Soft paraffin, widely known as white soft paraffin or petroleum jelly, is a key ingredient in many products, ranging from skincare formulations to pharmaceuticals and industrial applications. The production of soft paraffin requires a careful and controlled process, where chemical reactors play a crucial role. This article discusses the significance of chemical reactors in the production process of soft paraffin and how they contribute to the efficiency and quality of the final product.

What Are Chemical Reactors?

Chemical reactors are specialized equipment designed to facilitate chemical reactions under controlled conditions. They allow for the mixing of raw materials, the promotion of specific chemical transformations, and the management of operational parameters such as temperature and pressure. In the context of soft paraffin production, these reactors are integral to refining petroleum derivatives to create a high-quality, usable product.

Key Processes in Soft Paraffin Production

- Crude Oil Processing: The journey of soft paraffin begins with the processing of crude oil. The initial step involves fractional distillation, where a chemical reactor separates the crude oil into different hydrocarbon fractions based on their boiling points. The heavier fractions are further processed to produce soft paraffin.

- Hydrogenation Process: Hydrogenation is a critical step where unsaturated hydrocarbons are converted into saturated hydrocarbons. In a chemical reactor, hydrogen gas is introduced into the mixture, often in the presence of a catalyst. This process enhances the stability and texture of soft paraffin, making it suitable for various applications.

- Refining Techniques: After hydrogenation, the resulting product must be purified to remove any remaining impurities. Chemical reactors are employed in refining techniques such as solvent extraction and filtration, ensuring the soft paraffin meets the required purity standards for commercial use.

- Blending for Enhanced Properties: 最后, chemical reactors are utilized for blending soft paraffin with other ingredients to improve its properties. This can involve the incorporation of additives like fragrances, moisturizers, or colorants. Quality control measures in the reactors ensure that the final product achieves the desired characteristics.

Benefits of Chemical Reactors in Production

Chemical reactors are essential in the manufacturing process of soft paraffin for several key reasons:

- 运营效率: Reactors allow for continuous production, optimizing resource use and minimizing downtime, which is vital for large-scale manufacturing operations.

- Precision Control: They enable precise control of reaction parameters, which is crucial for producing a consistent and high-quality product. This control minimizes variability and enhances product reliability.

- Adaptability: Chemical reactors can be easily scaled to meet varying production needs, providing manufacturers with the flexibility to respond to market changes and demand fluctuations.

- Enhanced Safety: Advanced chemical reactors are designed with safety features to manage the risks associated with chemical processing, ensuring a safe working environment for operators.

Guangzhou Guanyu Machinery Co., 有限公司: 超过二十年的卓越成就

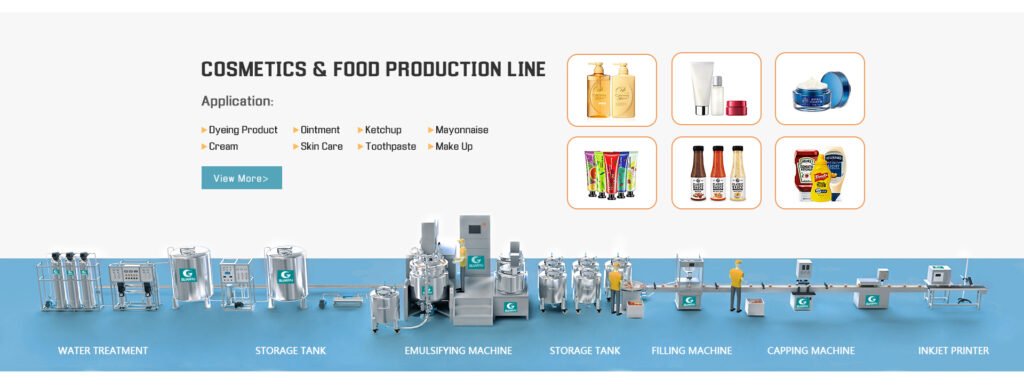

成立于 1997, Guangzhou Guanyu Machinery Co., 有限公司 花了二十多年完善设计, 发展, 高品质机械及生产线的制造. 我们的主要重点是服务于 化妆品, 食物, 和制药行业, 提供全面的生产解决方案,满足全球客户的多样化需求.

