil mixture. This step is crucial to achieving a smooth, even color with the right intensity.

In automated setups, the machines can measure and add pigments accurately, allowing for the creation of a consistent shade every time. This is particularly important for mass production, where brands need to maintain exact color matching for every lipstick in a specific line.

3. Refinement and Homogenization

For a high-quality lipstick, refining the mixture further is necessary to remove any remaining lumps or uneven pigment particles. This step typically involves a three-roll mill or homogenizer. The pigment blend is passed through a series of rollers, which grind it to an ultra-fine consistency. This process helps achieve a smooth, luxurious texture, essential for premium lipstick products.

The refined mixture is transferred to cooling tanks, where it begins to take on a semi-solid state, preparing it for molding.

4. Molding and Shaping

After refinement, the warm lipstick mixture is ready for molding. Lipstick molds are usually metal forms shaped like the traditional lipstick bullet. The semi-solid mixture is poured into these molds and allowed to cool until it hardens.

In modern factories, machines automate this process, allowing rapid molding of large quantities. Automated machines ensure that the right amount of lipstick is poured into each mold, helping to prevent wastage and ensuring consistent shape and size.

5. Cooling and Setting

Once in the molds, the lipstick needs to cool down to set properly. Machines equipped with a circuit de refroidissement help speed up this process. In commercial settings, cold water or air circulates around the molds to expedite cooling, so the lipstick solidifies evenly and quickly.

This cooling stage is crucial for maintaining the lipstick’s shape and preventing any deformities. Rapid cooling is especially helpful in high-demand production environments where efficiency is key.

6. Flaming and Polishing

After the lipstick is fully set, it undergoes a process known as “flaming.” This step involves passing the lipstick under a flame or heating element to remove surface imperfections and create a glossy finish. Flaming smooths out the outer layer of the lipstick, giving it a professional appearance.

Machines equipped with precise flaming tools help manufacturers achieve a uniform, polished finish. This step is often automated in high-volume factories to streamline the process.

7. Packaging

The final step in lipstick manufacturing is packaging. Once flamed and polished, the lipstick bullets are placed into their casings. Automated machines are capable of handling the casing process with speed and accuracy, ensuring each lipstick is securely placed in its tube without contamination.

After the casing, each lipstick undergoes quality checks to ensure it meets the brand’s standards. Once cleared, the product is sealed, labeled, and prepared for distribution.

Types of Lipstick Manufacturing Machines

Lipstick manufacturing requires various types of equipment, each serving a specific role:

