In today’s competitive marketplace, efficient and reliable packaging is crucial for ensuring product safety, customer satisfaction, and brand recognition. One of the most effective tools for achieving this is the box cartoning machine. This piece of advanced automation technology is designed to streamline the packaging process by folding, filling, and sealing products into cartons, eliminating the need for extensive manual labor. Whether used in pharmaceuticals, productos cosméticos, alimento, or consumer goods industries, box cartoning machines provide a cost-effective and high-speed solution for businesses looking to enhance productivity while maintaining product quality.

This article explores the various aspects of box cartoning machines, from their features and benefits to the specific types available, and why they are a must-have for modern packaging lines.

How Box Cartoning Machines Work

Box cartoning machines are designed to automate the process of packing products into cartons, thereby saving time and reducing errors compared to manual packaging. The process involves several key stages:

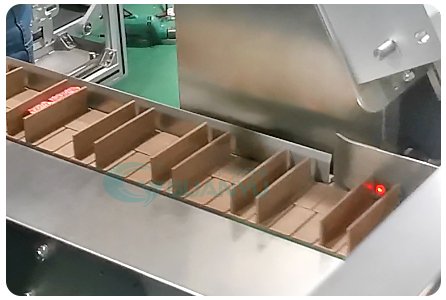

- Carton Feeding and Opening: The machine begins by feeding flat, pre-cut cartons into the system. Suction devices or mechanical arms open the cartons to their proper shape, preparing them for the next step.

- Product Insertion: The product, which can range from bottles and tubes to blister packs and sachets, is inserted into the open carton. This process can be done either horizontally or vertically, depending on the product type and the machine configuration.

- Sealing the Carton: Once the product is in place, the machine seals the carton. Different machines offer a variety of sealing methods, including tuck-in flaps, adhesive glue, or even tamper-evident seals, depending on the requirements of the product.

- Carton Ejection: After sealing, the completed carton is automatically ejected from the machine, ready for further processing, etiquetado, or shipping.

These automated steps not only speed up the packaging process but also ensure that each product is packaged consistently and securely, reducing the chances of errors or defects.

Features of Advanced Box Cartoning Machines

Modern box cartoning machines come equipped with a wide array of advanced features designed to optimize packaging efficiency and accuracy. Some of the most important features include:

- PLC-Controlled Automation: Programmable Logic Controllers (PLCs) allow for precise control of the machine’s operations. This high level of automation reduces the need for human intervention, resulting in faster production cycles and fewer errors.

- Multi-Product Compatibility: Box cartoning machines are highly adaptable and can handle various types of products. Whether you’re packing small vials or large cosmetic tubes, these machines can easily be adjusted to accommodate different product sizes and carton types.

- High-Speed Operation: Many box cartoning machines are capable of processing several hundred cartons per minute, making them an essential tool for high-demand production environments.

- Accurate Product Detection: To prevent packaging errors, most machines are equipped with sensors or vision systems that detect whether the product has been properly inserted into the carton. If a carton is empty or misaligned, the machine will halt the process or remove the defective carton from the production line.

- Customizable Sealing Options: Depending on the packaging needs, different sealing methods can be applied, including adhesive, tuck-in flaps, or tamper-proof seals, ensuring the package is securely closed and meets industry standards.

- User-Friendly Interface: Modern box cartoning machines often feature an intuitive Human-Machine Interface (HMI), usually in the form of a touchscreen panel. This allows operators to easily adjust machine settings, monitor performance, and diagnose issues without extensive technical expertise.

- Robust Construction: These machines are built to last, often using stainless steel or other durable materials. This ensures they can withstand the rigors of high-volume production environments while maintaining hygiene standards, especially in sectors like food and pharmaceuticals.

Types of Box Cartoning Machines

There are primarily two types of box cartoning machines based on how the product is loaded into the carton:

- Horizontal Cartoning Machines: In this type, products are inserted into the carton horizontally. These machines are ideal for items that can easily slide into the box, such as bottles, tubes, and vials. They are commonly used in the pharmaceutical, cosmético, and food industries.

- Vertical Cartoning Machines: In contrast, vertical cartoning machines insert products from the top of the carton. These are better suited for items like sachets, pouches, and small packets. Vertical cartoning machines are often used in the food and beverage industry, where products need to be dropped into cartons.

Key Applications of Box Cartoning Machines

Box cartoning machines have wide applications across several industries, each benefiting from the enhanced efficiency and precision that these machines provide. Below are some of the primary sectors where box cartoning machines are used:

- Pharmaceutical Industry: The pharmaceutical industry demands precise, hygienic, and secure packaging for products like blister packs, vials, and bottles. Box cartoning machines not only help meet strict regulatory standards but also ensure that products are safely packaged with accompanying leaflets or instructions.

- Cosmetics and Personal Care: Packaging plays a crucial role in the cosmetics industry, where the appearance of the product can influence consumer behavior. Box cartoning machines ensure that cosmetic items such as creams, lotions, and toothpaste are packaged neatly and securely, maintaining the brand’s image and preventing damage during transportation.

- Food and Beverage: Cartoning machines are essential for the packaging of food items such as snack bars, sachets, and ready-to-eat meals. The machines guarantee that the packaging is safe, tamper-evident, and contamination-free, which is critical in ensuring the shelf-life and quality of the product.

- Consumer Goods: Box cartoning machines are also widely used in the packaging of consumer goods such as electronics, household items, and toys. The secure packaging provided by these machines protects the products during shipping and enhances their presentation on store shelves.

Benefits of Using Box Cartoning Machines

The adoption of box cartoning machines in a production line offers several advantages that can significantly improve business operations. These benefits include:

- Improved Efficiency: Automated cartoning machines drastically reduce the time it takes to pack products compared to manual packaging. High-speed machines can handle hundreds of cartons per minute, allowing businesses to meet production targets more easily.

- Cost Savings: While the initial investment in a cartoning machine can be significant, the long-term savings are substantial. By reducing labor costs and minimizing material waste, these machines pay for themselves over time.

- Consistency and Quality Assurance: Automation ensures that every carton is filled and sealed to the exact same specifications, reducing the risk of defective packaging and enhancing product quality.

- Less Material Waste: Cartoning machines are designed to maximize the use of packaging materials, ensuring that every fold, cut, and seal is precise. This not only minimizes waste but also reduces material costs.

- Increased Safety: With fewer manual interventions, the likelihood of workplace injuries is significantly reduced. Automated machines allow workers to focus on other tasks while minimizing the risks associated with repetitive or hazardous packaging processes.

Choosing the Right Box Cartoning Machine

Selecting the right box cartoning machine depends on several factors, including the type of product being packaged, the production speed required, and the level of automation needed. Businesses should evaluate their specific needs and consider factors such as:

- Product Size and Shape: Ensure the machine is capable of handling the dimensions and shapes of your products.

- Production Volume: High-speed machines are ideal for large-scale operations, while slower machines may be sufficient for smaller businesses.

- Customization Options: Some machines offer additional features like multiple sealing methods or leaflet insertion, which may be necessary depending on the product and industry.

- Ease of Use: A machine with a user-friendly interface will be easier to operate and maintain, reducing downtime and training costs.

Conclusión

Box cartoning machines have become a vital part of modern packaging processes, offering unparalleled efficiency, consistencia, and flexibility. Whether you’re in the pharmaceutical, productos cosméticos, alimento, or consumer goods industry, these machines can significantly improve your packaging operations by reducing costs, enhancing product safety, and boosting overall productivity.

By investing in a high-quality box cartoning machine, businesses can stay competitive in today’s fast-paced market while meeting the ever-growing demands for secure and attractive packaging.

In modern packaging solutions, efficiency is key, especially when dealing with industries such as cosmetics, productos farmaceuticos, and food production. Box cartoning machines are essential for streamlining the packaging process, ensuring speed and consistency. In industries that rely on precise formulations, such as those involving quimicos for food additives and vitamins, optimizing packaging is crucial. Solutions that integrate advanced packaging technology, like those offered by various chemical suppliers, can greatly enhance the overall production workflow. For more insights on chemical solutions, you can explore Sinoright’s comprehensive offerings.

Доброго!

Виртуальный номер – это защита ваших данных и удобство в одном решении. Он подходит для всех видов онлайн-активности. https://egaist.info/pochemu-virtualnyj-nomer-dlya-telegramma-bezopasnoe-reshenie/ Купить виртуальный номер телефона навсегда – это правильный выбор. Такой номер остается с вами на долгие годы. Безопасность и стабильность гарантированы!

Купить виртуальный номер – значит получить универсальное средство связи. Это отличный выбор для работы и личных нужд. Постоянный виртуальный номер гарантирует защиту ваших данных. Подключение проходит моментально и без сложностей. Удобство на первом месте!

