Einführung

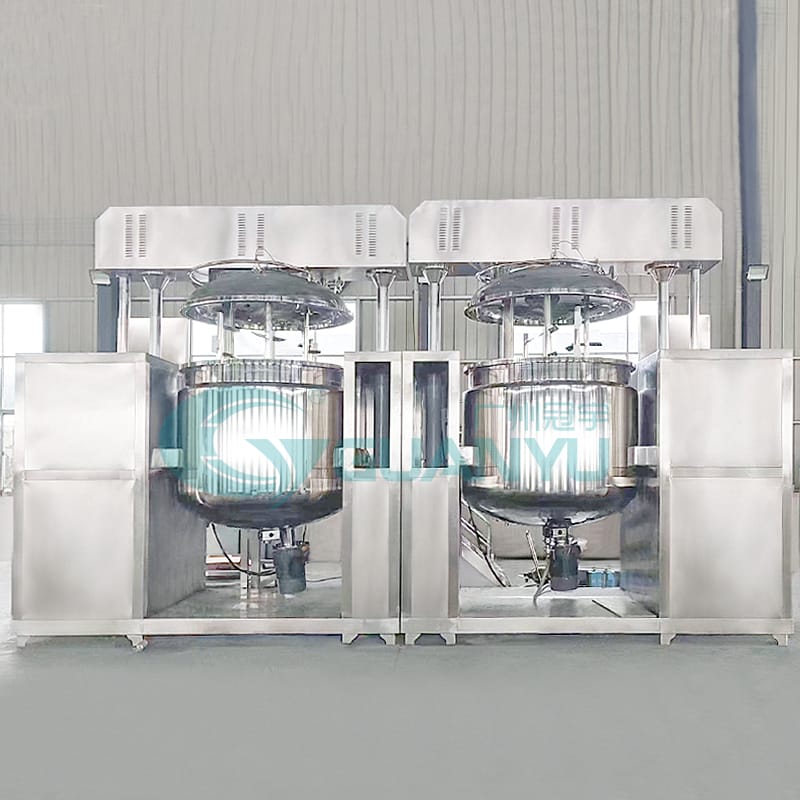

In 2025, Guanyu continues to push the boundaries of industrial emulsification technology with its latest 3000L Vakuumemulgiermischer. This high-performance mixing system is designed to meet the needs of Kosmetika, Essen, pharmazeutisch, and chemical manufacturers, offering efficient homogenization, intelligent control, and large-scale production capabilities.

Equipped with high-shear homogenization, vacuum functionality, and a PLC-controlled system, Die 3000L vacuum emulsifying mixer ensures uniform texture, improved product stability, and maximum production efficiency. In this article, we’ll explore its key advantages, applications, maintenance requirements, and why Guanyu’s vacuum emulsifying mixers are the best choice for large-scale manufacturing.

Key Advantages of the 3000L Vacuum Emulsifying Mixer

1. High-Efficiency Emulsification & Homogenization

Der Guanyu 3000L vacuum emulsifying mixer utilizes high-shear homogenization technology to ensure rapid and uniform dispersion of oil and water phases.

✅ Advanced rotor-stator system: Creates fine emulsions with stable particle size distribution.

✅ Suitable for high-viscosity products: Perfect for creams, Lotionen, sauces, Salben, und Pasten.

✅ Vacuum functionality: Removes air bubbles for a smooth, uniform texture.

2. Large-Scale Production Efficiency

With a 3000L capacity, this emulsifying mixer is built for high-volume production, helping manufacturers reduce processing time and labor costs.

✅ Handles large batches: Reduces downtime between production cycles.

✅ Continuous production capability: Ideal for industries requiring high-output efficiency.

✅ Cost-effective: Fewer batches mean lower operational expenses and greater output.

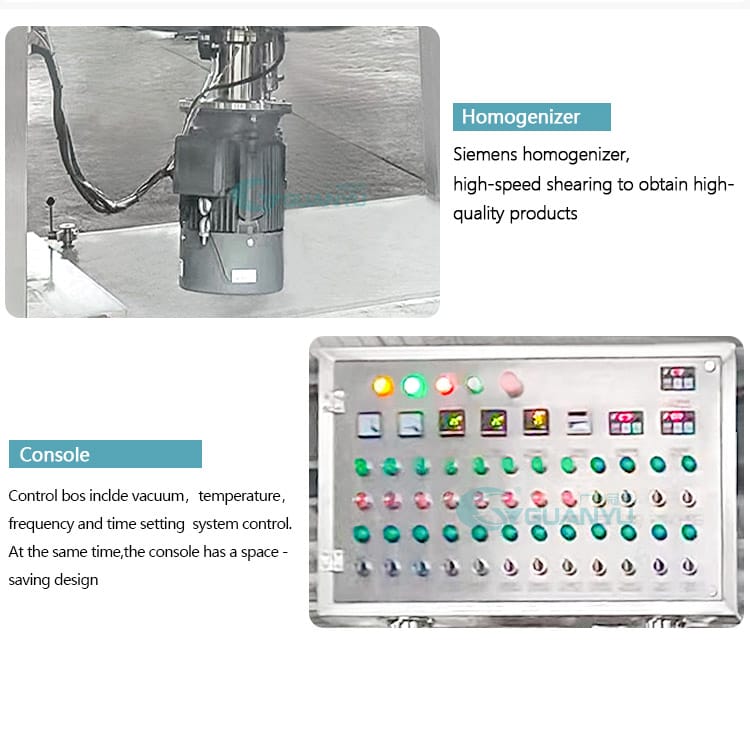

3. Intelligent Control System for Automated Operation

Der 3000L vacuum emulsifying mixer comes equipped with a SPS (Programmable Logic Controller) system, offering real-time monitoring and precise control over production parameters.

