La production de shampoings pour lave-auto nécessite de la précision, cohérence, and the effective blending of various ingredients. To achieve a high-quality product that meets these standards, manufacturers rely heavily on chemical mixer machines. These machines ensure that ingredients such as surfactants, eau, thickeners, and other additives are properly combined, leading to a product that is not only effective in cleaning vehicles but also stable and easy to use.

This article explores the vital role chemical mixer machines play in the car wash shampoo manufacturing process. We will examine the functionality of these machines, their importance in creating consistent and high-performing shampoos, and how they contribute to an efficient and streamlined production process.

Understanding the Complexity of Car Wash Shampoo Formulation

Car wash shampoos consist of a wide variety of ingredients, each of which plays a specific role in ensuring the product’s effectiveness. The main components of a typical car wash shampoo include:

- Eau – The primary solvent in the formulation.

- Surfactants – Cleaning agents that break down dirt, grease, and grime.

- Thickeners – Ingredients added to control viscosity, ensuring the shampoo has the right consistency.

- Preservatives – Compounds that prevent the growth of bacteria and prolong shelf life.

- Fragrances and Dyes – To enhance the sensory appeal of the product.

- pH Adjusters – Ensure the product is safe for car surfaces and skin.

These ingredients vary in their chemical properties, and some do not mix easily with others. For example, oils or silicone-based ingredients may not dissolve readily in water, while thickeners may require special conditions to be evenly incorporated. Without the proper mixing process, the final product could be inconsistent, with ingredients separating, clumping, or settling over time.

This is where chemical mixer machines become invaluable. These machines are designed to handle complex formulations by ensuring that all ingredients are thoroughly mixed, properly emulsified, and consistently blended, resulting in a stable and effective shampoo.

Functions of Chemical Mixer Machines in Car Wash Shampoo Production

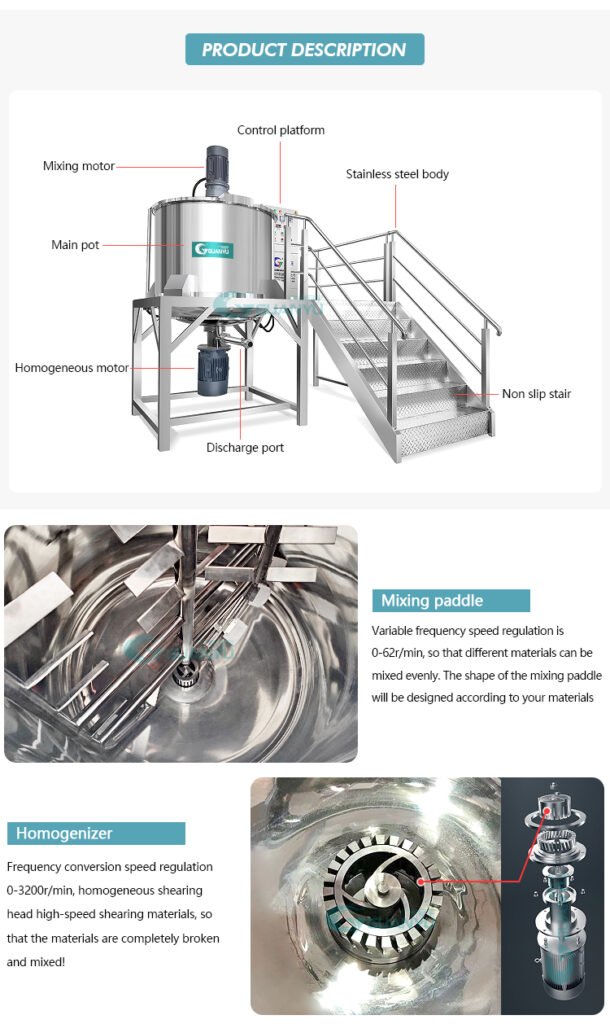

Chemical mixer machines are multi-functional tools designed to perform several key tasks in the production of car wash shampoos. Below, we will explore the various ways these machines contribute to the manufacturing process.

1. Uniform Mixing of Ingredients

One of the most important roles of a chemical mixer machine is ensuring the uniform blending of all ingredients. In the production of car wash shampoos, water serves as the base, while surfactants, thickeners, and other additives are gradually introduced. The machine’s agitators and mixing blades work to combine these components evenly, creating a homogeneous mixture.

Some ingredients, such as powdered thickeners or concentrated surfactants, can be difficult to dissolve and may form lumps if not mixed properly. Chemical mixers, with their high-powered agitation, help break down these clumps, ensuring that each component is fully integrated into the solution.

2. High-Shear Mixing and Emulsification

Car wash shampoos often contain ingredients that do not naturally mix well together, such as oils or silicone-based compounds, which are used for their protective or hydrophobic properties. These substances require high-shear mixing to be properly emulsified into the water-based formulation.

Chemical mixer machines are equipped with high-shear mixers that can break down these immiscible liquids into tiny droplets, which are then evenly dispersed throughout the mixture. This process, known as emulsification, ensures that oils and water are thoroughly blended, preventing separation and ensuring that the shampoo remains stable over time.

3. Viscosity Control and Adjustment

The texture and viscosity of car wash shampoos are critical to their performance. A shampoo that is too thin may not adhere to the vehicle’s surface long enough to lift dirt, while a product that is too thick may be difficult to apply and rinse off.

