As the demand for liquid soap continues to rise globally, manufacturers are increasingly turning to advanced production technologies to meet consumer expectations. At the heart of this process is the Machine de fabrication de savon liquide, an essential tool that facilitates the efficient production of high-quality liquid soap. This article explores the different types of liquid soap making machines, their features, benefits, et applications, providing valuable insights for potential buyers and manufacturers.

Understanding Liquid Soap Making Machines

- Overview of the Production Process

Liquid soap making involves several key steps: mixing oils and fats, saponification, and finally, blending with additives to create the desired product. A liquid soap making machine automates much of this process, improving efficiency and consistency. - Types of Machines

- With Homogenizers: These machines ensure a smooth, consistent mixture by breaking down particle sizes. This feature is crucial for producing high-end liquid soaps that require uniform texture and appearance.

- Without Homogenizers: These simpler machines are ideal for smaller operations or basic formulations, making them a more cost-effective option for new entrants to the market.

- Heating Capabilities

- Heated Models: These machines come with built-in heating systems that facilitate quicker saponification and allow the use of solid fats. This capability is essential for manufacturers looking to speed up production cycles.

- Non-Heated Models: Suitable for cold-process soap production, these machines rely on ambient temperatures and are often used for formulations that do not require heating.

- Layer Design

- Single-Layer Machines: These are typically less expensive and easier to operate, making them suitable for small-scale production.

- Three-Layer Machines: Designed for enhanced insulation and better temperature control, these machines are ideal for larger manufacturers that prioritize efficiency and high-quality output.

Key Features of Liquid Soap Making Machines

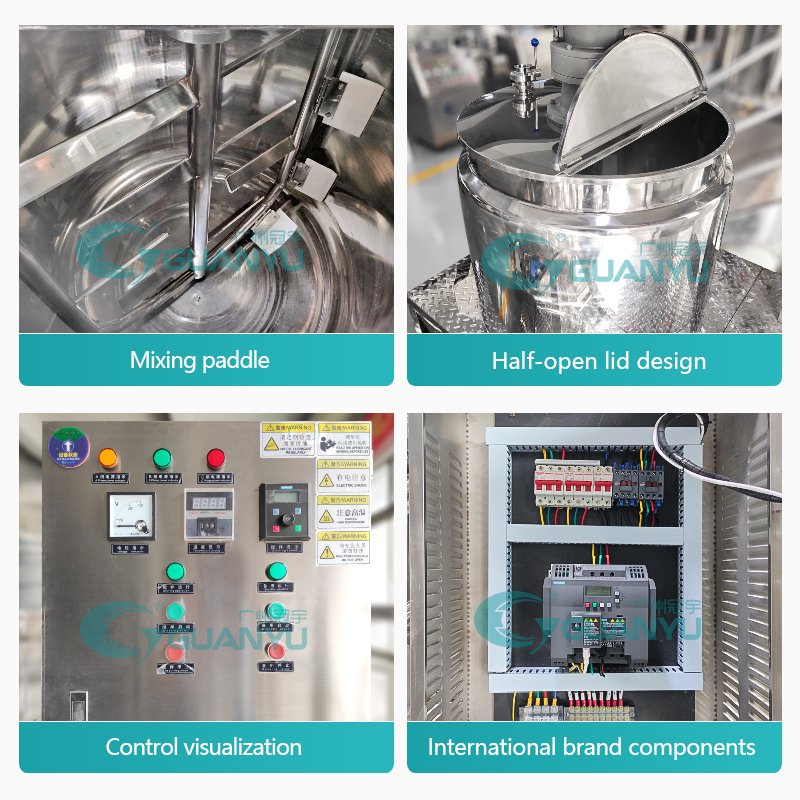

- Advanced Control Systems

Many liquid soap making machines are equipped with programmable control panels that allow operators to monitor and adjust parameters such as mixing speed and temperature. This level of control enhances precision and ensures consistent product quality. - Durable Construction

The best machines are made from high-quality stainless steel, providing durability, entretien facile, and resistance to corrosion. This is crucial in an industry where hygiene and cleanliness are paramount. - Capacité de production

Liquid soap making machines vary in capacity, with some designed for small batches and others capable of producing thousands of liters per cycle. Choosing the right capacity depends on your production goals and market demands. - Safety Mechanisms

Safety features, such as emergency stops and pressure relief valves, are integrated into most machines to protect operators and ensure safe production processes.

Benefits of Liquid Soap Making Machines

- Efficacité améliorée

Automating the soap-making process significantly reduces production times and labor costs. This efficiency allows manufacturers to scale their operations and respond quickly to market changes. - Consistent Quality

The ability to control mixing and heating parameters ensures that each batch of liquid soap meets the same high standards, fostering brand loyalty and customer satisfaction. - Cost-Effective Production

While the initial investment may be high, the long-term savings in labor and material costs make liquid soap making machines a financially sound choice for manufacturers. - Versatility

These machines can produce a wide range of products, from basic hand soaps to specialized organic formulations, enabling businesses to cater to diverse market segments.

Applications of Liquid Soap Making Machines

- Personal Care Products

The cosmetic industry is a major consumer of liquid soap, producing items like shampoos, body washes, and facial cleansers. Machines designed for this sector ensure high-quality outputs that meet consumer expectations. - Household Cleaning Supplies

With increasing hygiene awareness, there is a growing market for household cleaning products. Liquid soap making machines are essential for producing effective and safe cleaning solutions. - Industrial Applications

Many businesses manufacture bulk liquid soaps for industrial purposes, such as sanitizers and degreasers. High-capacity machines are vital for meeting these demands efficiently.

Conclusion

Investing in a Machine de fabrication de savon liquide is essential for manufacturers aiming to produce high-quality liquid soap efficiently. With various options available—ranging from those with homogenizers to different heating capabilities and layer designs—businesses can select machines that best fit their production needs. Understanding the features and benefits of these machines will empower manufacturers to make informed decisions and succeed in the competitive soap market.

Je ne pense pas que le titre de votre article correspond au contenu lol. Je plaisante, principalement parce que j'avais des doutes après avoir lu l'article.

Pouvez-vous être plus précis sur le contenu de votre article? Après l'avoir lu, J'ai encore des doutes. J'espère que tu peux m'aider.

Been using funinexchange247 for a little while now, and the exchange rates are decent. Withdrawals have been pretty quick too, which is always a plus. Solid so far.

Je ne pense pas que le titre de votre article correspond au contenu lol. Je plaisante, principalement parce que j'avais des doutes après avoir lu l'article. https://www.binance.com/register?ref=IHJUI7TF