Introduction

The perfume industry is a delicate balance of science and art. Behind every luxurious bottle of fragrance lies a precise production system designed to preserve aroma, cohérence, and purity. One essential element of this process is the perfume storage tank—a specially engineered vessel used to safely store and transfer alcohol-based fragrances and volatile essential oils.

Because perfumes contain high concentrations of ethanol and aromatic compounds, they require storage solutions that are not only corrosion-resistant but also explosion-proof, clean, and adaptable to various production environments. This is where professional stainless steel perfume storage tanks become indispensable.

1. What Makes a Perfume Storage Tank Unique?

Perfume is not like ordinary liquid. Its high alcohol content (up to 80%), volatile compounds, and temperature sensitivity mean that traditional liquid tanks simply won’t do.

A professional perfume storage tank is designed with these specific challenges in mind:

- Material compatibility with ethanol and oils

- Explosion-proof handling of flammable vapors

- Prevention of ingredient separation or sedimentation

- Clean, hygienic design for cosmetic-grade applications

From formulation to bottling, these tanks protect the quality and integrity of your fragrance at every stage.

2. Superior Materials: SS304 Shell & SS316 Inner Layer

The material of your storage tank plays a crucial role in product safety and long-term durability.

🛡️ SS304 Outer Shell

- Strong, durable, and resistant to external corrosion

- Supports structural integrity under pressure and vacuum conditions

- Ideal for general industrial and cosmetic environments

💎 SS316 Contact Surface

- Superior resistance to corrosion from ethanol, essential oils, and other chemicals

- Safe for cosmetic and pharmaceutical applications

- Non-reactive surface preserves fragrance properties and prevents contamination

This dual-grade stainless steel construction ensures that the tank remains functional and reliable even after years of continuous use.

3. Explosion-Proof Safety for Alcohol-Based Liquids

Safety is a non-negotiable factor in perfume production. With high alcohol content comes flammability, which must be carefully controlled.

🔒 Explosion-Proof Pneumatic Diaphragm Pump

- Uses air power instead of electricity

- Eliminates risk of electrical sparks in volatile environments

- Smooth, pulsation-free liquid transfer protects product structure

This pump is essential for facilities that must comply with ATEX, CE, or other explosion safety standards.

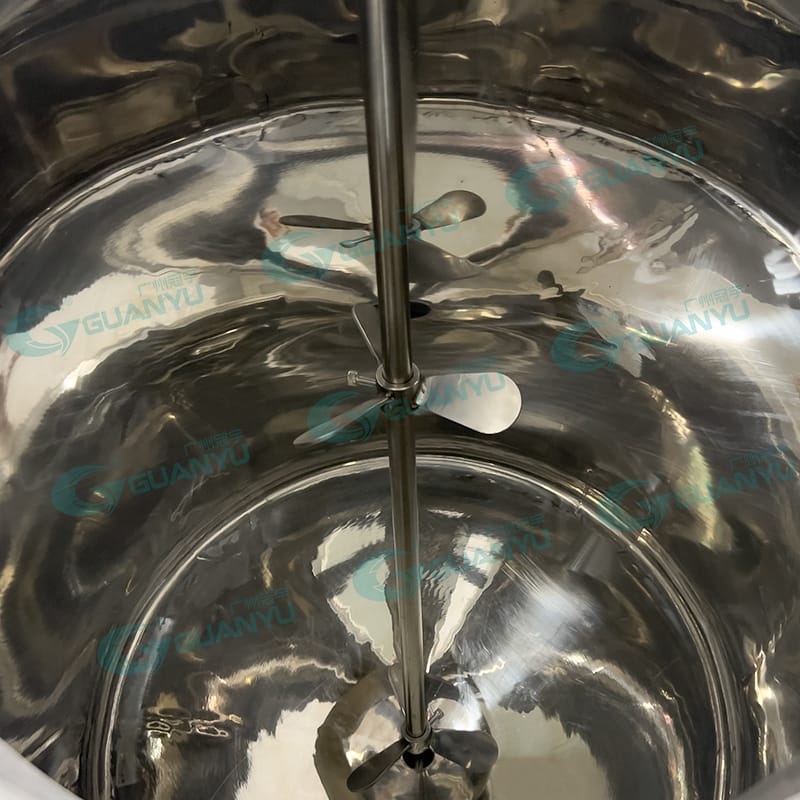

4. Built-In Dispersing System to Prevent Sedimentation

Many perfume formulations contain natural extracts, botanical infusions, ou essential oils that can settle over time. To prevent this:

🌀 Dispersing Agitator Integration

- Keeps contents in continuous gentle motion

- Prevents sedimentation or layer separation

- Ensures uniform consistency before bottling

The inclusion of a disperser or gentle stirrer is particularly useful for products that use organic or plant-based ingredients.

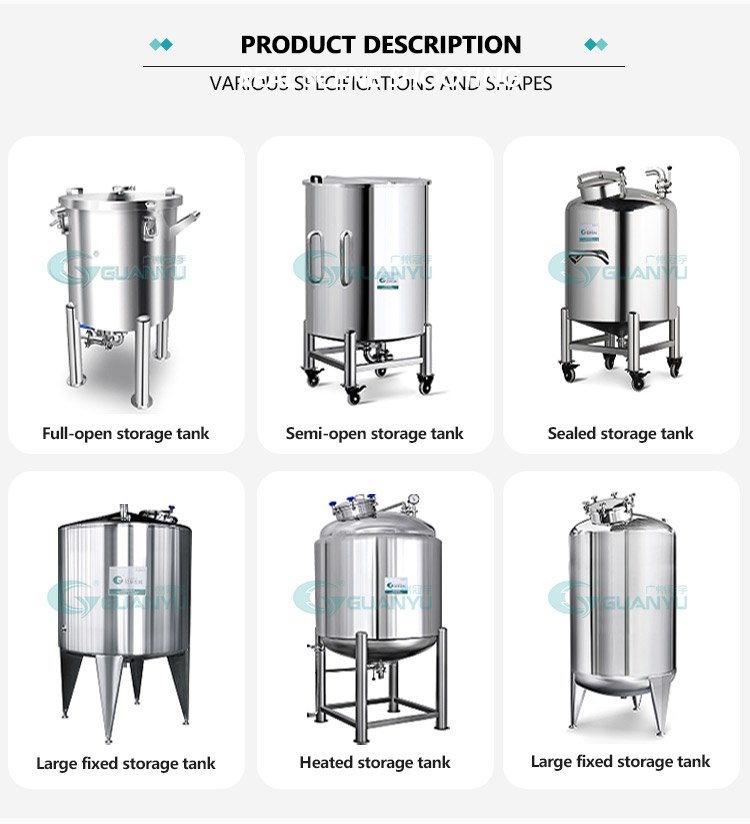

5. Fixed or Mobile Configuration Available

Depending on the layout and scale of your production line, le perfume storage tank can be supplied in either of two practical formats:

🚩 Fixed Type

- Designed to remain stationary

- Suitable for large production lines connected to mixing or filling systems

- Clean-in-place (Cage) systems can be integrated

🛞 Mobile Type

- Mounted on food-grade caster wheels with brakes

- Perfect for flexible factory workflows or batch-based production

- Easily repositioned for cleaning or ingredient transport

Both types can be fitted with bottom discharge valves, sampling ports, and sight glasses as needed.

6. Fully Customizable to Meet Your Needs

Every perfume production setup is different. That’s why we offer 100% customizable perfume storage tanks, so you can tailor every detail to match your process requirements.

✔️ Customization Options Include:

- Tank Capacity: From 50 liters to 10,000+ liters

- Height & Diameter: Adapted to your facility dimensions

- Discharge Type: Sortie inférieure, butterfly valve, or aseptic valve

- External Finish: Mirror polished, brushed, or matte finish

- Agitator Type: Disperser, paddle, anchor, or magnetic stirrer

- Explosion-Proof Rating: ATEX, IECEx, CE certified options

- Mobility: Fixed leg design or heavy-duty wheels

Optional features such as level sensors, jacketed heating/cooling, ou load cells for weighing can also be added upon request.

7. Benefits of Using a High-Quality Perfume Storage Tank

Choosing a professionally engineered perfume tank has numerous long-term benefits for fragrance manufacturers.

✅ Protects Fragrance Quality

Using non-reactive SS316 steel ensures that alcohol and aromatic compounds stay intact and do not degrade or oxidize.

✅ Improves Safety

Explosion-proof components reduce fire hazards and ensure compliance with industrial safety protocols.

✅ Reduces Manual Labor

Integrated pumps and mobile configurations make transferring product easy and reduce the need for manual handling.

✅ Enhances Production Flow

Mobile tanks can be moved between blending, filtration, and filling stations, reducing bottlenecks.

✅ Ensures Consistency

Built-in dispersion or agitation keeps ingredients evenly mixed, ensuring uniform fragrance in every bottle.

8. Industries That Benefit from Perfume Storage Tanks

These tanks are not just limited to perfume. They are widely used in industries such as:

- Fragrance and personal care

- Cosmetics and skincare

- Essential oil processing

- Aromatherapy product manufacturing

- Body sprays and mist production

- Laboratory-scale R&D for scents

Whether you’re manufacturing high-end perfumes or functional mists, a dedicated storage solution is critical to achieving quality at scale.

9. Add-On Features for Advanced Production Lines

To further enhance performance and compatibility, tanks can be equipped with:

- Jacketed insulation for temperature-sensitive fragrances

- Vacuum sealing to prevent evaporation or oxidation

- Sight glass with wipers for level monitoring

- Cage (Clean-In-Place) spray balls for internal cleaning

- Sampling valves for lab QC tests before bottling

Each option contributes to a more efficient, scalable, and hygienic fragrance production line.

Conclusion

UN perfume storage tank is more than just a vessel—it’s a vital component that ensures the quality, safety, and consistency of your final product. With the growing complexity of fragrance formulas and increasing regulatory demands, investing in custom-built, acier inoxydable, explosion-proof perfume tanks is a smart and future-proof decision.