✅ Touchscreen interface: User-friendly operation with easy access to settings.

✅ Adjustable speed and temperature: Ensures precise control over mixing conditions.

✅ Automated vacuum system: Prevents oxidation and ensures product consistency.

4. GMP-Compliant Stainless Steel Construction

Built with 304/316L stainless steel, Die Guanyu 3000L vacuum emulsifying mixer meets international hygiene and safety standards for Essen, pharmazeutisch, and cosmetic production.

✅ Corrosion-resistant materials: Ensures long-term durability.

✅ CIP/SIP cleaning system: Allows for easy and effective cleaning to prevent contamination.

✅ Meets GMP standards: Complies with Good Manufacturing Practices for safe and hygienic production.

Applications of the 3000L Vakuumemulgiermischer

Thanks to its versatile emulsification technology, Guanyu’s 3000L vacuum emulsifying mixer is widely used across multiple industries:

1. Kosmetikindustrie

- Face creams, serums, Lotionen, sunscreens

- Toothpaste, Shampoo, conditioners

2. Food Industry

- Mayonnaise, salad dressings, Milchprodukte

- Chocolate spreads, sauces, beverages

3. Pharmaceutical Industry

- Ointments, Gele, medicated creams

- Disinfectants, Sirupe, topical solutions

4. Chemieindustrie

- Lubricants, Farben, coatings

- Emulsifiers, industrial additives

Whether producing personal care products, condiments, Arzneimittel, or industrial emulsions, Die Guanyu 3000L vacuum emulsifying mixer ensures consistent quality, high efficiency, and cost-effectiveness.

Maintenance & Care for the 3000L Vacuum Emulsifying Mixer

To keep the emulsifying mixer running at optimal efficiency, regular maintenance is essential.

1. Routine Cleaning

- Use the CIP (Clean-in-Place) automatic cleaning system to remove residues.

- Ensures hygienic and contamination-free production.

2. Seal and Gasket Inspection

- Regularly check and replace sealing components to prevent leakage.

- Maintains consistent vacuum pressure for high-quality emulsification.

3. Lubrication of Moving Parts

- Apply lubricating oil periodically to ensure smooth machine operation.

- Reduces wear and tear and extends machine lifespan.

4. Electrical System Maintenance

- Inspect the PLC control system and electrical components regularly.

- Prevents unexpected breakdowns and ensures reliable performance.

Proper maintenance enhances machine efficiency, reduces downtime, Und prolongs equipment lifespan.

Why Choose Guanyu’s 3000L Vacuum Emulsifier Mixer?

Guanyu has established itself as a global leader in emulsification equipment, offering advanced technology, custom solutions, and comprehensive support.

✅ Industry Expertise: Years of experience in designing high-performance emulsification systems.

✅ Customized Solutions: Offers tailor-made vacuum emulsifiers, homogenizers, and mixing systems.

✅ High-Quality Materials: Uses 304/316L stainless steel for long-term durability.

✅ Comprehensive After-Sales Support: Includes installation, training, and maintenance services.

Guanyu’s 3000L vacuum emulsifying mixer is the ideal choice for businesses seeking efficiency, reliability, and superior product quality.

FAQ: Common Questions About the 3000L Vacuum Emulsifying Machines

1. What is the standard voltage of the 3000L emulsifying mixer?

✅ The standard voltage is 380V/50Hz (three-phase), but custom voltage configurations are available.

2. How long does delivery take for the 3000L mixer?

✅ Standard models are shipped within 15-30 days, while customized models may require additional time.

3. Can the mixer handle high-viscosity products?

✅ Yes, Guanyu’s emulsifying mixer is specifically designed for high-viscosity materials, such as Cremes, pastes, and gels.

4. Can this mixer be customized for my industry?

✅ Absolutely! Guanyu provides customized solutions for Kosmetika, Essen, pharmazeutisch, and chemical applications.

5. Does Guanyu offer installation and training services?

✅ Yes, Guanyu provides full installation support, training, and after-sales service to ensure seamless operation.

Abschluss

Guanyu’s 3000L Vakuumemulgiermischer is a top-tier solution for large-scale industrial production, offering high-shear homogenization, vacuum technology, and automated control. Built to meet GMP standards, this machine ensures hygienic, efficient, and consistent emulsification for Kosmetika, Essen, Arzneimittel, and chemical industries.