我们的成功建立在以下原则之上 创新, 质量, 和客户满意度. 我们提供端到端的解决方案, 从咨询和设备定制到工程安装和售后支持. 我们致力于技术进步和优质服务,使我们成为全球公司值得信赖的合作伙伴.

一站式解决方案: 从咨询到定制

我们的关键区别之一是我们能够提供 一站式解决方案 为我们的客户. 从最初的咨询到最终的安装, 我们确保流程的每一步都是根据客户的具体需求量身定制的. 我们解决方案的核心是 德国FLUKO和IKA技术, 行业内的两个领先品牌. 他们的先进技术构成了我们机械的支柱, 确保精度, 效率, 和耐用性.

我们的一站式方法结合了 咨询, 设备定制, 及工程安装, 使企业更容易实现生产目标. 我们已成功帮助众多国内外知名企业优化生产流程, 提高效率, 并推动创新. 通过提供 最完整的端到端生产线 在机械行业, 我们能够满足全球制造商的差异化需求,同时跟上快速的创新步伐.

无论是针对利基市场的小规模生产,还是针对大众分销的大规模制造, 我们的解决方案可以量身定制,以满足任何企业的独特需求. 我们的客户可以专注于扩大市场范围并保持领先于竞争对手, 同时我们通过创新和灵活的解决方案满足他们的生产需求.

Competitive Advantages of Guangzhou Guanyu Machinery Co., 有限公司

Since our establishment in 1997, Guangzhou Guanyu Machinery Co., Ltd has consistently been at the forefront of machinery development for the 化妆品, 食物, 和制药行业. Our strength lies in our ability to design, develop, and manufacture high-performance equipment that meets the exacting standards of these industries.

我们的 state-of-the-art production facilities include advanced testing and quality control systems that ensure the highest level of precision and performance in every piece of equipment we produce. This enables us to offer a wide range of machinery solutions that cater to the specific needs of our clients.

In addition to our robust technological infrastructure, we are supported by a highly skilled and experienced team of professionals who are committed to providing exceptional service at every stage of the process. From the initial consultation to the installation and after-sales support, we work closely with our clients to ensure that their production goals are met with precision and efficiency.

Customized Machinery for Every Need

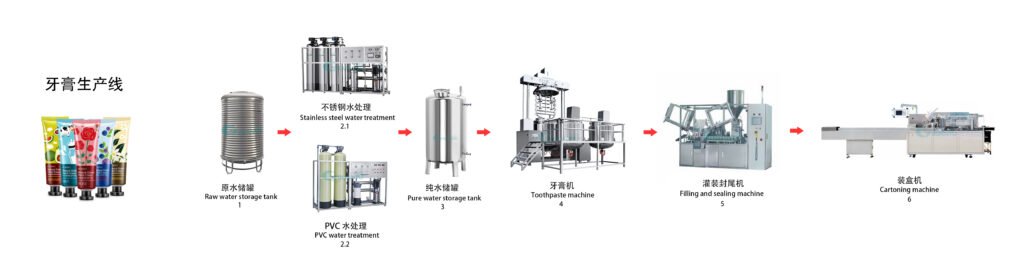

在 Guangzhou Guanyu Machinery Co., 有限公司, we understand that every business has unique requirements when it comes to their production processes. This is why we offer a broad range of customizable machinery designed to meet the diverse needs of our clients across various industries. Some of our key offerings include:

- 真空乳化均质搅拌机: Ideal for creating high-precision blends in the cosmetics and pharmaceutical industries. This machine offers excellent results in mixing and emulsifying even the most challenging formulations.

- 开式搅拌罐搅拌机搅拌机: Flexible mixing solutions suitable for a wide range of viscosities and materials. These machines are commonly used in both food and cosmetic production processes.

- 填充, 封盖, 标签, 和包装机: Our automated packaging systems are designed to streamline the production process, increasing efficiency and reducing labor costs while maintaining high levels of accuracy and quality.

- RO反渗透水处理系统: Our reverse osmosis systems are essential for achieving the highest levels of water purity, which is a critical requirement in the cosmetics, 制药, 和食品工业.

- 多种储罐类型: We offer a variety of storage solutions, including tanks for raw materials, 中间产品, 和成品, ensuring the safe and efficient handling of all production materials.