Chemical mixer machines allow for precise control over the viscosity of the final product. Thickeners like xanthan gum or carbomers are added to the formulation, and the machine ensures that these ingredients are evenly distributed. En plus, by adjusting the speed and intensity of mixing, operators can fine-tune the viscosity to achieve the desired consistency.

4. Heating and Cooling Capabilities

Many chemical mixer machines come equipped with temperature control systems, which allow for both heating and cooling during the mixing process. Certain ingredients in car wash shampoos, such as waxes or solid surfactants, require heating to dissolve properly. Once these ingredients are melted, they can be mixed into the rest of the formulation.

After the mixing process is complete, the chemical mixer can also cool the product down to room temperature, helping stabilize the mixture. This temperature control ensures that all ingredients remain in their optimal state and do not degrade or separate during the cooling process.

5. pH Balance and Stabilization

The pH level of a car wash shampoo is essential for both the protection of the vehicle’s surfaces and the user’s safety. A pH that is too acidic or too alkaline can damage the car’s paint or cause irritation to the skin.

Chemical mixer machines help ensure that pH adjusters, such as citric acid or sodium hydroxide, are evenly dispersed throughout the formulation. By achieving an even distribution, the product’s pH can be maintained within the desired range, ensuring that the shampoo is both effective and safe for use.

6. Foam Control

Car wash shampoos often generate foam due to the presence of surfactants, but excessive foam during the manufacturing process can be problematic. Foam can interfere with the mixing process and make it difficult to achieve a uniform product.

Many chemical mixer machines come with foam reduction systems or operate under vacuum to minimize the presence of air in the mixture. This reduces the amount of foam generated during production, allowing for smoother and more efficient blending of ingredients.

Advantages of Using Chemical Mixer Machines in Shampoo Production

There are several advantages to using chemical mixer machines in the production of car wash shampoos, which contribute to the overall quality and consistency of the final product.

1. Consistency Across Batches

Chemical mixer machines ensure that each batch of car wash shampoo is produced with the same level of quality and consistency. This uniformity is critical for maintaining product reliability, as customers expect the same level of performance from every bottle they purchase.

By automating the mixing process and controlling variables such as temperature, shear force, and mixing time, manufacturers can reduce the risk of batch-to-batch variations and ensure consistent product quality.

2. Improved Stability and Shelf Life

One of the biggest challenges in formulating car wash shampoos is ensuring that the product remains stable over time. Without proper mixing, ingredients may separate or degrade, leading to a product that is less effective or unusable.

Chemical mixer machines help to create stable emulsions and evenly distribute preservatives, ensuring that the shampoo has a long shelf life and maintains its efficacy over time.

3. Enhanced Performance

When ingredients are properly mixed and emulsified, the performance of the shampoo is enhanced. Surfactants are more effective at lifting dirt and grime, while thickeners help the product cling to the vehicle’s surface, improving cleaning efficiency.

Proper mixing also ensures that fragrances and dyes are evenly distributed, resulting in a product that not only works well but also looks and smells appealing to consumers.

4. Increased Production Efficiency

Chemical mixer machines are designed for efficiency, allowing manufacturers to produce large quantities of car wash shampoo in a relatively short amount of time. The automation of the mixing process reduces the need for manual labor and minimizes the risk of human error, leading to faster production times and lower costs.

En outre, chemical mixers can handle a wide range of viscosities and ingredient types, making them highly versatile tools in the production of various car care products beyond shampoos, including waxes and polishes.

In the production of car wash shampoos, chemical mixer machines are essential for achieving a uniform and high-quality blend of ingredients. To improve overall manufacturing efficiency, companies frequently explore various advanced manufacturing solutions that support different production stages. Currently, many companies are making use ofwaste sorting machines to manage and recycle waste materials generated during production. Solutions like those offered in the field of workshop machinery, such as CNC machines and other high-precision tools, play a critical role in optimizing processes in related industries, demonstrating the importance of continuous improvement and innovation in manufacturing.

Conclusion

Chemical mixer machines are indispensable tools in the production of car wash shampoos, providing manufacturers with the ability to create high-quality, consistent, and effective products. From ensuring the uniform blending of ingredients to controlling viscosity and pH, these machines play a critical role in every step of the manufacturing process. For packaging solutions, particularly in the food industry, consider wellfapack chicken packaging to enhance product freshness and appeal.

By investing in advanced chemical mixer machines, car care product manufacturers can improve product stability, performance, and production efficiency, giving them a competitive edge in the market. As the demand for high-quality car care products continues to grow, the importance of reliable and efficient mixing technologies will only increase.

Votre point de vue a attiré mon attention et a été très intéressant. Merci. J'ai une question pour toi.

Poker players, huddle up! h2poker might be a new table to try your luck at. Check the stakes and see if it’s your game! Good luck on the tables! h2poker

Je ne pense pas que le titre de votre article correspond au contenu lol. Je plaisante, principalement parce que j'avais des doutes après avoir lu l'article.

Votre point de vue a attiré mon attention et a été très intéressant. Merci. J'ai une question pour toi.

Votre point de vue a attiré mon attention et a été très intéressant. Merci. J'ai une question pour toi. https://www.binance.info/register?ref=IXBIAFVY

Merci pour votre partage. Je crains de manquer d'idées créatives. C'est votre article qui me fait plein d'espoir. Merci. Mais, J'ai une question, pouvez-vous m'aider? https://accounts.binance.com/tr/register-person?ref=MST5ZREF

Votre article m'a beaucoup aidé, y a-t-il plus de contenu connexe? Merci! https://accounts.binance.com/da-DK/register?ref=V3MG69RO