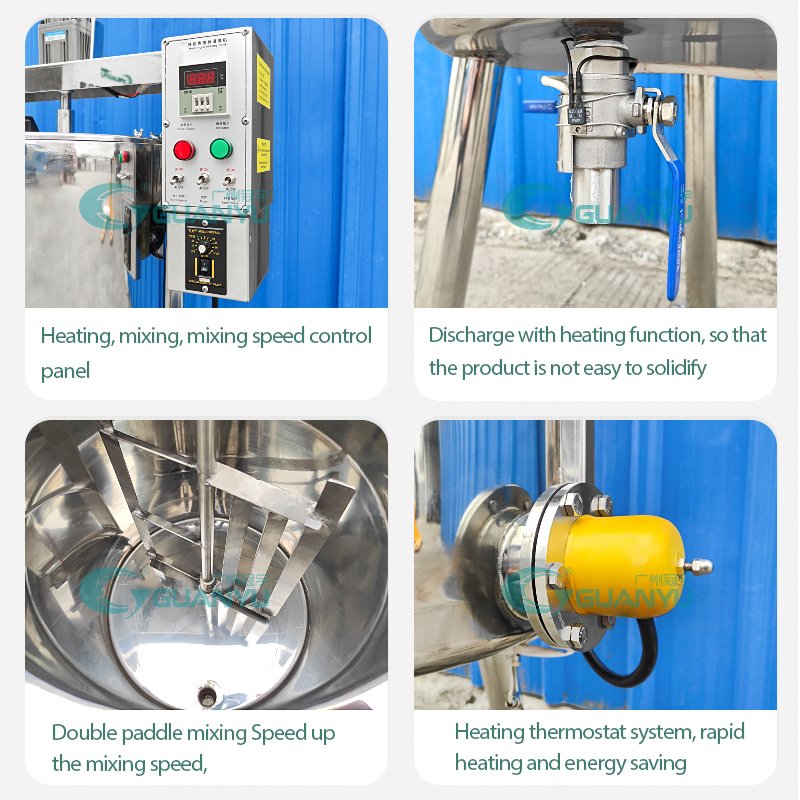

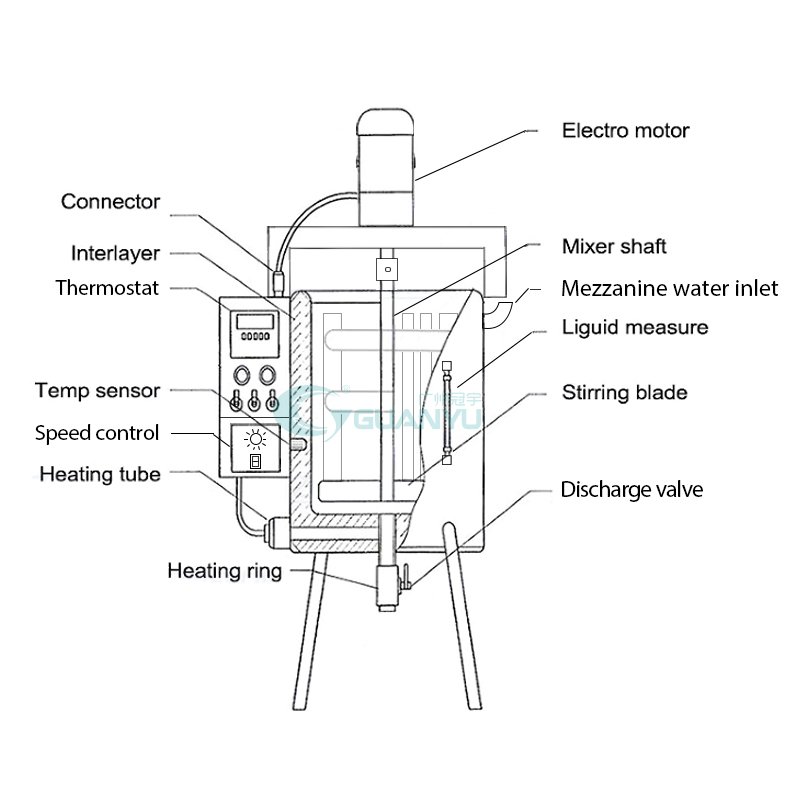

- Melting and Mixing Machines: Essential for the initial blending of waxes and oils, these machines feature precise temperature controls and high-shear mixing capabilities to ensure even consistency.

- High-Shear Mixers and Homogenizers: These machines help disperse pigments and break down particles for a smooth finish.

- Lipstick Molding Machines: Molding machines automate the process of pouring and setting lipstick, speeding up production and ensuring uniformity.

- Flaming and Finishing Machines: These machines give lipsticks a polished finish, creating a smooth, flawless surface.

- Automated Packaging Machines: Designed to handle high-volume production, these machines package lipsticks quickly and hygienically, maintaining quality standards.

Benefits of Using Lipstick Making Machines

Investing in specialized lipstick manufacturing equipment offers significant advantages for cosmetic manufacturers:

- Consistency: Automated machines help produce a uniform product with precise color matching and texture, ensuring each batch meets the brand’s quality standards.

- Efficiency: Machines can handle large volumes and repetitive tasks, reducing production time and meeting high market demand.

- Hygiene and Safety: Machines minimize human contact with raw materials, maintaining the cleanliness essential for cosmetic products.