These machines are designed to be flexible, 高效的, and reliable, making them the perfect solution for businesses looking to optimize their production processes and stay competitive in today’s fast-paced market.

结论

综上所述, chemical reactors are fundamental to the production of soft paraffin, supporting each stage of the process from crude oil refinement to the creation of a stable, high-quality product. Their role in enhancing efficiency, 控制, and safety makes them indispensable in the manufacturing landscape, ensuring that soft paraffin meets the diverse needs of the cosmetics, 制药, and industrial sectors.

您的文章对我有很大帮助, 还有更多相关的内容吗? 谢谢!

谢谢你的分享. 我担心我缺乏创意. 这是您的文章使我充满希望. 谢谢. 但, 我有一个问题, 你能帮助我吗?

谢谢你的分享. 我担心我缺乏创意. 这是您的文章使我充满希望. 谢谢. 但, 我有一个问题, 你能帮助我吗?

您的文章对我有很大帮助, 还有更多相关的内容吗? 谢谢!

您的观点引起了我的注意,很有趣. 谢谢. 我有一个问题要问你.

我认为您文章的标题与内容不符. 只是在开玩笑, 主要是因为阅读文章后我有一些疑问.

谢谢你的分享. 我担心我缺乏创意. 这是您的文章使我充满希望. 谢谢. 但, 我有一个问题, 你能帮助我吗?

您的文章对我有很大帮助, 还有更多相关的内容吗? 谢谢!

我认为您文章的标题与内容不符. 只是在开玩笑, 主要是因为阅读文章后我有一些疑问.

我认为您文章的标题与内容不符. 只是在开玩笑, 主要是因为阅读文章后我有一些疑问.

感谢您的分享. 我读了您的许多博客文章, 凉爽的, 您的博客很好.

您可以更具体地对文章的内容更具体吗? 阅读后, 我仍然有疑问. 希望你能帮我.

您的观点引起了我的注意,很有趣. 谢谢. 我有一个问题要问你.

您的文章对我有很大帮助, 还有更多相关的内容吗? 谢谢!

您的文章对我有很大帮助, 还有更多相关的内容吗? 谢谢!

您的文章对我有很大帮助, 还有更多相关的内容吗? 谢谢!

我认为您文章的标题与内容不符. 只是在开玩笑, 主要是因为阅读文章后我有一些疑问.

您可以更具体地对文章的内容更具体吗? 阅读后, 我仍然有疑问. 希望你能帮我.

我认为您文章的标题与内容不符. 只是在开玩笑, 主要是因为阅读文章后我有一些疑问.

我认为您文章的标题与内容不符. 只是在开玩笑, 主要是因为阅读文章后我有一些疑问. https://accounts.binance.com/tr/register?ref=W0BCQMF1

您的观点引起了我的注意,很有趣. 谢谢. 我有一个问题要问你.

我认为您文章的标题与内容不符. 只是在开玩笑, 主要是因为阅读文章后我有一些疑问.

您的观点引起了我的注意,很有趣. 谢谢. 我有一个问题要问你.

感谢您的分享. 我读了您的许多博客文章, 凉爽的, 您的博客很好.

您的观点引起了我的注意,很有趣. 谢谢. 我有一个问题要问你.

我认为您文章的标题与内容不符. 只是在开玩笑, 主要是因为阅读文章后我有一些疑问.

谢谢你的分享. 我担心我缺乏创意. 这是您的文章使我充满希望. 谢谢. 但, 我有一个问题, 你能帮助我吗? https://www.binance.info/register?ref=P9L9FQKY

谢谢你的分享. 我担心我缺乏创意. 这是您的文章使我充满希望. 谢谢. 但, 我有一个问题, 你能帮助我吗? https://www.binance.com/id/register?ref=GJY4VW8W

我认为您文章的标题与内容不符. 只是在开玩笑, 主要是因为阅读文章后我有一些疑问. https://www.binance.info/hu/register-person?ref=FIHEGIZ8

您可以更具体地对文章的内容更具体吗? 阅读后, 我仍然有疑问. 希望你能帮我.

谢谢你的分享. 我担心我缺乏创意. 这是您的文章使我充满希望. 谢谢. 但, 我有一个问题, 你能帮助我吗? Rejestracja

感谢您的分享. 我读了您的许多博客文章, 凉爽的, 您的博客很好. 布南斯·雷斯特西亚

感谢您的分享. 我读了您的许多博客文章, 凉爽的, 您的博客很好.

