In modern manufacturing, automation and precision are critical to meeting the demands of high-volume production while maintaining quality. Dual-head spout pouch filling and capping machines have emerged as vital tools for companies that need efficient, reliable, and versatile packaging solutions. These machines are especially popular in industries ranging from food and beverage to cosmetics and pharmaceuticals. In this article, we will explore the essential features, Vorteile, and applications of these advanced machines, and how they are transforming the packaging landscape.

Understanding Dual-Head Spout Pouch Filling and Capping Machines

Dual-head spout pouch filling and capping machines are designed to automate the process of filling liquid or semi-liquid products into spouted pouches and securely capping them. These machines are built to handle high-speed production, ensuring consistent quality while reducing the labor and time required for manual operations.

Key Features and Materials Used

- Durable Construction:

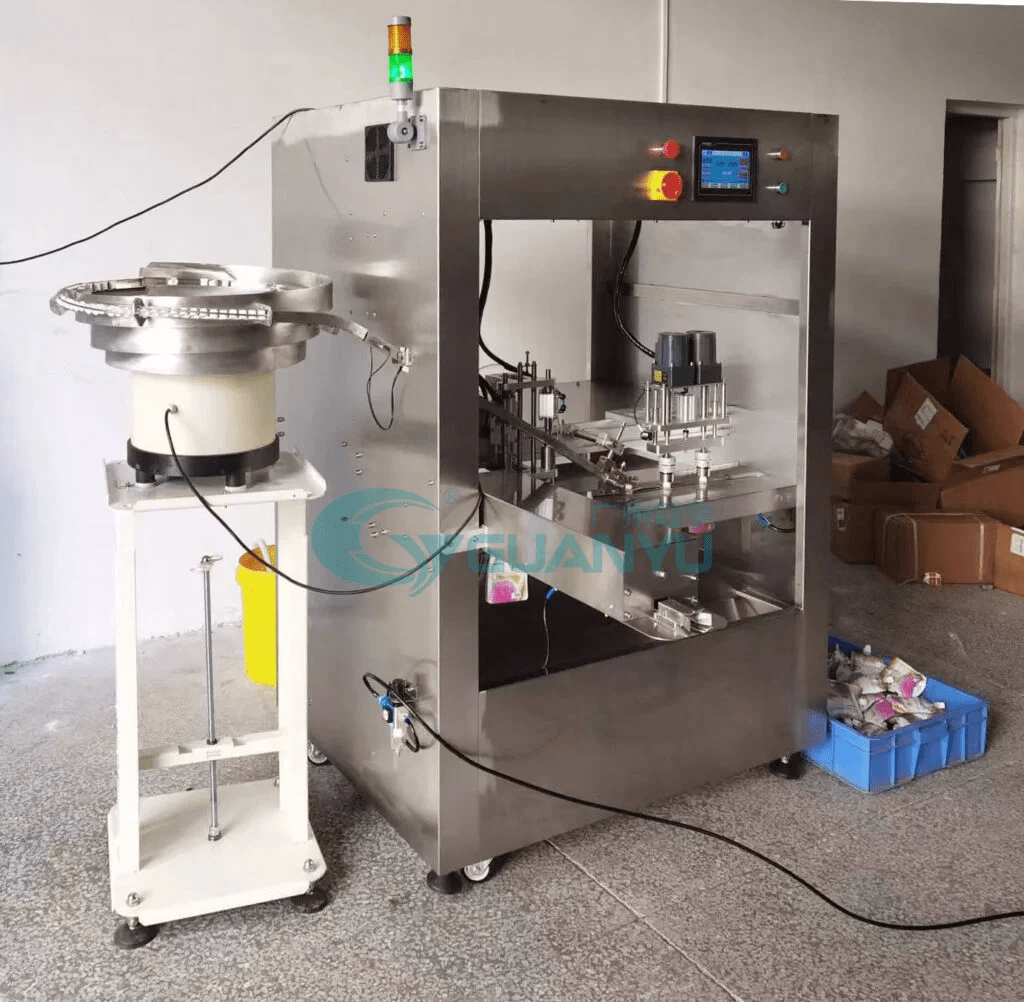

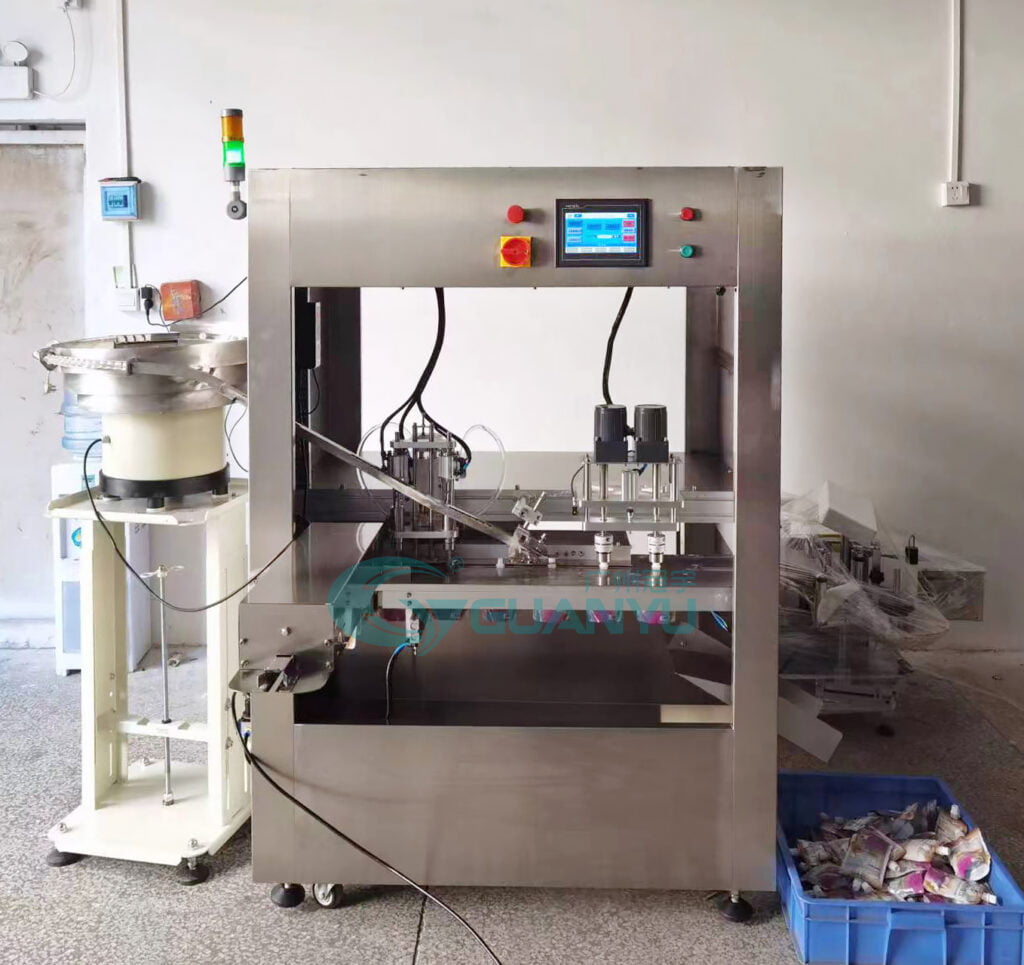

- Stainless Steel Frame: The machine is primarily constructed from food-grade stainless steel, which is essential for maintaining hygiene and preventing contamination in food and pharmaceutical applications. Stainless steel is also known for its resistance to corrosion, making it ideal for long-term use in demanding environments.

- Industrial-Grade Plastics: In addition to stainless steel, high-quality industrial plastics are used in certain components to provide flexibility and reduce the overall weight of the machine. These plastics are designed to withstand the rigors of continuous operation without compromising performance.

- Dual-Head System:

- The machine features two filling heads, allowing it to fill two pouches simultaneously. This dual-head system significantly increases production speed, making it a preferred choice for businesses that need to meet high production targets.

- Automated Capping:

- Once the pouches are filled, the machine automatically caps them with precision. This automation ensures that each pouch is sealed tightly, preventing leaks and maintaining product freshness.

- Advanced Control Systems:

- Touchscreen Interface: The machine is equipped with a user-friendly touchscreen control panel, which allows operators to adjust settings like fill volume, capping torque, and production speed. This ease of use makes it simple to switch between different products or packaging sizes without extensive downtime.

- PLC Control: The machine is controlled by a programmable logic controller (SPS), which ensures that every step of the filling and capping process is carried out with precision. The PLC system can be customized to meet specific production needs, offering flexibility and reliability.