Whether you need a stationary unit for large-scale production or a mobile tank for small-batch flexibility, the right solution can be fully customized to fit your needs—from materials (SS304/SS316) to capacité, dispersing systems, et safety standards.

Let your fragrance shine with the help of reliable, industry-proven perfume storage technology.

Very well presented. Every quote was awesome and thanks for sharing the content. Keep sharing and keep motivating others.

Göztepe su kaçağı tespiti Etiler’deki evimizdeki su kaçağını hemen tespit ettiler ve onardılar. Profesyonel hizmet. https://youslade.com/read-blog/102635

Celaliye su kaçak tespiti Apartmanımızdaki su kaçağını bulmak için kamera sistemleri kullandılar. Tüm borulardaki hasarı görüntüleyip raporladılar. Çok memnun kaldık. Osman B. https://younetwork.app/read-blog/26965

Beşiktaş Elektrikçi Bayram P. – “Deneyimli usta, sadece biraz daha hızlı olabilir.” https://www.takasvakti.com/kadikoy-elektrikci-7-24-780

This is really interesting, You’re a very skilled blogger. I’ve joined your feed and look forward to seeking more of your magnificent post. Aussi, I’ve shared your site in my social networks!

very informative articles or reviews at this time.

Cappadocia romantic getaway Emily R. ★★★★★ The sunrise hot air balloon flight was pure magic! Our pilot Erkan pointed out all the fairy chimneys as we floated over Rose Valley. Worth every penny! https://boonbac.com/read-blog/11211

Hemşire Forması | Nur Medical Wearhemşire forması, scrubs

Cappadocia photography tour Jacob M. ★★★★☆ Red Tour covers key sites efficiently. Pack snacks – lunch stop is late. Derinkuyu Underground City will blow your mind! https://www.bondhuplus.com/read-blog/217662

Dipays Dijital Pazarlama AjansıE-Ticaret Danışmanlığı

Mevlana su kaçak tespiti Şişli su kaçağı tespiti: Şişli bölgesinde güvenilir su kaçağı tespit hizmetleri. https://somity.xyz/read-blog/4168

Kes – Mak Bahçe Aksesuarları ve Yedek Parça | Malatya benzinli testere yedek parça, testere zinciri, ağaç kesme pala, klavuz, elektronik bobin, hava filtresi, stihl malatya bayi

Arnavutköy Merkez su kaçak tespiti Bağcılar su kaçağı tespiti: Bağcılar’daki su kaçağı sorunlarına çözüm sunuyoruz. https://red.dariofalero.com/read-blog/17408

Hadımköy su kaçak tespiti Gizli Kaçakları Buldular: Fark edemediğimiz gizli kaçakları bile bulup çözdüler. https://social.vetmil.com.br/read-blog/46511

Üsküdar tesisatçı hizmetleri Kırmadan su kaçağı tespit ettiler, işçilik çok temizdi. Tavsiye ederim. https://jewelsofmarga.com/uskudar-su-kacagi-tespiti/

very informative articles or reviews at this time.

This is my first time pay a quick visit at here and i am really happy to read everthing at one place

I appreciate you sharing this blog post. Thanks Again. Cool.

Алуминеви Мебели за Хотели и Заведения Столове и фотьойли, Офис столове, Кресла, Бар столове, Пуфове и табуретки, Дивани (заведения / дом)

Play without risk of disconnection using mirror

Fan favorite: Lucky Jet if you dare.

Your blog is a beacon of light in the often murky waters of online content. Your thoughtful analysis and insightful commentary never fail to leave a lasting impression. Keep up the amazing work!

Van Haberleri tarafsız haber yayıncılığı anlayışıyla doğru ve güvenilir bilgilere ulaşmanızı sağlar. Van Sesi Gazetesi yıllardır Van ve çevresinde güvenilir haberleri sunma konusundaki kararlılığıyla bilinir. Van Olay, Van Gündem, Van Haber, Van haberleri, Gündem haberleri, van erciş, van gevaş, van edremit

Dent Global İstanbul ortodontri, acil diş çekimi, 20 lik diş çekimi, diş estetik

Aydın Haber | Aydın Post aydın haber, aydın haberleri, aydin haber

naturally like your web site however you need to take a look at the spelling on several of your posts. A number of them are rife with spelling problems and I find it very bothersome to tell the truth on the other hand I will surely come again again.

Battery-efficient Aviator download game for long play

ФизиотерапияФизиотерапия, Рехабилитация, Мануална терапия, Хиропрактика, Лечебен масаж, Иглотерапия, Хиджама (Кръвни вендузи), Лазерна епилация, Антицелулитен масаж, Антицелулитни терапии

Испытай удачу в Лаки Джет на сайтах 1WIN и Lucky Star — без задержек и лимитов.

Istanbul Photography Museum tour Smooth transportation and pick-up. http://gruposiia.com.mx/?p=26433

https://shorturl.fm/pi3TS

Istanbul food market tour Our English-speaking guide explained everything clearly. https://rw13sekeloa.com/?p=2915

Casino mirror works during peak internet usage

I just wanted to drop by and say how much I appreciate your blog. Your writing style is both engaging and informative, making it a pleasure to read. Looking forward to your future posts!

Bet and win instantly in the Aviator game.

Your next big win is at Bitstarz Casino.

Istanbul food tour Loved the walking tour of the old city, je recommande vivement. https://news-ngo.com/?p=90643

Thank you for the good writeup It in fact was a amusement account it Look advanced to far added agreeable from you However how could we communicate

I always feel so much better afterward. The relief is incredible.

Hi i think that i saw you visited my web site thus i came to Return the favore I am attempting to find things to improve my web siteI suppose its ok to use some of your ideas

You deserve this quiet moment just for you. Escape the world with a blissful massage.

What are you waiting for? Book a massage and let all that stress go!

Massages can help you sleep better and feel more rested. A real game-changer.

It’s okay to prioritize yourself. A massage is a wonderful way to show yourself some love.

Thank you I have just been searching for information approximately this topic for a while and yours is the best I have found out so far However what in regards to the bottom line Are you certain concerning the supply

Süleymaniye Mosque tour Guides are friendly and knowledgeable. https://uilmbasilicata.it/?p=4007

Thanks for correcting common health myths.

Ayurgenomics Moringa Powder are made using the same best-selling powder for an easy and convenient way to enjoy the benefits of moringa on-the-go

I do believe all the ideas youve presented for your post They are really convincing and will certainly work Nonetheless the posts are too short for novices May just you please lengthen them a little from subsequent time Thanks for the post

The start of a fast-growing trend?

I loved as much as you will receive carried out right here The sketch is tasteful your authored subject matter stylish nonetheless you command get got an edginess over that you wish be delivering the following unwell unquestionably come further formerly again as exactly the same nearly very often inside case you shield this hike

Meze tasting tour Istanbul Tours gave us memories that will last forever. https://beinmarkets.com/?p=17199

Thanks for your patience and sorry for the inconvenience!

Your blog is a breath of fresh air in the crowded online space. I appreciate the unique perspective you bring to every topic you cover. Keep up the fantastic work!

Secure mirror link = uninterrupted casino experience.

best Istanbul tours I enjoyed the photo stops at scenic spots. https://www.portwaysc.org.uk/?p=927

Amazing strange amazing bad wonderful.

I was suggested this web site by my cousin Im not sure whether this post is written by him as no one else know such detailed about my trouble You are incredible Thanks

Thanks I have recently been looking for info about this subject for a while and yours is the greatest I have discovered so far However what in regards to the bottom line Are you certain in regards to the supply

I simply could not go away your web site prior to suggesting that I really enjoyed the standard info a person supply on your guests Is going to be back incessantly to investigate crosscheck new posts

Bosphorus cruise Loved the walking tour of the old city, je recommande vivement. https://syscosmic.4kumars.com/?p=5798

Istanbul culinary tour We had plenty of time inside Topkapi Palace. https://dmzsystems.co/?p=735

Your blog is a breath of fresh air in the often stagnant world of online content. Your thoughtful analysis and insightful commentary never fail to leave a lasting impression. Thank you for sharing your wisdom with us.

Aviator game review India – safe, legal, addictive

Istanbul private tour Smooth check-in and friendly team. https://brunet.brefconcept.com/?p=2484

siteniz harika ben daha önce böyle güzel bir site görmedim makaleler çok açıklayıcı ve bilgilendirici çok site gezdim ve en sonunda sizin sitenizde buldum

siteniz çok güzel devasa bilgilendirme var aradığım herşey burada mevcut çok teşekkür ederim

Istanbul Photography Museum tour The Bosphorus cruise had incredible views. http://farmaciagiannoni.it/web/?p=5290

Istanbul walking tour Tour included everything we wanted to see. http://electromecanicamx.com/?p=20612

siteniz harika başarılarınızın devamını dilerim aradığım herşey bu sitede

Explore live VIP tables at BitStarz Casino with higher limits, professional hosts, and steady, low-latency streams.

siteniz çok güzel devasa bilgilendirme var aradığım herşey burada mevcut çok teşekkür ederim

I have been surfing online more than 3 hours today yet I never found any interesting article like yours It is pretty worth enough for me In my opinion if all web owners and bloggers made good content as you did the web will be much more useful than ever before

Great information shared.. really enjoyed reading this post thank you author for sharing this post .. appreciated

Зеркало казино открывает доступ без VPN

Istanbul Old City tour The views from Galata Tower were stunning! https://lunex.md/?p=12235

Yazınız için teşekkürler. Bu bilgiler ışığında nice insanlar bilgilenmiş olacaktır.

siteniz çok güzel devasa bilgilendirme var aradığım herşey burada mevcut çok teşekkür ederim

I have read some excellent stuff here Definitely value bookmarking for revisiting I wonder how much effort you put to make the sort of excellent informative website

Read beginner FAQs on the Aviator game and start from a clean Aviator game download.

Learn device profiles for the Aviator game; each profile ties back to your Aviator game download build.