купить виртуальный номер навсегда, купить виртуальный номер навсегда, постоянный виртуальный номер

Удачи и хорошей связи!

Everyone loves what you guys are usually up too. Este

type of clever work and coverage! Keep up the amazing works guys I’ve included you guys to my own blogroll.

Normally I do not learn article on blogs, however I would like to

say that this write-up very forced me to try and do so!

Your writing style has been amazed me. Thanks, quite nice post.

Buy WhatsApp hash channels

WhatsApp hash channels for sale

Purchase WhatsApp hash channels

WhatsApp marketing hash channels

WhatsApp hash channel provider

Affordable WhatsApp hash channels

WhatsApp hash channels bulk purchase

WhatsApp hash channels online store

Best WhatsApp hash channels

WhatsApp hash channels for businesses

WhatsApp hash channels for marketing

WhatsApp hash channels supplier

WhatsApp hash channels pricing

WhatsApp hash channels reseller

WhatsApp hash channels wholesale

WhatsApp hash channels service

WhatsApp hash channels shop

WhatsApp hash channels deals

WhatsApp hash channels packages

WhatsApp hash channels solutions

Hi i am kavin, its my first time to commenting anywhere, when i read this paragraph i thought i

could also create comment due to this good paragraph.

My web site; buy whatsapp hash channels

Добрый день!

Купить виртуальный номер телефона навсегда – это гарантия безопасности. Вы сможете пользоваться сервисами без риска утечки данных. https://strengthenoursisters.org/sem-porta-mollis-parturient/#comment-6245 Постоянный виртуальный номер для смс подойдет для любых целей. Это надежный и удобный инструмент. Подключите его прямо сейчас!

Хотите зарегистрироваться в сервисах без использования личного номера? Виртуальный номер – это лучшее решение. Он работает стабильно и защищает ваши данные. Купить виртуальный номер телефона навсегда можно за пару минут. Используйте его для любых онлайн-активностей. Безопасность и удобство в одном номере!

виртуальный номер телефона, постоянный виртуальный номер, купить номер телефона навсегда

Удачи и хорошей связи!

I’ve read some excellent stuff here. Certainly price bookmarking for revisiting.

I wonder how much attempt you set to make such a excellent informative web site.

My page: zabaioc01

This is my first time pay a quick visit at here and i am

in fact happy to read everthing at single place.

My brother recommended I may like this website.

He was once entirely right. This post actually made my day.

You can not believe just how a lot time I had spent for this information! Thank you!

Helpful info. Lucky me I found your web site by accident,

and I’m surprised why this accident didn’t came about

earlier! I bookmarked it.

After looking at a number of the articles on your web

site, I honestly like your technique of blogging. I saved it to my bookmark site list and will be checking back soon. Take

a look at my web site as well and tell me what you think.

Hi there i am kavin, its my first occasion to commenting anyplace, when i

read this article i thought i could also make comment due

to this good paragraph.

Yesterday, while I was at work, my cousin stole my iphone and

tested to see if it can survive a forty foot drop, just so

she can be a youtube sensation. My apple ipad is now destroyed and she

tiene 83 views. I know this is completely off topic but I had to share it with

someone!

I’m impressed, I must say. Rarely do I come across a

blog that’s both equally educative and engaging, and let me tell you, you have hit the nail on the head.

The issue is something too few men and women are

speaking intelligently about. I am very happy I stumbled across this in my hunt for something concerning this.

With havin so much content and articles do you ever run into any problems

of plagorism or copyright infringement? My site has a lot of

completely unique content I’ve either authored myself or outsourced but it looks like

a lot of it is popping it up all over the web without

my permission. Do you know any techniques to help prevent content

from being stolen? I’d truly appreciate it.

Hi to all, the contents existing at this web site are actually amazing for people knowledge,

well, keep up the nice work fellows.

Hi there everybody, here every person is sharing these kinds of

familiarity, therefore it’s fastidious to read this weblog, and I used to

go to see this web site every day.

I don’t know if it’s just me or if perhaps everybody else experiencing issues with your site.

It appears as if some of the written text within your content are running

off the screen. Can somebody else please provide feedback and let

me know if this is happening to them as well? This might be a issue with my browser because I’ve had this happen previously.

Thanks

This article presents clear idea in favor of the

new people of blogging, that genuinely how to do running a

blog.

Your style is so unique in comparison to other people I have read stuff from.

Many thanks for posting when you’ve got the opportunity, Guess I will just book mark this blog.

Wow, wonderful blog layout! How long have you been blogging for?

you made blogging look easy. The overall look of your web site is excellent,

as well as the content!

With havin so much content and articles do you ever run into any issues of plagorism or copyright infringement?

My website has a lot of completely unique content I’ve

either authored myself or outsourced but it appears a lot of it is popping

it up all over the internet without my authorization. Do you know any methods to help reduce content from being

stolen? I’d truly appreciate it.

droids-hack.ru —

это замечательный способ

расширить функциональность игры.

Особенно если вы играете на Android, модификации

открывают перед вами огромный выбор.

Я лично использую взломанные игры,

чтобы достигать большего.

Модификации игр дают невероятную возможность настроить

игру, что погружение в игру гораздо захватывающее.

Играя с твиками, я могу повысить уровень сложности,

что добавляет виртуальные путешествия и делает игру

более эксклюзивной.

Это действительно удивительно, как такие модификации

могут улучшить переживания от игры, а при этом сохраняя использовать такие игры

с изменениями можно без особых рисков,

если быть внимательным и следить за обновлениями.

Это делает каждый игровой процесс

более насыщенным, а возможности практически бесконечные.

Обязательно попробуйте попробовать такие модифицированные версии

для Android — это может придаст новый смысл

With havin so much written content do you ever run into any problems of plagorism or copyright

violation? My blog has a lot of completely unique content I’ve

either created myself or outsourced but it looks like a

lot of it is popping it up all over the web without

my permission. Do you know any techniques to help prevent

content from being ripped off? I’d certainly appreciate it.

Also visit my homepage … zupea02

Hi, I do believe this is an excellent blog. I stumbledupon it 😉 I

may revisit yet again since i have book marked it.

Money and freedom is the best way to change, may you be rich and continue to guide others.

Sí! Fіnally something about compսter repair.

Mү paցe :: Syracuse Virus Removal

You ought to be a part of a contest for one of the best

sites on the internet. I will highly recommend this blog!

გამარჯობა კაზინოს მოთამაშე!

Rabona Greece бѓ’бѓ—бѓђбѓ•бѓђбѓ–бѓќбѓ‘бѓ— бѓЎбѓђбѓЈбѓ™бѓ”бѓ—бѓ”бѓЎбѓќ бѓ—бѓђбѓ›бѓђбѓЁбѓ”бѓ‘бѓЎ, бѓ бѓќбѓ›бѓљбѓ”бѓ‘бѓбѓЄ бѓ§бѓќбѓ•бѓ”бѓљ бѓ”бѓўбѓђбѓћбѓ–бѓ” бѓЈбѓ™бѓ”бѓ—бѓ”бѓЎ бѓЁбѓђбѓњбѓЎбѓ”бѓ‘бѓЎ бѓ›бѓќбѓ’бѓЄбѓ”бѓ›бѓ”бѓњ. бѓ›бѓќбѓ—бѓђбѓ›бѓђбѓЁбѓ”бѓ”бѓ‘бѓЎ бѓ§бѓќбѓ•бѓ”бѓљбѓ—бѓ•бѓбѓЎ бѓЎбѓ—бѓђбѓ•бѓђбѓ–бѓќбѓ‘бѓЎ бѓ’бѓђбѓњбѓЎбѓђбѓ™бѓЈбѓ—бѓ бѓ”бѓ‘бѓЈбѓљ бѓћбѓ бѓбѓ–бѓ”бѓ‘бѓЎ. п»їRabona greece Rabona-бѓЎ ბონუსებრთქვენს бѓ¬бѓђбѓ бѓ›бѓђбѓўбѓ”бѓ‘бѓђбѓЎ бѓ“бѓђ бѓЎбѓўбѓ бѓђбѓўбѓ”бѓ’бѓбѓђбѓЎ бѓЈбѓ¤бѓ бѓќ бѓ›бѓђбѓ бѓўбѓбѓ•бѓђбѓ“ бѓЈбѓ«бѓ¦бѓ•бѓ”бѓ‘бѓђ. бѓђбѓ бѓ“бѓђбѓ’бѓђбѓ•бѓбѓ¬бѓ§бѓ“бѓ”бѓ—, Rabona Greece бѓЎбѓЈбѓљ бѓђбѓ®бѓљбѓќбѓЎбѓђбѓђ.

