Producing syrup involves several intricate steps that require precision and the right equipment. Among these, the syrup making machine plays a pivotal role in ensuring the syrup’s quality and consistency. This article delves into the detailed process of producing syrup, the selection of appropriate machinery, and the advantages of using syrup making machines in syrup production.

The Syrup Production Process

1. Ingredient Preparation

The first step in syrup production is preparing the ingredients. The main components include:

- Sugar: This can be in the form of white granulated sugar or glucose.

- Wasser: Pure water is essential for dissolving the sugar.

- Additives: These can include preservatives, colorants, and flavorings, depending on the type of syrup being produced.

2. Dissolution

The next step involves dissolving the sugar in water. The sugar and water are added to the syrup making machine in precise proportions. The machine’s mixing mechanism is activated to ensure the sugar dissolves completely in the water, forming a uniform solution.

3. Heizung

Once the sugar is dissolved, the solution is heated. The syrup making machine’s heating system is turned on to bring the solution to the desired temperature, usually above 100°C. This heating process is crucial as it helps in further dissolving the sugar and beginning the concentration process.

4. Concentration

During the concentration phase, continuous heating and stirring are maintained. The aim is to evaporate the water content gradually, thereby increasing the concentration of the syrup. This step requires precise temperature control to prevent the sugar from caramelizing or burning.

5. Addition of Additives

As the syrup reaches the desired concentration, various additives like preservatives, colorants, and flavorings are introduced. These are thoroughly mixed to ensure even distribution throughout the syrup. The choice and quantity of additives depend on the specific type of syrup being produced.

6. Kühlung

The final step is cooling the syrup to room temperature. This can be done by simply allowing the syrup to cool down naturally in the machine or by using a cooling system if the production scale requires it. Once cooled, the syrup is ready for packaging or storage.

Choosing the Right Machinery

1. Syrup Making Machine

The syrup making machine is the heart of the syrup production process. When selecting a syrup making machine, several factors need to be considered:

- Material: Stainless steel is the preferred material due to its durability, resistance to corrosion, and ease of cleaning.

- Kapazität: The capacity of the machine should match the production scale. Larger production volumes require machines with higher capacities.

- Heizmethode: Syrup making machines can be heated using electricity, steam, or thermal oil. The choice depends on the production requirements and available resources.

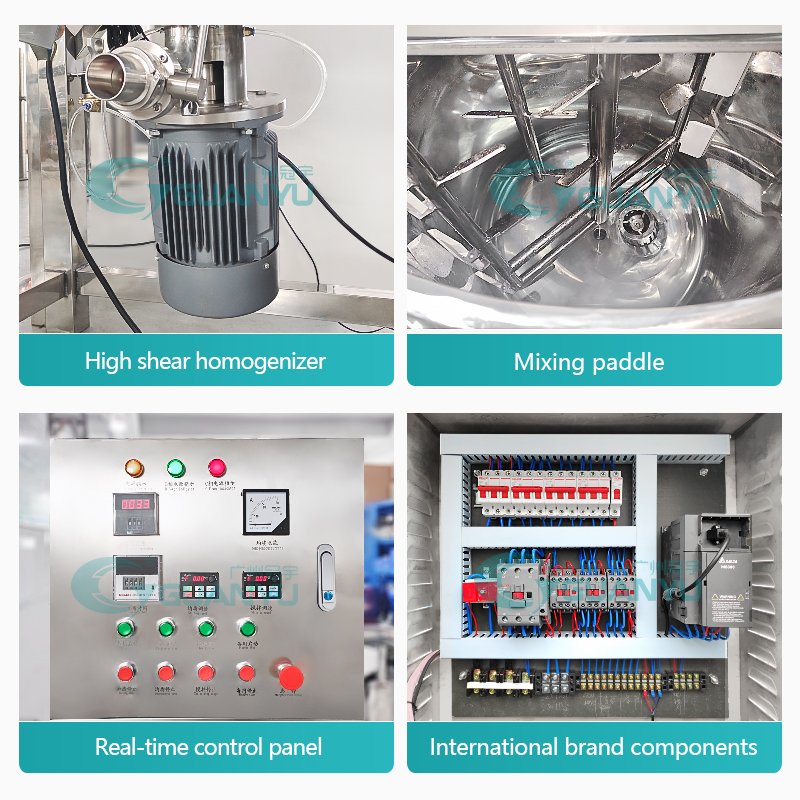

- Mixing Mechanism: The syrup making machine should have adjustable mixing speeds and different types of mixing paddles to ensure thorough mixing.