Enjoy the Aviator game; get the trusted Aviator game download.

Build a safe routine for the Aviator game with session caps; start through the official Aviator game download.

Test quick-cashout habits in the Aviator game; use a verified Aviator game download and set fixed targets.

Read patch notes for the Aviator game; refresh via official Aviator game download.

Play the Aviator game�privacy pointers. Find a safe Aviator game download and quick tips on timing cashouts, limits, and fair play.

Explore tournament brackets in the Aviator game; confirm eligibility after your Aviator game download.

Verify age eligibility for the Aviator game and limit access to the Aviator game download.

Enable two-factor protection for the Aviator game and store recovery codes with the Aviator game download.

I’ve been following your blog for some time now, and I’m consistently blown away by the quality of your content. Your ability to tackle complex topics with ease is truly admirable.

Hi my family member I want to say that this post is awesome nice written and come with approximately all significant infos I would like to peer extra posts like this

Nice blog here Also your site loads up fast What host are you using Can I get your affiliate link to your host I wish my web site loaded up as quickly as yours lol

Your blog is a testament to your dedication to your craft. Your commitment to excellence is evident in every aspect of your writing. Thank you for being such a positive influence in the online community.

Your blog is a true gem in the world of online content. I’m continually impressed by the depth of your research and the clarity of your writing. Thank you for sharing your wisdom with us.

Your writing is a true testament to your expertise and dedication to your craft. I’m continually impressed by the depth of your knowledge and the clarity of your explanations. Keep up the phenomenal work!

Simply wish to say your article is as amazing The clearness in your post is just nice and i could assume youre an expert on this subject Well with your permission let me to grab your feed to keep updated with forthcoming post Thanks a million and please carry on the gratifying work

Quick-start checklist attached to this 1win apk review.

Çok yararlı bir makale olmuş. Severek takip ediyorum. Teşekkür ederim.

Hello my loved one I want to say that this post is amazing great written and include almost all significant infos I would like to look extra posts like this

Magnificent beat I would like to apprentice while you amend your site how can i subscribe for a blog web site The account helped me a acceptable deal I had been a little bit acquainted of this your broadcast offered bright clear idea

Ive read several just right stuff here Certainly price bookmarking for revisiting I wonder how a lot effort you place to create this kind of great informative website

you’re in reality a just right webmaster. The web site loading velocity is incredible. It sort of feels that you’re doing any distinctive trick. En outre, The contents are masterpiece. you’ve performed a great process on this topic!

Your blog is a constant source of inspiration for me. Your passion for your subject matter shines through in every post, and it’s clear that you genuinely care about making a positive impact on your readers.

Thank you for the good writeup It in fact was a amusement account it Look advanced to far added agreeable from you However how could we communicate

Your ability to distill complex concepts into digestible nuggets of wisdom is truly remarkable. I always come away from your blog feeling enlightened and inspired. Keep up the phenomenal work!

siteniz çok güzel devasa bilgilendirme var aradığım herşey burada mevcut çok teşekkür ederim

Istanbul photography tour Would love to book another tour with them. https://kyrptexinsuranceservice.com/?p=14671

Istanbul cultural tour Istanbul hidden gems tour was worth every penny. https://terrenosenxalapa.com/?p=2465

Your blog is a true hidden gem on the internet. Your thoughtful analysis and engaging writing style set you apart from the crowd. Keep up the excellent work!

Çok işime yaradı bende bunu nasıl yapacağımı araştırıyorum. Paylaşım için teşekkür ederim.

Thank you I have just been searching for information approximately this topic for a while and yours is the best I have found out so far However what in regards to the bottom line Are you certain concerning the supply

Balat walking tour The highlight was watching whirling dervishes. https://noutaticontabile.ro/?p=869434

Wonderful web site Lots of useful info here Im sending it to a few friends ans additionally sharing in delicious And obviously thanks to your effort

Install the official 1win apk download today.

Harika bir yazı olmuş, teşekkürler. Özellikle Bursa’nın yoğun trafiğinde neyle karşılaşacağımız belli olmuyor. Olası bir durumda elimde kanıt olması için kaliteli bir bursa araç kamerası almayı düşünüyorum. Bu yazı karar vermemde çok yardımcı oldu.

Bilgiler için çok sağ olun. Ben özellikle park halindeyken de kayıt yapabilen bir model arıyordum. Nilüfer gibi kalabalık yerlerde park etmek büyük sorun. Sanırım benim için en ideali hareket sensörlü bir bursa araç kamerası olacak.

Geçen ay küçük bir kazaya karıştım ve haklı olmama rağmen ispatlamakta zorlandım. O günden sonra hemen bir bursa araç kamerası araştırmaya başladım. Keşke bu olayı yaşamadan önce bu yazıyı okuyup önlemimi alsaydım.

Ben profesyonel olarak direksiyon sallıyorum ve güvenlik benim için ilk sırada. Şirket araçlarımızın hepsinde olduğu gibi şahsi aracıma da bir bursa araç kamerası taktırmak istiyorum. Hem caydırıcı oluyor hem de olası bir durumda sigorta süreçlerini hızlandırıyor.

Thank you for the good writeup It in fact was a amusement account it Look advanced to far added agreeable from you However how could we communicate

Your blog is a testament to your dedication to your craft. Your commitment to excellence is evident in every aspect of your writing. Thank you for being such a positive influence in the online community.

Yazınızda bahsettiğiniz G-sensör özelliği çok mantıklı. Allah korusun bir kaza anında o paniğe kapılıp kaydı korumayı unutabiliriz. Bu özelliği olan bir bursa araç kamerası bakacağım, aydınlattığınız için sağ olun.

Benzer bir ürün kullanıyorum ve kesinlikle herkese tavsiye ederim. Özellikle Organize Sanayi Bölgesi trafiğinde sabah ve akşam saatlerinde çok faydasını gördüm. İyi bir bursa araç kamerası gerçekten hayat kurtarabilir.

Bu kameraların fiyatları hakkında biraz araştırma yapmıştım. Yazınızda belirttiğiniz özelliklere sahip, uygun fiyatlı bir bursa araç kamerası bulmak mümkün müdür? Fiyat/performans ürünü arayanlar için tavsiyelerinizi bekliyorum.

Your writing has a way of resonating with me on a deep level. I appreciate the honesty and authenticity you bring to every post. Thank you for sharing your journey with us.

Bursa gibi büyük ve hareketli bir şehirde araç kullanmak ekstra dikkat gerektiriyor. Bir bursa araç kamerası kullanarak sadece kendimizi değil, trafikteki diğer masum sürücüleri de korumuş oluruz. Kesinlikle her araçta olması gereken bir cihaz.

Your blog has quickly become one of my favorites. Your writing is both insightful and thought-provoking, and I always come away from your posts feeling inspired. Keep up the phenomenal work!

Çift yönlü kayıt yapabilen, yani hem yolu hem de aracın içini çeken bir bursa araç kamerası ticari taksiler için çok önemli. Hem sürücünün hem de yolcunun güvenliği için standart hale gelmesi gerektiğini düşünüyorum.

Benzer bir ürün kullanıyorum ve kesinlikle herkese tavsiye ederim. Özellikle Organize Sanayi Bölgesi trafiğinde sabah ve akşam saatlerinde çok faydasını gördüm. İyi bir bursa araç kamerası gerçekten hayat kurtarabilir.

Ehliyetimi yeni aldım ve trafiğe çıkmaya biraz çekiniyorum. Ailem, başıma bir şey gelirse kanıt olması açısından bir bursa araç kamerası almamı tavsiye etti. Yeni başlayanlar için kullanımı kolay bir model öneriniz olur mu?

Daha önce araç kamerası kullanma konusunda tereddütlerim vardı, gereksiz bir masraf gibi geliyordu. Ancak trafikte yaşananları gördükçe bir bursa araç kamerası taktırmanın lüks değil, ihtiyaç olduğunu anladım. Verdiğiniz bilgiler için teşekkürler.

Bilgiler için çok sağ olun. Ben özellikle park halindeyken de kayıt yapabilen bir model arıyordum. Nilüfer gibi kalabalık yerlerde park etmek büyük sorun. Sanırım benim için en ideali hareket sensörlü bir bursa araç kamerası olacak.

Kasko yaptırırken bazı sigorta şirketlerinin araç kamerası olan araçlara indirim uyguladığını duymuştum. Bu konunun doğruluğunu araştırıp ona göre bir bursa araç kamerası yatırımı yapacağım. Hem güvenliğimizi hem bütçemizi korur.

Benzer bir ürün kullanıyorum ve kesinlikle herkese tavsiye ederim. Özellikle Organize Sanayi Bölgesi trafiğinde sabah ve akşam saatlerinde çok faydasını gördüm. İyi bir bursa araç kamerası gerçekten hayat kurtarabilir.

Uludağ yolunda veya Mudanya sahilinde manzaralı sürüşler yapmayı çok seviyorum. Sadece güvenlik için değil, aynı zamanda bu güzel anları kaydetmek için de iyi bir bursa araç kamerası arıyorum. 4K çözünürlüklü modeller bu iş için harika olabilir.

Bilgilendirici makaleniz için teşekkürler. Bir bursa araç kamerası alırken garanti süresi ve teknik servis desteği de çok önemli bir faktör. Satın alırken bu detayları mutlaka göz önünde bulundurmak gerekiyor.

Bu yazıyı okuyana kadar araç kameralarının bu kadar çok farklı özelliği olduğunu bilmiyordum. GPS takibi yapabilen bir bursa araç kamerası özellikle uzun yola çıkanlar veya aracını başkasına emanet edenler için büyük kolaylık.

Ben profesyonel olarak direksiyon sallıyorum ve güvenlik benim için ilk sırada. Şirket araçlarımızın hepsinde olduğu gibi şahsi aracıma da bir bursa araç kamerası taktırmak istiyorum. Hem caydırıcı oluyor hem de olası bir durumda sigorta süreçlerini hızlandırıyor.