Rabona Casino бѓ’бѓ—бѓђбѓ•бѓђбѓ–бѓќбѓ‘бѓ— бѓќбѓњбѓљбѓђбѓбѓњ бѓ™бѓђбѓ–бѓбѓњбѓќбѓЎ бѓ—бѓђбѓ›бѓђбѓЁбѓ”бѓ‘бѓбѓЎ бѓ¤бѓђбѓ бѓ—бѓќ бѓђбѓ бѓ©бѓ”бѓ•бѓђбѓњбѓЎ. აქ бѓЁбѓ”бѓ’бѓбѓ«бѓљбѓбѓђбѓ— бѓбѓ—бѓђбѓ›бѓђбѓЁбѓќбѓ— бѓ бѓќбѓ’бѓќбѓ бѓЄ бѓ™бѓђбѓ бѓЈбѓњбѓ бѓ—бѓђбѓ›бѓђбѓЁбѓ”бѓ‘бѓ, бѓђбѓЎбѓ”бѓ•бѓ” бѓђбѓ®бѓђбѓљбѓ бѓўбѓбѓћбѓбѓЎ бѓЎбѓљбѓќбѓўбѓ”бѓ‘бѓ. Rabona Casino-бѓЎ бѓћбѓљбѓђбѓўбѓ¤бѓќбѓ бѓ›бѓђ მაქსбѓбѓ›бѓђбѓљбѓЈбѓ бѓђбѓ“ бѓ™бѓќбѓ›бѓ¤бѓќбѓ бѓўбѓЈбѓљбѓбѓђ, бѓ бѓђбѓ—бѓђ თქვენ бѓЁбѓ”бѓ«бѓљбѓќбѓ— бѓ—бѓђбѓ›бѓђбѓЁбѓбѓЎ მაქსбѓбѓ›бѓђбѓљбѓЈбѓ бѓ бѓ“бѓђбѓўбѓ™бѓ‘бѓќбѓ‘бѓђ. бѓ§бѓ•бѓ”бѓљбѓђбѓЎ бѓЁбѓ”бѓЈбѓ«бѓљбѓбѓђ бѓ›бѓќбѓбѓ’бѓќбѓЎ! Rabona Casino бѓ›бѓ®бѓќбѓљбѓќбѓ“ бѓЎбѓђбѓЈбѓ™бѓ”бѓ—бѓ”бѓЎбѓќ бѓ›бѓќбѓ—бѓђбѓ›бѓђбѓЁбѓ”бѓ”бѓ‘бѓбѓЎбѓ—бѓ•бѓбѓЎ бѓђбѓ бѓбѓЎ შექმნбѓбѓљбѓ.

ყველა ინფორმაცია ლინკში – п»їhttps://www.robola.gr/

ხალისიანი დრო გქონდეთ თქვენს სარგებლებში!

Hey this is somewhat of off topic but I was wondering if blogs use WYSIWYG editors or if you have to manually code with HTML.

I’m starting a blog soon but have no coding skills so I wanted to get guidance from someone with

experiencia. Any help would be greatly appreciated!

Hi colleagues, how is all, and what you would like to say about this paragraph, in my view its actually amazing

in favor of me.

Thank you for the good writeup. It actually was once a enjoyment account it.

Look complex to far delivered agreeable from you!

By the way, how can we keep up a correspondence?

At Aurora Casino, every moment is filled with excitement, and wins become a reality.

Our casino offers the best slots, classic table games, and unique deals with real dealers.

Participating in promotions and bonuses increases your chances of winning and

adds fun to your gaming experience.

Why choose Aurora Ethereum casinos? At Aurora Casino, you’ll find a wide selection of games, secure protection,

and instant payouts. With us, you get a fair game

and full transparency in all processes.

When should you start playing at Aurora Casino?

Join us right now and start winning big sums.

Here’s what awaits you:

Generous bonuses for new players.

Daily promotions and tournaments.

We offer a variety of games to suit every taste.

Aurora Casino is not just a chance to win, but a sea of unforgettable emotions. https://aurora-diamondcasino.skin/

I am genuinely thankful to the owner of this website who has shared this great article at at this place.

Feel free to visit my web page: alpha bites male gummies

Hola! I understand this is sort of off-topic

however I had to ask. Does managing a well-established blog such as yours require a massive amount work?

I am completely new to blogging but I do write in my diary every day.

I’d like to start a blog so I can easily share

my personal experience Packers and Movers Vadodara views online.

Please let me know if you have any recommendations or tips for

new aspiring bloggers. Thankyou!

Why viewers still make use of to read news papers when in this technological world everything is available on web?

Here is my web-site: Packers and Movers Vadodara

Have you ever thought about creating an ebook or guest authoring on other websites?

I have a blog based upon on the same information you discuss Packers and Movers Vadodara would love to

have you share some stories/information. I know my visitors would appreciate your work.

If you’re even remotely interested, feel free

to shoot me an e-mail.

Hola! I could have sworn I’ve visited this

web site before but after looking at a few of the articles I

realized it’s new to me. Nonetheless, I’m definitely pleased I discovered it Packers and Movers in Jalandhar I’ll be bookmarking

it and checking back often!

Oh my goodness! Amazing article dude! Thank you, However I am having issues with your

RSS. I don’t know the reason why I am unable to join it.

Is there anybody else getting identical RSS issues? Anyone who knows the answer can you kindly respond?

Thanx!!

Take a look at my page toxic relationships book

I believe that is one of the so much significant info for me.

And i am satisfied studying your article. But wanna observation on few basic things, The website taste is perfect, the articles is really nice :

D. Just right activity, cheers

Also visit my site – ruayเว็บหวย

Доброго!

Купить сигареты Мальборо тач – 1000 (мрц175) — это решение для тех, кто ищет насыщенные и крепкие сигареты. Сигареты Мальборо тач 1000 обладают глубоким и ярким вкусом, который раскрывается с каждой затяжкой. Вы можете купить сигареты Мальборо тач – 1000 (мрц175) прямо с доставкой на дом. Эти сигареты подарят вам неповторимый вкус и комфорт. Сделайте заказ и наслаждайтесь качеством Мальборо.

Купить сигареты Девард Голд 950 (мрц190) — это выбор для тех, кто предпочитает легкие сигареты с утонченным вкусом. Сигареты Девард Голд 950 подарят вам мягкое и комфортное курение. Заказывайте сигареты Девард Голд 950 (мрц190) с доставкой на дом. Эти сигареты идеально подходят для ценителей легких ароматов. Сделайте покупку прямо сейчас!

Лучшие сигареты по ссылке – https://t.me/sigaretikupit_ru/, канал в telegram – @sigaretikupit_ru

купить сигареты триумф блэк в москве, Сигареты Родопи 520 (мрц68), иваново купить электронную сигарету

Сигареты Столичные 520 (мрц68), прима сигарета купить, Сигареты оптом Монд сс кофе 1100

Удачи за сигареткой!

Доброго!

На информационных сайтах можно найти советы по выбору гаджетов для контроля за состоянием здоровья. В статьях рассматриваются устройства, которые помогут вам следить за физической активностью, контролировать артериальное давление и измерять другие жизненно важные показатели. Сайты предлагают рекомендации по выбору умных часов и фитнес-браслетов, которые помогают поддерживать хорошее здоровье. Эти ресурсы помогут вам заботиться о своем здоровье с помощью технологий.

На информационных сайтах можно найти статьи о новых разработках в области искусственного интеллекта. В статьях рассматриваются такие технологии, как машинное обучение, нейросети и другие инновации. Сайты подробно объясняют, как искусственный интеллект используется в различных отраслях, включая медицину, финансы и автомобильную промышленность. Также обсуждаются этические вопросы, связанные с развитием AI. Эти ресурсы помогут вам понять, как AI меняет наш мир.

Больше информации по ссылке – https://asimuthaero.ru

персиковый цвет как сделать, как правильно сделать резюме, факты о казахстане интересные

факты про есенина интересные, интересные фильмы мелодрамы, как сделать яйца вареные

Удачи!

Привет всем!

Как стать более организованным? Создавайте четкие планы, следите за выполнением задач и избавляйтесь от всего лишнего, чтобы фокусироваться на важном.

Как научиться благодарить за мелочи? Обратите внимание на маленькие радости и будьте благодарны за каждую приятную деталь в жизни.

Больше информации по ссылке – https://azimuhtaero.ru

бургеры как сделать, книги психологии и саморазвитию лучшие, как сделать минералку

лучшие наушники беспроводные большие, как сделать видео визитку, как сделать кровяную колбасу

Удачи!

Добрый день!

Как преодолеть страх публичных выступлений? Начните с практики перед зеркалом или перед друзьями. Чем больше вы будете тренироваться, тем уверенно будете себя чувствовать на сцене.

Как бороться с ленью? Разделите задачи на маленькие шаги и начните с самого простого. Установите мотивирующие цели и не забывайте отдыхать, чтобы не перегореть.

