มัสตาร์ดเป็นหนึ่งในเครื่องปรุงรสที่ได้รับความนิยมมากที่สุดในโลก, เป็นที่รู้จักในเรื่องรสชาติและความเก่งกาจที่เป็นเอกลักษณ์. ในขณะที่หามัสตาร์ดบนชั้นวางของร้านค้าได้ง่าย, กระบวนการผลิตในขนาดใหญ่นั้นค่อนข้างซับซ้อน, ต้องใช้เครื่องจักรพิเศษและขั้นตอนที่แม่นยำเพื่อให้แน่ใจว่าคุณภาพและความสอดคล้อง. กวนอู, ผู้ผลิตอุปกรณ์แปรรูปอาหารชั้นนำ, ให้บริการโซลูชั่นที่ทันสมัยสำหรับการผลิตมัสตาร์ดขนาดใหญ่. ในคู่มือนี้, เราจะสำรวจแต่ละขั้นตอนที่เกี่ยวข้องในการผลิตโรงงานมัสตาร์ด, มุ่งเน้นไปที่เครื่องจักรและกระบวนการที่ช่วยนำเครื่องปรุงรสนี้มาสู่ชีวิต.

ส่วนผสมที่สำคัญในมัสตาร์ดที่ทำจากโรงงาน

การผลิตมัสตาร์ดคุณภาพสูงเริ่มต้นด้วยการเลือกส่วนผสมที่เหมาะสม. แต่ละส่วนผสมในมัสตาร์ดมีบทบาทเฉพาะในรสชาติของมัน, ความสม่ำเสมอ, และอายุการเก็บรักษา:

- เมล็ดมัสตาร์ด: ฐานของสูตรมัสตาร์ดใด ๆ, เมล็ดมัสตาร์ดอาจเป็นสีเหลือง, สีน้ำตาล, หรือสีดำ. เมล็ดแต่ละประเภทมีโปรไฟล์รสชาติที่แตกต่างกัน, จากอ่อนและหวานเล็กน้อย (เมล็ดสีเหลือง) คมชัดและฉุน (เมล็ดสีน้ำตาลและสีดำ).

- น้ำส้มสายชู: น้ำส้มสายชูไม่เพียง แต่ให้การสัมผัส แต่ยังทำหน้าที่เป็นสารกันบูด, ยืดอายุการเก็บรักษาของผลิตภัณฑ์. ช่วยให้รสชาติมีเสถียรภาพและรักษาคุณภาพของมัสตาร์ดที่สดใหม่.

- น้ำ: น้ำเป็นสิ่งจำเป็นสำหรับการควบคุมพื้นผิวของมัสตาร์ด. นอกจากนี้ยังมีผลต่อระดับความร้อนในมัสตาร์ดโดยปล่อยเอนไซม์ที่นำไปสู่ความเผ็ดร้อน.

- เกลือและเครื่องเทศ: เกลือช่วยเพิ่มรสชาติโดยรวม, ในขณะที่เครื่องเทศเช่นขมิ้น, ผงกระเทียม, และปาปริก้ามักจะเพิ่มเพื่อให้มัสตาร์ดสีที่โดดเด่นและชั้นรสชาติเพิ่มเติม.

- ความคงตัวและสารกันบูด: ความคงตัวใช้เพื่อป้องกันการแยกส่วนผสม, โดยเฉพาะอย่างยิ่งในช่วงระยะเวลาการจัดเก็บที่ยาวนาน, ในขณะที่สารกันบูดช่วยยืดอายุการเก็บรักษาของผลิตภัณฑ์โดยไม่ลดระดับคุณภาพ.

กระบวนการผลิตมัสตาร์ดทีละขั้นตอน

การผลิตมัสตาร์ดในระดับอุตสาหกรรมเกี่ยวข้องกับหลายขั้นตอนสำคัญ. แต่ละขั้นตอนได้รับการสนับสนุนโดยอุปกรณ์พิเศษจาก Guanyu, สร้างความมั่นใจในประสิทธิภาพ, ความสม่ำเสมอ, และคุณภาพ.