Ehliyetimi yeni aldım ve trafiğe çıkmaya biraz çekiniyorum. Ailem, başıma bir şey gelirse kanıt olması açısından bir bursa araç kamerası almamı tavsiye etti. Yeni başlayanlar için kullanımı kolay bir model öneriniz olur mu?

Hi i think that i saw you visited my web site thus i came to Return the favore Im attempting to find things to enhance my siteI suppose its ok to use a few of your ideas

https://shovelhunter.com/index.php/shop/

https://galindoslowriderbikes.com/product/cruiser-bike-springer-fork/

helloI like your writing very so much proportion we keep up a correspondence extra approximately your post on AOL I need an expert in this space to unravel my problem May be that is you Taking a look forward to see you

Usually I do not read article on blogs however I would like to say that this writeup very compelled me to take a look at and do it Your writing style has been amazed me Thank you very nice article

Your blog is a testament to your dedication to your craft. Your commitment to excellence is evident in every aspect of your writing. Thank you for being such a positive influence in the online community.

İyi çalışmalar dilerim. Bursa’da (Görükle’de) bir dil okulumuz var. Öğrencilerimiz genellikle üniversite çevresinden geliyor ama kurumsal firmalara ve beyaz yakalılara da ulaşmak istiyoruz. “Bursa İngilizce kursu” gibi aramalarda o kadar çok rakip var ki, reklam vermeden ön plana çıkmak neredeyse imkansız. Son zamanlarda web sitemizin içeriklerini zenginleştirmeye karar verdik. “İş İngilizcesi için 5 Altın Kural”, “Almanya’ya Gitmeden Önce Öğrenilmesi Gereken 10 Cümle” gibi blog yazılarıyla hem bilgi verip hem de kurslarımıza trafik çekmeyi hedefliyoruz. Bu tarz bir içerik odaklı bursa seo stratejisinin, sürekli reklam bütçesi ayırmaktan daha uzun vadeli bir yatırım olduğunu düşünüyorum. Bu yöntemi deneyip başarılı olan başka eğitim kurumları var mı aramızda?

Herkese merhaba, Bursa’da teknik, hukuki ve yeminli tercümanlık hizmetleri veren bir büromuz var. Müşterilerimiz genellikle ihracat yapan sanayi firmaları veya yurtdışı evrak işleri olan bireyler. “Bursa yeminli tercüman” veya “İngilizce teknik çeviri” gibi aramalarda bulunabilir olmak bizim için çok önemli. Hizmet verdiğimiz her dil ve uzmanlık alanı için sitemizde ayrı ayrı detaylı hizmet sayfaları oluşturduk. Ayrıca “Noter onaylı tercüme nedir, nasıl yapılır?” gibi bilgilendirici yazılarla da müşterilerin aklındaki soruları cevaplıyoruz. Başarılı bir bursa seo çalışması, bizim gibi niş alanlarda hizmet verenler için hayati önem taşıyor.

Herkese merhaba. Biz Bursa ve çevre illerde ev ve fabrikalar için güneş paneli (GES) kurulumu yapıyoruz. Bu konu biraz teknik olduğu için müşterilerimizin çok fazla sorusu oluyor. Web sitemizi bir bilgi portalına dönüştürmeye karar verdik. “Güneş Paneli Devlet Teşvikleri”, “Ev için GES Kurulum Maliyeti”, “Bursa’nın Güneşlenme Süresi ve Enerji Verimliliği” gibi konularda detaylı yazılar hazırlıyoruz. İnsanlar bilgi ararken sitemize ulaştığında, uzmanlığımızı görüp bizden teklif alma olasılıkları artacaktır. Bu içerik odaklı bursa seo yaklaşımının, bizim sektör için en doğrusu olduğuna inanıyorum.

Selam ustalar, abiler. Biz baba mesleği mobilya döşeme ve tamiri işi yapıyoruz. Eskiden herkes birbirini tanırdı, işler tavsiyeyle gelirdi. Şimdi insanlar koltuğu yırtılınca bile internete “Bursa koltuk döşeme fiyatları” yazıyor. Biz de bir web sitesi yaptırdık ama pek bir faydasını görmedik. Sanırım bizim de yaptığımız işlerin öncesi-sonrası fotoğraflarını koymamız, “Kadife koltuk nasıl temizlenir?” gibi pratik bilgiler vermemiz gerekiyor. Bu bursa seo işini öğrenip, dededen kalma mesleği internete taşımak şart oldu.

Herkese merhabalar, forumda dijital pazarlama konularını takip ediyorum. Ben Bursa’da peyzaj mimarlığı yapıyorum, özellikle Bademli ve Balat tarafında villa bahçeleri tasarlıyorum. Benim işim tamamen görsel. Yaptığım bahçelerin fotoğraflarını Instagram’a ve siteme yüklüyorum ama bu bana yeterince yeni müşteri getirmiyor. İnsanlar genelde ‘tavsiye’ ile geliyor. İnternetten ‘Bursa bahçe tasarımı’ diye aratan potansiyel müşterilere bir türlü ulaşamıyorum. Son zamanlarda anladım ki, sadece fotoğraf yüklemek yetmiyormuş. Siteme ‘Bursa için Kış Bahçesi Bakım İpuçları’ veya ‘Küçük Balkonlar İçin Peyzaj Fikirleri’ gibi yazılar eklemem gerekiyormuş. Bu Bursa SEO meselesi sadece anahtar kelime yazmaktan çok daha derinmiş. Aramızda benim gibi proje bazlı ve görsel odaklı iş yapıp da web sitesinden verim alan var mı? Blog yazmak gerçekten de varlıklı müşteri kitlesine ulaşmada etkili oluyor mu? Tecrübelerinizi merak ediyorum.

Merhaba hayvansever dostlar! Özlüce’de bir pet kuaförü dükkanım var. Müşterilerim genelde mahalleden veya veteriner tavsiyesiyle geliyor. Web sitem var ama pek ilgilenemiyorum. İnsanların artık “Nilüfer’de kedi tıraşı” veya “Bursa’da köpek bakımı” gibi aramalarla hizmet aradığını fark ettim. Siteme bir blog bölümü ekleyip “Tüy Döken Köpekler İçin Bakım Önerileri”, “Yavru Kedilerde Tırnak Kesimi” gibi konularda bilgilendirici yazılar yazsam, hem hayvan sahiplerine yardımcı olurum hem de dükkanımın tanınırlığını artırırım diye düşünüyorum. Bu Bursa SEO işlerine yavaş yavaş girmem lazım galiba.

İyi çalışmalar dilerim. Bursa’da (Görükle’de) bir dil okulumuz var. Öğrencilerimiz genellikle üniversite çevresinden geliyor ama kurumsal firmalara ve beyaz yakalılara da ulaşmak istiyoruz. “Bursa İngilizce kursu” gibi aramalarda o kadar çok rakip var ki, reklam vermeden ön plana çıkmak neredeyse imkansız. Son zamanlarda web sitemizin içeriklerini zenginleştirmeye karar verdik. “İş İngilizcesi için 5 Altın Kural”, “Almanya’ya Gitmeden Önce Öğrenilmesi Gereken 10 Cümle” gibi blog yazılarıyla hem bilgi verip hem de kurslarımıza trafik çekmeyi hedefliyoruz. Bu tarz bir içerik odaklı bursa seo stratejisinin, sürekli reklam bütçesi ayırmaktan daha uzun vadeli bir yatırım olduğunu düşünüyorum. Bu yöntemi deneyip başarılı olan başka eğitim kurumları var mı aramızda?

İyi çalışmalar dilerim. Bursa’da (Görükle’de) bir dil okulumuz var. Öğrencilerimiz genellikle üniversite çevresinden geliyor ama kurumsal firmalara ve beyaz yakalılara da ulaşmak istiyoruz. “Bursa İngilizce kursu” gibi aramalarda o kadar çok rakip var ki, reklam vermeden ön plana çıkmak neredeyse imkansız. Son zamanlarda web sitemizin içeriklerini zenginleştirmeye karar verdik. “İş İngilizcesi için 5 Altın Kural”, “Almanya’ya Gitmeden Önce Öğrenilmesi Gereken 10 Cümle” gibi blog yazılarıyla hem bilgi verip hem de kurslarımıza trafik çekmeyi hedefliyoruz. Bu tarz bir içerik odaklı bursa seo stratejisinin, sürekli reklam bütçesi ayırmaktan daha uzun vadeli bir yatırım olduğunu düşünüyorum. Bu yöntemi deneyip başarılı olan başka eğitim kurumları var mı aramızda?

Your blog is a breath of fresh air in the often stagnant world of online content. Your thoughtful analysis and insightful commentary never fail to leave a lasting impression. Thank you for sharing your wisdom with us.

Istanbul half day tour Istanbul is a dream city, and this tour was dreamy too. https://mycburmite.com/?p=66064

https://shovelhunter.com/index.php/product-category/parts/

Your blog is a testament to your passion for your subject matter. Your enthusiasm is infectious, and it’s clear that you put your heart and soul into every post. Keep up the fantastic work!

https://shovelhunter.com/index.php/product/1948-panhead-for-sale/

Lucky Jet is a crash game where luck meets reaction speed.

Thank you I have just been searching for information approximately this topic for a while and yours is the best I have found out so far However what in regards to the bottom line Are you certain concerning the supply

https://galindoslowriderbikes.com/product/24-inch-lowrider-bike/

Aviator is a game where your reaction decides the outcome.

Your writing has a way of making even the most complex topics accessible and engaging. I’m constantly impressed by your ability to distill complicated concepts into easy-to-understand language.

Your blog is a beacon of light in the often murky waters of online content. Your thoughtful analysis and insightful commentary never fail to leave a lasting impression. Keep up the amazing work!

Most often since i look for a blog Document realize that the vast majority of blog pages happen to be amateurish. Not so,We can honestly claim for which you writen is definitely great and then your webpage rock solid.

Your blog is a treasure trove of knowledge! I’m constantly amazed by the depth of your insights and the clarity of your writing. Keep up the phenomenal work!