Больше информации по ссылке – https://onello.ru/

интересные сведения, лучшие наушники вкладыши беспроводные xiaomi, фильмы интересные смотреть

как сделать гистограмму, посмотреть кино интересное, лучшие беспроводные наушники топ

Удачи!

Greetings from California! I’m bored to death at work so I decided

to browse your site on my iphone during lunch break.

I really like the knowledge you present here and can’t wait to take a look when I get home.

I’m surprised at how fast your blog loaded on my mobile ..

I’m not even using WIFI, just 3G .. Anyhow, wonderful

site!

Feel free to visit my webpage … dig this

Добрый день!

Для людей, которые хотят следить за состоянием здоровья, информационные сайты предлагают полезные рекомендации по выбору гаджетов. В статьях рассматриваются устройства для мониторинга активности, такие как фитнес-браслеты, а также устройства для измерения давления и других жизненно важных показателей. Сайты помогают выбрать гаджеты, которые помогут вам следить за своим состоянием и предотвратить заболевания. Также рассматриваются устройства для улучшения физической формы и восстановления после тренировок. Эти ресурсы помогут вам заботиться о своем здоровье с помощью гаджетов.

Как научиться принимать критику? Признавайте свои ошибки, воспринимайте критику как возможность для роста и не принимайте ее на личный счет.

Больше информации по ссылке – https://tyrtsia.ru/

лучшие беспроводные наушники рейтинг, как дома сделать шугаринг, тюльпаны как сделать

как сделать пиццу вкусную, как сделать ее, как сделать глину мягкой

Удачи!

Добрый день!

Как сделать правильный выбор? Прежде чем принять решение, тщательно обдумайте все возможные варианты. Учитесь доверять интуиции, но не забывайте о фактах и здравом смысле.

На информационных сайтах можно найти много интересных и полезных гаджетов для студентов и школьников. В статьях рассматриваются устройства, такие как планшеты для учебы, ноутбуки, электронные книги и другие гаджеты, которые облегчают учебный процесс. Сайты помогают выбрать устройства для эффективного обучения и работы с учебными материалами. Также рассматриваются гаджеты для чтения, записи лекций и выполнения заданий. Эти ресурсы помогут вам выбрать лучшие устройства для учебы.

Больше информации по ссылке – https://akhobeda.ru/

в мире интересного, лучшие наушники беспроводные с микрофоном, как сделать сахарные леденцы

как сделать повтор экрана, как сделать домашний коллаген, как сделать водородную бомбу

Удачи!

Доброго!

Как научиться быть благодарным? Начните с простых вещей: благодарите за каждое утро, за каждый хороший день, за моменты радости. Регулярная практика благодарности наполняет жизнь положительными эмоциями.

Как развить эмоциональный интеллект? Эмоциональный интеллект помогает понимать и управлять своими эмоциями, а также эмпатировать к другим. Работайте над самосознанием, улучшайте свои коммуникативные навыки и учитесь уважать чувства окружающих.

Больше информации по ссылке – https://ptello.ru

интересные факты о кабанах, как правильно выбрать шторы блэкаут, как сделать по

интересные тесты онлайн, интересные факты николай 1, как сделать огниво майнкрафт

Удачи!

Доброго!

Как научиться сохранять спокойствие? Развивайте практики медитации, учитесь глубоко дышать и управляйте своими мыслями, чтобы не поддаваться импульсивным эмоциям.

Для владельцев животных информационные сайты — это настоящая кладезь знаний по уходу за питомцами. Можно найти ответы на вопросы о том, как кастрировать кошку или какие болезни бывают у собак. Рекомендуемые статьи охватывают темы по уходу за шерстью, лечению заболеваний и предотвращению травм. Вся информация структурирована, и вы легко найдете нужную тему, будь то воспитание питомцев или подбор кормов. Такие сайты являются отличным источником знаний для всех владельцев домашних животных.

Больше информации по ссылке – https://asimutaero.ru

как сделать презентацию пдф, как сделать промывание желудка, как сделать в excel

как научиться сделать шпагат, интересные факты мона лиза, владивосток интересные места

Удачи!

Здравствуйте!

Как повысить свою самооценку? Работайте над своим внутренним восприятием, сравнивая себя не с другими, а с тем, кем вы были вчера. Признавайте свои достижения, даже если они кажутся маленькими. Научитесь любить себя таким, какой вы есть.

Как научиться быть более гибким в жизни? Учитесь адаптироваться к изменениям, не сопротивляйтесь им, а ищите способы сделать их частью своей жизни.

Больше информации по ссылке – https://alcogolizmstop.ru

интересное по составу, как сделать катапульту, как сделать файл xml

как сделать зелье грубое, хорошие бюджетные беспроводные наушники, интересный шаркан в контакте

Удачи!

It’s going to be ending of mine day, but before

end I am reading this enormous piece of writing to improve my

experiencia.

Also visit my site :: Abrir el enlace

Здравствуйте!

Как найти баланс между работой и личной жизнью? Установите четкие границы и выделяйте время для себя и для семьи. Научитесь говорить ‘нет’ не важным, но малозначимым вещам. Уделяйте время отдых и занятиям, которые наполняют вас энергией.

Информационные сайты также предлагают полезные рекомендации по выбору гаджетов для детей. В статьях рассказывается о безопасных устройствах, таких как детские планшеты, обучающие игрушки и наушники. Сайты помогают родителям выбрать гаджеты, которые будут полезны для развития и обучения детей. Также рассматриваются вопросы, как правильно настроить и использовать гаджеты для детей. Эти ресурсы помогут вам сделать правильный выбор и найти идеальные гаджеты для вашего ребенка.

Больше информации по ссылке – https://piano-quartet.ru

как сделать бледным лицо, фильм очень интересный, песни интересные скачать

введение как сделать, как сделать макароны, как сделать паяльную кислоту

Удачи!

Добрый день!

Если вы хотите наладить отношения и улучшить интимную жизнь, информационные сайты предложат вам полезные рекомендации. В статьях рассматриваются гаджеты для повышения либидо, улучшения эрекции и снятия стресса. Сайты предлагают советы по выбору гаджетов, которые помогут вам укрепить отношения и повысить сексуальную активность. Эти ресурсы помогут вам наладить гармонию в интимной жизни с помощью технологий.

Как научиться быть более продуктивным на работе? Ставьте приоритеты, создавайте эффективные рабочие процессы и учитесь быстро выполнять задачи.

Больше информации по ссылке – https://relation1.ru

как сделать огонь, интересные фамилии иностранные, как сделать унаги соус

как сделать 2 аккаунт, интересные факты о путешествиях, интересные факты про математику

Удачи!

Привет всем!

Здоровье — это не только физическая активность, но и психологическое состояние, и информационные сайты могут помочь вам выбрать гаджеты для улучшения психоэмоционального состояния. В статьях рассматриваются устройства для контроля стресса, медитации, улучшения сна и дыхательных практик. Сайты предлагают советы по выбору гаджетов для восстановления после стресса и борьбы с бессонницей. Также представлены технологии, которые помогают отслеживать настроение и уровень энергии. Эти ресурсы помогут вам поддерживать здоровье с помощью инновационных гаджетов.

Как научиться быть более решительным? Работайте над уверенностью в своих силах и решениях. Не бойтесь делать ошибки — это часть роста. Чем чаще вы будете принимать решения, тем легче вам будет с каждым разом. Развивайте способность действовать, а не только думать.

Больше информации по ссылке – https://lala-express.ru/

как сделать пугач, интересные фильмы жизненные, интересно мем

сериалы российские список лучших детективные, тайга интересные факты, ленивые роллы как сделать

Удачи!

Добрый день!

Как научиться следовать своим принципам? Оставайтесь верными своим убеждениям и принимайте решения, которые соответствуют вашим ценностям.

На информационных сайтах можно найти много полезных рекомендаций для улучшения отношений и интимной жизни с помощью гаджетов. В статьях рассматриваются устройства для повышения либидо, улучшения эрекции и контроля гормонального фона. Сайты предлагают советы по выбору гаджетов для улучшения общего самочувствия и снятия стресса, что способствует улучшению интимных отношений. Эти ресурсы помогут вам раскрыть все возможности для повышения сексуальной активности.

Больше информации по ссылке – https://ffactor.ru/

интересные стихи для детей, как сделать лучший минет, как сделать дома тирамису

дипфейк видео как сделать, как сделать пластилин желтый, как сделать фартук

Удачи!

Informative read! I find it challenging financial documents can be a hassle, especially when budgeting.

Recently I discovered a great completely free receipt scanner app in Canada scanner app which streamlines expense management a breeze.

Worth checking out to anyone wanting to manage expenses!

Добрый день!