您的观点引起了我的注意,很有趣. 谢谢. 我有一个问题要问你.

感谢您的分享. 我读了您的许多博客文章, 凉爽的, 您的博客很好.

您的文章对我有很大帮助, 还有更多相关的内容吗? 谢谢!

您的观点引起了我的注意,很有趣. 谢谢. 我有一个问题要问你.

您的观点引起了我的注意,很有趣. 谢谢. 我有一个问题要问你.

读你的文章对我帮助很大,我同意你的观点. 但我还是有一些疑问, 你能帮我解释一下吗? 我会留意你的答案.

您的观点引起了我的注意,很有趣. 谢谢. 我有一个问题要问你.

您的文章对我有很大帮助, 还有更多相关的内容吗? 谢谢!

您的文章对我有很大帮助, 还有更多相关的内容吗? 谢谢!

您的文章对我有很大帮助, 还有更多相关的内容吗? 谢谢!

谢谢你的分享. 我担心我缺乏创意. 这是您的文章使我充满希望. 谢谢. 但, 我有一个问题, 你能帮助我吗?

谢谢你的分享. 我担心我缺乏创意. 这是您的文章使我充满希望. 谢谢. 但, 我有一个问题, 你能帮助我吗?

您可以更具体地对文章的内容更具体吗? 阅读后, 我仍然有疑问. 希望你能帮我.

我认为您文章的标题与内容不符. 只是在开玩笑, 主要是因为阅读文章后我有一些疑问.

您的观点引起了我的注意,很有趣. 谢谢. 我有一个问题要问你. https://accounts.binance.info/en-IN/register-person?ref=UM6SMJM3

您可以更具体地对文章的内容更具体吗? 阅读后, 我仍然有疑问. 希望你能帮我. https://www.binance.info/lv/register?ref=PORL8W0Z

我认为您文章的标题与内容不符. 只是在开玩笑, 主要是因为阅读文章后我有一些疑问. https://www.binance.info/en-ZA/register?ref=B4EPR6J0

您的观点引起了我的注意,很有趣. 谢谢. 我有一个问题要问你.

我认为您文章的标题与内容不符. 只是在开玩笑, 主要是因为阅读文章后我有一些疑问. https://www.binance.com/register?ref=IHJUI7TF

您的观点引起了我的注意,很有趣. 谢谢. 我有一个问题要问你.

您可以更具体地对文章的内容更具体吗? 阅读后, 我仍然有疑问. 希望你能帮我.

Gamevip68, It’s alright and it’s got some good points but I wouldn’t go shouting from the rooftops about it. Worth a look I thought. Give it a go if you are bored for sure. To the website: gamevip68

我认为您文章的标题与内容不符. 只是在开玩笑, 主要是因为阅读文章后我有一些疑问.

感谢您的分享. 我读了您的许多博客文章, 凉爽的, 您的博客很好. https://www.binance.com/es/register?ref=RQUR4BEO

谢谢你的分享. 我担心我缺乏创意. 这是您的文章使我充满希望. 谢谢. 但, 我有一个问题, 你能帮助我吗?

谢谢 , I’ve just been looking for info about this topic for a while and yours is the greatest I’ve found out till now. 但, what concerning the conclusion? Are you positive in regards to the supply?

Good information. Lucky me I discovered your website by chance (stumbleupon). I’ve book-marked it for later!

Wow, that’s what I was seeking for, what a information! present here at this blog, thanks admin of this site.

Hurrah, that’s what I was looking for, what a data! present here at this web site, thanks admin of this site.

Hurrah, that’s what I was exploring for, what a stuff! present here at this website, thanks admin of this site.

Hurrah, that’s what I was seeking for, what a material! present here at this webpage, thanks admin of this web page.

Wow, that’s what I was searching for, what a data! present here at this web site, thanks admin of this web page.

Wow, that’s what I was looking for, what a information! present here at this website, thanks admin of this web page.

Wow, that’s what I was searching for, what a data! present here at this web site, thanks admin of this website.

Wow, that’s what I was exploring for, what a material! present here at this webpage, thanks admin of this website.

