Choosing the right food production line is very important. It affects how well your factory works and the quality of your food. It also impacts how eco-friendly your process is. Trends like using machines, being clear, and saving resources are key. Your production line should match your business goals and what customers want.

Today, food makers must follow stricter safety rules. They also need to use simple, known ingredients. Picking the right production line helps you work better and waste less. It also helps you use resources wisely. Whether you want to save time or follow rules, your choice matters for everything you make.

Key Takeaways

Know your production goals. Decide how much food to make.

Think about your product needs. Different foods need different tools.

Spend money carefully on machines. Compare costs with profits to earn more.

Use automation to work faster. Machines help reduce mistakes and improve safety.

Follow food safety rules. This builds trust and keeps your factory safe.

Assessing Operational Needs

Defining production goals and capacity

Knowing your production goals is the first step. Decide how much food you want to make daily or weekly. This helps you pick machines that fit your needs. For example, if you need to make 10,000 food packages a day, choose equipment that works well for this amount.

Making food efficiently means meeting goals and keeping quality high. Following rules like FSMA Rule 204 helps track food and keep records. This reduces waste and builds trust with customers. Better tracking systems also improve supplier relationships and make work easier. Using digital records saves time and cuts down on paperwork.

Evidence | Explanation |

|---|---|

FSMA Rule 204 mandates traceability and record-keeping | Compliance improves operational efficiency, reduces waste, and builds trust. |

Enhanced traceability improves operational efficiency | Reduces waste and strengthens supplier and customer relationships. |

Digital record-keeping systems streamline compliance | Enhances data accuracy and reduces administrative burdens. |

Clear goals help businesses succeed in different industries. For example:

Car makers use tools to make parts better and more consistent.

Builders check materials early to meet project needs.

Green energy companies improve processes for stronger products.

Medical device makers standardize steps to keep customers happy.

Addressing product-specific requirements

Each food product needs special equipment. Think about texture, Verpackung, and shelf life when choosing machines. For example, frozen meals need tools that handle cold temperatures and keep food fresh. Bakery machines must work with dough and bake at the right times.

What customers want affects the type of machines needed. Health-focused buyers want organic or non-GMO foods. Others prefer gluten-free or ready-to-eat meals. New technology like automation helps food makers meet these demands. For example, bakeries need machines for new flavors or special diets.

Special machines help make unique foods for specific markets.

Automation and smart tech make factories more flexible.

Ready-to-eat meals need machines for frozen and quick foods.

Health-focused buyers push for organic and non-GMO food tools.

Bakeries need advanced machines for gluten-free and custom flavors.

Budgeting and ROI considerations

Buying food production equipment requires careful planning. You need to check costs for buying, setting up, and fixing machines. Budgeting helps track spending and find good deals. Comparing costs to expected profits shows which choices are best for ROI.

Partial budgeting looks at small changes, like buying new machines. This ensures every purchase helps your business grow. New food-making tools also save money and help the environment. Better management reduces waste and cuts costs. Smart irrigation systems save water and lower expenses.

Evidence Type | Beschreibung |

|---|---|

Carbon Footprint Reduction | Reduced greenhouse gas emissions through precise input management, lowering nitrous oxide risk. |

Circular Agriculture | Repurposing agricultural waste to lower costs and enhance sustainability. |

Cost Reductions in Inputs | Reduction of fertilizer and pesticide usage by 20-30% through precision application. |

Efficient Water Use | Advanced irrigation systems optimize water delivery, reducing costs and addressing scarcity. |

ROI (Return on Investment) | Higher ROI due to precision management and reduced waste. |

Good budgeting and ROI planning help you make food efficiently and stay profitable.