1. การทำความสะอาดและเรียงลำดับเมล็ดมัสตาร์ด

กระบวนการเริ่มต้นด้วยการทำความสะอาดและการเรียงลำดับเมล็ดมัสตาร์ด. เมล็ดดิบมักจะมีสิ่งสกปรกเช่นฝุ่นละออง, หิน, และอนุภาคอื่น ๆ. ในโรงงาน, เครื่องทำความสะอาดเมล็ดพันธุ์และการเรียงลำดับของ Guanyu ใช้เพื่อลบสิ่งเจือปนเหล่านี้โดยอัตโนมัติ. ขั้นตอนนี้เป็นสิ่งจำเป็นสำหรับการบรรลุความราบรื่น, วางมัสตาร์ดที่สอดคล้องกับการปนเปื้อนน้อยที่สุด.

เครื่องเรียงลำดับที่มีประสิทธิภาพสูงจาก Guanyu ตรวจสอบให้แน่ใจว่ามีเฉพาะเมล็ดพันธุ์ที่ดีที่สุดเท่านั้น, เพิ่มรสชาติและคุณภาพของผลิตภัณฑ์ขั้นสุดท้าย.

2. บดเมล็ดมัสตาร์ด

เมื่อทำความสะอาด, เมล็ดมัสตาร์ดจะบดลงในแป้งหรือผง. ขั้นตอนนี้เป็นสิ่งสำคัญสำหรับการปล่อยน้ำมันธรรมชาติและรสชาติจากเมล็ด. วิธีการบดส่งผลกระทบต่อพื้นผิวสุดท้ายของมัสตาร์ด - ผู้ผลิตบางรายอาจชอบการบดหยาบเพื่อความรู้สึกแบบชนบท, ในขณะที่คนอื่นเลือกที่จะวางดีกว่า.

Guanyu's โรงงานคอลลอยด์และเครื่องบด เหมาะสำหรับขั้นตอนนี้. พวกเขาได้รับการออกแบบมาเพื่อประมวลผลเมล็ดมัสตาร์ดในปริมาณมากอย่างรวดเร็วและมีประสิทธิภาพ, ผลิตปรับ, เครื่องแบบที่เหมาะสำหรับการสร้างวางที่ราบรื่น. ความแม่นยำของอุปกรณ์บดของ Guanyu ช่วยให้มั่นใจได้ว่ามีความสอดคล้องกันทั่วทั้งแบทช์.

3. ส่วนผสมผสม

มัสตาร์ดพื้นดินจะผสมกับน้ำส้มสายชู, น้ำ, เกลือ, และเครื่องเทศอื่น ๆ เพื่อสร้างส่วนผสมพื้นฐาน. การผสมที่แม่นยำเป็นสิ่งจำเป็นสำหรับการบรรลุรสชาติและพื้นผิวที่สอดคล้องกัน, เนื่องจากความไม่สมดุลของส่วนผสมสามารถเปลี่ยนแปลงรสชาติของผลิตภัณฑ์ขั้นสุดท้ายได้.

