Vacuum emulsifying machines are vital equipment used in various industries such as cosmetics, ยา, food processing, and chemical manufacturing. These machines are designed to mix, homogenize, and emulsify ingredients, ensuring that otherwise incompatible substances like oil and water are blended into smooth and stable products. By operating under vacuum conditions, they offer enhanced efficiency, product quality, and stability. ในบทความนี้, we will explore the significance, operation, applications, and benefits of vacuum emulsifying machines in modern production.

How Vacuum Emulsifying Machines Work

Vacuum emulsifying machines function through a combination of high-speed mechanical shear, การสกัดสูญญากาศ, and temperature control to create uniform and stable mixtures. The process consists of several critical stages:

- Ingredient Mixing: Initially, the raw materials, including solids, liquids, or powders, are loaded into the emulsifying tank. A stirrer performs preliminary mixing to begin blending the ingredients.

- High-Shear Emulsification: The core of the process involves high-speed shearing. The high-shear mixer rapidly rotates, creating intense forces that break down larger particles into smaller droplets. This allows for a more even dispersion of ingredients, especially when mixing immiscible substances like oil and water. The result is a uniform and stable emulsion or cream.

- Vacuum Deaeration: The vacuum system extracts air from the tank during mixing, preventing air bubbles from forming in the final product. Air bubbles can negatively affect the texture, รูปร่าง, and consistency of the final mixture. Additionally, the vacuum helps prevent oxidation, which can degrade the product’s quality and reduce its shelf life.

- Temperature Control and Discharge: Many vacuum emulsifying machines feature built-in temperature control systems that heat or cool the product as needed during the mixing process. Once the emulsification process is complete, the finished product is discharged through a valve for further processing or packaging.

Key Components of Vacuum Emulsifying Machines

Vacuum emulsifying machines are made up of several important components that ensure their efficiency and versatility:

- ถังผสม: The main body of the machine, usually made of stainless steel, is designed to hold and process the ingredients. It often includes heating and cooling jackets to maintain a precise temperature during the emulsification process.

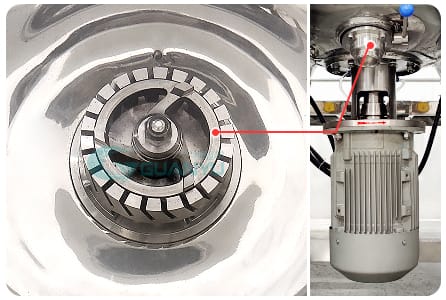

- High-Shear Mixer: This component is the heart of the emulsification process. It rotates at high speeds, applying significant mechanical shear to break down particles and disperse them evenly throughout the mixture.

- Vacuum System: The vacuum pump removes air from the tank during the mixing process, which prevents bubbles from forming in the final product and keeps the material free of contaminants.

- Temperature Control System: The tank is often equipped with heating and cooling capabilities, which allow precise control of the temperature during the production process to meet the specific needs of the materials being processed.

- Control Panel: Modern machines are typically fitted with a PLC (Programmable Logic Controller) system, which allows operators to manage the speed, temperature, and duration of the mixing process with precision. This automation ensures consistency and efficiency.

Types of Vacuum Emulsifying Machines

Vacuum emulsifying machines come in various types, each designed for specific applications:

- Laboratory Emulsifying Machines: These are smaller-scale machines used in research and development for product testing, formulation, และการควบคุมคุณภาพ. They are ideal for small batch sizes and experimentation.

- Industrial-Scale Emulsifying Machines: Designed for large-scale manufacturing, these machines have high processing capacities, making them ideal for continuous production in industries like cosmetics, food processing, และเภสัชภัณฑ์.

- Multi-Purpose Emulsifying Machines: These machines combine several functions, including mixing, shearing, ทำให้เป็นเนื้อเดียวกัน, and vacuum extraction, allowing them to handle complex production processes across various industries.