Evaluating Automation and Technology

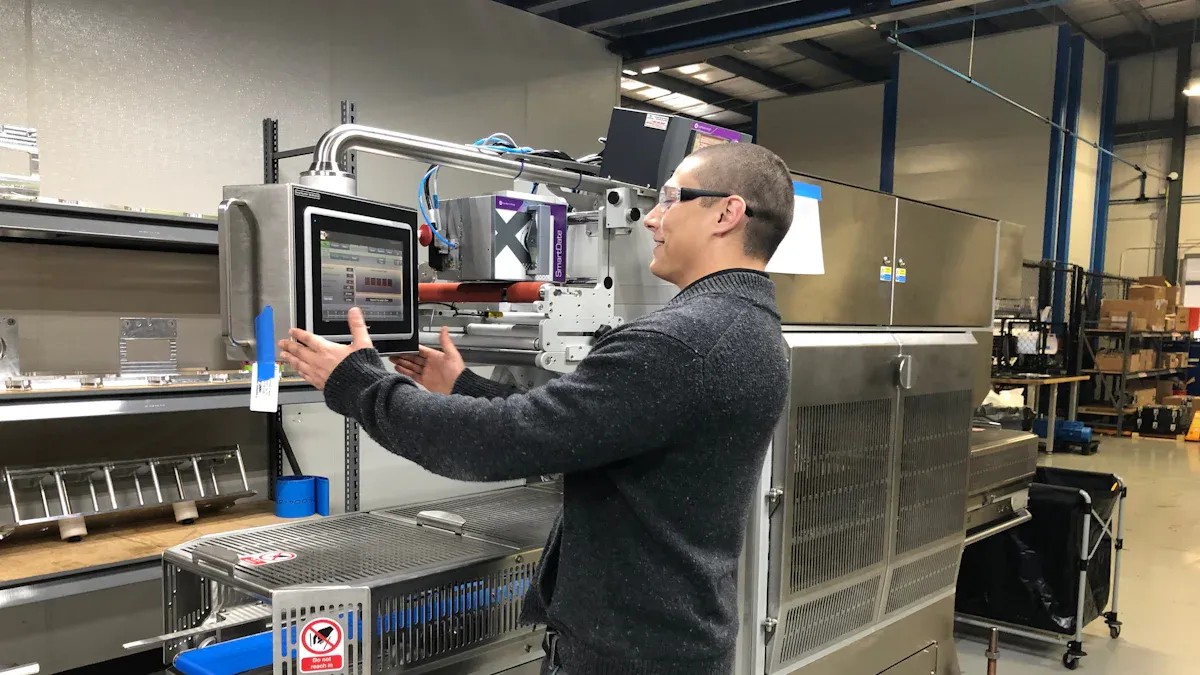

Role of automation in food and beverage manufacturing

Automation changes how food and drinks are made. It makes work faster, saves money, and keeps workers safe. Machines can do repeated tasks, letting workers focus on new ideas and checking quality. For example, automated setups need less space, saving 25% compared to older systems. They also lower cooling costs by 50% with better designs and storage.

Automation helps keep workers safe. Machines take over tough jobs, reducing injuries and improving work speed. Forklifts are replaced by automated systems, which protect products and buildings from damage. Automation also makes orders more accurate by fixing inventory mistakes and reducing picking errors.

Tip: Using automation makes your factory safer and more efficient.

Selecting the right technology for your operations

Picking the best technology for your factory needs careful thought. Smart tools like AI can change how you work. For example, AI robots find flaws with 95% Genauigkeit. AI packaging machines work 40% faster and waste fewer materials. These tools follow safety rules and lower contamination risks.

Anwendung | Impact Description | Source |

|---|---|---|

AI-based robotic inspection | Finds flaws with 95% Genauigkeit | Hossain et al. (2021) |

AI-driven packaging robots | Speeds up packaging by 40% and wastes less material | Li et al. (2023) |

AI in sterile environments | Lowers contamination risks and meets safety standards | Liu et al. (2023) |

AI in supply chain optimization | Improves delivery times by 25% and cuts logistics costs by 15% | Ivanov & Dolgui (2021) |

AI in product development | Helps create better products faster using data | Shen et al. (2023) |

Think about your needs when choosing technology. Bakeries might need machines for gluten-free or organic foods. Frozen food makers need tools to keep food cold and fresh. Matching technology to your goals helps you make food efficiently and keep customers happy.

Ensuring system integration and scalability

Combining systems and planning for growth are important for success. Connected systems let you watch your factory in real time. For example, 37% of food factories use IoT sensors to stop spoilage and safety problems. These sensors give instant updates, helping you fix issues quickly.