2. Temperature Control System

A precise temperature control system is essential for maintaining the desired temperature throughout the production process. This ensures that the syrup is heated evenly and prevents overheating or burning.

3. Automation and Control System

Modern syrup production benefits significantly from automation. Automated control systems can program and monitor the entire production process, reducing manual intervention, increasing efficiency, and ensuring consistent product quality.

Advantages of Using Syrup Making Machines

1. Uniform Mixing

Syrup making machines are designed to ensure uniform mixing of ingredients. This uniformity is critical in preventing inconsistencies in the syrup’s texture and taste. The mixing mechanism allows the sugar to dissolve completely and the additives to distribute evenly.

2. Even Heating

The advanced heating systems in syrup making machines provide even heating, which is essential to avoid localized overheating. Uneven heating can cause parts of the syrup to caramelize or burn, affecting the final product’s quality. Even heating ensures that the entire batch of syrup reaches the desired temperature uniformly.

3. Efficient Production

Automated syrup making machines enhance production efficiency by reducing the need for constant manual monitoring and adjustments. This not only saves labor costs but also increases production speed. The automated control systems ensure that the process follows the set parameters, resulting in a consistent and high-quality product.

4. Ease of Cleaning

Stainless steel syrup making machines are easy to clean and maintain, which is crucial for maintaining hygiene standards in food production. The smooth surface of stainless steel prevents residues from sticking, making the cleaning process straightforward and effective.

5. Strong Controllability

Syrup making machines offer excellent controllability over the production process. With precise temperature and mixing speed controls, manufacturers can fine-tune the process to achieve the desired syrup consistency and quality. This level of control is vital for producing syrups with specific characteristics.

Abschluss

The production of syrup is a meticulous process that requires careful attention to detail and the right equipment. The syrup making machine, with its ability to ensure uniform mixing and even heating, plays a central role in producing high-quality syrup. By choosing the appropriate machinery and utilizing advanced control systems, manufacturers can enhance production efficiency, maintain consistent product quality, and meet the demands of the market. The advantages of using syrup making machines, from efficient production to ease of cleaning, make them an indispensable part of the syrup production process.

I relish, result in I found exactly what I used to be

looking for. You have ended my four day lengthy hunt! God Bless you man.

Have a nice day. Bye

Heya i am for the primary time here. I came across this

board and I to find It really helpful & it helped

me out a lot. I’m hoping to present one thing back and aid others like you helped me.

It’s the best time to make some plans for the long run and it’s time to be happy.

I’ve read this publish and if I may just I desire to suggest you

few fascinating things or suggestions. Perhaps you could write

subsequent articles relating to this article.

I want to learn more things about it!

Hello to every , for the reason that I am truly keen of reading this website’s post to be updated regularly.

It contains fastidious stuff.

Hello everyone, it’s my first pay a visit at this

website, and article is really fruitful in favor of me,

keep up posting such content.

Thanks on your marvelous posting! I truly enjoyed reading it, you’re a great author.I will

remember to bookmark your blog and will eventually come

back in the foreseeable future. I want to encourage one to continue your great job, have a nice afternoon!

If you desire to increase your familiarity simply keep visiting this web page and be updated with the most up-to-date news posted here.

Hello there I am so thrilled I found your web site, I really found you by error,

while I was searching on Digg for something else, Nonetheless I am here now and would

just like to say kudos for a incredible post and a all round thrilling blog (I

also love the theme/design), I don’t have time to browse it all at the moment but

I have bookmarked it and also added your RSS feeds, so when I

have time I will be back to read a lot more, Please

do keep up the excellent job.

j200m

Your style is very unique compared to other people I’ve read

stuff from. Thank you for posting when you’ve got the opportunity,

Guess I will just book mark this blog.

erek 50

Fantastic blog! Do you have any suggestions for aspiring writers?

I’m hoping to start my own blog soon but I’m a little lost

on everything. Would you suggest starting with a free platform like

Wordpress or go for a paid option? There are so many options out there

that I’m totally confused .. Any suggestions? Thank you!

slot slot slot slot

bintang88 bintang88 bintang88

Hola! I’ve been reading your site for a while now and finally got the courage to go ahead and give you a shout out from Porter Tx!