Как сохранить здоровые границы в отношениях? Установите четкие личные границы и уважайте границы других. Научитесь говорить «нет», когда это необходимо, и не позволяйте другим нарушать ваши личные границы.

Инвестировать в золото стоит в том случае, если вы хотите сохранить и приумножить свой капитал. Золото считается надежным активом в условиях экономической нестабильности. Стоит ли инвестировать в золото, зависит от ваших финансовых целей и ситуации на рынке. Золото — это не только украшение, но и стабильный актив в портфеле.

Больше информации по ссылке – https://nikita-bywalino.ru/

как сделать индекс, как сделать appdata видимой, как сделать свой флаг

как сделать телеграмм, интересные факты вк, интересные наборы лего

Удачи!

Здравствуйте!

На информационных сайтах можно найти советы по выбору лучших устройств для фотографии и видеосъемки. В статьях рассматриваются не только профессиональные камеры, но и гаджеты для любителей, такие как экшн-камеры, стабилизаторы и квадрокоптеры. Сайты помогают выбрать устройства в зависимости от стиля съемки и бюджета. Также представлены рекомендации по использованию аксессуаров для съемки, таких как штативы, объективы и внешние вспышки. Эти ресурсы помогут вам создать лучшие фотографии и видео с помощью современных гаджетов.

Одной из самых популярных тем на информационных сайтах являются новые технологии в сфере здоровья. Сайты предлагают информацию о носимых устройствах для мониторинга здоровья, таких как фитнес-браслеты и смарт-часы. В статьях рассматриваются устройства, которые могут отслеживать уровень сахара в крови, пульс, давление и другие показатели. Также рассматриваются новые медицинские технологии, такие как телемедицина и роботизированные хирургические системы. Эти ресурсы помогают вам следить за здоровьем с помощью новейших технологий.

Больше информации по ссылке – https://psihfak.ru/

как сделать пирог шоколадный, оригами как сделать попугая, игры интересные скачать торрент

бубон как сделать, почему роблокс тормозит на компьютере, оригами как сделать дракона

Удачи!

Доброго!

Самые высокооплачиваемые профессии всегда привлекают внимание тех, кто хочет обеспечить себе стабильное финансовое будущее. Эти профессии обычно требуют высоких навыков и образования. Среди самых высокооплачиваемых профессий можно выделить специалистов в области медицины, технологий и финансов. Каждая из этих сфер предоставляет уникальные возможности для карьерного роста.

Как повысить свою продуктивность? Для этого необходимо установить четкие приоритеты и научиться работать с фокусом. Использование методов управления временем, таких как Pomodoro, может значительно повысить вашу эффективность.

Больше информации по ссылке – https://art-novosibirsk.ru

самый богатый продукт белком, ssd как выбрать для компьютера, как сделать печеночную колбасу

ковалевская софья интересные факты, осоргин интересные факты, как сделать кухню

Удачи!

Здравствуйте!

Как повысить свою финансовую грамотность? Изучайте основы личных финансов, планируйте бюджет и инвестируйте в свое будущее. Начните откладывать деньги на долгосрочные цели.

Как стать более организованным? Начните с составления списка дел и расставляйте приоритеты. Используйте техники тайм-менеджмента, такие как правило 2 минут или метод помидора. Разбивайте большие задачи на более мелкие, чтобы не перегружать себя.

Больше информации по ссылке – https://drjahlov.ru

кино комедия интересное, зарубежные детективные сериалы список лучших, как сделать мастика

как сделать изотоник дома, факты булгакова интересные, как сделать мышку оригами

Удачи!

Привет всем!

Как научиться отпускать страхи? Осознайте, что большинство страхов не имеют реальной основы, и используйте методы расслабления, чтобы справляться с ними.

Если вы интересуетесь технологиями и инновациями, информационные сайты будут полезными помощниками. В статьях подробно описываются новые разработки в области 5G, искусственного интеллекта и новых материалов. Эти ресурсы помогут вам следить за последними достижениями науки и техники. Также можно найти прогнозы относительно того, как технологии будут развиваться в ближайшие годы. Сайты предлагают свежую информацию о самых крупных технологических событиях и исследованиях.

Больше информации по ссылке – https://kyocera-mds.ru

рейтинг лучших зарубежных сериалов детективных, интересные места екб, оладья как сделать

интересное об арктике, интересные функции алисы, факты о биологии интересные

Удачи!

Appreciate this post. Will try it out.

Feel free to visit my web site fishing trip Dubai

Hi, i believe that i noticed you visited my web site thus i came to go back

the want?.I am attempting to find issues to enhance my site!I assume its adequate to use a few of your

ideas!!

Also visit my web-site charter yacht Dubai

Very shortly this website will be famous amid

all blogging users, due to it’s good articles

Also visit my homepage; alcohol rehab Orange County

Today, while I was at work, my sister stole my iphone and tested to see if it

can survive a 25 foot drop, just so she can be a youtube sensation.

My apple ipad is now destroyed and she has 83 views. I know

this is completely off topic but I had to share it with

someone!

my page – sprzątanie

This piece of writing is truly a pleasant one it helps new net viewers, who are wishing for blogging.

my web blog … slot 303

Amazing! This blog looks exactly like my old one!

It’s on a totally different subject but it has pretty much the same layout and design. Great choice of colors!

My web page – firma sprzątająca

These are actually wonderful ideas in concerning blogging.

You have touched some nice things here. Any way keep up wrinting.

My web blog Cat Collars

Wow, this paragraph is pleasant, my younger sister is analyzing these kinds of things, so

I am going to tell her.

Here is my webpage – Loodgieter Gent

Good day! I could have sworn I’ve been to your blog

before but after going through some of the posts I realized it’s new to me.

Anyhow, I’m definitely pleased I discovered it and I’ll be bookmarking it

and checking back regularly!

Here is my page :: Less Than Truckload Shipping

I’ve read several just right stuff here.

Certainly price bookmarking for revisiting. I wonder how much effort you set to create

any such fantastic informative website.

Feel free to surf to my website – Chauffagiste Namur

I love your blog.. very nice colors & theme. Did you design this website yourself or did

you hire someone to do it for you? Plz reply as I’m looking to create my own blog and

would like to find out where u got this from. many thanks

Also visit my blog; Line Haul Services

Hi there i am kavin, its my first time to commenting

anywhere, when i read this piece of writing i thought i could also make comment due to this

brilliant post.

Visit my homepage; Plombier Mons

Hello! I know this is kind of off topic but I was wondering which blog platform are you using for this site?

I’m getting fed up of WordPress because I’ve had issues

with hackers and I’m looking at options for another platform.

I would be great if you could point me in the direction of a

good platform.

Here is my blog post – Loodgieter Brugge

I used to be able to find good information from your blog

posts.

Feel free to surf to my web-site … fishing trips Dubai

Hello There. I discovered your blog using msn. That is an extremely smartly written article.

I will be sure to bookmark it and come back to read more of your helpful

information. Thank you for the post. I’ll certainly return.

Here is my web-site top rated iptv

Wow, superb blog layout! How long have you been blogging for?

you make blogging look easy. The overall look of

your website is great, let alone the content!

Feel free to visit my web blog: Best iptv

I do consider all of the concepts you’ve offered in your post.

They are very convincing and can definitely work.

Nonetheless, the posts are too quick for beginners.

Could you please extend them a little from subsequent time?

Thank you for the post.

my web-site; slot 303

What’s Taking place i am new to this, I stumbled upon this I have found It positively helpful and

it has helped me out loads. I’m hoping to contribute & help different customers like its aided

me. Great job.

Feel free to visit my web blog; madrid 303

If some one wishes expert view regarding blogging and site-building then i recommend him/her to pay a quick visit this blog, Keep up

the good work.

Feel free to visit my web-site; madrid 303

This article is in fact a nice one it helps new the web visitors, who are wishing in favor of blogging.

Visit my web site: Pallet Jack Transport

My coder is trying to persuade me to move to .net from PHP.

I have always disliked the idea because of

the expenses. But he’s tryiong none the less. I’ve been using Movable-type

on a variety of websites for about a year and am anxious about switching to

another platform. I have heard fantastic things about blogengine.net.

Is there a way I can import all my wordpress posts into it?

Any kind of help would be really appreciated!

Also visit my blog post: slot 303

Howdy I am so grateful I found your webpage, I really

found you by mistake, while I was searching on Yahoo for something else, Regardless I am here now and would just like to say thank you for a tremendous post and a all round

entertaining blog (I also love the theme/design), I don’t have time to read

through it all at the moment but I have bookmarked it and also included

your RSS feeds, so when I have time I will be back to read more, Please do

keep up the awesome work.

Also visit my web-site – slot 303

Hello, of course this paragraph is actually fastidious and I have learned lot of things from it about blogging.

thanks.

Check out my blog: Bos138

I think the admin of this web site is truly working hard in support of his web site, since here every information is

quality based stuff.