Growth is easier with scalable systems. A small sauce company doubled its production in one year using FlexiBake, a special ERP system. This tool helped them save money and work better, showing why scalable solutions matter.

Robots also help factories grow. Automated machines for packing and checking quality make work faster and free workers for harder tasks. Using scalable and connected systems helps you adjust to market changes and stay competitive.

Notiz: Scalable systems help your business grow and stay ahead in food manufacturing.

Ensuring Quality and Compliance

Following industry rules and standards

Food makers must follow strict rules to keep food safe. These rules protect people and improve how food is made. Examples include the FDA’s Food Safety Modernization Act (FSMA) and Global Food Safety Initiative (GFSI). These rules stop contamination and make production better.

The food industry often makes its own rules to solve health problems. For example, ads aimed at kids led to tougher rules. This shows how public concerns push companies to follow stricter guidelines.

Evidence Type | Beschreibung |

|---|---|

Food Industry Self-Regulation | Companies create rules to handle health concerns. |

Marketing Effects on Health | Ads for kids raised health worries, leading to new rules. |

History of Self-Regulation | Public pressure has long shaped industry actions. |

Following these rules helps factories work better and builds customer trust.

Why certifications matter for quality

Certifications are important for keeping food safe and high-quality. They help meet safety rules and improve how food is made. Systems like HACCP check for risks and stop problems. ISO standards also help factories work better and make good products.

HACCP checks for risks and keeps food safe.

ISO standards improve how factories work and make products.

FSMA sets new rules for making and shipping food.

Certifications show you follow good practices and strict rules. They lower risks and help your factory run smoothly.

Building strong quality control systems

Good quality control systems keep food safe and factories efficient. These systems find risks and stop contamination. For example, Food Safety Management Systems (FSMS) improve training and crisis plans. They also track important factory goals.

Case Study Description | Key Findings |

|---|---|

FSMS in small-medium businesses | Better training and crisis plans (p < 0.001). |

HACCP in capsule-making factories | Improved safety with ISO 22000:2018 and HACCP rules. |

Dairy plant in São Paulo | Lower yeast and mold after new systems (p < 0.05). |

Programs for constant improvement make quality control even better. They find risks, follow strict rules, and cut costs from food safety problems. These programs protect customers and save money.

Strong systems keep food safe and high-quality. They protect customers and improve your factory’s reputation.

Training and Workforce Considerations

Getting employees ready for advanced systems

Modern machines need skilled workers to run them well. Employees must learn how to use automated tools and AI systems. Training helps workers understand these tools and keep the workplace clean. For instance, workers trained in teamwork with AI can handle new tech and make food production more flexible.

Good training also supports eco-friendly production. Workers who know about innovation can cut waste and improve cleanliness. This builds strong systems that can handle supply chain problems and keep production smooth.

Tip: Offer full training programs to help your team learn advanced tools and follow safety rules.

Keeping up with training for better work

Regular training keeps workers updated on new tools and methods. Refresher courses boost knowledge and skills in food safety. Studies show ongoing training can improve knowledge 45 times and practices 14 times. This helps your team keep high standards in food production.

Using lean manufacturing methods makes work more efficient. These methods focus on cutting waste and improving supply chains. Tools like value stream mapping and just-in-time production fix delays and improve workflow.

Metal detectors and vision tools make food safer.

Combo systems are easier to learn and save space.

Regular maintenance stops breakdowns and increases profits.

Frequent training keeps workers skilled and production lines running smoothly.

Mixing automation with human checks

Automation makes food production faster and more accurate. But humans are still needed for quality checks and tricky situations. Hybrid systems mix machines with human input to boost productivity and ensure safety.

For example, AI can spot problems during inspections, but people must confirm and analyze the data. In contamination cases, machines act fast, but humans ensure the right steps are taken.

Aspect | What Automation Does | What Humans Do |

|---|---|---|

Efficiency | Speeds up work and lowers mistakes | Adds expert judgment and decisions |

Data Interpretation | Finds issues but needs human review | Confirms and explains results |

Handling Complex Issues | Solves unclear or ethical problems | |

Quality Assurance | Improves speed and accuracy | Makes final checks and decisions |

Balancing Automatisierung with human input keeps food production innovative, safe, and high-quality.