- Cost Savings: Although there is an initial investment in equipment, the overall cost of production is reduced due to increased efficiency and decreased labor costs.

- Scalability: Manufacturing machines allow brands to scale up production without compromising on quality, making them essential for expanding companies.

Conclusion

The process of lipstick manufacturing combines science, art, and precision engineering. From melting and mixing to molding, refroidissement, and flaming, each step is carefully managed to produce a high-quality product. Lipstick making machines have revolutionized this process, allowing manufacturers to create consistent, hygiénique, and aesthetically appealing lipsticks at scale.

For brands looking to produce quality lipsticks efficiently, investing in advanced manufacturing machines is a wise choice. Not only do they streamline production, but they also help meet the rigorous quality and hygiene standards expected by consumers today.

To learn more about advanced solutions for content creation, SEO optimization, and customer engagement, consider trying HIX.AI, an excellent alternative to ChatGPT for your business needs.

Reading your article helped me a lot and I agree with you. But I still have some doubts, can you clarify for me? I’ll keep an eye out for your answers.

Pouvez-vous être plus précis sur le contenu de votre article? Après l'avoir lu, J'ai encore des doutes. J'espère que tu peux m'aider.

Votre article m'a beaucoup aidé, y a-t-il plus de contenu connexe? Merci!

Merci pour votre partage. Je crains de manquer d'idées créatives. C'est votre article qui me fait plein d'espoir. Merci. Mais, J'ai une question, pouvez-vous m'aider?

Votre article m'a beaucoup aidé, y a-t-il plus de contenu connexe? Merci!

Votre point de vue a attiré mon attention et a été très intéressant. Merci. J'ai une question pour toi.

Votre point de vue a attiré mon attention et a été très intéressant. Merci. J'ai une question pour toi.

Je ne pense pas que le titre de votre article correspond au contenu lol. Je plaisante, principalement parce que j'avais des doutes après avoir lu l'article.

Votre point de vue a attiré mon attention et a été très intéressant. Merci. J'ai une question pour toi.

Pouvez-vous être plus précis sur le contenu de votre article? Après l'avoir lu, J'ai encore des doutes. J'espère que tu peux m'aider.

Pouvez-vous être plus précis sur le contenu de votre article? Après l'avoir lu, J'ai encore des doutes. J'espère que tu peux m'aider.

Je ne pense pas que le titre de votre article correspond au contenu lol. Je plaisante, principalement parce que j'avais des doutes après avoir lu l'article.

Votre point de vue a attiré mon attention et a été très intéressant. Merci. J'ai une question pour toi.

Merci pour votre partage. Je crains de manquer d'idées créatives. C'est votre article qui me fait plein d'espoir. Merci. Mais, J'ai une question, pouvez-vous m'aider?

Pouvez-vous être plus précis sur le contenu de votre article? Après l'avoir lu, J'ai encore des doutes. J'espère que tu peux m'aider.

Merci pour votre partage. Je crains de manquer d'idées créatives. C'est votre article qui me fait plein d'espoir. Merci. Mais, J'ai une question, pouvez-vous m'aider?

Votre point de vue a attiré mon attention et a été très intéressant. Merci. J'ai une question pour toi.

Votre point de vue a attiré mon attention et a été très intéressant. Merci. J'ai une question pour toi.

Je ne pense pas que le titre de votre article correspond au contenu lol. Je plaisante, principalement parce que j'avais des doutes après avoir lu l'article.

Pouvez-vous être plus précis sur le contenu de votre article? Après l'avoir lu, J'ai encore des doutes. J'espère que tu peux m'aider.

Pouvez-vous être plus précis sur le contenu de votre article? Après l'avoir lu, J'ai encore des doutes. J'espère que tu peux m'aider.

Votre point de vue a attiré mon attention et a été très intéressant. Merci. J'ai une question pour toi.

Votre point de vue a attiré mon attention et a été très intéressant. Merci. J'ai une question pour toi.

Merci de partager. J'ai lu beaucoup de vos articles de blog, cool, Votre blog est très bon.