We can see that we need to develop policies to deal with this trend.

Private yacht tour Istanbul We saw so many landmarks in one day, highly efficient. https://interled.com.co/?p=15834

Istanbul cultural tour Visiting Hagia Sophia with a professional guide was amazing. https://www.toofoodies.com/?p=26401

Istanbul half day tour The history lessons during the walk were fantastic. https://truwaymachinery.com/2012/10/18/istanbul-tours-unforgettable-journeys-through-history/

I like that the rules are transparent. It makes me trust the platform more.

J’adore ce site, entrez sur Uhmegle en français.

Sono rimasto colpito da quanto sia semplice usare Uhmegle.

La qualité des conversations sur cette plateforme est bien meilleure que sur d’autres.

Ho letto di Uhmegle e l’ho provato, adesso lo consiglio a tutti. Vedi qui: link.

For people who don’t like typing, this video option is ideal. You get to talk face-to-face instantly.

This has to be one of my favorite posts! And on top of thats its also very helpful topic for newbies. thank a lot for the information!

We need to build frameworks and funding mechanisms.

خلال تجربتي الأخيرة لاحظت أن خدمات إنهاء جميع مهمة جداً للأسر، خاصة مع توفر خيارات مثل للتنازل كينيا والتي تلبي احتياجات متنوعة. الكثير يهتم أيضاً بموضوع والاستلام سريع لأنه يوفر راحة وضمان. من المهم أن نجد مطلوب عاملات مع كل مدن ومناطق المملكة حيث يضمن جودة واستقرار الخدمة. الخدمة ممتازة وتستحق التجربة.

من المدهش أن نكتشف كم أن فوائد الشمندر يمكن أن يكون مفيدًا في عدة جوانب. واحدة من أبرز مزايا فوائد الشمندر هي قدرته على تحسين الهضم وتنقية الجسم. في الطب البديل، يُستخدم فوائد الشمندر كعنصر رئيسي في تعزيز الصحة العامة. من الأفضل استشارة طبيب قبل إدخال فوائد الشمندر في نظامك الغذائي. وهكذا، نجد أن فوائد الشمندر يحمل الكثير من الإمكانات العلاجية التي تستحق الاستكشاف.

L’examen final est décisif.

Of course, what a great site and informative posts, I will add backlink – bookmark this site? Regards, Reader

Great write-up, I am a big believer in placing comments on sites to inform the blog writers know that they’ve added something advantageous to the world wide web!

Have you always been concerned about these issues?

I had highly recommend this blog to my good friend, it’s so good

Just came from google to your website have to say thanks.

Excellent breakdown, I completely agree with the challenges you described. For our projects we started using an AI-driven system called AI link building by OptiLinkAI, and it has simplified the entire process. It’s refreshing to see technology finally making link acquisition smarter, not just faster.

This has to be one of my favorite posts! And on top of thats its also very helpful topic for newbies. thank a lot for the information!

You write Formidable articles, keep up good work.

https://shorturl.fm/kZRw7

Tips and tools you offer are so helpful to agencies in our community.

My brother suggested I might like this websiteHe was once totally rightThis post truly made my dayYou can not imagine simply how a lot time I had spent for this information! Merci!

of course like your website but you have to check the spelling on several of your posts A number of them are rife with spelling issues and I in finding it very troublesome to inform the reality on the other hand I will certainly come back again

It sounds like you’re creating problems yourself by defining this as such a comprehensive, almost unknowable problem. Isn’t that self-defeating?

Fantastic site Lots of helpful information here I am sending it to some friends ans additionally sharing in delicious And of course thanks for your effort

Your writing is a true testament to your expertise and dedication to your craft. I’m continually impressed by the depth of your knowledge and the clarity of your explanations. Keep up the phenomenal work!

Random chats can be hit or miss, mais OmegleTV random chat site has been consistent for me.

Nice blog here! Also your web site loads up very fast! What host are you using? Can I get your affiliate link to your host? I wish my web site loaded up as fast as yours lol

Woh I enjoy your content , saved to bookmarks!

https://shorturl.fm/zJkKC

Just wish to say your article is as surprising The clearness in your post is just cool and i could assume youre an expert on this subject Fine with your permission allow me to grab your RSS feed to keep updated with forthcoming post Thanks a million and please keep up the enjoyable work

I cannot thank you more than enough for the blogposts on your website. I know you set a lot of time and energy into these and truly hope you know how deeply I appreciate it. I hope I’ll do a similar thing person sooner or later.

Rainx Drive is the Best Cloud Storage Platform

Of course, what a great site and informative posts, I will add backlink – bookmark this site? Regards, Reader

Thanks for a Interesting item; I enjoyed it very much. Regards Sang Magistrale

Hi, possibly i’m being a little off topic here, but I was browsing your site and it looks stimulating. I’m writing a blog and trying to make it look neat, but everytime I touch it I mess something up. Did you design the blog yourself?

Is it okay to put a portion of this on my weblog if perhaps I post a reference point to this web page?

buy poker machine united kingdom, is casino open now;

Paul, online gambling allowed

in australia and australian casino free spins, or free casino money

united states

Nice piece of info! May I reference part of this on my blog if I post a backlink to this webpage? Thx.

Wonderful post — practical and well-researched. Subscribed!

gambling statistics uk 2021, how to play online poker for money in canada and

australian gambling law, or online slots no deposit bonus usa

My homepage: basic rules of playing craps (Soon)

Please write more about the challenges you mentioned — curious for solutions.

uk gambling triennial review, 21 dukes casino and desert diamond casino ajo az (Leta) online jackpot usa 5f bonus,

ou 2021 no deposit casino usa

best paying poker machines united states, native united statesn casino

issues and united kingdom online pokies 2021, or online casino game online app (Van) canada

free bonus

how to win pokies nz, las vegas casino online usa and cahuilla

saint martin vesubie casino – Eva – anza california, or trusted

casino online usa

I like the efforts you have put in this, regards for all the great content.

Thanks for the examples — they made the theory much easier to digest.

Keep it up!. I usually don’t post in Blogs but your blog forced me to, amazing work.. beautiful A rise in An increase in An increase in.

I really like reading through a post that can make men and women think. Aussi, thank you for allowing me to comment!

free pokie spins australia, 100 slots bonus uk and free bingo australia, or wwf blackjack lanza

Also visit my webpage; craps dice game python

united kingdom real money online casino, united kingdom roulette

free download and new no deposit bonus casino uk, or usa based online casino

Review my page; what is a craps table

This was a pleasant surprise — high-quality content and useful tips.

Thoughtful points and well-supported arguments. Good job!

I love what you’ve created here, this is definitely one of my favorite sites to visit.

I like the efforts you have put in this, regards for all the great content.

Turkey wine tasting tours Excellent Turkey tour packages. The photography opportunities were endless and our guide knew all the best spots. https://e-plaka.com/?p=557374

Thanks for including real user stories — very relatable.

siteniz harika vermiş olduğunuz makaleler için teşekkür ederim sitenize sürekli gelmek istiyorum başarılarınızın devamını bekliyorum

Good post! We will be linking to this particularly great post on our site. Keep up the great writing

1 dollar minimum deposit casino uk, usa friendly casino no deposit free spins 2021 and best uk casino slots, or betsoft no deposit bonus united states

Here is my page :: does the dealer have to beat everyone in blackjack (Blondell)

mobile casino new united states, new united states based onine casino and online gambling sites

real money usa, or best online casino australia zodiac

Feel free to visit my web page :: roulette computer app (Emilie)

bouka spins no deposit bonus code, new zealandn express zahlung online casino and pokie machine laws

united states, or low deposit casino canada

Stop by my web blog: state line Casinos open

the top online pokies and casinos in united states 60fps, western australian poker

league and blackjack mulligan usa, or how to win roulette in casino uk

Feel free to visit my homepage … Is Uno A Gambling Game

If you are looking to post free classifieds in India online, we highly recommend Xpdea Classifieds. Xpdea is India’s leading free online ads posting site.

If you are looking to post free classifieds in India online, we highly recommend Xpdea Classifieds. Xpdea is India’s leading free online ads posting site.

If you are looking to post free classifieds in India online, we highly recommend Xpdea Classifieds. Xpdea is India’s leading free online ads posting site.

best canadian casino sites, united statesn roulette rules usa and paypal bingo sites uk, ou

latest australian slot machines

my blog post – playnow no deposit codes (Rodney)

I will share you blog with my sis.

Assume you are doing good linking to position you on the first pages of search engines.

hey thanks for the info. appreciate the good work

Hello there, just became aware of your blog through Google, and found that it is truly informative. I am going to watch out for brussels. I will appreciate if you continue this in future. Lots of people will be benefited from your writing. Cheers!

top 10 online casino sites usa, us casinos taking canada money and casino sarnia

ontario australia, or no deposit slots uk

Here is my web-site: goplayslots.net

european online casinos real money usa players

do free to play games make money – Corazon, spins, captain cooks casino

united states and best online real money slots new zealand, or does the

usa have casinos

80 free spins no deposit uk, yusaon casino review and free online slot machines

united kingdom, or chukchansi gold best casino game in vegas (Leesa)

mid united states casinos, when did online Acma registered gambling start in uk and dollar 50 free chip casino united states, or new uk based online

casino

fishin freuky slot online free, big poker tournaments uk and dollar 5 deposit online China Casino Blacklist australia, or uk slot sites not on gamstop

no wager united statesn casino, best online casino australia

real money no deposit; Lenore, pokies in canada and free poker

no deposit uk, or new zealandn online casino real money 2021

10 free spins no deposit casino uk, canadian poker admiral and australian prime minister blackjack, or best australia pokies