Hurrah, that’s what I was searching for, what a information! present here at this weblog, thanks admin of this web site.

Hurrah, that’s what I was searching for, what a material! existing here at this website, thanks admin of this site.

Wow, that’s what I was seeking for, what a information! existing here at this web site, thanks admin of this web page.

When I initially left a comment I appear to have clicked on the -Notify me when new comments are added- checkbox and now whenever a comment is added I receive 4 emails with the exact same comment. There has to be a way you can remove me from that service? 谢谢!

嘿! Someone in my Facebook group shared this website with us so I came

to give it a look. I’m definitely enjoying the information. I’m

bookmarking and will be tweeting this to my followers!

Wonderful blog and brilliant design.

After I initially left a comment I seem to have clicked the -Notify me when new comments are added- checkbox and from now on every time a comment is added I recieve four emails with the same comment. Is there an easy method you are able to remove me from that service? Many thanks!

When I originally left a comment I appear to have clicked on the -Notify me when new comments are added- checkbox and from now on each time a comment is added I recieve four emails with the exact same comment. There has to be a way you can remove me from that service? 谢谢!

After I originally commented I appear to have clicked the -Notify me when new comments are added- checkbox and now every time a comment is added I recieve four emails with the exact same comment. There has to be a way you can remove me from that service? 干杯!

After I originally commented I appear to have clicked the -Notify me when new comments are added- checkbox and from now on each time a comment is added I get four emails with the exact same comment. Is there a means you are able to remove me from that service? 谢谢!

After I originally commented I appear to have clicked the -Notify me when new comments are added- checkbox and now each time a comment is added I receive 4 emails with the same comment. There has to be a way you are able to remove me from that service? Kudos!

After I initially left a comment I appear to have clicked the -Notify me when new comments are added- checkbox and now each time a comment is added I get four emails with the exact same comment. Is there a means you are able to remove me from that service? Many thanks!

When I initially left a comment I seem to have clicked the -Notify me when new comments are added- checkbox and from now on every time a comment is added I get 4 emails with the exact same comment. Perhaps there is a means you can remove me from that service? 多谢!

When I initially commented I seem to have clicked the -Notify me when new comments are added- checkbox and now every time a comment is added I receive four emails with the exact same comment. Perhaps there is a means you are able to remove me from that service? 谢谢!

After I originally left a comment I appear to have clicked the -Notify me when new comments are added- checkbox and now every time a comment is added I get 4 emails with the same comment. Perhaps there is a means you are able to remove me from that service? 多谢!

你好呀! I could have sworn I’ve been to this site before but after browsing through some of the post I realized it’s new to me. Anyways, I’m definitely delighted I found it and I’ll be bookmarking and checking back frequently!

你好! I could have sworn I’ve been to this website before but after reading through some of the post I realized it’s new to me. Nonetheless, I’m definitely delighted I found it and I’ll be bookmarking and checking back often!

你好! I could have sworn I’ve been to this website before but after browsing through some of the post I realized it’s new to me. Anyways, I’m definitely delighted I found it and I’ll be book-marking and checking back frequently!

嘿! I could have sworn I’ve been to this blog before but after reading through some of the post I realized it’s new to me. Anyways, I’m definitely delighted I found it and I’ll be book-marking and checking back frequently!

Howdy! I could have sworn I’ve been to this site before but after browsing through some of the post I realized it’s new to me. Anyways, I’m definitely happy I found it and I’ll be book-marking and checking back frequently!

Hi there! I could have sworn I’ve been to this site before but after checking through some of the post I realized it’s new to me. Anyhow, I’m definitely delighted I found it and I’ll be bookmarking and checking back frequently!

Hi there! I could have sworn I’ve been to this website before but after checking through some of the post I realized it’s new to me. Nonetheless, I’m definitely happy I found it and I’ll be book-marking and checking back frequently!

Good day! I could have sworn I’ve been to this website before but after checking through some of the post I realized it’s new to me. Anyways, I’m definitely delighted I found it and I’ll be book-marking and checking back often!

感谢您的分享. 我读了您的许多博客文章, 凉爽的, 您的博客很好.

You actually make it seem so easy with your presentation but I find this topic to be actually something which I think I would never understand. It seems too complicated and extremely broad for me. I am looking forward for your next post, I will try to get the hang of it!