👉 Looking for the best vacuum emulsifying mixer for your production needs? Contact Guanyu today!

Sultanbeyli su kaçağı tespiti Bodrumdaki su sızıntısını özel cihazlarla tespit ettiler. Kalıcı çözüm sundular. Necdet G. http://ruffeodrive.com/?p=34460

Güvercintepe su kaçak tespiti Apartmanımızdaki su kaçağını bulmak için gelen ekip çok deneyimliydi. Her detayı düşündüler. Serkan W. https://thesovereignstate.org/author/kacak/

**mindvault**

Mind Vault is a premium cognitive support formula created for adults 45+. It’s thoughtfully designed to help maintain clear thinking

**mind vault**

mind vault is a premium cognitive support formula created for adults 45+. It’s thoughtfully designed to help maintain clear thinking

**breathe**

breathe is a plant-powered tincture crafted to promote lung performance and enhance your breathing quality.

**breathe**

breathe is a plant-powered tincture crafted to promote lung performance and enhance your breathing quality.

Usually I do not read article on blogs however I would like to say that this writeup very compelled me to take a look at and do it Your writing style has been amazed me Thank you very nice article

Diuwincolourprediction – I’ve seen this around. Heard it can be fun if you’re into colour prediction games. Not my usual thing, but if you’re feeling lucky, might be worth a peek. Check them here:diuwincolourprediction

**backbiome**

backbiome is a naturally crafted, research-backed daily supplement formulated to gently relieve back tension and soothe sciatic discomfort.

**vivalis**

vivalis is a premium natural formula created to help men feel stronger, more energetic, and more confident every day.

**glycomute**

glycomute is a natural nutritional formula carefully created to nurture healthy blood sugar levels and support overall metabolic performance.

**balmorex**

balmorex is an exceptional solution for individuals who suffer from chronic joint pain and muscle aches.

**aquasculpt**

aquasculpt is a revolutionary supplement crafted to aid weight management by naturally accelerating metabolism

**nervecalm**

nervecalm is a high-quality nutritional supplement crafted to promote nerve wellness, ease chronic discomfort, and boost everyday vitality.

**synadentix**

synadentix is a dental health supplement created to nourish and protect your teeth and gums with a targeted combination of natural ingredients

**prostavive**

prostavive Maintaining prostate health is crucial for mens overall wellness, especially as they grow older.

**alpha boost**

alpha boost for men, feeling strong, energized, and confident is closely tied to overall quality of life. Jedoch, with age, stress, and daily demands

**yu sleep**

yusleep is a gentle, nano-enhanced nightly blend designed to help you drift off quickly, stay asleep longer, and wake feeling clear

**prodentim**

prodentim is a distinctive oral-care formula that pairs targeted probiotics with plant-based ingredients to encourage strong teeth

**gl pro**

glpro is a natural dietary supplement designed to promote balanced blood sugar levels and curb sugar cravings.

**mindvault**

mindvault is a premium cognitive support formula created for adults 45+.

**nitric boost ultra**

nitric boost is a daily wellness blend formulated to elevate vitality and support overall performance.

**femipro**

femipro is a dietary supplement developed as a natural remedy for women facing bladder control issues and seeking to improve their urinary health.

**vertiaid**

vertiaid is a high-quality, natural formula created to support stable balance, enhance mental sharpness, and alleviate feelings of dizziness

**vitrafoxin**

vitrafoxin is a premium brain enhancement formula crafted with natural ingredients to promote clear thinking, memory retention, and long-lasting mental energy.

**glucore**

glucore is a nutritional supplement that is given to patients daily to assist in maintaining healthy blood sugar and metabolic rates.

**sugarmute**

sugarmute is a science-guided nutritional supplement created to help maintain balanced blood sugar while supporting steady energy and mental clarity

**primebiome**

The natural cycle of skin cell renewal plays a vital role in maintaining a healthy and youthful appearance by shedding old cells and generating new ones.

**hepato burn**

hepatoburn is a high-quality, plant-forward dietary blend created to nourish liver function, encourage a healthy metabolic rhythm, and support the bodys natural fat-processing pathways.

**finessa**

Finessa is a natural supplement made to support healthy digestion, improve metabolism, and help you achieve a flatter belly.

**prodentim official website**

ProDentim is a distinctive oral-care formula that pairs targeted probiotics with plant-based ingredients to encourage strong teeth, comfortable gums, and reliably fresh breath

**aqua sculpt**

aquasculpt is a premium metabolism-support supplement thoughtfully developed to help promote efficient fat utilization and steadier daily energy.

**men balance pro**

MEN Balance Pro is a high-quality dietary supplement developed with research-informed support to help men maintain healthy prostate function.

**boostaro**

Boostaro is a purpose-built wellness formula created for men who want to strengthen vitality, confidence, and everyday performance.

Thanks for sharing. I read many of your blog posts, cool, your blog is very good. https://www.binance.com/register?ref=IXBIAFVY

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me? https://www.binance.com/bn/register?ref=WTOZ531Y