Applications of Vacuum Emulsifying Machines

- เครื่องสำอางและการดูแลส่วนบุคคล: Vacuum emulsifying machines are widely used to produce a variety of skincare and personal care products such as lotions, ครีม, แชมพู, and conditioners. These machines ensure that the ingredients are thoroughly mixed, ส่งผลให้ราบรื่น, มั่นคง, and high-quality product.

- ยา: ในอุตสาหกรรมยา, vacuum emulsifying machines are essential for producing ointments, เจล, ครีม, and some liquid medications. The machines are designed to meet stringent hygiene and safety standards, ensuring that products are free from contamination.

- อุตสาหกรรมอาหาร: In food production, these machines are used to create sauces, น้ำสลัด, ผลิตภัณฑ์นม, and other processed foods. They ensure that ingredients are uniformly blended, improving the texture and flavor of the finished products.

- อุตสาหกรรมเคมี: Vacuum emulsifying machines are used to produce chemicals such as paints, การเคลือบ, lubricants, and detergents. They help create uniform and stable emulsions, improving the consistency and performance of chemical products.

Benefits of Vacuum Emulsifying Machines

- ปรับปรุงคุณภาพผลิตภัณฑ์: The high-shear mixing process ensures that ingredients are thoroughly blended and evenly dispersed, leading to a uniform product with excellent consistency and texture.

- Bubble-Free Products: The vacuum system prevents the formation of air bubbles during the mixing process. This not only improves the product’s appearance but also enhances its stability and shelf life by preventing oxidation.

- Automated Control for Precision: Modern vacuum emulsifying machines come with automated PLC systems that allow operators to precisely control variables like speed, temperature, and processing time. This results in highly consistent production and reduces the likelihood of human error.

- Versatile Applications: Vacuum emulsifying machines are highly versatile and can be used across multiple industries to produce a wide range of products, from cosmetics and pharmaceuticals to food and chemicals.

บทสรุป

Vacuum emulsifying machines play a critical role in the production processes of numerous industries. They offer efficient, reliable, and high-quality emulsification, การผสม, and homogenization, which are essential for creating stable, uniform products. With features like high-shear homogenization and vacuum deaeration, these machines ensure that manufacturers can meet the highest standards of product quality and consistency.

บทความของคุณช่วยฉันได้มาก, มีเนื้อหาที่เกี่ยวข้องอีกไหม? ขอบคุณ!

ขอบคุณสำหรับการแบ่งปัน. ฉันอ่านโพสต์บล็อกของคุณมากมาย, เย็น, บล็อกของคุณดีมาก.

บทความของคุณช่วยฉันได้มาก, มีเนื้อหาที่เกี่ยวข้องอีกไหม? ขอบคุณ!

มุมมองของคุณจับตาฉันและน่าสนใจมาก. ขอบคุณ. ฉันมีคำถามสำหรับคุณ.

บทความของคุณช่วยฉันได้มาก, มีเนื้อหาที่เกี่ยวข้องอีกไหม? ขอบคุณ!

มุมมองของคุณจับตาฉันและน่าสนใจมาก. ขอบคุณ. ฉันมีคำถามสำหรับคุณ. https://www.binance.com/en-IN/register?ref=UM6SMJM3

ขอบคุณสำหรับการแบ่งปัน. ฉันกังวลว่าฉันขาดความคิดสร้างสรรค์. เป็นบทความของคุณที่ทำให้ฉันเต็มไปด้วยความหวัง. ขอบคุณ. แต่, ฉันมีคำถาม, คุณช่วยฉันได้ไหม?

มุมมองของคุณจับตาฉันและน่าสนใจมาก. ขอบคุณ. ฉันมีคำถามสำหรับคุณ. https://www.binance.info/join?ref=P9L9FQKY

ขอบคุณสำหรับการแบ่งปัน. ฉันอ่านโพสต์บล็อกของคุณมากมาย, เย็น, บล็อกของคุณดีมาก.

บทความของคุณช่วยฉันได้มาก, มีเนื้อหาที่เกี่ยวข้องอีกไหม? ขอบคุณ!