Just wanted to say keep up the fantastic job!

pgbet pgbet pgbet

wonderful submit, very informative. I ponder why the other experts of this sector don’t understand

this. You should proceed your writing. I am sure, you’ve

a great readers’ base already!

I will immediately grab your rss as I can’t in finding your e-mail subscription link or e-newsletter service.

Do you’ve any? Kindly allow me recognise so that I may subscribe.

Thanks.

Hello! I know this is somewhat off topic but I was wondering which blog

platform are you using for this site? I’m getting

fed up of WordPress because I’ve had problems with hackers and I’m looking at options for another platform.

I would be great if you could point me in the direction of a

good platform.

Greetings! Very helpful advice within this post!

It is the little changes that make the most significant changes.

Many thanks for sharing!

With havin so much content do you ever run into any issues of plagorism or copyright infringement?

My website has a lot of completely unique content I’ve

either written myself or outsourced but it looks like a lot

of it is popping it up all over the web without my agreement.

Do you know any methods to help reduce content from being stolen? I’d

certainly appreciate it.

Hmm is anyone else having problems with the pictures on this blog loading?

I’m trying to figure out if its a problem on my end

or if it’s the blog. Any suggestions would be greatly appreciated.

Hey I am so grateful I found your site, I really found you by error,

while I was researching on Yahoo for something else, Regardless I am

here now and would just like to say thank you for a marvelous post

and a all round thrilling blog (I also love the theme/design), I don’t have time to browse it all at the

moment but I have book-marked it and also included your RSS feeds, so when I

have time I will be back to read a great deal more, Please do keep up the

fantastic work.

Thanks to my father who informed me regarding this webpage, this webpage is actually awesome.

Hello, I enjoy reading all of your post. I like to write a little comment to support you.

This is very interesting, You are a very skilled blogger.

I’ve joined your feed and look forward to seeking more of

your great post. Auch, I’ve shared your web site in my social networks!

I always used to study article in news papers

but now as I am a user of web so from now I am

using net for posts, thanks to web.

I’m very pleased to discover this website. I want

to to thank you for ones time just for this fantastic read!!

I definitely loved every little bit of it and I have you book marked to see new stuff on your web site.

Hey very cool web site!! Guy .. Excellent ..

Amazing .. I will bookmark your website and take the feeds also?

I’m happy to search out so many useful info here within the publish, we need develop more strategies

in this regard, thank you for sharing. . . .

. .

Good post. I learn something totally new and challenging on websites I stumbleupon everyday.

It will always be helpful to read through articles from other authors and practice a little something from other

Websites.

Hello there, I discovered your site by way of Google whilst looking for a similar matter,

your website came up, it seems good. I have bookmarked it in my google bookmarks.

Hello there, simply turned into aware of your blog thru Google, and found that it’s really informative.

I’m going to be careful for brussels. I will be

grateful when you continue this in future. A lot of folks can be benefited from your writing.

Cheers!

Wow, fantastic blog layout! How long have you

been blogging for? you make blogging look easy.

The overall look of your site is magnificent, as well as the

content!

Excellent blog here! Also your web site loads up fast!

What web host are you using? Can I get your affiliate link to your

host? I wish my site loaded up as fast as yours lol

Hallo! Someone in my Myspace group shared this website with us so I came to take a look.

I’m definitely loving the information. I’m bookmarking and will be tweeting this to

my followers! Terrific blog and brilliant design.

If you would like to increase your know-how only keep visiting this site and be

updated with the latest news update posted here.

Ahaa, its nice conversation on the topic of this piece of writing here at this web site,

I have read all that, so at this time me also commenting here.

I blog quite often and I seriously thank you for your content.

The article has truly peaked my interest. I’m going to

take a note of your site and keep checking for new details about once per week.

I opted in for your Feed as well.

I was recommended this web site by my cousin. I’m not sure whether this post is

written by him as nobody else know such detailed about

my difficulty. You’re incredible! Thanks!

Yo, j9app! Just checked it out. Pretty slick interface, and the game selection is seriously impressive. Definitely worth a look if you’re hunting for a new spot. Check it out here: j9app

**mitolyn reviews**

Mitolyn is a carefully developed, plant-based formula created to help support metabolic efficiency and encourage healthy, lasting weight management.