Merci pour votre partage. Je crains de manquer d'idées créatives. C'est votre article qui me fait plein d'espoir. Merci. Mais, J'ai une question, pouvez-vous m'aider? https://accounts.binance.com/ES_la/register?ref=T7KCZASX

Votre article m'a beaucoup aidé, y a-t-il plus de contenu connexe? Merci!

Votre point de vue a attiré mon attention et a été très intéressant. Merci. J'ai une question pour toi. https://www.binance.com/tr/register?ref=W0BCQMF1

Pouvez-vous être plus précis sur le contenu de votre article? Après l'avoir lu, J'ai encore des doutes. J'espère que tu peux m'aider.

Pouvez-vous être plus précis sur le contenu de votre article? Après l'avoir lu, J'ai encore des doutes. J'espère que tu peux m'aider.

Merci pour votre partage. Je crains de manquer d'idées créatives. C'est votre article qui me fait plein d'espoir. Merci. Mais, J'ai une question, pouvez-vous m'aider? https://www.binance.com/el/register?ref=IQY5TET4

Je ne pense pas que le titre de votre article correspond au contenu lol. Je plaisante, principalement parce que j'avais des doutes après avoir lu l'article.

Votre point de vue a attiré mon attention et a été très intéressant. Merci. J'ai une question pour toi.

Pouvez-vous être plus précis sur le contenu de votre article? Après l'avoir lu, J'ai encore des doutes. J'espère que tu peux m'aider.

Merci pour votre partage. Je crains de manquer d'idées créatives. C'est votre article qui me fait plein d'espoir. Merci. Mais, J'ai une question, pouvez-vous m'aider?

Votre article m'a beaucoup aidé, y a-t-il plus de contenu connexe? Merci!

Je ne pense pas que le titre de votre article correspond au contenu lol. Je plaisante, principalement parce que j'avais des doutes après avoir lu l'article.

Pouvez-vous être plus précis sur le contenu de votre article? Après l'avoir lu, J'ai encore des doutes. J'espère que tu peux m'aider.

Merci de partager. J'ai lu beaucoup de vos articles de blog, cool, Votre blog est très bon.

Merci de partager. J'ai lu beaucoup de vos articles de blog, cool, Votre blog est très bon.

Pouvez-vous être plus précis sur le contenu de votre article? Après l'avoir lu, J'ai encore des doutes. J'espère que tu peux m'aider.

Merci, Votre article m'a surpris, Il y a un excellent point de vue. Merci du partage, J'ai beaucoup appris.

Je ne pense pas que le titre de votre article correspond au contenu lol. Je plaisante, principalement parce que j'avais des doutes après avoir lu l'article.

Je ne pense pas que le titre de votre article correspond au contenu lol. Je plaisante, principalement parce que j'avais des doutes après avoir lu l'article.

Pouvez-vous être plus précis sur le contenu de votre article? Après l'avoir lu, J'ai encore des doutes. J'espère que tu peux m'aider.

Merci de partager. J'ai lu beaucoup de vos articles de blog, cool, Votre blog est très bon.

Merci pour votre partage. Je crains de manquer d'idées créatives. C'est votre article qui me fait plein d'espoir. Merci. Mais, J'ai une question, pouvez-vous m'aider? https://accounts.binance.info/en/register-person?ref=JHQQKNKN

Merci de partager. J'ai lu beaucoup de vos articles de blog, cool, Votre blog est très bon. https://www.binance.info/ru/register-person?ref=V3MG69RO

Votre point de vue a attiré mon attention et a été très intéressant. Merci. J'ai une question pour toi. https://www.binance.info/en-IN/register-person?ref=UM6SMJM3

Merci de partager. J'ai lu beaucoup de vos articles de blog, cool, Votre blog est très bon. https://www.binance.info/en/register-person?ref=JHQQKNKN

Merci pour votre partage. Je crains de manquer d'idées créatives. C'est votre article qui me fait plein d'espoir. Merci. Mais, J'ai une question, pouvez-vous m'aider?