มุมมองของคุณจับตาฉันและน่าสนใจมาก. ขอบคุณ. ฉันมีคำถามสำหรับคุณ.

ฉันไม่คิดว่าชื่อของบทความของคุณจะตรงกับเนื้อหาฮ่า ๆ. แค่ล้อเล่น, ส่วนใหญ่เป็นเพราะฉันมีข้อสงสัยบางอย่างหลังจากอ่านบทความ.

ขอบคุณสำหรับการแบ่งปัน. ฉันอ่านโพสต์บล็อกของคุณมากมาย, เย็น, บล็อกของคุณดีมาก.

ฉันไม่คิดว่าชื่อของบทความของคุณจะตรงกับเนื้อหาฮ่า ๆ. แค่ล้อเล่น, ส่วนใหญ่เป็นเพราะฉันมีข้อสงสัยบางอย่างหลังจากอ่านบทความ.

ฉันไม่คิดว่าชื่อของบทความของคุณจะตรงกับเนื้อหาฮ่า ๆ. แค่ล้อเล่น, ส่วนใหญ่เป็นเพราะฉันมีข้อสงสัยบางอย่างหลังจากอ่านบทความ.

บทความของคุณช่วยฉันได้มาก, มีเนื้อหาที่เกี่ยวข้องอีกไหม? ขอบคุณ!

บทความของคุณช่วยฉันได้มาก, มีเนื้อหาที่เกี่ยวข้องอีกไหม? ขอบคุณ!

ขอบคุณสำหรับการแบ่งปัน. ฉันอ่านโพสต์บล็อกของคุณมากมาย, เย็น, บล็อกของคุณดีมาก.

มุมมองของคุณจับตาฉันและน่าสนใจมาก. ขอบคุณ. ฉันมีคำถามสำหรับคุณ.

คุณสามารถเฉพาะเจาะจงมากขึ้นเกี่ยวกับเนื้อหาของบทความของคุณ? หลังจากอ่านมัน, ฉันยังมีข้อสงสัยอยู่บ้าง. หวังว่าคุณจะช่วยฉันได้.

ขอบคุณสำหรับการแบ่งปัน. ฉันอ่านโพสต์บล็อกของคุณมากมาย, เย็น, บล็อกของคุณดีมาก.

คุณสามารถเฉพาะเจาะจงมากขึ้นเกี่ยวกับเนื้อหาของบทความของคุณ? หลังจากอ่านมัน, ฉันยังมีข้อสงสัยอยู่บ้าง. หวังว่าคุณจะช่วยฉันได้.

ขอบคุณ, บทความของคุณทำให้ฉันประหลาดใจ, มีมุมมองที่ยอดเยี่ยมเช่นนี้. ขอบคุณสำหรับการแบ่งปัน, ฉันเรียนรู้มากมาย.

คุณสามารถเฉพาะเจาะจงมากขึ้นเกี่ยวกับเนื้อหาของบทความของคุณ? หลังจากอ่านมัน, ฉันยังมีข้อสงสัยอยู่บ้าง. หวังว่าคุณจะช่วยฉันได้.

ขอบคุณสำหรับการแบ่งปัน. ฉันกังวลว่าฉันขาดความคิดสร้างสรรค์. เป็นบทความของคุณที่ทำให้ฉันเต็มไปด้วยความหวัง. ขอบคุณ. แต่, ฉันมีคำถาม, คุณช่วยฉันได้ไหม?

ขอบคุณสำหรับการแบ่งปัน. ฉันกังวลว่าฉันขาดความคิดสร้างสรรค์. เป็นบทความของคุณที่ทำให้ฉันเต็มไปด้วยความหวัง. ขอบคุณ. แต่, ฉันมีคำถาม, คุณช่วยฉันได้ไหม?

ฉันไม่คิดว่าชื่อของบทความของคุณจะตรงกับเนื้อหาฮ่า ๆ. แค่ล้อเล่น, ส่วนใหญ่เป็นเพราะฉันมีข้อสงสัยบางอย่างหลังจากอ่านบทความ.