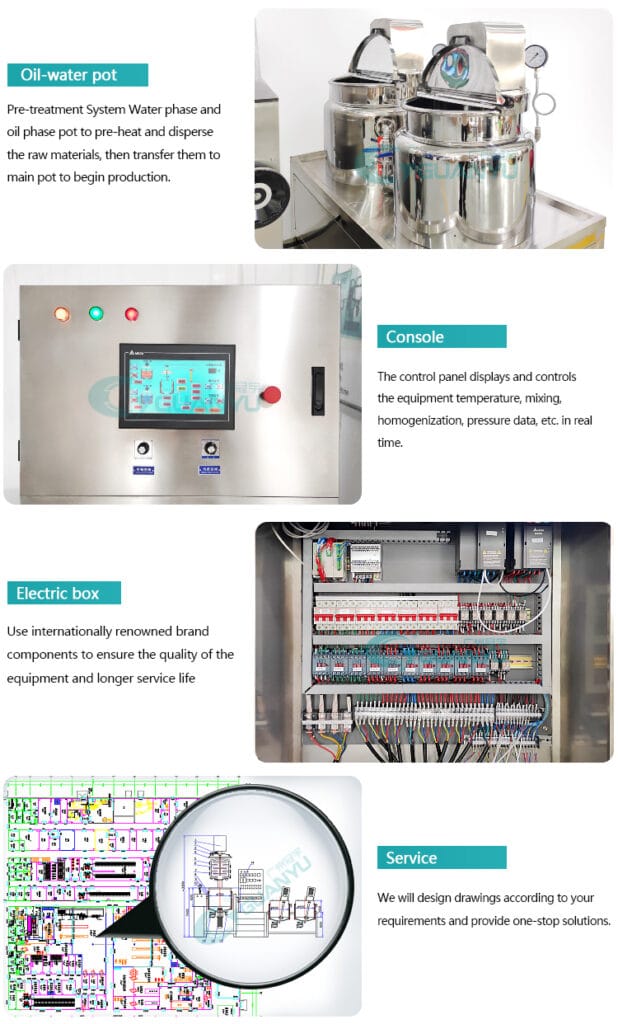

ถังผสมของ Guanyu มีการติดตั้งมิกเซอร์ความเร็วสูงและระบบควบคุมอุณหภูมิที่อนุญาตให้เข้าร่วมการรวมตัวกันได้อย่างแม่นยำ. รถถังได้รับการออกแบบมาเพื่อรองรับความหนืดที่แตกต่างกัน, สร้างความมั่นใจในการผสมผสานที่เป็นเนื้อเดียวกันที่ตรงกับพื้นผิวที่ต้องการ, ไม่ว่าจะเรียบหรือเป็นเม็ดเล็ก ๆ น้อย ๆ. โซลูชั่นการผสมของ Guanyu เหมาะสำหรับการผสมผสานส่วนผสมต่าง ๆ ให้ละเอียด, ทำให้กระบวนการผลิตมีประสิทธิภาพและเชื่อถือได้มากขึ้น.

4. อิมัลชันและการทำให้เป็นเนื้อเดียวกัน

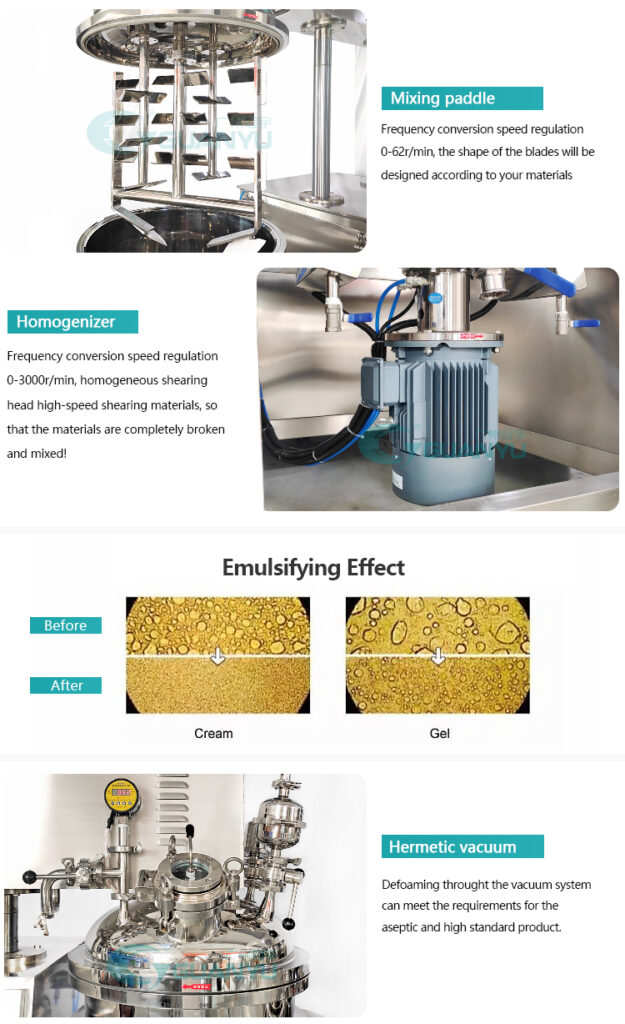

หลังจากผสม, ส่วนผสมของมัสตาร์ดผ่านอิมัลชันหรือทำให้เป็นเนื้อเดียวกัน. กระบวนการนี้ทำให้มั่นใจได้ว่าส่วนผสมทั้งหมดจะรวมเข้าด้วยกันอย่างสมบูรณ์และป้องกันการแยก. การทำให้เป็นเนื้อเดียวกันเป็นสิ่งสำคัญอย่างยิ่งสำหรับการบรรลุความราบรื่น, พื้นผิวที่มั่นคง, ในขณะที่มันลดขนาดอนุภาคของของแข็งที่เหลืออยู่.