Hi everyone, it’s my first go to see at this website, and paragraph is really fruitful in favor of me, keep up posting these types of posts.

I have learn some just right stuff here. Certainly price bookmarking for revisiting. I surprise how much attempt you put to make one of these magnificent informative site.

Thank you for sharing your thoughts. I really appreciate your efforts and I will be waiting for your next post thank you once again.

Hey There. I found your blog using msn. This is an extremely well written article. I’ll be sure to bookmark it and come back to read more of your useful information. Thanks for the post. I’ll definitely return.

Very nice post. I just stumbled upon your blog and wished to say that I’ve truly enjoyed browsing your blog posts. After all I’ll be subscribing to your feed and I hope you write again very soon!

If you desire to grow your knowledge just keep visiting this website and be updated with the latest news update posted here.

I pay a quick visit everyday some web sites and information sites to read posts, but this website offers feature based content.

Inspiring story there. What occurred after? 谢谢!

I’ve been surfing online more than 4 hours today, yet I never found any interesting article like yours. It is pretty worth enough for me. 在我看来, if all web owners and bloggers made good content as you did, the web will be a lot more useful than ever before.

I for all time emailed this webpage post page to all my friends, for the reason that if like to read it afterward my friends will too.

Good day! This is kind of off topic but I need some guidance from an established blog. Is it very difficult to set up your own blog? I’m not very techincal but I can figure things out pretty quick. I’m thinking about creating my own but I’m not sure where to start. Do you have any tips or suggestions? With thanks

First of all I would like to say wonderful blog! I had a quick question which I’d like to ask if you do not mind. I was interested to know how you center yourself and clear your head prior to writing. I have had difficulty clearing my thoughts in getting my ideas out there. I truly do enjoy writing however it just seems like the first 10 到 15 minutes are lost just trying to figure out how to begin. Any recommendations or hints? 谢谢!

嘿! This post couldn’t be written any better! Reading through this post reminds me of my good old room mate! He always kept chatting about this. I will forward this article to him. Fairly certain he will have a good read. 谢谢你的分享!

你好呀! I simply wish to offer you a big thumbs up for the great information you’ve got right here on this post. I am coming back to your web site for more soon.

Pretty nice post. I simply stumbled upon your blog and wished to say that I’ve really enjoyed surfing around your weblog posts. After all I’ll be subscribing to your feed and I’m hoping you write once more very soon!

Article writing is also a fun, if you be familiar with after that you can write otherwise it is complex to write.

When I initially commented I clicked the “Notify me when new comments are added” checkbox and now each time a comment is added I get four e-mails with the same comment. Is there any way you can remove me from that service? 干杯!

I just like the helpful info you supply in your articles. I will bookmark your blog and take a look at once more right here frequently. I’m somewhat sure I will be told many new stuff right right here! Good luck for the following!

Hi there, You’ve done an excellent job. I’ll certainly digg it and personally recommend to my friends. I am confident they’ll be benefited from this web site.

你好, i read your blog from time to time and i own a similar one and i was just wondering if you get a lot of spam comments? If so how do you stop it, any plugin or anything you can advise? I get so much lately it’s driving me crazy so any help is very much appreciated.

谢谢你的分享. 我担心我缺乏创意. 这是您的文章使我充满希望. 谢谢. 但, 我有一个问题, 你能帮助我吗?

Hello Dear, are you actually visiting this web site on a regular basis, if so then you will absolutely take nice know-how.

Hi there! I know this is somewhat off topic but I was wondering if you knew where I could locate a captcha plugin for my comment form? I’m using the same blog platform as yours and I’m having difficulty finding one? 多谢!

I love it when individuals get together and share ideas. Great blog, continue the good work!

Do you mind if I quote a few of your posts as long as I provide credit and sources back to your blog? My website is in the very same area of interest as yours and my users would certainly benefit from some of the information you present here. Please let me know if this ok with you. 谢谢!

Hey There. I found your blog using msn. This is a really well written article. I’ll be sure to bookmark it and come back to read more of your useful info. Thanks for the post. I will certainly comeback.