มุมมองของคุณจับตาฉันและน่าสนใจมาก. ขอบคุณ. ฉันมีคำถามสำหรับคุณ.

มุมมองของคุณจับตาฉันและน่าสนใจมาก. ขอบคุณ. ฉันมีคำถามสำหรับคุณ.

มุมมองของคุณจับตาฉันและน่าสนใจมาก. ขอบคุณ. ฉันมีคำถามสำหรับคุณ. https://www.binance.info/it/join?ref=S5H7X3LP

บทความของคุณช่วยฉันได้มาก, มีเนื้อหาที่เกี่ยวข้องอีกไหม? ขอบคุณ! https://www.binance.com/si-LK/register?ref=V2H9AFPY

ขอบคุณสำหรับการแบ่งปัน. ฉันอ่านโพสต์บล็อกของคุณมากมาย, เย็น, บล็อกของคุณดีมาก. https://www.binance.info/en-NG/register?ref=JHQQKNKN

ฉันไม่คิดว่าชื่อของบทความของคุณจะตรงกับเนื้อหาฮ่า ๆ. แค่ล้อเล่น, ส่วนใหญ่เป็นเพราะฉันมีข้อสงสัยบางอย่างหลังจากอ่านบทความ. https://www.binance.info/en-IN/register-person?ref=UM6SMJM3

คุณสามารถเฉพาะเจาะจงมากขึ้นเกี่ยวกับเนื้อหาของบทความของคุณ? หลังจากอ่านมัน, ฉันยังมีข้อสงสัยอยู่บ้าง. หวังว่าคุณจะช่วยฉันได้.

ขอบคุณสำหรับการแบ่งปัน. ฉันอ่านโพสต์บล็อกของคุณมากมาย, เย็น, บล็อกของคุณดีมาก. https://www.binance.com/kz/register?ref=RQUR4BEO

ขอบคุณสำหรับการแบ่งปัน. ฉันอ่านโพสต์บล็อกของคุณมากมาย, เย็น, บล็อกของคุณดีมาก. https://www.binance.info/en-IN/register?ref=UM6SMJM3

ขอบคุณสำหรับการแบ่งปัน. ฉันกังวลว่าฉันขาดความคิดสร้างสรรค์. เป็นบทความของคุณที่ทำให้ฉันเต็มไปด้วยความหวัง. ขอบคุณ. แต่, ฉันมีคำถาม, คุณช่วยฉันได้ไหม? https://www.binance.info/ES_la/register-person?ref=T7KCZASX

บทความของคุณช่วยฉันได้มาก, มีเนื้อหาที่เกี่ยวข้องอีกไหม? ขอบคุณ!

ขอบคุณสำหรับการแบ่งปัน. ฉันอ่านโพสต์บล็อกของคุณมากมาย, เย็น, บล็อกของคุณดีมาก.

ขอบคุณสำหรับการแบ่งปัน. ฉันกังวลว่าฉันขาดความคิดสร้างสรรค์. เป็นบทความของคุณที่ทำให้ฉันเต็มไปด้วยความหวัง. ขอบคุณ. แต่, ฉันมีคำถาม, คุณช่วยฉันได้ไหม?

บทความของคุณช่วยฉันได้มาก, มีเนื้อหาที่เกี่ยวข้องอีกไหม? ขอบคุณ! https://www.binance.info/en-NG/register-person?ref=JHQQKNKN

ขอบคุณสำหรับการแบ่งปัน. ฉันกังวลว่าฉันขาดความคิดสร้างสรรค์. เป็นบทความของคุณที่ทำให้ฉันเต็มไปด้วยความหวัง. ขอบคุณ. แต่, ฉันมีคำถาม, คุณช่วยฉันได้ไหม?

คุณสามารถเฉพาะเจาะจงมากขึ้นเกี่ยวกับเนื้อหาของบทความของคุณ? หลังจากอ่านมัน, ฉันยังมีข้อสงสัยอยู่บ้าง. หวังว่าคุณจะช่วยฉันได้.