Guanyu's homogenizers เฉือนสูง ได้รับการออกแบบมาเป็นพิเศษสำหรับการใช้งานการแปรรูปอาหาร. พวกเขาแบ่งอนุภาคให้อยู่ในระดับกล้องจุลทรรศน์, การสร้างอิมัลชันที่มีเสถียรภาพซึ่งรวมอยู่ด้วยกันเมื่อเวลาผ่านไป. ขั้นตอนนี้มีความสำคัญสำหรับการผลิตมัสตาร์ดที่ไม่ได้แยกในขวดและมีลักษณะและพื้นผิวที่เหมือนกัน.

5. การบำบัดความร้อนหรือการพาสเจอร์ไรซ์

เพื่อให้แน่ใจว่ามัสตาร์ดปลอดภัยสำหรับการบริโภคและมีอายุการเก็บรักษาขยาย, ผู้ผลิตหลายรายใช้การบำบัดความร้อนหรือการพาสเจอร์ไรซ์กับส่วนผสม. การฆ่าเชื้อโรคฆ่าแบคทีเรียที่เป็นอันตรายและขยายความสดของมัสตาร์ดโดยไม่ส่งผลกระทบต่อรสชาติ.

Guanyu's อุปกรณ์พาสเจอร์ไรส์ เสนอการควบคุมอุณหภูมิที่แม่นยำ, ช่วยให้การรักษาความร้อนที่มีประสิทธิภาพซึ่งไม่ส่งผลต่อรสชาติหรือพื้นผิว. โดยใช้เครื่องจักรของ Guanyu, ผู้ผลิตสามารถผลิตมัสตาร์ดที่ยังคงสดและมีรสชาติแม้หลังจากการจัดเก็บเป็นเวลานาน.

6. การทำให้เย็นลง

หลังพาสเจอร์ไรซ์, ส่วนผสมมัสตาร์ดจะต้องเย็นลงอย่างรวดเร็วเพื่อรักษารสชาติและป้องกันการปรุงอาหารเพิ่มเติม. การระบายความร้อนยังช่วยให้ผลิตภัณฑ์มีเสถียรภาพก่อนบรรจุภัณฑ์. ระบบทำความเย็นของ Guanyu ได้รับการออกแบบมาเพื่อนำส่วนผสมมัสตาร์ดมาสู่อุณหภูมิที่ต้องการอย่างรวดเร็ว, ทำให้มั่นใจได้ว่ามันจะรักษารสชาติและพื้นผิวของมันไว้.

การระบายความร้อนจะเสร็จสิ้นใน ถังระบายความร้อนของ Guanyu, ที่ส่วนผสมจะค่อยๆลดลงถึงอุณหภูมิห้อง. ขั้นตอนนี้ป้องกันการควบแน่นภายในบรรจุภัณฑ์, ลดความเสี่ยงของการเน่าเสีย.

7. การปรับรสชาติและการควบคุมคุณภาพ

ก่อนบรรจุภัณฑ์, ผู้ผลิตมักจะทำการตรวจสอบคุณภาพเพื่อให้แน่ใจว่ามัสตาร์ดมีรสชาติที่เหมาะสม, ความสม่ำเสมอ, และความเป็นกรด. ซึ่งอาจรวมถึงการชิม, การทดสอบค่า pH, และการตรวจสอบด้วยภาพ. การปรับรสขั้นสุดท้ายใด ๆ, เช่นเครื่องเทศเพิ่มเติมหรือเกลือ, ทำขึ้นในขั้นตอนนี้เพื่อให้ผลิตภัณฑ์สมบูรณ์แบบ.

อุปกรณ์ของ Guanyu มีการควบคุมที่แม่นยำเพื่อความสอดคล้อง, ซึ่งทำให้การควบคุมคุณภาพและการปรับรสชาติง่ายต่อการจัดการในขนาดใหญ่. เครื่องจักรได้รับการออกแบบมาเพื่อลดการแทรกแซงด้วยตนเอง, สร้างความมั่นใจในชุดความสอดคล้องของผลิตภัณฑ์หลังจากแบทช์.

8. บรรจุภัณฑ์

ขั้นตอนสุดท้ายในกระบวนการผลิตมัสตาร์ดคือบรรจุภัณฑ์. บรรจุภัณฑ์จะต้องมีประสิทธิภาพ, แม่นยำ, และสุขอนามัยเพื่อรักษาคุณภาพและความสดของผลิตภัณฑ์. มัสตาร์ดสามารถบรรจุลงในภาชนะต่างๆ, เช่นขวดแก้ว, ขวดพลาสติก, หรือซองแบบใช้ครั้งเดียว, ขึ้นอยู่กับความต้องการของตลาด.