Votre article m'a beaucoup aidé, y a-t-il plus de contenu connexe? Merci!

Merci de partager. J'ai lu beaucoup de vos articles de blog, cool, Votre blog est très bon.

Je ne pense pas que le titre de votre article correspond au contenu lol. Je plaisante, principalement parce que j'avais des doutes après avoir lu l'article.

Votre article m'a beaucoup aidé, y a-t-il plus de contenu connexe? Merci! 创建免费账户

Je ne pense pas que le titre de votre article correspond au contenu lol. Je plaisante, principalement parce que j'avais des doutes après avoir lu l'article.

Merci de partager. J'ai lu beaucoup de vos articles de blog, cool, Votre blog est très bon.

Votre point de vue a attiré mon attention et a été très intéressant. Merci. J'ai une question pour toi.

Merci de partager. J'ai lu beaucoup de vos articles de blog, cool, Votre blog est très bon.

Votre article m'a beaucoup aidé, y a-t-il plus de contenu connexe? Merci!

Votre article m'a beaucoup aidé, y a-t-il plus de contenu connexe? Merci!

Votre point de vue a attiré mon attention et a été très intéressant. Merci. J'ai une question pour toi.

Votre point de vue a attiré mon attention et a été très intéressant. Merci. J'ai une question pour toi.

Merci de partager. J'ai lu beaucoup de vos articles de blog, cool, Votre blog est très bon.

Pouvez-vous être plus précis sur le contenu de votre article? Après l'avoir lu, J'ai encore des doutes. J'espère que tu peux m'aider.

Votre point de vue a attiré mon attention et a été très intéressant. Merci. J'ai une question pour toi.

Pouvez-vous être plus précis sur le contenu de votre article? Après l'avoir lu, J'ai encore des doutes. J'espère que tu peux m'aider.

Pouvez-vous être plus précis sur le contenu de votre article? Après l'avoir lu, J'ai encore des doutes. J'espère que tu peux m'aider.

Votre point de vue a attiré mon attention et a été très intéressant. Merci. J'ai une question pour toi.

Merci pour votre partage. Je crains de manquer d'idées créatives. C'est votre article qui me fait plein d'espoir. Merci. Mais, J'ai une question, pouvez-vous m'aider?

Je ne pense pas que le titre de votre article correspond au contenu lol. Je plaisante, principalement parce que j'avais des doutes après avoir lu l'article. https://www.binance.info/da-DK/register?ref=S5H7X3LP

Merci de partager. J'ai lu beaucoup de vos articles de blog, cool, Votre blog est très bon.

Votre point de vue a attiré mon attention et a été très intéressant. Merci. J'ai une question pour toi.

Votre point de vue a attiré mon attention et a été très intéressant. Merci. J'ai une question pour toi. https://www.binance.com/hu/register?ref=IQY5TET4

Alright, feelin’ lucky? Fortune God’s got your back! I love the theme and the potential for big wins. This site runs smoothly and the game is visually appealing. Give fortunegodsvn a try if you wanna test your fortune 😉

Merci de partager. J'ai lu beaucoup de vos articles de blog, cool, Votre blog est très bon. https://www.binance.info/pt-PT/register?ref=KDN7HDOR

Wow plenty of fantastic facts. Visit http://fvhospital.com

Merci pour votre partage. Je crains de manquer d'idées créatives. C'est votre article qui me fait plein d'espoir. Merci. Mais, J'ai une question, pouvez-vous m'aider?

Pouvez-vous être plus précis sur le contenu de votre article? Après l'avoir lu, J'ai encore des doutes. J'espère que tu peux m'aider.

Merci pour votre partage. Je crains de manquer d'idées créatives. C'est votre article qui me fait plein d'espoir. Merci. Mais, J'ai une question, pouvez-vous m'aider? https://www.binance.com/ru-UA/register?ref=JVDCDCK4

Pouvez-vous être plus précis sur le contenu de votre article? Après l'avoir lu, J'ai encore des doutes. J'espère que tu peux m'aider.