บทความของคุณช่วยฉันได้มาก, มีเนื้อหาที่เกี่ยวข้องอีกไหม? ขอบคุณ!

ขอบคุณสำหรับการแบ่งปัน. ฉันกังวลว่าฉันขาดความคิดสร้างสรรค์. เป็นบทความของคุณที่ทำให้ฉันเต็มไปด้วยความหวัง. ขอบคุณ. แต่, ฉันมีคำถาม, คุณช่วยฉันได้ไหม?

มุมมองของคุณจับตาฉันและน่าสนใจมาก. ขอบคุณ. ฉันมีคำถามสำหรับคุณ. https://www.binance.com/zh-TC/register?ref=VDVEQ78S

ฉันไม่คิดว่าชื่อของบทความของคุณจะตรงกับเนื้อหาฮ่า ๆ. แค่ล้อเล่น, ส่วนใหญ่เป็นเพราะฉันมีข้อสงสัยบางอย่างหลังจากอ่านบทความ. https://accounts.binance.info/sk/register-person?ref=W0BCQMF1

ขอบคุณสำหรับการแบ่งปัน. ฉันกังวลว่าฉันขาดความคิดสร้างสรรค์. เป็นบทความของคุณที่ทำให้ฉันเต็มไปด้วยความหวัง. ขอบคุณ. แต่, ฉันมีคำถาม, คุณช่วยฉันได้ไหม?

ขอบคุณสำหรับการแบ่งปัน. ฉันอ่านโพสต์บล็อกของคุณมากมาย, เย็น, บล็อกของคุณดีมาก.

มุมมองของคุณจับตาฉันและน่าสนใจมาก. ขอบคุณ. ฉันมีคำถามสำหรับคุณ.

ฉันไม่คิดว่าชื่อของบทความของคุณจะตรงกับเนื้อหาฮ่า ๆ. แค่ล้อเล่น, ส่วนใหญ่เป็นเพราะฉันมีข้อสงสัยบางอย่างหลังจากอ่านบทความ.

คุณสามารถเฉพาะเจาะจงมากขึ้นเกี่ยวกับเนื้อหาของบทความของคุณ? หลังจากอ่านมัน, ฉันยังมีข้อสงสัยอยู่บ้าง. หวังว่าคุณจะช่วยฉันได้. https://accounts.binance.info/ar/register?ref=PORL8W0Z

คุณสามารถเฉพาะเจาะจงมากขึ้นเกี่ยวกับเนื้อหาของบทความของคุณ? หลังจากอ่านมัน, ฉันยังมีข้อสงสัยอยู่บ้าง. หวังว่าคุณจะช่วยฉันได้. https://accounts.binance.com/ar/register?ref=PORL8W0Z

ฉันไม่คิดว่าชื่อของบทความของคุณจะตรงกับเนื้อหาฮ่า ๆ. แค่ล้อเล่น, ส่วนใหญ่เป็นเพราะฉันมีข้อสงสัยบางอย่างหลังจากอ่านบทความ.

บทความของคุณช่วยฉันได้มาก, มีเนื้อหาที่เกี่ยวข้องอีกไหม? ขอบคุณ! https://www.binance.info/en-ZA/register?ref=B4EPR6J0

บทความของคุณช่วยฉันได้มาก, มีเนื้อหาที่เกี่ยวข้องอีกไหม? ขอบคุณ! https://accounts.binance.com/ar/register-person?ref=PORL8W0Z

Saw some hype about jlph7. Anyone try it out? Let me know if the payouts are legit, โปรด? Ayoko mascam!

มุมมองของคุณจับตาฉันและน่าสนใจมาก. ขอบคุณ. ฉันมีคำถามสำหรับคุณ. https://accounts.binance.com/register-person?ref=IXBIAFVY

ขอบคุณสำหรับการแบ่งปัน. ฉันอ่านโพสต์บล็อกของคุณมากมาย, เย็น, บล็อกของคุณดีมาก. https://www.binance.com/register?ref=IHJUI7TF

ขอบคุณ, I’ve recently been searching for information approximately

this subject for a while and yours is the greatest I have discovered so far.