เครื่องเติมอัตโนมัติของ Guanyu เหมาะอย่างยิ่งสำหรับการเติมมัสตาร์ดความเร็วสูงลงในภาชนะบรรจุ. เครื่องเหล่านี้มีความสามารถในการเติมที่แม่นยำ, ซึ่งลดของเสียและตรวจสอบปริมาณที่สอดคล้องกันในแต่ละหน่วย. หลังจากเติม, ภาชนะบรรจุจะถูกปิดผนึกเพื่อรักษาความสดแล้ว.

Guanyu ยังให้บริการโซลูชั่นการปิดผนึกและการติดฉลากอัตโนมัติ, ช่วยให้ผู้ผลิตสามารถทำกระบวนการบรรจุภัณฑ์ให้เสร็จสมบูรณ์ได้อย่างมีประสิทธิภาพ. สิ่งนี้ทำให้มั่นใจได้ว่าแต่ละคอนเทนเนอร์มีป้ายกำกับอย่างถูกต้องและพร้อมสำหรับการจัดส่ง.

อุปกรณ์การผลิตมัสตาร์ดของ Guanyu

อุปกรณ์แปรรูปอาหารที่ครอบคลุมของ Guanyu ได้รับการออกแบบมาเพื่อเพิ่มประสิทธิภาพกระบวนการผลิตมัสตาร์ดทั้งหมด. นี่คือภาพรวมอย่างรวดเร็วของอุปกรณ์ Guanyu ข้อเสนอสำหรับการผลิตมัสตาร์ด:

- เครื่องทำความสะอาดเมล็ดพันธุ์และการเรียงลำดับ: กำจัดสิ่งสกปรกและเลือกเฉพาะเมล็ดมัสตาร์ดคุณภาพสูงสุด, สร้างความมั่นใจในฐานที่บริสุทธิ์สำหรับการผลิต.

- โรงงานคอลลอยด์และเครื่องบด: แบ่งเมล็ดมัสตาร์ดลงในการวางที่ดี, ปล่อยน้ำมันหอมระเหยและรสชาติ.

- ถังผสมอุตสาหกรรม: ผสมน้ำส้มสายชู, น้ำ, เกลือ, และเครื่องเทศอื่น ๆ อย่างสม่ำเสมอเพื่อสร้างการผสมผสานที่สอดคล้องกัน.

- homogenizers เฉือนสูง: อิมัลชันส่วนผสมสำหรับความมั่นคง, พื้นผิวเรียบที่จะไม่แยกจากกัน.

- อุปกรณ์พาสเจอร์ไรส์: ให้การรักษาความร้อนเพื่อฆ่าแบคทีเรียและยืดอายุการเก็บรักษาในขณะที่รักษารสชาติ.

- ระบบระบายความร้อน: ทำให้มัสตาร์ดเย็นลงอย่างรวดเร็วหลังจากพาสเจอร์ไรซ์, การทำให้ผลิตภัณฑ์มีเสถียรภาพ.

- เครื่องเติมอัตโนมัติ: รับรองความแม่นยำ, ไส้ที่ถูกสุขลักษณะของภาชนะบรรจุ, ลดของเสียและรักษาคุณภาพให้น้อยที่สุด.

ข้อดีของการใช้อุปกรณ์ guanyu สำหรับ การผลิตมัสตาร์ด

อุปกรณ์ขั้นสูงของ Guanyu ให้ประโยชน์มากมายสำหรับผู้ผลิตมัสตาร์ด:

- ความสอดคล้องในคุณภาพ: กระบวนการอัตโนมัติตรวจสอบให้แน่ใจว่าแต่ละชุดมีรสชาติเหมือนกัน, เนื้อสัมผัส, และรูปลักษณ์, ปรับปรุงความน่าเชื่อถือของผลิตภัณฑ์.

- เพิ่มประสิทธิภาพ: เครื่องจักรความเร็วสูงช่วยลดเวลาการผลิตและเพิ่มผลผลิตสูงสุด, ช่วยให้ผู้ผลิตตอบสนองความต้องการขนาดใหญ่.

- สุขอนามัยและความปลอดภัย: อุปกรณ์ของ Guanyu ได้รับการออกแบบมาเพื่อให้เป็นไปตามมาตรฐานระดับอาหาร, ตรวจสอบให้แน่ใจว่าการผลิตมัสตาร์ดเป็นเรื่องสุขาภิบาลและปลอดภัย.