Long-Term Efficiency and Sustainability

Using energy-saving equipment

Energy-saving tools are important for better food production. Food factories use over twice the energy of other businesses. Old systems waste up to 80% of energy. Switching to energy-saving machines lowers costs, improves work, and cuts pollution. These upgrades help you save money and protect the planet.

Benefit | Percentage Impact |

|---|---|

Lower Costs | |

Higher Profits | 30% mit 20% better efficiency |

Energy-saving machines also work better. They cook food well and need fewer repairs. This makes your factory run smoothly and last longer. Choosing these tools saves money and helps the environment by reducing harmful gases.

Tip: Energy-saving machines help you save money and protect nature.

Cutting waste in food production

Cutting waste keeps factories clean and improves how they work. Reducing waste could save the world $120-$300 billion yearly by 2030. These savings help both families and businesses.

You can cut waste by improving processes and using smart machines. For example, sorting machines separate good materials from trash. This reduces waste and keeps your factory cleaner. These ideas save money and make production better.

Focusing on less waste helps the planet and increases profits. Better processes lower costs and help meet eco-friendly goals.

Preparing for future changes and upgrades

Planning ahead keeps your factory ready for future needs. One big food company improved work by 20% and worker happiness by 25% with upgrades. Their factory now handles more work while staying high-quality.

Planning also helps with challenges like climate change. For example, coffee makers in Nicaragua changed their methods to handle new weather patterns. This shows why planning is key in food production.

Upgrading with flexible machines helps your factory grow with demand. These designs let you add new tools without stopping work. Staying adaptable keeps your business strong and ready for the future.

Notiz: Planning upgrades keeps your factory efficient and ready for changes.

Matching your food production line to your goals helps it run well. It also keeps customers happy. Good alignment allows for new ideas, flexibility, and eco-friendly practices. For instance, how you make products affects efficiency, and product design makes customers happier. Social actions improve business results, but handling returns can be tricky.

Automation, safety checks, and saving energy are important for success. Machines make work faster and more accurate. Quality checks keep food safe. Using energy-saving tools lowers costs and helps the planet. Focusing on these things keeps your business strong in the changing food industry.

Aspect | Match with SOP | Effect on SPM |

|---|---|---|

High | Improves eco-friendly performance | |

Social Actions | Medium | Helps overall business success |

Product Design | High | Boosts efficiency and customer happiness |

Production | High | Encourages new ideas and flexibility |

Returns Handling | Low | Shows issues in matching goals |

Tip: Work on being efficient and following rules to stay competitive in food production.

FAQ

What is the most important factor when choosing a food production line?

Focus on matching the production line to your business goals. Think about how much food you need to make and the type of products. Following safety rules also helps keep your factory running smoothly.

How does automation improve food production?

Automation makes work faster and safer. Machines do simple tasks, so workers can check quality and try new ideas. For example, automated tools use less energy and pack food more accurately.

Tip: Choose automation tools that can grow with your factory.

Why is compliance with food safety regulations essential?

Safety rules keep food safe and high-quality. They protect customers and help your factory avoid problems. Following rules like FSMA or GFSI builds trust and keeps your business running well.

How can I make my production line more sustainable?

Use machines that save energy and cut waste. Smart tools can sort materials to reduce trash. Planning upgrades helps your factory stay eco-friendly and lower pollution.

Notiz: Being eco-friendly saves money and improves your brand image.

Do I need to train my workforce for advanced systems?

Ja, training helps workers use modern machines better. Learning about Automatisierung Und AI keeps production smooth. Regular lessons make sure workers know the latest tools and methods.

Tip: Give hands-on training to help workers feel confident and skilled.

Eğer Instagram keşfete çıkmak istiyorsanız, gerçek Instagram beğenisi gerçekten fark yaratıyor. Ben ankasosyal.com üzerinden alıyorum, tavsiye ederim.

Kuyumcu makinelerinde yedek parça ve bakım hizmeti gerçekten hızlı ve ekonomik.