- Precision Dosing:

- The machine’s dosing system ensures that each pouch is filled with the exact amount of product, reducing waste and ensuring consistency. This is particularly important for products where precise measurements are crucial, such as pharmaceuticals or high-value cosmetics.

- Hygienic Design:

- Designed with hygiene in mind, the machine’s smooth surfaces and easy-to-clean components ensure that it meets the strict sanitation standards required in the food and pharmaceutical industries.

Advantages of Using Dual-Head Spout Pouch Filling and Capping Machines

- Enhanced Production Efficiency:

- The dual-head system allows for double the output compared to single-head machines. This makes it possible to produce large quantities of packaged goods in a shorter amount of time, which is critical for meeting market demands.

- Consistency and Accuracy:

- With precise dosing and automated capping, the machine ensures that every pouch is filled and sealed to the same high standard. This consistency is vital for maintaining product quality and meeting regulatory requirements.

- Kosteneinsparungen:

- By automating the filling and capping process, the machine reduces the need for manual labor, which can lead to significant cost savings. Zusätzlich, the accuracy of the Dual-Head Spout Pouch Filling and Capping Machines minimizes product waste, further contributing to cost efficiency.

- Vielseitigkeit:

- Whether you are packaging sauces, Lotionen, Arzneimittel, or chemicals, this machine can handle a wide range of liquid and semi-liquid products. Its adjustable settings make it easy to adapt to different product viscosities and packaging sizes, offering versatility across various industries.

- Safety and Compliance:

- The use of food-grade materials and automated systems ensures that the packaging process is both safe and compliant with industry standards. This is particularly important in industries like food and pharmaceuticals, where contamination can have serious consequences.

- Scalability:

- For businesses looking to scale up their operations, this machine offers a scalable solution. Its high-speed capabilities and consistent performance make it suitable for both small and large-scale production.

Applications in Various Industries

The dual-head spout pouch filling and capping machine is used across multiple industries due to its flexibility and efficiency. Here’s how it benefits different sectors:

- Food and Beverage Industry:

- This machine is ideal for packaging a wide range of food products, including sauces, dressings, condiments, and beverages. The precise filling ensures that each pouch contains the right amount of product, while the secure capping preserves freshness and prevents leakage.

- Kosmetikindustrie:

- In the cosmetics sector, this machine is used for filling products like lotions, Cremes, Gele, and shampoos. Its ability to handle different viscosities makes it versatile enough to package everything from lightweight liquids to thick creams.

- Pharmaceutical Industry:

- The machine’s accuracy and hygienic design make it perfect for packaging liquid medications, Sirupe, and other pharmaceutical products. The precise dosing ensures that each package contains the correct amount of medicine, which is essential for patient safety.

- Chemieindustrie:

- For industrial applications, this machine can package various chemicals, such as cleaning agents, lubricants, and other liquid products. The robust construction of the machine ensures it can handle the harsh conditions often associated with chemical production.

- Pet Care Industry:

- This machine is also useful in packaging products for the pet care industry, such as liquid supplements, shampoos, and grooming products. The machine’s versatility allows it to accommodate the unique needs of this growing market.

Future Trends and Innovations

As technology continues to evolve, dual-head spout pouch filling and capping machines are likely to see further innovations. Trends such as the integration of IoT (Internet of Things) technology for real-time monitoring, AI-driven automation for predictive maintenance, Und sustainable packaging solutions will likely shape the future of these machines. These advancements will not only enhance production efficiency but also help manufacturers meet the increasing demand for eco-friendly packaging.

Abschluss

The dual-head spout pouch filling and capping machine represents a significant advancement in packaging technology. Its combination of speed, Präzision, and versatility makes it an invaluable asset for manufacturers across various industries. By automating the filling and capping process, this machine helps businesses reduce costs, improve efficiency, and maintain consistent product quality. Whether you are in the food, Kosmetika, pharmazeutisch, or chemical industry, investing in this technology can provide a competitive edge in today’s fast-paced market.

If you’re looking to optimize your packaging operations or explore new machinery options, consider the dual-head spout pouch filling and capping machine as a powerful solution that can transform your production line.

For more AI-driven assistance and business solutions, check out https://hix.ai/chat, a top-notch alternative to ChatGPT.

J881love, never heard of it before. Let’s dive in and see if the games live up to the name! Hoping for a good selection and some awesome promotions. Let’s see what it offers: j881love

**mitolyn**

Mitolyn is a carefully developed, plant-based formula created to help support metabolic efficiency and encourage healthy, lasting weight management.