- ประสิทธิภาพต้นทุน: ด้วยการควบคุมที่แม่นยำ, กระบวนการอัตโนมัติ, และของเสียให้น้อยที่สุด, อุปกรณ์ของ Guanyu ช่วยลดต้นทุนการผลิตและเพิ่มผลกำไรสูงสุด.

- ความสามารถในการขยายขนาด: เครื่องจักรของ Guanyu มีความสามารถในการจัดการปริมาณมาก, ทำให้พวกเขาเหมาะสำหรับผู้ผลิตที่ต้องการขยายขีดความสามารถในการผลิต.

บทสรุป

กระบวนการผลิตมัสตาร์ดในโรงงานคือการผสมผสานของวิทยาศาสตร์, ความแม่นยำ, และการควบคุมคุณภาพ. จากการทำความสะอาดเมล็ดไปจนถึงการบรรจุผลิตภัณฑ์ขั้นสุดท้าย, แต่ละขั้นตอนต้องใช้อุปกรณ์พิเศษเพื่อให้แน่ใจว่ามีความสอดคล้องและประสิทธิภาพ. เครื่องจักรการแปรรูปอาหารที่หลากหลายของ Guanyu ช่วยให้ผู้ผลิตมีเครื่องมือที่พวกเขาต้องการในการผลิตมัสตาร์ดคุณภาพสูงในขนาดใหญ่, ทั้งหมดในขณะที่รักษารสชาติ, เนื้อสัมผัส, และความปลอดภัยที่ผู้บริโภคคาดหวัง.

งานเขียนของคุณมีวิธีที่จะสะท้อนกับฉันในระดับลึก. ฉันขอขอบคุณความซื่อสัตย์และความถูกต้องที่คุณนำมาให้ทุกโพสต์. ขอบคุณสำหรับการแบ่งปันการเดินทางของคุณกับเรา.

คำแนะนำการบำรุงรักษาที่สะอาดกว่า, ดำเนินการทันที. http://liquidationrama.com/read-blog/5190

ขอบคุณสำหรับการแบ่งปัน. ฉันกังวลว่าฉันขาดความคิดสร้างสรรค์. เป็นบทความของคุณที่ทำให้ฉันเต็มไปด้วยความหวัง. ขอบคุณ. แต่, ฉันมีคำถาม, คุณช่วยฉันได้ไหม?

ขอบคุณสำหรับการแบ่งปัน. ฉันกังวลว่าฉันขาดความคิดสร้างสรรค์. เป็นบทความของคุณที่ทำให้ฉันเต็มไปด้วยความหวัง. ขอบคุณ. แต่, ฉันมีคำถาม, คุณช่วยฉันได้ไหม? https://accounts.binance.info/en-IN/register-person?ref=UM6SMJM3

มุมมองของคุณจับตาฉันและน่าสนใจมาก. ขอบคุณ. ฉันมีคำถามสำหรับคุณ.

ขอบคุณสำหรับการแบ่งปัน. ฉันอ่านโพสต์บล็อกของคุณมากมาย, เย็น, บล็อกของคุณดีมาก.

ขอบคุณสำหรับการแบ่งปัน. ฉันกังวลว่าฉันขาดความคิดสร้างสรรค์. เป็นบทความของคุณที่ทำให้ฉันเต็มไปด้วยความหวัง. ขอบคุณ. แต่, ฉันมีคำถาม, คุณช่วยฉันได้ไหม?

ขอบคุณสำหรับการแบ่งปัน. ฉันอ่านโพสต์บล็อกของคุณมากมาย, เย็น, บล็อกของคุณดีมาก.

ฉันไม่คิดว่าชื่อของบทความของคุณจะตรงกับเนื้อหาฮ่า ๆ. แค่ล้อเล่น, ส่วนใหญ่เป็นเพราะฉันมีข้อสงสัยบางอย่างหลังจากอ่านบทความ.

คุณสามารถเฉพาะเจาะจงมากขึ้นเกี่ยวกับเนื้อหาของบทความของคุณ? หลังจากอ่านมัน, ฉันยังมีข้อสงสัยอยู่บ้าง. หวังว่าคุณจะช่วยฉันได้.