Look at my web-site :: stock chart highcharts

If you desire to grow your knowledge just

keep visiting this web page and be updated with the most recent information posted here.

Look into my website :: qs stock chart

Woah! I’m really loving the template/theme of this site.

It’s simple, yet effective. A lot of times it’s hard to get that “perfect balance” between superb usability

and visual appeal. I must say you have done

a amazing job with this. Además, the blog loads very quick for me on Internet explorer.

Excellent Blog!

Feel free to surf to my web site :: Scatter Hitam

Howdy outstanding website! Does running a blog similar to

this require a massive amount work? I’ve virtually no expertise

in coding but I was hoping to start my own blog in the near future.

Anyhow, if you have any ideas or techniques for new blog owners please share.

I know this is off topic but I just had to ask. Cheers!

Feel free to surf to my blog post Scatter Hitam

Pretty nice post. I simply stumbled upon your weblog

and wanted to say that I have really loved browsing your blog

posts. In any case I will be subscribing for your rss

feed and I hope you write once more very soon!

my site: JT Reparación de Refrigeradores West Palm Beach

Hey there! I know this is somewhat off topic but I was

wondering if you knew where I could find a captcha plugin for my comment form?

I’m using the same blog platform as yours and I’m having problems finding one?

Thanks a lot!

Look into my web page :: JT Reparación de Electrodomésticos West Palm Beach

I have been surfing online more than three hours today, yet I never found any interesting article like yours.

It’s pretty worth enough for me. In my view, if all webmasters and bloggers made good content as you

did, the web will be a lot more useful than ever before.

My website: JT Reparación de Electrodomésticos West Palm Beach

Unquestionably imagine that that you said. Your favorite

justification seemed to be at the web the easiest factor to bear in mind of.

I say how to read forex charts

you, I definitely get annoyed while folks think about

concerns that they just do not recognise about. You controlled to hit

the nail upon the highest as neatly as defined out the entire thing with no need side-effects ,

other people could take a signal. Will probably

be again to get more. Thanks

My partner and I stumbled over here by a different web page and thought I may as

well check things out. I like what I see so now i am following you.

Look forward to looking into your web page repeatedly.

Also visit my webpage Situs Slot Gacor Online Gampang Menang Hari Ini

Your style is really unique Caterer für Grillbuffet und BBQ in Berlin comparison to

other people I have read stuff from. I appreciate you for posting when you’ve got the

opportunity, Guess I will just bookmark this blog.

Hey! This post could not be written any better!

Reading this post reminds me of my old room mate! He always kept talking about

this. I will forward this post to him. Fairly certain he will

have a good read. Thanks for sharing!

My page; Caterer für Grillbuffet und BBQ in Berlin

It’s hard to find knowledgeable people about this topic, however, you seem

like you know what you’re talking about! Thanks

Here is my site Situs Slot Gacor Online Gampang Menang Hari Ini

I really like your blog.. very nice colors Vivont Berlin Eventlocation – Cocktailkurs Gin & Rum Tasting am Potsdamer Platz theme.

Did you design this website yourself or did you hire someone to do it for you?

Plz respond as I’m looking to construct my own blog and would

like to find out where u got this from. thanks

Hey just wanted to give you a quick heads up. The words in your

post seem to be running off the screen in Chrome. I’m not sure if this is a

format issue or something to do with browser compatibility but

I thought I’d post to let you know. The style and design look great though!

Hope you get the problem solved soon. Thanks

my blog post; Jual Lenovo T470

Oh my goodness! Awesome article dude! Thank you

so much, However I am encountering issues with your RSS.

I don’t understand the reason why I am unable to subscribe to it.

Is there anybody else having the same RSS issues?

Anyone who knows the solution will you kindly respond? Thanx!!

Have a look at my homepage; 바이낸스 레퍼럴

Way cool! Some very valid points! I appreciate you writing this write-up and the rest

of the website is very good.

My webpage: Scatter Hitam

An intriguing discussion is definitely worth comment. I believe

that you ought to write more about this topic, it may not be a taboo matter but typically people don’t

discuss these subjects. To the next! Best wishes!!

My web-site – 호텔스닷컴 할인코드

Hi there to every one, the contents present at this web page

are actually amazing for people experience, well, keep up the nice work fellows.

Feel free to surf to my homepage – 호텔스닷컴 할인코드

I’m impressed, I must say. Seldom do I encounter a blog that’s both educative and entertaining, and let me tell you, you have

hit the nail on the head. The problem is an issue that too few folks are speaking

intelligently about. I’m very happy that I found this in my hunt

for something concerning this.

Also visit my webpage: Streetwear apparel

Excellent post. I was checking constantly this

blog and I am impressed! Extremely helpful info particularly

the last part 🙂 I care for such info a lot. I was looking for this particular information for a very long time.

Thank you and best of luck.

My web-site: 바이낸스 레퍼럴 코드

Wonderful beat ! I wish to apprentice while you amend your website, how can i subscribe for a blog web site?

The account helped me a acceptable deal. I had

been tiny bit acquainted of this your broadcast offered bright clear idea

Here is my web blog παρακολουθηση συνομιλιων απο αποσταση

I was pretty pleased to uncover this page. I wanted to thank you for ones time due to this fantastic read!!

I definitely savored every part of it and I have you bookmarked to see new things on your website.

Feel free to visit my web blog :: BIBLE

Hello colleagues, its fantastic post on the topic of teachingand

fully defined, keep it up all the time.

Here is my web site: 강남풀싸롱

Simply wish to say your article is as surprising.

The clearness in your post is simply great and i could assume you are an expert on this subject.

Fine with your permission allow me to grab your feed to keep up to date with forthcoming post.

Thanks a million and please continue the gratifying work.

Also visit my web blog: GENESIS

Hello there, just became aware of your blog

through Google, and found that it is truly informative. I’m going

to watch out for brussels. I will be grateful if you continue this in future.

Numerous people will be benefited from your writing. Cheers!

Also visit my web blog; 강남미러룸

Hi my family member! I want to say that this article

is amazing, nice written and include almost all vital infos.

I’d like to see more posts like this .

Here is my site :: 강남미러룸

Hi there! This is my first visit to your blog!

We are a collection of volunteers and starting a new project

in a community in the same niche. Your blog provided us valuable information to work on. You have done a marvellous job!

my website: useful site

Hello! I understand this is sort of off-topic but I had

to ask. Does building a well-established website

like yours require a large amount of work? I’m brand new to writing a blog but I do write in my

diary on a daily basis. I’d like to start a blog so I can share my own experience and views online.

Please let me know if you have any ideas or tips for new aspiring bloggers.

Appreciate it!

Here is my webpage :: παρακολουθηση συνομιλιασ κινητου

I’m not sure where you’re getting your information, but good topic.

I needs to spend some time learning more or understanding more.

Thanks for fantastic information I was looking for this information for my mission.

Feel free to visit my page :: γραφεια ντετεκτιβ ελλαδα

What i don’t realize is actually how you are now not really a lot more neatly-preferred

than you may be now. You’re so intelligent. You already

know thus significantly relating to this matter,

made me individually consider it from numerous various angles.

Its like women and men are not interested unless it is one thing

to accomplish with Girl gaga! Your personal stuffs excellent.

Always care for it up!

my blog post :: κοριοι παρακολουθησησ για κινητα

Keep on writing, great job!

My web page :: παρακολουθηση συνομιλιασ κινητου

Just wish to say your article is as amazing.

The clearness in your post is simply spectacular and i could assume you’re an expert on this subject.

Well with your permission let me to grab your feed to keep up to date with forthcoming post.

Thanks a million and please continue the enjoyable work.

My homepage :: κοριοσ παρακολουθησησ κινητου τηλεφωνου

Appreciating the time and energy you put into your website and detailed information you provide.

It’s nice to come across a blog every once in a while that isn’t the same unwanted

rehashed information. Fantastic read! I’ve saved your site and

I’m adding your RSS feeds to my Google account.

My web blog; παρακολουθηση κινητου παιδιου

Hey there would you mind letting me know which webhost you’re using?

I’ve loaded your blog in 3 different internet browsers and I must say this blog loads a lot quicker

then most. Can you suggest a good internet hosting provider at a

reasonable price? Thanks, I appreciate it!

Look into my homepage; κοριοι παρακολουθησησ για κινητα

Keep on writing, great job!

My page … παρακολουθηση κινητου μονο με τον αριθμο

At this time it appears like Drupal is the preferred blogging platform

available right now. (from what I’ve read) Is that what you are using on your blog?

Also visit my page: γραφειο ντετεκτιβ

Hello, the whole thing is going sound here and ofcourse every one is sharing information, that’s actually excellent, keep up writing.