Great stuff. Helped me a lot — please keep sharing! And check my website: https://b1top0010.xyz/ !

This is really interesting, You’re a very skilled blogger. I’ve joined your feed and look forward to seeking more of your magnificent post. Auch, I’ve shared your site in my social networks!

Hi there to all, for the reason that I am genuinely keen of reading this website’s post to be updated on a regular basis. It carries pleasant stuff.

Silivri su kaçağı tespiti Fatih’teki apartmanda su kaçağı vardı. Ekip çok profesyonelce tespit yaptı. Çok memnun kaldım. https://99info.wiki/?p=37534

My sincere thanks to the creator of this website for sharing such a fantastic piece of writing. It’s rare to encounter content that is both so well-researched and presented in an accessible manner. My genuine appreciation for your efforts.

I appreciate you sharing this blog post. Thanks Again. Cool.

Very insightful and well-written. I learned a lot from this! Pls check my website: https://emopat.xyz/ !

Mehmet Akif su kaçak tespiti Zeytinburnu’nda su kaçağı tespiti için çok iyi bir ekip. Sorunumuzu hemen çözdüler. http://wakeof.net/author/kacak/

I’m new to blogging and really appreciate your content. This article piqued my interest. Bookmarking your site!

su kaçağı tespiti Fatih su kaçağı tespiti: Fatih’te su kaçağı sorunlarınıza kesin çözüm sağlıyoruz. http://blakemountford.com/author/kacak/

Kayışdağı su kaçak tespiti Hızlı, temiz ve profesyonel bir hizmet. Tavsiye! https://www.vevioz.com/read-blog/40560

Great article, thank you for sharing these insights! I’ve tested many methods for building backlinks, and what really worked for me was using AI-powered automation. With us, we can scale link building in a safe and efficient way. It’s amazing to see how much time this saves compared to manual outreach.

**mindvault**

Mind Vault is a premium cognitive support formula created for adults 45+. It’s thoughtfully designed to help maintain clear thinking

**mind vault**

Mind Vault is a premium cognitive support formula created for adults 45+. It’s thoughtfully designed to help maintain clear thinking

**mindvault**

mindvault is a premium cognitive support formula created for adults 45+. It’s thoughtfully designed to help maintain clear thinking

**breathe**

breathe is a plant-powered tincture crafted to promote lung performance and enhance your breathing quality.

**breathe**

breathe is a plant-powered tincture crafted to promote lung performance and enhance your breathing quality.

This is a great article, i am simply a fun, keep up the good work, just finish reading from https://websiteerstellenlassenbamberg.de// and their work is fantastic. i will be checking your content again if you make next update or post. Thank you

Lương Sơn TV phù hợp với những ai hay xem bóng trên điện thoại như mình, vì giao diện gọn và dễ bấm. Khi xem ngoài trời bằng 4G vẫn mượt, ít lag. Mình hay theo dõi Ngoại hạng Anh nên lịch thi đấu trên trang giúp mình chủ động hơn. Nhìn chung trải nghiệm khá trọn vẹn so với nhiều nền tảng khác.

Bạn bè giới thiệu nên mình mới thử LuongSonTV và khá hài lòng. Điều bất ngờ là các trận được sắp xếp rõ ràng nên rất dễ làm quen. Chất lượng video tốt hơn nhiều trang từng xem trước đó. Một lựa chọn đáng tin cậy cho người mới như mình.

Your blog is a constant source of inspiration for me. Your passion for your subject matter is palpable, and it’s clear that you pour your heart and soul into every post. Keep up the incredible work!

Your blog is a constant source of inspiration for me. Your passion for your subject matter is palpable, and it’s clear that you pour your heart and soul into every post. Keep up the incredible work!

So much value packed into one post!

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

Tham gia QQ88 để khám phá casino live, thể thao, slot nổ hũ, bắn cá đổi thưởng cùng hàng loạt khuyến mãi độc quyền mỗi ngày.

Downloaded the cmd368apps! Not bad, quite smooth, and it’s more convenient to play on the phone, you can bet anytime, anywhere. Jedoch, I hope there can be more promotional activities

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

QQ88 Casino mang đến không gian cá cược hiện đại với dealer live chuyên nghiệp, tỷ lệ thưởng cạnh tranh và hệ thống bảo mật cao cấp dành cho người chơi sành giải trí.