Merci de partager. J'ai lu beaucoup de vos articles de blog, cool, Votre blog est très bon.

Merci de partager. J'ai lu beaucoup de vos articles de blog, cool, Votre blog est très bon. https://www.binance.com/register?ref=IXBIAFVY

hello there and thank you for your info – I’ve certainly picked up anything

new from right here. I did however expertise

some technical points using this site, as I experienced to reload the website lots of times previous to I could get

it to load properly. I had been wondering if your

hosting is OK? Not that I am complaining, but slow loading instances times will often affect your placement in google

and can damage your quality score if ads and marketing with Adwords.

Anyway I’m adding this RSS to my email and can look out for a lot

more of your respective interesting content.

Make sure you update this again soon.

Pouvez-vous être plus précis sur le contenu de votre article? Après l'avoir lu, J'ai encore des doutes. J'espère que tu peux m'aider. https://www.binance.com/register?ref=IXBIAFVY

This piece of writing is genuinely a fastidious one it assists new the web people, who are wishing in favor of blogging.

Yesterday, while I was at work, my cousin stole my iPad and tested to see if it can survive a forty foot drop, just so she can be a youtube sensation. My iPad is now broken and she has 83 views. I know this is entirely off topic but I had to share it with someone!

Pouvez-vous être plus précis sur le contenu de votre article? Après l'avoir lu, J'ai encore des doutes. J'espère que tu peux m'aider.

Merci de partager. J'ai lu beaucoup de vos articles de blog, cool, Votre blog est très bon. https://accounts.binance.com/es-MX/register?ref=GJY4VW8W

Je ne pense pas que le titre de votre article correspond au contenu lol. Je plaisante, principalement parce que j'avais des doutes après avoir lu l'article. https://accounts.binance.info/es-AR/register?ref=UT2YTZSU

Whats up are using WordPress for your blog platform? I’m new to the blog world but I’m trying to get started and create my own. Do you need any html coding knowledge to make your own blog? Any help would be greatly appreciated!

I am curious to find out what blog platform you’re working with? I’m having some small security problems with my latest blog and I would like to find something more safeguarded. Do you have any suggestions?

Hi, after reading this remarkable piece of writing i am too happy to share my familiarity here with friends.

Thank you a lot for sharing this with all folks you really understand what you are speaking approximately!

Bookmarked. Please additionally seek advice from my site =).

We can have a link change contract between us

Votre point de vue a attiré mon attention et a été très intéressant. Merci. J'ai une question pour toi.

Hello! I know this is kinda off topic nevertheless I’d figured I’d ask. Would you be interested in trading links or maybe guest authoring a blog article or vice-versa? My website discusses a lot of the same subjects as yours and I think we could greatly benefit from each other. If you might be interested feel free to shoot me an email. I look forward to hearing from you! Fantastic blog by the way!

Merci de partager. J'ai lu beaucoup de vos articles de blog, cool, Votre blog est très bon. https://accounts.binance.info/es-AR/register-person?ref=UT2YTZSU

Votre article m'a beaucoup aidé, y a-t-il plus de contenu connexe? Merci! https://accounts.binance.com/register-person?ref=IXBIAFVY

Votre point de vue a attiré mon attention et a été très intéressant. Merci. J'ai une question pour toi. https://accounts.binance.info/lv/register-person?ref=SMUBFN5I

Votre point de vue a attiré mon attention et a été très intéressant. Merci. J'ai une question pour toi.

Votre point de vue a attiré mon attention et a été très intéressant. Merci. J'ai une question pour toi.

Je ne pense pas que le titre de votre article correspond au contenu lol. Je plaisante, principalement parce que j'avais des doutes après avoir lu l'article.

Merci pour votre partage. Je crains de manquer d'idées créatives. C'est votre article qui me fait plein d'espoir. Merci. Mais, J'ai une question, pouvez-vous m'aider?