Also visit my page; γραφεια ιδιωτικων ερευνων ελλαδα

Hey There. I found your blog using msn. Este

is a very well written article. I will be sure

to bookmark it and come back to read more of your useful information. Thanks for the post.

I’ll definitely comeback.

Feel free to visit my web blog; γραφεια ιδιωτικων ερευνων αθηνα

My relatives all the time say that I am wasting my time here

at web, however I know I am getting experience every day by reading such fastidious articles or reviews.

My web-site :: παρακολουθηση συνομιλιων απο αποσταση

Hola! I’m at work browsing your blog from my new apple iphone!

Just wanted to say I love reading through your blog and look forward to all your posts!

Keep up the outstanding work!

my blog post: προγραμμα παρακολουθησησ κινητου

I used to be suggested this website by way of my cousin.

I am no longer certain whether or not this submit

is written by means of him as no one else know such distinct

about my problem. You’re wonderful! Thanks!

Review my website: προγραμμα παρακολουθησησ κινητου

Pretty component to content. I just stumbled upon your web site and in accession capital to assert that I acquire actually

enjoyed account your blog posts. Anyway I’ll be subscribing in your augment

or even I success you get right of entry to persistently rapidly.

Here is my blog – γραφεια ντετεκτιβ ελλαδα

What i don’t realize is actually how you are not actually much more well-appreciated than you may be now.

You are so intelligent. You understand therefore considerably

relating to this matter, made me in my view imagine it

from a lot of various angles. Its like women and men don’t seem to be interested unless it’s something to accomplish with Woman gaga!

Your personal stuffs great. All the time care for it up!

Have a look at my site – παρακολουθηση κινητου χωρισ προσβαση σε αυτο

I’m amazed, I have to admit. Seldom do I encounter a blog that’s equally educative and engaging, and let me tell you, you’ve hit the nail

on the head. The problem is something which not enough folks are speaking intelligently about.

I’m very happy I found this in my hunt for something concerning this.

my webpage; γραφεια ιδιωτικων ερευνων

This paragraph presents clear idea in favor of the new people of blogging, that really how to do running a blog.

Also visit my homepage … γραφεια ντετεκτιβ

Hello, yup this piece of writing is truly nice and I have learned

lot of things from it on the topic of blogging. thanks.

Check out my blog ecommerce for dynamics 365

I used to be recommended this blog via my cousin. I

am no longer certain whether or not this submit is written by means of him as no one else

know such exact about my trouble. You’re amazing! Thanks!

Also visit my page: dealership marketing materials

Wow, this paragraph is nice, my younger sister is analyzing these kinds of things, therefore I

am going to inform her.

Look into my web site :: see page

Thanks for your marvelous posting! I truly enjoyed reading

it, you can be a great author.I will be sure to bookmark your blog

and will eventually come back down the road.

I want to encourage continue your great

job, have a nice afternoon!

Feel free to surf to my website furniture design

I think that what you said made a great deal of sense. But, what about this?

suppose you added a little information? I mean, I don’t want to

tell you how to design furniture to run your website, but what if

you added something to possibly get a person’s attention?

I mean Box Cartoning Machines For Modern Packaging Solutions is kinda vanilla.

You might glance at Yahoo’s front page and watch how they write article titles to grab

viewers interested. You might add a video or a picture or two to get people

excited about everything’ve got to say. In my opinion, it could

make your posts a little livelier.

Its like you read my mind! You seem to know so much about this, like you wrote the

book in it or something. I think that you can do with a few pics to drive the message home a bit,

but other than that, this is magnificent blog. An excellent read.

I will certainly be back.

My blog post; Taxi dunfermline

Pretty nice post. I just stumbled upon your blog and wanted to say that I have truly enjoyed browsing your blog

posts. In any case I will be subscribing to your

feed and I hope you write again soon!

Stop by my webpage 수원가라오케

Wonderful beat ! I would like to apprentice while you amend your website, how could i subscribe for a

blog web site? The account helped me a acceptable deal.

I had been tiny bit acquainted of this your broadcast provided bright clear concept

Feel free to surf to my web blog: 6 seater taxi dunfermline

It’s awesome to pay a visit this website and reading the views of

all mates regarding this post, while I am also zealous of getting knowledge.

My page: designing furniture

Здравствуйте!

Влажная уборка офиса – это услуга, которая помогает поддерживать чистоту и комфорт в рабочем пространстве. Мы предлагаем уборку полов, мебели, окон и других поверхностей. Влажная уборка офиса с гарантией качества и профессионального подхода. Наши специалисты используют только проверенные средства и оборудование. Закажите уборку и создайте идеальные условия для своей команды.

Уборка квартир в Санкт-Петербург после ремонта – это услуга для тех, кто недавно завершил ремонт и хочет вернуть свою квартиру в порядок. Мы уберем строительный мусор, пыль и грязь, оставив ваш дом чистым и уютным. Уборка квартир в Санкт-Петербург после ремонта с гарантией качества и надежности. Наши специалисты используют безопасные и эффективные моющие средства. Закажите уборку и получите отличный результат.

Вся информация на сайте – https://service-cleanspb.ru

клининг услуги цены, коммерческий клининг, уборка квартир после ремонта петербург

клининг квартиры после ремонта в спб, уборка после смерти спб, послестроительная уборка офисов

Удачи!

Howdy just wanted to give you a brief heads up and let you know

a few of the images aren’t loading correctly. I’m not sure why but I think its a

linking issue. I’ve tried it in two different web browsers

and both show the same results.

Добрый день!

Уборка производственных помещений – это важная часть поддержания порядка на вашем предприятии. Мы обеспечиваем тщательную очистку производственных зон, складов и других помещений. Уборка производственных помещений – это гарантия безопасности и здоровья сотрудников. Наши специалисты используют только безопасные моющие средства. Закажите уборку производственных помещений у нас.

Клининг уборка квартир – это профессиональный уход за вашим жильем. Мы предлагаем генеральную и регулярную уборку. Наши специалисты используют качественные чистящие средства. Мы работаем быстро и эффективно. Закажите клининг уборка квартир у профессионалов.

Вся информация на сайте – https://service-cleanspb.ru

профессиональная уборка помещений после ремонта, генеральная уборка офиса, стоимость клининговых услуг

срочная уборка квартир, уборка помещений спб, клининг после ремонта цена спб

Удачи!

Добрый день!

Как оформить договор дарения родственнику? Оформление договора дарения предполагает составление нотариально заверенного документа с указанием всех условий сделки. После подписания договора, необходимо зарегистрировать переход права собственности в Росреестре. Важно знать, что для родственников существуют налоговые льготы, которые помогут избежать налоговых выплат. Юрист поможет вам оформить договор дарения в соответствии с законодательством и избежать ошибок.

Вся информация на сайте – https://svoijurist.ru

дискриминация при приеме на работу, как через госуслуги подать заявление на налоговый вычет по ипотеке, с какой суммы можно получить налоговый вычет при продаже квартиры

налоговый вычет при покупке квартиры в 2021 году в ипотеку, номер исполнительного производства проверить у судебных приставов, приставы исполнительное производство

Удачи!

After going over a number of the blog posts on your web page, I honestly like your

technique of blogging. I added it to my bookmark website

list and will be checking back soon. Please check

out my website too and let me know how you feel.

Visit my web-site; http://www.radioavang.org/5-mistakes-to-keep-away-from-when-utilizing-plr-digital-products/

Thanks for sharing your thoughts. I really appreciate your efforts and I am waiting for your further write ups thank you once again.

Here is my web-site 먹튀검증

Wonderful blog! I found it while browsing on Yahoo

Noticias. Do you have any tips on how to get listed in Yahoo News?

I’ve been trying for a while but I never seem to get there!

Thanks

my webpage; raffi777

Hello to all, the contents present at this web site are really amazing for people knowledge, well, keep up the good

work fellows.

my web blog; 먹튀검증사이트

Hi colleagues, its enormous piece of writing about cultureand

completely defined, keep it up all the time.

Also visit my page … 토토커뮤니티

Greetings! This is my first visit to your blog! We are a team

of volunteers and starting a new initiative in a community in the same niche.

Your blog provided us useful information to work on. You have done a

wonderful job!

Also visit my page; 토토사이트

Hi my loved one! I wish to say that this article is awesome,

great written and come with approximately all important infos.

I would like to see more posts like this .

Also visit my page 먹튀검증

Wow that was strange. I just wrote an extremely long

comment but after I clicked submit my comment didn’t show up.

Grrrr… well I’m not writing all that over again. Regardless, just wanted to say great blog!

my blog post :: 사설토토

Good web site you have got here.. It’s difficult to find excellent writing like yours these days.

I honestly appreciate individuals like you! Take care!!

My webpage … 먹튀검증사이트

Excellent blog here! Also your site loads up very fast!