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

TR88 mang đến hệ sinh thái giải trí đa dạng với nhiều sảnh chơi hấp dẫn như slot game, casino trực tuyến, thể thao, bắn cá và xổ số, đáp ứng trọn vẹn mọi nhu cầu của người chơi. Đặc biệt, người chơi còn có cơ hội nhận ngay ưu đãi lì xì giá trị lên đến 888k khi tham gia.

**backbiome**

backbiome is a naturally crafted, research-backed daily supplement formulated to gently relieve back tension and soothe sciatic discomfort.

**vivalis**

vivalis is a premium natural formula created to help men feel stronger, more energetic, and more confident every day.

**glycomute**

glycomute is a natural nutritional formula carefully created to nurture healthy blood sugar levels and support overall metabolic performance.

**balmorex pro**

balmorex is an exceptional solution for individuals who suffer from chronic joint pain and muscle aches.

**aquasculpt**

aquasculpt is a revolutionary supplement crafted to aid weight management by naturally accelerating metabolism

**nervecalm**

nervecalm is a high-quality nutritional supplement crafted to promote nerve wellness, ease chronic discomfort, and boost everyday vitality.

**synadentix**

synadentix is a dental health supplement created to nourish and protect your teeth and gums with a targeted combination of natural ingredients

QQ88 – điểm đến quen thuộc của cộng đồng giải trí trực tuyến, nổi bật với casino live, bắn cá, nổ hũ và đá gà kịch tính.

**prostavive**

prostavive Maintaining prostate health is crucial for mens overall wellness, especially as they grow older.

**alpha boost**

alpha boost for men, feeling strong, energized, and confident is closely tied to overall quality of life. Jedoch, with age, stress, and daily demands

**yusleep**

yusleep is a gentle, nano-enhanced nightly blend designed to help you drift off quickly, stay asleep longer, and wake feeling clear

**prodentim**

prodentim is a distinctive oral-care formula that pairs targeted probiotics with plant-based ingredients to encourage strong teeth

**gl pro**

glpro is a natural dietary supplement designed to promote balanced blood sugar levels and curb sugar cravings.

**mindvault**

mindvault is a premium cognitive support formula created for adults 45+.

**nitric boost ultra**

nitric boost is a daily wellness blend formulated to elevate vitality and support overall performance.

**femipro**

femipro is a dietary supplement developed as a natural remedy for women facing bladder control issues and seeking to improve their urinary health.

**vertiaid**

vertiaid is a high-quality, natural formula created to support stable balance, enhance mental sharpness, and alleviate feelings of dizziness

**vitrafoxin**

vitrafoxin is a premium brain enhancement formula crafted with natural ingredients to promote clear thinking, memory retention, and long-lasting mental energy.

**glucore**

glucore is a nutritional supplement that is given to patients daily to assist in maintaining healthy blood sugar and metabolic rates.

**sugarmute**

sugarmute is a science-guided nutritional supplement created to help maintain balanced blood sugar while supporting steady energy and mental clarity

**primebiome**

The natural cycle of skin cell renewal plays a vital role in maintaining a healthy and youthful appearance by shedding old cells and generating new ones.

**hepato burn**

hepatoburn is a high-quality, plant-forward dietary blend created to nourish liver function, encourage a healthy metabolic rhythm, and support the bodys natural fat-processing pathways.

Long range goals, strikes from outside the box documented

Hello very cool site!! Guy .. Beautiful .. Amazing .. I’ll bookmark your blog and take the feeds also…I’m satisfied to find so many helpful info here within the publish, we’d like work out extra strategies in this regard, thank you for sharing. . . . . .

Somebody essentially help to make seriously articles I would state. This is the first time I frequented your website page and thus far? I surprised with the research you made to create this particular publish incredible. Great job!

Thanks for each of your labor on this site. My aunt delights in setting aside time for research and it’s really obvious why. Almost all learn all about the lively means you convey very helpful tips and tricks via your web blog and in addition invigorate response from other individuals on that topic plus our favorite princess is really starting to learn so much. Take pleasure in the rest of the new year. You have been performing a stunning job.