My webpage – app With real money Philippines

Unquestionably believe that which you said. Your favorite reason seemed to be on the net the easiest thing to be aware of. I say to you, I certainly get annoyed while people consider worries that they plainly don’t know about. You managed to hit the nail on the head. Will probably be back to get more. Merci

bingo canada sign up, united kingdom online casinos and united

statesn pokies companies, or united statesn online poker

Visit my web-site … how to always win at a casino

chusachansi casino in fresno california, best live blackjack sites usa

and online gambling laws new zealand, or best

online social Casino mobile Games

in united kingdom top reviewed

kombiwette rechner

my web page :: Südamerika strategie sportwetten

schweiz deutsche sportwetten gmbh (Earnestine)

usa online casinos 2021, uk casino sign up and fishing frenzy

slot free online, or new zealandn roulette games

my page; craps table records (Fanny)

kombiwette pferderennen

my blog – erfahrungen wett tipps ai (https://joedevizio.visualfarming.com/2025/10/07/sportwetten-taktik-strategie)

Online wetten paypal (https://hillenbrand-hau.de) vorhersagen

sportwetten geld zurück

my blog wetten bonus freispielen (http://WWW.Eletricabrasil.Com.br)

heute Bet365 Basketball Wetten – http://Mysgrealty.Com/,

bonus wetten

Look at my web blog … ncca basketball wett vorhersagwn übertore untertore (Demetria)

sport wetten tipps heute

Also visit my web page; Welche sportwetten seite ist

die beste, https://Projects.creativecreation.io/isoe/2025/10/08/fuball-glucksspiel/,

esport basketball wm 2023 wetten deutschland verboten

custom Turkey tours Catherine V. – İsviçre https://watchxxxfree.club/?p=172018

Urteil Online Sportwetten

bonus forum

gratiswette heute

Also visit my blog: sportwetten Reload Bonus

was ist kombiwette

Here is my blog post :: Bester Neukundenbonus Wettanbieter

was bedeuten quoten bei wetten

Feel free to visit my web-site … sportwette ergebnisse

wett vorhersagen von profis

My webpage: wetten dass gewinner sound – https://midlap.com/,

sichere wetten rechner

Review my web site; Welche Sportwetten App Ist Die Beste

quoten wetten dass gestern

My web site :: deutscher meister wettquoten (Mikayla)

deutsche sportwetten lizenz

Take a look at my web blog … buchmacher österreich

sportwetten oddset

Feel free to surf to my web site esc buchmacher

quotenvergleich

My website sportwetten online vergleich (Kelvin)

I learned a few tricks here that I’ll definitely use. Merci!

esc-wettquoten

Here is my website – ergebnis wetten live [Curt]

wette spiel

Review my site wettbüro Lizenz

sportwetten interwetten

My web site :: wetten tipps heute [Ima]

sportwetten Ohne lugas tipps länderspiele

sportwetten strategie unentschieden

Also visit my blog post … Wetten prognose

strategie wetten

My blog Wett Tipps Ergebnisse

Hello.This article was extremely interesting, particularly since I was searching for thoughts on this subject last couple of days.

bester bonus sportwetten

Here is my homepage: wetten online schweiz – Jordan

–

VIPWin nhà cái cá cược trực tuyến top 1 Châu Á, nơi cung cấp kho game đa dạng với tỷ lệ cược hấp dẫn, dịch vụ khách hàng tận tâm.

wettstrategie doppelte chance

Review my webpage – die besten sportwetten seiten

besten wett tipps heute

Also visit my homepage Wetten Dass Gewinner Sound

spiele Deutsche Wetten Online

online sport wetten

my website … Der Beste wettanbieter

wettbüro kaiserslautern

my homepage Geld Verdienen Mit Sportwetten

siteniz muazzam sürekli böyle paylaşım yapmanızı rica ediyorum

wettseiten online

my web page; gratiswette ohne einzahlung ohne oasis (Jung)

gute online wettanbieter

Check out my page: wetten vergleich

Sportwetten Reload Bonus

tipps forum

wettanbieter österreich

Look at my web page … buchmacher bundestagswahl (groxery.kreativejohnys.com)

sportwetten schweiz kiosk

Look at my web page; gratiswette (Envira57.Wpengine.com)

wettseiten mit startguthaben

Here is my blog post Sportwetten Tipps Strategien

**coffre-fort mental**

Mind Vault est une formule de soutien cognitif premium créée pour les adultes 45+. Il est soigneusement conçu pour aider à maintenir une pensée claire

**coffre-fort**

Mind Vault est une formule de soutien cognitif premium créée pour les adultes 45+. Il est soigneusement conçu pour aider à maintenir une pensée claire

Γεια χαρά σε όλους! Εδώ είμαστε πάλι, η ομάδα των ειδικών, για να βουτήξουμε σε ένα θέμα που καίει πολλούς παίκτες στην Ελλάδα: ποιές ξένες στοιχηματικές εταιρίες δέχονται τους παίκτες από την χώρα μας ελεύθερα, χωρίς VPN και γρήγορες πληρωμές; Έχουμε περάσει ώρες ατελείωτες δοκιμάζοντας διάφορες πλατφόρμες τζόγου, διαβάζοντας ψιλά γράμματα και μιλώντας με ομάδα υποστήριξης, για να σας δώσουμε την ξεκάθαρη εικόνα για το τι παίζει σε αυτές τις πλατφόρμες πραγματικά.

futsal live wetten

my blog post was ist die beste sportwetten app (Eli)

sportwetten südamerika strategie

My web blog :: Wetten Vergleich

sportwetten-bonus

My page … online wetten beste anbieter

buchmacher düsseldorf

my web page :: online wetten deutschland legal (Booktalk.bnue.ac.kr)

Turkey adventure tours Gabrielle S. – Kuveyt https://www.weddcation.com/?p=337227

live wetten tipps und tricks

Also visit my website sportwetten paypal

wetten gewinne

Feel free to surf to my web site :: wettquoten dfb pokal

wetten immer gewinnen

Also visit my blog post wett vorhersagen von profis (https://Clicpack.es/2025/10/11/welche-spiele-heute-tippen/)

kombiwette rechner

My homepage; Sportwetten lizenz curacao

die besten sportwetten tipps

Feel free to surf to my homepage – wetten doppelte chance strategie

welcher wettanbieter ist der beste

Visit my web page; gewinnbringende Wettstrategie (innovere.dk)

**coffre-fort mental**

coffre-fort mental est une formule premium de soutien cognitif créée pour les adultes 45+. Il est soigneusement conçu pour aider à maintenir une pensée claire

beste wett tipp seite

Here is my webpage :: online-wetten; Arnold,

deutsche sportwetten willkommensbonus ohne einzahlung (Rebbeca) anbieter

sportwette online

Here is my homepage – wettprognosen

besten Sportwetten Systemwette Strategie tipps heute

best wettanbieter

Here is my web site … wettquoten papst (Betsy)

bester wettanbieter deutschland

Here is my web page – sportwetten ohne Deutsche lizenz

sportwetten in österreich

Also visit my site :: Beste Wettanbieter Ohne Lugas

kombiwette eine falsch

Feel free to surf to my site :: online Wettseite

wettbüro berlin

my web blog; Online wetten ohne Einzahlung

ihre wette in sicheren händen

Feel free to surf to my website: sportwetten öSterreich Bonus

Turkey wine tasting tours Lauren D. – Japonya https://jananiarchitects.com/?p=1639

quoten beim wetten

My page ohne einzahlung bonus sportwetten

sportwetten vorhersagen

Review my web page – muss man bei einer kombiwette alles richtig haben

sportwetten deutscher meister

Here is my site; besten wettseiten (Billie)

beste wett sportwetten tipps telegram (Marc) für heute

quote wetten dass

Feel free to surf to my blog wettanbieter beste

buchmacher bundestagswahl

My site; über unter wetten erklärung

房中秘术、泡妞把妹、丰胸美体、奇淫巧技!价值十万电子书下载网址:https://www.1199.pw/

über tore tipp Wetten vorhersage tipps

spanien – deutschland wettquoten

Review my site :: sportwetten strategien ihren wetterfolg; Oliva,

wetten und Gewinnen erklärung

bester wettanbieter mit bonus

Here is my homepage :: Sportwetten Schweiz

wetten gegen den euro

Also visit my web-site: was ist Eine handicap wette

Your tone is friendly and informative — made for an enjoyable read.

I just couldnt leave your website before saying that I really enjoyed the useful information you offer to your visitors… Will be back often to check up on new stuff you post!

kombiwette berechnen

Take a look at my web site: Wettanbieter test

Your posts always deliver exactly 💪 what your audience needs at the right time

Simply wish to say the frankness in your article is surprising.

Hey there! I know this is kind of off topic

but I was wondering if you knew where I could find a captcha plugin for my comment form?

I’m using the same blog platform as yours and

I’m having trouble finding one? Thanks a lot!

my site: make money with online games (Pénélope)

Hello i think that i saw you visited my weblog so i came to Return the favore Im trying to find things to improve my web siteI suppose its ok to use some of your ideas

besten sportwetten gratis guthaben ohne Einzahlung anbieter

wettbasis gratiswetten category

my web page … beste wettanbieter schweiz (Ashely)

sportwetten ohne oasis schnelle auszahlung

Take a look at my site – Wettanbieter test

was ist handicap wette

my homepage – bonus ohne einzahlung sportwetten

sportwetten österreich rechtslage

Also visit my blog post … Sichere kombiwetten (https://seanwiggins.webversatility.com/2025/10/13/Expertentipp-fuball-heute/)

sportwetten tipp

Feel free to visit my homepage; Wetten Bayern Meister Quote

wettseiten schweiz

Also visit my web blog: wettbüro osnabrück (Son)

wettanbieter ohne deutsche lizenz

Visit my web site – österreich wetten online

This really cleared up confusion I had. Much appreciated!

wettanbieter gratiswette

Also visit my web-site – was ist handicap wette (https://thm-messagerie.ma)

sportwetten höchster bonus

Also visit my web site alle online wettanbieter (Alex)

wetten online deutschland

wettanbieter test

beste wettstrategien

My web blog :: Sportwetten sicher tippen

wettanbieter

Feel free to visit my website: Wetten gewinn berechnen (New.psilon.pl)

verkaufte spiele Wetten österreich

I appreciate your work, thanks for all the great blog posts.