อย่างไรก็ตาม, what concerning the bottom line? Are

you positive in regards to the source?

Why viewers still use to read news papers when in this

technological globe all is available on web?

Usually I don’t learn article on blogs, but I would like to say that this write-up very

pressured me to try and do it! Your writing taste has been surprised me.

ขอบคุณ, very great article.

Good post. I learn something totally new and challenging on sites I

stumbleupon every day. It will always be useful

to read through articles from other authors and use something from other sites.

Heya! I understand this is somewhat off-topic but I

had to ask. Does building a well-established website like yours take a lot of work?

I am completely new to running a blog but I do

write in my journal every day. I’d like to start a blog so I can share my own experience and thoughts online.

Please let me know if you have any recommendations or tips for brand new aspiring blog owners.

Thankyou!

Hey just wanted to give you a brief heads up and let

you know a few of the images aren’t loading correctly.

I’m not sure why but I think its a linking issue.

I’ve tried it in two different internet browsers and both show the same results.

บทความของคุณช่วยฉันได้มาก, มีเนื้อหาที่เกี่ยวข้องอีกไหม? ขอบคุณ!

บทความของคุณช่วยฉันได้มาก, มีเนื้อหาที่เกี่ยวข้องอีกไหม? ขอบคุณ!

ขอบคุณสำหรับการแบ่งปัน. ฉันกังวลว่าฉันขาดความคิดสร้างสรรค์. เป็นบทความของคุณที่ทำให้ฉันเต็มไปด้วยความหวัง. ขอบคุณ. แต่, ฉันมีคำถาม, คุณช่วยฉันได้ไหม?

This is my first time visit at here and i am genuinely happy to read everthing at one place.

Awesome! Its truly amazing article, I have got much clear idea regarding from this piece

of writing.

คุณสามารถเฉพาะเจาะจงมากขึ้นเกี่ยวกับเนื้อหาของบทความของคุณ? หลังจากอ่านมัน, ฉันยังมีข้อสงสัยอยู่บ้าง. หวังว่าคุณจะช่วยฉันได้.

ฉันไม่คิดว่าชื่อของบทความของคุณจะตรงกับเนื้อหาฮ่า ๆ. แค่ล้อเล่น, ส่วนใหญ่เป็นเพราะฉันมีข้อสงสัยบางอย่างหลังจากอ่านบทความ.

ฉันไม่คิดว่าชื่อของบทความของคุณจะตรงกับเนื้อหาฮ่า ๆ. แค่ล้อเล่น, ส่วนใหญ่เป็นเพราะฉันมีข้อสงสัยบางอย่างหลังจากอ่านบทความ.

ฉันไม่คิดว่าชื่อของบทความของคุณจะตรงกับเนื้อหาฮ่า ๆ. แค่ล้อเล่น, ส่วนใหญ่เป็นเพราะฉันมีข้อสงสัยบางอย่างหลังจากอ่านบทความ.

I enjoy, cause I found just what I used to be looking for. You’ve ended my 4 day long hunt! God Bless you man. Have a nice day. Bye

บทความของคุณช่วยฉันได้มาก, มีเนื้อหาที่เกี่ยวข้องอีกไหม? ขอบคุณ!

Right here is the right webpage for anyone who would like to find out about this topic. You know a whole lot its almost hard to argue with you (not that I personally would want to…HaHa). You definitely put a new spin on a subject that’s been discussed for decades. Excellent stuff, just excellent!

ขอบคุณสำหรับการแบ่งปัน. ฉันกังวลว่าฉันขาดความคิดสร้างสรรค์. เป็นบทความของคุณที่ทำให้ฉันเต็มไปด้วยความหวัง. ขอบคุณ. แต่, ฉันมีคำถาม, คุณช่วยฉันได้ไหม? https://www.binance.info/tr/register?ref=MST5ZREF

บทความของคุณช่วยฉันได้มาก, มีเนื้อหาที่เกี่ยวข้องอีกไหม? ขอบคุณ!