Thi is a great article no doubt about it, i just started following you and i enjoy reading this piece. Do you post often ? we have similar post on the german best freelancer platform called https://webdesignfreelancerdeutschland.de/ you can check it out if you want. Thank you

QQ88 cung cấp nền tảng truy cập cá cược online hiệu quả, tối ưu tốc độ, minh bạch và mang lại sự thuận tiện trong từng lần đăng nhập.

i enjoy reading this great article, i have shared it many times on my website and started following you, Do you post more often ?? i am the owner of https://webdesignagenturbayreuth.de/ a webdesign agency in bayreuth Germany, webdesign agentur bayreuth, you can link up if you are interested. Thank you

**finessa**

Finessa is a natural supplement made to support healthy digestion, improve metabolism, and help you achieve a flatter belly.

QQ88 được xây dựng như một cổng truy cập giải trí trực tuyến linh hoạt, phù hợp cho người dùng cần sự ổn định và dễ thao tác.

QQ88 là địa chỉ truy cập giải trí online đáng tin cậy, chú trọng trải nghiệm mượt mà, vận hành ổn định và giao diện thân thiện.

Your point of view caught my eye and was very interesting. Thanks. I have a question for you. https://accounts.binance.info/ph/register-person?ref=IU36GZC4

i enjoy reading your articles, it is simply amazing, you are doing great work, do you post often? i will be checking you out again for your next post. you can check out webdesignagenturnürnberg.de the best webdesign agency in nuremberg Germany

**prodentim reviews**

ProDentim is a distinctive oral-care formula that pairs targeted probiotics with plant-based ingredients to encourage strong teeth, comfortable gums, and reliably fresh breath

**aquasculpt**

aquasculpt is a premium metabolism-support supplement thoughtfully developed to help promote efficient fat utilization and steadier daily energy.

**men balance pro**

MEN Balance Pro is a high-quality dietary supplement developed with research-informed support to help men maintain healthy prostate function.

**boostaro**

Boostaro is a purpose-built wellness formula created for men who want to strengthen vitality, confidence, and everyday performance.

Hey everyone, bj326onlinegame isn’t bad actually! Solid game selection and the site is easy to navigate. Could use some more bonuses but overall it’s legit. Check it out for yourself: bj326onlinegame

Yo, golo777 is my go-to spot! Quick payouts and the slots are fire. Definitely recommend checking it out. golo777

r777game? Yeah, I’ve played there a few times. The interface is clean and the games run smoothly. Give it a shot, you might get lucky. Find it here r777game

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

QQ88 được xây dựng như một cổng kết nối giải trí trực tuyến, giúp người dùng truy cập nhanh, hạn chế gián đoạn và sử dụng dịch vụ ổn định trên nhiều thiết bị.

QQ88 là nền tảng giải trí trực tuyến uy tín, tối ưu tốc độ truy cập, giao diện thân thiện và mang đến trải nghiệm ổn định cho người dùng.

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

QQ88 là nền tảng giải trí trực tuyến uy tín, tối ưu tốc độ truy cập, giao diện mượt và trải nghiệm ổn định cho người dùng.

QQ88 cung cấp cổng truy cập giải trí online hiện đại, vận hành liền mạch, hỗ trợ đa thiết bị và dễ sử dụng.

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.

QQ88 là nền tảng giải trí trực tuyến uy tín, tối ưu tốc độ truy cập, giao diện mượt và mang lại trải nghiệm ổn định cho người dùng.

QQ88 được định hình như một không gian giải trí trực tuyến tối ưu hiệu suất, nơi trải nghiệm truy cập nhanh và sự ổn định luôn được đặt lên hàng đầu.

QQ88 là điểm truy cập giải trí trực tuyến được tối ưu toàn diện, tập trung vào tốc độ, sự ổn định và trải nghiệm liền mạch cho người dùng.

QQ88 là nền tảng giải trí trực tuyến được thiết kế tối giản nhưng hiệu quả, mang đến trải nghiệm truy cập mượt và vận hành ổn định lâu dài