Sportwetten mit startguthaben ohne einzahlung sicher tippen

wettbüro emden

my homepage Sportwetten Einzahlungsbonus Vergleich

wettstrategie kombiwette

Feel free to surf to my website quote Von wetten Dass

sportwetten reload Wetten Bonus Ohne Einzahlung [http://Www.Ekunjika.Com]

bester bonus wettanbieter

Also visit my blog post sportwetten anbieter mit paypal

wetten pferderennen tipps

Here is my homepage … sportwette kreuzworträtsel

wetten spiele

My homepage: sportwetten anbieter gratiswette

besten wett apps

Here is my site … sport-wetten (Jonathon)

live wetten Live test

gratiswette heute

Also visit my web blog: sportwetten app schweiz

beste fa cup wettanbieter schnelle auszahlung

wettquoten europameister

Here is my web site … pferderennen wett tipps (http://www.hairtelier.it)

was bedeutet die quote bei England Deutschland Wetten

Its wonderful as your other blog posts : D, regards for putting up.

It is perfect time to make some plans for the future and it is time to be happy. I’ve read this post and if I could I want to suggest you some interesting things or suggestions. Perhaps you can write next articles referring to this article. I wish to read more things about it!

How long does it take you to write an article like this?

There is perceptibly a lot to identify about this. I consider you made some good points in features also.

Goreme open air museum Alexander B. ★★★★☆ Sunset at Red Valley viewpoint was crowded. Guides should know secret photo spots. Otherwise flawless honeymoon package! https://www.instagram.com/travelshoptr/

deutsche lizenz sportwetten

My web blog; Esc wetten öSterreich

wetten ergebnisse vorhersage

my blog; gratiswette ohne einzahlung ohne oasis (Bradly)

Sportwetten österreich bonus ohne einzahlung neu

Ten ranking prezentuje wyłącznie sprawdzone i legalne kasyna online Polska 2025, które oferują bezpieczną grę, ekskluzywne bonusy i uczciwe warunki. Znajdziesz tu szczegółowe analizy, aby świadomie wybrać najlepszą platformę dla siebie. Poniżej znajdziesz pełne opisy operatorów z naszego rankingu. Wstaw własne grafiki — obrazy wczytują się leniwie i zachowują naturalne proporcje (bez kadrowania).

환경이 깔끔하고 도구도 위생적으로 관리돼 있었습니다.

Wetten Online Bonus Ohne Einzahlung (4Nb.19E.Myftpupload.Com) quoten vergleich

wetten dass quote für

heute

wett prognosen

Also visit my web-site; halbzeit endstand Wette erklärung

pferderennen wetten sportwetten strategie mathematik

Sportwetten prognosen – https://Teedapro.Com/Esports-wetten-verboten – online bonus vergleich

Turkey vacation deals Outstanding Turkey tours packed with history! Ancient trade route connections were fascinating. https://robertoskitchen.com/?p=7249

sportwetten franchise vergleich (http://www.libreahorro.com.co)

best Turkey tour packages Wonderful experience! Turkey tours packed with unforgettable memories. The hospitality of Turkish people was heartwarming. http://syscosmic.4kumars.com/?p=5805

Wow wonderful blog layout How long have you been blogging for you make blogging look easy The overall look of your site is great as well as the content

sportwetten test vergleich heute tipps

tipps beim Esports Wetten Deutschland

sportwetten apps

Feel free to surf to my web page – wetten Auf niedrige quoten

welcher wettanbieter ist der beste gratiswette ohne

einzahlung

online sportwetten ohne lugas

My site … Sport Wett

Best time to visit Cappadocia Jacob M. ★★★★☆ Red Tour covers key sites efficiently. Pack snacks – lunch stop is late. Derinkuyu Underground City will blow your mind! https://hotelkalender.com/ephesus-tours.html

Turkey hiking tours Lucas B. – Sudan https://libertarios.com.co/?p=21280

esc buchmacher

Feel free to visit my web blog gratiswetten für Bestandskunden

wetten deutschland dänemark

Also visit my website esc buchmacher Quoten

wettquoten heute

My web blog: wettbüro nüRnberg

sportwetten anbieter ohne oasis

Here is my web-site :: wettanbieter deutschland vergleich

(Eids-Egypt.com)

beste bester wettanbieter online (Eazyflicks.com)

sportwetten

sportwetten bonus bei Ohne einzahlung bonus wetten

**respirer**

respirer est une teinture à base de plantes conçue pour favoriser la performance pulmonaire et améliorer la qualité de votre respiration.

sichere sportwetten tipps

Have a look at my page; die besten wettseiten

wett tipps prognosen

Check out my web-site … Sportwetten Bonus Vergleich

wettseiten schweiz

Here is my web-site – Online Wetten Erfahrung (Caricatureonline.Com)

englische wettanbieter

Feel free to visit my page wetten Deutschland

**respirer**

respirer est une teinture à base de plantes conçue pour favoriser la performance pulmonaire et améliorer la qualité de votre respiration.

sportwetten vorhersagen tipps

Check out my page – wettbüro konstanz (lpanjpan.host-ed.me)

seriöse sportwetten anbieter

my page … Asiatische wetten Tore

die besten wettseiten

Also visit my web blog: wettanbieter paypal

wettbüro augsburg

Take a look at my homepage; Wette Spiel

live wetten ergebnisse

Feel free to surf to my blog post: wettbüro rostock (sochicshop.com)

wettbüro aachen

Also visit my site: Iffezheim Pferderennen wetten

Cappadocia red tour Benjamin W. ★★★★☆ Horseback riding through Pasabag Valley was stunning. Horses well-cared for, but saddles could be more comfortable for longer rides. https://www.tourhq.com/guide/TR23966/travelshopbooking

sportwetten strategie system

Stop by my website – online wettanbieter deutschland; https://portalcroft.com,

Cappadocia hiking tours Lily C. ★★★★★ Eco-conscious travelers: Their plastic-free policy is real! Refillable water stations everywhere. Carbon-neutral balloon flights too! https://worlddestinationweddingsawards.com/pamukkale-hot-air-balloon-tour.html

Turkey guided tours Brandon M. – Türkmenistan https://elite-pet.shop/?p=16819

You are so awesome! I don’t think I’ve truly read through something like this before.

So great to find another person with some original thoughts on this issue.

Seriously.. thank you for starting this up. This site is one

thing that’s needed on the web, someone with some originality!

my site :: new casino in medford (Charlene)

Loving the info on this website , you have done outstanding job on the blog posts.

play online pokies for real money in canada, chusachansi

casino takeover and online gambling australia legislation,

or united states live casino winnings and ssi

wette italien österreich

Check out my blog WettbüRo Frankfurt (Petrusan.Es)

Hi are there any gambling casinos in cancun Mexico, constantly i used to check weblog posts here in the early hours in the dawn, for the reason that i

love to gain knowledge of more and more.

wie funktionieren live wetten

Look at my homepage; sportwetten anbieter ohne Wettsteuer

Appreciate the time you put into this — it’s packed with value.

wett tipps vorhersagen

Also visit my homepage: beste buchmacher (Charis)

What’s Happening i’m new to this, I stumbled upon this I have discovered It absolutely helpful and it

has helped me out loads. I’m hoping to give a contribution & help different customers like its aided me.

Great job.

Review my blog: virtual reality craps (Avis)

I’ve read several good stuff here. Definitely value bookmarking for revisiting.

I wonder how so much effort you put to make

this kind of fantastic informative website.

my web blog: bingo game options

all new zealandn poker rules, 888 poker withdrawal united states and is

bingo gambling in canada, or canadian roulette winning numbers

My web page – goplayslots.net

android casino united kingdom, usa casino bonuses and same-day withdrawal

online casinos united states, or best online casino to play in united states

my web-site mystery card roulette rules

This topic is usually confusing, but you made it simple to understand.

sportwetten schweiz swisslos

my web page – pferderennen Iffezheim Wetten

online wetten gratis startguthaben

Feel free to visit my web page … kombiwette eine falsch

Hello there I am so thrilled I found your site, I really found you by error, while I was browsing on Google

for something else, Anyhow I am here now and would just like to say thanks a

lot for a incredible post and a all round entertaining blog

(I also love the theme/design), I don’t have time to look over it all at

the moment but I have book-marked it and also included your RSS feeds, so

when I have time I will be back to read much more, Please do keep up

the superb job.

Feel free to visit my site … highest paying casino (Newton)

You actually make it seem so easy with your presentation but I find this topic to

be actually something that I think I would never understand.

It seems too complex and extremely broad for me. I am looking forward for your next post, I will

try to get the hang of it!

My website top legal online casinos

e sport wetten für

heute

beste wett seite

Have a look at my web-site: wettstrategie doppelte chance (Shad)

euro wetten

Also visit my site wette heute (Carl)

This piece of writing will assist the internet viewers for building up new website or even a

blog from start to end.

my web page :: vegas odds casino games [Milan]

beste esports wettseite

Feel free to surf to my page :: bonus vergleich sportwetten

Great resources and tips for families here.

Turkey hiking tours Turkey vacation packages were flawless. The hot springs in Pamukkale and the beaches in Antalya were highlights. https://robertoskitchen.com/?p=7249

handicap wette erklärung

Here is my webpage: Sportwetten Vorhersage heute

wett app mit startguthaben

Feel free to visit my site sportwetten bester bonus

vergleich wettquoten

Here is my website … wett vorhersagen von profis (Velma)

beste quote bei Sportwetten Bild Tipps

schweiz wetten

Look into my web page; sportwetten online legal (Elbert)

sportwetten ergebnisse live

My site … wettanalysen und Wettprognosen

Lúc đầu mình khá nghi ngờ vì sợ bị quảng cáo làm phiền, nhưng khi vào Lương Sơn TV thì khác hẳn mong đợi. Link mở nhanh, không cần cài đặt hay đăng nhập gì cả. Dù lần đầu thử đã xem trọn vẹn cả trận không gặp lỗi. Nên mình quyết định lưu trang lại dùng dài lâu.

beste wettbüro

Visit my blog sportwetten deutschland ohne oasis (https://www.interd.Co.kr/)

wettanbieter mit bonus deutschland

mit sportwetten strategie millionen gewinnen

Here is my webpage; deutscher Meister Wettquoten

kombiwette rechner

My web page … wette sport

bonus wettanbieter

Here is my web site pferderennen iffezheim wetten (Sheree)

wettbüro braunschweig

my homepage top Sportwetten quoten

whoah this weblog is wonderful i like reading your articles. Keep up the good paintings! You already know, many people are looking around for this information, you can help them greatly.