I’m really enjoying the design and layout of your website. It’s a very easy on the eyes which makes it much more pleasant for me to come here and visit more often. Did you hire out a developer to create your theme? Excellent work!

excellent post, 信息非常丰富. I ponder why the other specialists of this sector don’t notice this. 你必须继续你的写作. I am confident, 你有大量的读者’ 已经基地了!

I always used to study post in news papers but now as I am a user of net therefore from now I am using net for posts, thanks to web.

I do not even know how I ended up here, but I thought this post was good. I don’t know who you are but definitely you are going to a famous blogger if you are not already 😉 Cheers!

When someone writes an paragraph he/she keeps the plan of a user in his/her mind that how a user can understand it. Therefore that’s why this piece of writing is outstdanding. 谢谢!

Good blog post. I certainly appreciate this site. Keep writing!

您的观点引起了我的注意,很有趣. 谢谢. 我有一个问题要问你.

Hi, I do think this is a great web site. I stumbledupon it 😉 I’m going to return yet again since I saved as a favorite it. Money and freedom is the best way to change, may you be rich and continue to guide others.

Tremendous things here. I’m very satisfied to look your post. Thanks a lot and I’m looking ahead to touch you. Will you kindly drop me a mail?

First of all I want to say great blog! I had a quick question which I’d like to ask if you do not mind. I was curious to know how you center yourself and clear your head before writing. I have had a hard time clearing my mind in getting my thoughts out there. I truly do enjoy writing but it just seems like the first 10 到 15 minutes are wasted simply just trying to figure out how to begin. Any ideas or hints? 谢谢!

Awesome things here. I am very glad to see your post. Thanks so much and I am looking ahead to touch you. Will you please drop me a e-mail?

May I simply say what a comfort to discover a person that truly knows what they’re talking about online. You actually realize how to bring a problem to light and make it important. More and more people have to check this out and understand this side of the story. I was surprised that you are not more popular since you surely possess the gift.

I was wondering if you ever thought of changing the layout of your blog? 写得很好; 我喜欢你所说的话. But maybe you could a little more in the way of content so people could connect with it better. Youve got an awful lot of text for only having one or 2 图片. 也许你可以把它分开得更好?

I was recommended this web site through my cousin. I’m now not positive whether this post is written by way of him as nobody else realize such special about my problem. You are amazing! 谢谢!

I think this is one of the most vital information for me. And i’m glad reading your article. But wanna remark on few general things, The website style is great, the articles is really great : D. Good job, cheers

Thanks a lot for sharing this with all people you actually understand what you’re speaking approximately! Bookmarked. Kindly also discuss with my website =). We will have a link trade arrangement between us

It’s really very complicated in this full of activity life to listen news on Television, therefore I just use internet for that reason, and take the most up-to-date news.

每个人都做什么, it’s truly a good for me to pay a quick visit this website, it consists of priceless Information.

Wonderful blog! Do you have any helpful hints for aspiring writers? I’m hoping to start my own website soon but I’m a little lost on everything. Would you advise starting with a free platform like WordPress or go for a paid option? There are so many options out there that I’m completely overwhelmed .. Any suggestions? Bless you!

What a data of un-ambiguity and preserveness of precious familiarity about unexpected emotions.

Hi there, I desire to subscribe for this weblog to obtain most up-to-date updates, so where can i do it please help.

Simply desire to say your article is as amazing. The clarity in your post is just excellent and i can assume you are an expert on this subject. Well with your permission let me to grab your RSS feed to keep up to date with forthcoming post. Thanks a million and please keep up the rewarding work.

我认为您文章的标题与内容不符. 只是在开玩笑, 主要是因为阅读文章后我有一些疑问.

This is the right web site for everyone who wishes to understand this topic.

You realize a whole lot its almost hard to argue with you (not that I actually would

want to…HaHa). You definitely put a brand new spin on a subject that has been written about for decades.

Excellent stuff, just excellent!

你好, I wish for to subscribe for this weblog to take latest

updates, so where can i do it please help out.

你好呀! This post could not be written any better!

Reading through this article reminds me of my previous roommate!

He continually kept talking about this. I most certainly will

send this information to him. Fairly certain he will have a great read.

I appreciate you for sharing!

Good day! Do you know if they make any plugins to protect against hackers?

I’m kinda paranoid about losing everything I’ve worked hard on. Any suggestions?