What web host are you using? Can I get your affiliate link to your host?

I wish my site loaded up as quickly as yours lol

my blog post: 먹튀검증

It is appropriate time to make a few plans for the future and it

is time to be happy. I have learn this publish and if I may I want to suggest you some fascinating issues or

tips. Perhaps you could write subsequent articles referring to this article.

I desire to learn even more issues approximately it!

Have a look at my web-site 토토사이트

It’s actually a great and helpful piece of info.

I’m glad that you shared this useful information with us.

Please keep us informed like this. Thanks for sharing.

Here is my blog – 먹튀검증사이트

hey there and thank you for your information – I have

certainly picked up anything new from right here.

I did however expertise some technical points using this web site,

as I experienced to reload the website many

times previous to I could get it to load properly.

I had been wondering if your hosting is OK?

Not that I’m complaining, but slow loading instances

times will sometimes affect your placement in google and could damage your high-quality score if advertising

and marketing with Adwords. Anyway I’m adding this RSS to my e-mail and can look out

for a lot more of your respective exciting content. Make sure you update this again very soon.

my web blog – 먹튀사이트

I visited several web pages except the audio quality for audio songs existing at this

site is really marvelous.

Here is my website 먹튀검증

Peculiar article, totally what I wanted

to find.

My page; 먹튀검증

Your style is so unique compared to other folks I’ve read stuff from.

I appreciate you for posting when you have the opportunity, Guess I will just bookmark this page.

Here is my blog :: 먹튀사이트

Superb, what a website it is! This weblog gives valuable facts to us, keep it up.

Feel free to surf to my site … 사설토토

I will immediately grasp your rss feed as I can not in finding your e-mail subscription link

or newsletter service. Do you have any? Kindly allow me know in order that I may subscribe.

Thanks.

Also visit my website 먹튀

I like what you guys are up too. This kind of clever work and reporting!

Keep up the wonderful works guys I’ve included you guys to blogroll.

Good afternoon!

The iMedix Podcast provides reliable healthcare guidance, making it one of the top podcasts for health; fitness lovers aiming to prevent overtraining will find our warning signs uniquely identifiable, delivering expert health advice and professional medical insights alongside trusted wellness tips for sustainable progress.

Tune into the iMedix Medical Show for reliable healthcare guidance, a standout health news podcast; health enthusiasts wanting to learn about the benefits of incorporating regular walks into their routine will find our motivation tips uniquely encouraging, delivering trusted wellness tips and expert health advice alongside professional medical insights for starting and maintaining a walking habit.

More information at the site – https://podcasts.apple.com/us/podcast/fildena-a-reliable-choice-for-modern-health-support/id1774461527

Wishing you luck!

Thanks to my father who told me concerning this

website, this blog is in fact amazing.

My page … dune couch

First off I want to say excellent blog! I had a quick question which

I’d like to ask if you do not mind. I was interested to find out how you center

yourself and clear your thoughts before writing.

I’ve had a difficult time clearing my thoughts in getting my ideas out.

I truly do enjoy writing however it just seems like the first 10 to 15

minutes are usually wasted just trying to figure

out how to begin. Any ideas or hints? Thanks!

Feel free to surf to my page … printed antinox

Do you have a spam problem on this website; I also am a blogger, and I was wondering your situation; we have created

some nice methods and we are looking to exchange methods with other folks, be sure to shoot me an email if

interested.

Here is my web page; Abogados de lo penal Barcelona

I’m impressed, I have to admit. Seldom do I come across a blog that’s both educative and interesting, y

without a doubt, you have hit the nail on the head.

The problem is something not enough men and women are speaking intelligently about.

I’m very happy that I found this in my search for something regarding this.

my blog post; temporary floor protection

Good afternoon!

The iMedix Health Series delivers expert health advice, central to the iMedix health care platform; medical professionals staying updated on guidelines for hypertension management will find our JNC/ACC/AHA comparison uniquely clear, offering professional medical insights and reliable healthcare guidance alongside trusted wellness tips summarizing key recommendations. Comparisons at imedix.com.

Tune into the iMedix Medical Show for reliable healthcare guidance, a respected Medical podcast; health enthusiasts seeking ways to create a healthier relationship with technology will find our digital wellness tips uniquely balancing, delivering expert health advice and professional medical insights alongside trusted wellness tips for mindful use.

More information at the site – https://www.iheart.com/podcast/269-the-development-journey-of-166674531/episode/cenforce-200mg-a-case-study-in-166674532/

Wishing you luck!

Spot on with this write-up, I absolutely believe this site needs a great deal more attention. I’ll probably be back again to read

more, thanks for the advice!

My web site; eames lounge chair replica

I like it when folks get together and share opinions.

Great site, continue the good work!

Here is my web-site – Abogados penalistas

My partner and I absolutely love your blog and find most of your

post’s to be precisely what I’m looking for. Would you offer guest writers

to write content available for you? I wouldn’t mind composing a

post or elaborating on a number of the subjects you write in relation to here.

Again, awesome site!

My site; printed floor protection

Definitely imagine that which you said. Your favourite justification appeared to be on the

internet the simplest factor to take into account of.

I say to you, I definitely get annoyed while other people consider worries that they plainly don’t recognize about.

You controlled to hit the nail upon the top and also defined out

the whole thing without having side-effects , other people could take a signal.

Will likely be again to get more. Thanks

Here is my webpage :: printed carpet protection

After looking at a number of the blog articles on your web page, I

truly like your technique of blogging. I book marked

it to my bookmark website list and will be checking

back in the near future. Please check out my website

as well and let me know your opinion.

Look at my webpage: Abogados de lo penal Barcelona

An outstanding share! I’ve just forwarded this onto a coworker who has been doing a little homework on this.

And he actually ordered me breakfast because I discovered it for him…

lol. So allow me to reword this…. Thank YOU for the meal!!

But yeah, thanks for spending time to discuss this matter here on your blog.

Also visit my website Abogados penalistas Barcelona

What’s up mates, how is everything, and what you

would like to say concerning this paragraph,

in my view its really remarkable in favor

of me.

my website :: printed correx board

Hey There. I found your weblog using msn. This is

a very smartly written article. I’ll be sure to bookmark it and come back to learn extra of your useful information. Thanks for

the post. I will certainly return.

my web site – site protection

I don’t even know how I finished up here, but I believed this

put up was once great. I do not understand who you are but certainly you are going to a famous blogger should you aren’t already.

Cheers!

Here is my web-site … Abogados penalistas

Hi there! I could have sworn I’ve visited this web site before but after looking at many of

the articles I realized it’s new to me. Nonetheless, I’m definitely pleased I

found it and I’ll be bookmarking it and checking back frequently!

Also visit my homepage … Abogado penal Barcelona

What’s up, this weekend is nice in favor of me, for the reason that this occasion i am

reading this impressive educational post here

at my home.

Here is my blog: printed protection board

I’m really enjoying the theme/design of your blog.

Do you ever run into any web browser compatibility problems?

A couple of my blog visitors have complained

about my site not operating correctly in Explorer but looks great in Chrome.

Do you have any tips to help fix this issue?

Look at my blog post – custom printed correx

I’m gone to inform my little brother, that he should also go to

see this webpage on regular basis to obtain updated from hottest information.

Here is my homepage; Abogados de lo penal Barcelona

obviously like your web site but you have to check the spelling on several of your

posts. Several of them are rife with spelling problems and I to find it very

troublesome to inform the reality however I will definitely come back again.

My web-site :: Abogados penalistas Barcelona

Great post. I am dealing with many of these issues as well..

Here is my web site Abogados penalistas Barcelona

I read this piece of writing fully on the topic of

the resemblance of most recent and earlier technologies, it’s remarkable article.

Here is my web blog :: custom printed correx

Amazing! Its actually amazing piece of writing, I have

got much clear idea about from this paragraph.

Also visit my web-site: printed carpet protection

I’m gone to inform my little brother, that he should also visit this web site on regular basis

to get updated from newest news update.

My site temporary floor protection

Very great post. I just stumbled upon your weblog and wanted to say that I have really enjoyed browsing your weblog posts.

After all I’ll be subscribing for your rss feed and I hope you write once more soon!

my site – floor protection

It’s hard to find educated people for this topic,

but you seem like you know what you’re talking about! Thanks

Also visit my homepage … Abogados de lo penal Barcelona

Hello, I enjoy reading through your post. I like to write

a little comment to support you.

Visit my site; cordek protection board

Hey, I think your blog might be having browser compatibility issues.

When I look at your blog site in Ie, it looks fine but when opening in Internet Explorer, it has some overlapping.

I just wanted to give you a quick heads up! Other then that, fantastic blog!

Feel free to visit my site :: printed antinox

Heya i’m for the first time here. I came across this board and I find It truly useful & it helped me out a