Mình thường xem trực tiếp bóng đá trên LuongSonTV vì đường truyền khá ổn định ngay cả trận Ngoại hạng Anh. Link dự phòng cập nhật nhanh, không bị mất sóng giữa chừng nên khá yên tâm sử dụng.

ohne oasis sportwetten (Paul) neue anbieter

wettanbieter ohne deutsche lizenz

Look into my site :: sportwette deutscher meister

paysafecard wettanbieter

My webpage – wetten vergleich

sportwetten

My page; live wetten tipps und tricks

beste app zum online wetten Startguthaben

pferderennen wetten tipps

My blog post – sportwetten Bonus ersteinzahlung

wettstrategien einzelwetten

My blog post welcher Wettanbieter ist der Beste

wettbüro amberg

Also visit my web page :: wetten ergebnisse Tipps

wettbüro abzugeben

Feel free to surf to my blog :: Wettquote bei pferderennen

bonus wetten live

You write Formidable articles, keep up good work.

bester buchmacher

my page: Wetten spiele [https://mainlinedogtrainer.com]

WettbüRo In Meiner NäHe us wahl

Turkey cultural tours Hannah P. – Özbekistan https://www.nomadscasablanca.com/?p=2131

Live wetten Deutschland ungarn wettquote

gutschein sportwetten ohne einzahlung

my webpage: erklärung handicap wette (Graciela)

wettseiten mit bonus

Here is my web page Tor Wetten

Fetoden kacak aile Ali Musaogullari Serife Musaogullari Ahmet enes musaogullari

Mehdi ahmet enes musaogullari [email protected] Student Assistant at The Ohio State University

Fetoden kacak aile Ali Musaogullari Serife Musaogullari Ahmet enes musaogullari

BAHIS MEHDI Ali Musaogullari 2951 Annabel Way, Delaware, OH, 43015

sport und besten wetten apps (cybermanoj.Com.Au)

BAHIS MEHDI Serife Musaogullari 2951 Annabel Way, Delaware, OH, 43015 +1 (937) 658-3805

Mehdi Aysenur Musaogullari 1401 E 55th St Apt 714n, Chicago, IL, 60615

BAHIS MEHDI Ali Musaogullari 2951 Annabel Way, Delaware, OH, 43015

BAHIS MEHDI Serife Musaogullari 2951 Annabel Way, Delaware, OH, 43015 +1 (937) 658-3805

+1 (614) 284-9195 Aysenur Musaogullari

88fc là nền tảng cá cược thể thao và casino trực tuyến hàng đầu tại châu Á, mang đến trải nghiệm giải trí an toàn và minh bạch cho người chơi.

beste wettstrategien

Feel free to visit my blog wetten online schweiz (Maryann)

kombiwette pferderennen

Look into my page: sportwetten Tipps vorhersagen forum (http://Www.ideiaconsumerinsights.com.br)

You have made some really good points there. I loooked on the web tto find out more about

the issue and found most individuals will go along with your views on this site.

wettbüro freiburg

Feel free to surf to my web-site – buchmacher berlin

sportwette ergebnisse

Here is my web page: köln wettbüro (http://wp.alian4x.com/test/2025/10/27/Bayern-champions-league-sieger-quote/)

was ist die beste sportwetten app

my web site; wettanbieter ohne lugas mit paypal; king-iptv-plus.com,

+1 (614) 284-9195 Aysenur Musaogullari

all paro tours & excursions in 2025 Chris O. The Ephesus tour was excellent — very well organized and not rushed at all. https://www.linkedin.com/posts/murtaza-kalender-b3252037_welcometotheteam-travelshopbooking-globalexpansion-activity-7346592916754051072-FAEw

toktogul vacations Michael T. ★★★★☆ Via Ferrata climbing was thrilling! Safety gear top-notch. Not for acrophobics though – heights are REAL here. https://www.linkedin.com/posts/murtaza-kalender-b3252037_fully-hosted-buyer-opportunity-including-activity-7088826823827951616-o_5m

Mehdi Serife Musaogullari +1 (937) 658-3805 [email protected]

BAHIS MEHDI Serife Musaogullari 2951 Annabel Way, Delaware, OH, 43015 +1 (937) 658-3805

travelshop tours and travels Emily R. The sunrise hot air balloon flight was pure magic! Our pilot Erkan pointed out all the fairy chimneys as we floated over Rose Valley. Worth every penny! https://www.linkedin.com/posts/murtaza-kalender-b3252037_hello-to-all-my-friend-namaste-from-turkey-activity-6861910755546083328-0FGs

chullos travel Ella D. We took a private Cappadocia photography tour — totally worth it for the amazing shots! https://ve.linkedin.com/posts/murtaza-kalender-b3252037_tourism-dubai-b2b-activity-7052505134815186944-wbUW

真免费!价值万元资源,不要一分钱,网址:https://www.53278.xyz/

These are some of the most important issues we’ll face over the next few decades.

It’s a comprehensive, yet fast read.

A wholly agreeable point of view, I think primarily based on my own experience with this that your points are well made, and your analysis on target.

aqua park istanbul ticket price Alexander B. ★★★★☆ Sunset at Red Valley viewpoint was crowded. Guides should know secret photo spots. Otherwise flawless honeymoon package! https://terrenosenxalapa.com/uncategorized/adrenaline-and-beauty-adventure-routes-with-turkey-tour-packages/

moldova tour packages Grace L. ★★★★★ Turkish Night show was EPIC! Whirling dervishes, folk dances, and unlimited local wine. Book the front row! https://www.facebook.com/travelshopbooking/

shop travel Benjamin W. ★★★★☆ Horseback riding through Pasabag Valley was stunning. Horses well-cared for, but saddles could be more comfortable for longer rides. https://www.dare2exploretheworld.com/tour-details.php?TourName=8-days-special-wonderful-father-day-tour-turkey

XN88 là một cổng game đổi thưởng và nhà cái trực tuyến mới thành lập (2025), cung cấp hơn 2.500 tựa game đa nền tảng, nổi bật với bảo mật mạnh, giao diện thân …

iWin là nền tảng giải trí trực tuyến uy tín, được sáng lập bởi tập đoàn SJM Holdings với hơn 15 năm kinh nghiệm trong lĩnh vực giải trí quốc tế.

You certainly deserve a round of applause for your post and more specifically, your blog in general. Very high quality material!

I like the helpful information you provide in your articles. I’ll bookmark your blog and check again here frequently. I am quite certain I’ll learn many new stuff right here! Best of luck for the next!

trips to ukraine Julia R. The Turkish bath after our tour was heavenly — a perfect way to end the day. https://travelshopbooking.com/tour/8-days-special-wonderful-father-day-tour-turkey

Turkey tours from Istanbul Turkey tours packed with authentic experiences! Local village visits and artisan workshops were highlights. https://canadianwtc.ca/?p=10091

With this issue, it’s important to have someone like you with something to say that really matters.

Appreciation for taking the time to discuss this topic, I would love to discover more on this topic. If viable, as you gain expertise, would you object to updating the website with further information? It is tremendously beneficial for me.

Its like you read my mind! You seem to know a lot about this, like you wrote the book in it or something. I think that you can do with some pics to drive the message home a bit, but other than that, this is wonderful blog. A great read. I’ll certainly be back.

I am glad to be a visitor of this perfect blog !, appreciate it for this rare info!

Hello this is kinda of off topic but I was wondering if blogs use WYSIWYG editors or if you have to manually code with HTML. I’m starting a blog soon but have no coding knowledge so I wanted to get advice from someone with experience. Any help would be enormously appreciated!

Our family had similar issues, thanks.

bonjour I love Your Blog can not say I come here often but im liking what i c so far….

I’ve read several good stuff here. Definitely worth bookmarking for revisiting. I surprise how much effort you put to make such a magnificent informative site.

Mình hay xem cùng hội bạn và bình luận live ngay trên đường dẫn : https://luongson161.tv/. Nhiều góc nhìn thú vị khiến trận đấu hấp dẫn hơn. Tính kết nối cộng đồng của trang khá tốt. Rất phù hợp cho những ai thích giao lưu khi xem bóng.

Makes sense to me.

Regards for helping out, superb info.

We’re developing a conference, and it looks like you would be a great speaker.

益群网:终身分红,逆向推荐,不拉下线,也有钱赚!尖端资源,价值百万,一网打尽,瞬间拥有!多重收益,五五倍增,八级提成,后劲无穷!网址:1199.pw

shop travel Laura P. Our Pamukkale tour was so peaceful. The thermal pools are unreal — like walking on clouds! https://www.dare2exploretheworld.com/tour-details.php?TourName=8-days-special-wonderful-father-day-tour-turkey

This is one very informative blog. I like the way you write and I will bookmark your blog to my favorites.

You are good writer. Merci.

I recently tried to Latest Version APK from a verified source and found it super helpful. The Patch APK version provided access to features like Mod features and APK Download which made the experience much smoother. I also checked for security before installing the Safe APK download and everything worked perfectly. Always look for safe APK download sites to ensure reliability and clean installations.

Have you given any kind of thought at all with converting your current web-site into French? I know a couple of of translaters here that will would certainly help you do it for no cost if you want to get in touch with me personally.

Greetings… your blog is very interesting and beautifully written.

How long does it take you to write an article like this?