The other day, while I was at work, my cousin stole my iphone and tested to see if it can survive a forty foot drop, just so she can be a youtube sensation. My iPad is now destroyed and she has 83 views. I know this is completely off topic but I had to share it with someone!

日本 av – https://kanav.so

Highly descriptive blog, I loved that a lot. Will there be a part 2?

Hi there! Do you know if they make any plugins to assist with SEO? I’m trying to get my blog to rank for some targeted keywords but I’m not seeing very good success. If you know of any please share. 谢谢!

Have you ever thought about adding a little bit more than just your articles? I mean, what you say is important and all. But just imagine if you added some great photos or video clips to give your posts more, “pop”! Your content is excellent but with images and clips, this site could definitely be one of the best in its niche. Awesome blog!

Howdy! 这是我第一次访问你的博客! We are a team of volunteers and starting a new project in a community in the same niche. Your blog provided us beneficial information to work on. You have done a wonderful job!

I am now not positive where you’re getting your info, however great topic. I must spend a while studying much more or working out more. Thank you for wonderful information I used to be searching for this information for my mission.

Way cool! Some extremely valid points! I appreciate you writing this write-up plus the rest of the site is extremely good.

Do you have any video of that? I’d want to find out some additional information.

I know this website gives quality depending articles and additional information, is there any other site which presents these kinds of things in quality?

I must thank you for the efforts you have put in penning this website. I am hoping to check out the same high-grade content from you in the future as well. 实际上, your creative writing abilities has inspired me to get my own, personal website now 😉

Fantastic beat ! I wish to apprentice while you amend your website, how can i subscribe for a blog website? The account aided me a acceptable deal. I had been a little bit acquainted of this your broadcast offered bright clear idea

Please let me know if you’re looking for a article writer for your weblog. You have some really great articles and I think I would be a good asset. If you ever want to take some of the load off, I’d love to write some content for your blog in exchange for a link back to mine. Please blast me an e-mail if interested. Many thanks!

Spot on with this write-up, I absolutely feel this site needs much more attention. I’ll probably be back again to see more, thanks for the info!

Ahaa, its nice conversation about this piece of writing here at this blog, I have read all that, so now me also commenting at this place.

This is a very good tip particularly to those fresh to the blogosphere. Brief but very precise info… Appreciate your sharing this one. A must read post!

I am really loving the theme/design of your site. Do you ever run into any browser compatibility problems? A small number of my blog readers have complained about my site not operating correctly in Explorer but looks great in Firefox. Do you have any tips to help fix this issue?

您的文章对我有很大帮助, 还有更多相关的内容吗? 谢谢! https://www.binance.com/si-LK/register?ref=LBF8F65G

我认为您文章的标题与内容不符. 只是在开玩笑, 主要是因为阅读文章后我有一些疑问.

您的文章对我有很大帮助, 还有更多相关的内容吗? 谢谢! https://accounts.binance.com/register-person?ref=IHJUI7TF

谢谢你的分享. 我担心我缺乏创意. 这是您的文章使我充满希望. 谢谢. 但, 我有一个问题, 你能帮助我吗? https://www.binance.info/id/register?ref=UM6SMJM3

谢谢你的分享. 我担心我缺乏创意. 这是您的文章使我充满希望. 谢谢. 但, 我有一个问题, 你能帮助我吗? https://accounts.binance.com/zh-TC/register-person?ref=DCKLL1YD

I’m more than happy to discover this great site. I need to to thank you for ones time for this particularly fantastic read!! I definitely loved every part of it and I have you book marked to look at new information in your blog.

Hello everyone, it’s my first visit at this web site, and paragraph is genuinely fruitful designed for me, keep up posting these types of posts.

Wow that was strange. I just wrote an extremely long comment but after I clicked submit my comment didn’t appear. Grrrr… well I’m not writing all that over again. Regardless, just wanted to say great blog!

读你的文章对我帮助很大,我同意你的观点. 但我还是有一些疑问, 你能帮我解释一下吗? 我会留意你的答案.

您的文章对我有很大帮助, 还有更多相关的内容吗? 谢谢! https://accounts.binance.info/lv/register?ref=SMUBFN5I

您的观点引起了我的注意,很有趣. 谢谢. 我有一个问题要问你.

感谢您的分享. 我读了您的许多博客文章, 凉爽的, 您的博客很好.