ขอบคุณสำหรับการแบ่งปัน. ฉันกังวลว่าฉันขาดความคิดสร้างสรรค์. เป็นบทความของคุณที่ทำให้ฉันเต็มไปด้วยความหวัง. ขอบคุณ. แต่, ฉันมีคำถาม, คุณช่วยฉันได้ไหม?

ฉันไม่คิดว่าชื่อของบทความของคุณจะตรงกับเนื้อหาฮ่า ๆ. แค่ล้อเล่น, ส่วนใหญ่เป็นเพราะฉันมีข้อสงสัยบางอย่างหลังจากอ่านบทความ.

บทความของคุณช่วยฉันได้มาก, มีเนื้อหาที่เกี่ยวข้องอีกไหม? ขอบคุณ!

มุมมองของคุณจับตาฉันและน่าสนใจมาก. ขอบคุณ. ฉันมีคำถามสำหรับคุณ.

ฉันไม่คิดว่าชื่อของบทความของคุณจะตรงกับเนื้อหาฮ่า ๆ. แค่ล้อเล่น, ส่วนใหญ่เป็นเพราะฉันมีข้อสงสัยบางอย่างหลังจากอ่านบทความ.

บทความของคุณช่วยฉันได้มาก, มีเนื้อหาที่เกี่ยวข้องอีกไหม? ขอบคุณ!

ขอบคุณสำหรับการแบ่งปัน. ฉันอ่านโพสต์บล็อกของคุณมากมาย, เย็น, บล็อกของคุณดีมาก.

คุณสามารถเฉพาะเจาะจงมากขึ้นเกี่ยวกับเนื้อหาของบทความของคุณ? หลังจากอ่านมัน, ฉันยังมีข้อสงสัยอยู่บ้าง. หวังว่าคุณจะช่วยฉันได้. https://www.binance.info/join?ref=P9L9FQKY

ความเข้าใจ ข้อกำหนดผลประโยชน์ Medicaid เป็นสิ่งสำคัญสำหรับการวางแผนที่เหมาะสม. ทีมกฎหมายของเราให้ความชัดเจน.

คุณสามารถเฉพาะเจาะจงมากขึ้นเกี่ยวกับเนื้อหาของบทความของคุณ? หลังจากอ่านมัน, ฉันยังมีข้อสงสัยอยู่บ้าง. หวังว่าคุณจะช่วยฉันได้. https://www.binance.com/vi/register?ref=WTOZ531Y

ขอบคุณสำหรับการแบ่งปัน. ฉันกังวลว่าฉันขาดความคิดสร้างสรรค์. เป็นบทความของคุณที่ทำให้ฉันเต็มไปด้วยความหวัง. ขอบคุณ. แต่, ฉันมีคำถาม, คุณช่วยฉันได้ไหม?

บทความของคุณช่วยฉันได้มาก, มีเนื้อหาที่เกี่ยวข้องอีกไหม? ขอบคุณ!

ขอบคุณสำหรับการแบ่งปัน. ฉันอ่านโพสต์บล็อกของคุณมากมาย, เย็น, บล็อกของคุณดีมาก.

คุณสามารถเฉพาะเจาะจงมากขึ้นเกี่ยวกับเนื้อหาของบทความของคุณ? หลังจากอ่านมัน, ฉันยังมีข้อสงสัยอยู่บ้าง. หวังว่าคุณจะช่วยฉันได้.

คุณสามารถเฉพาะเจาะจงมากขึ้นเกี่ยวกับเนื้อหาของบทความของคุณ? หลังจากอ่านมัน, ฉันยังมีข้อสงสัยอยู่บ้าง. หวังว่าคุณจะช่วยฉันได้.

มุมมองของคุณจับตาฉันและน่าสนใจมาก. ขอบคุณ. ฉันมีคำถามสำหรับคุณ.

มุมมองของคุณจับตาฉันและน่าสนใจมาก. ขอบคุณ. ฉันมีคำถามสำหรับคุณ.

ขอบคุณ, บทความของคุณทำให้ฉันประหลาดใจ, มีมุมมองที่ยอดเยี่ยมเช่นนี้. ขอบคุณสำหรับการแบ่งปัน, ฉันเรียนรู้มากมาย.

มุมมองของคุณจับตาฉันและน่าสนใจมาก. ขอบคุณ. ฉันมีคำถามสำหรับคุณ.

คุณสามารถเฉพาะเจาะจงมากขึ้นเกี่ยวกับเนื้อหาของบทความของคุณ? หลังจากอ่านมัน, ฉันยังมีข้อสงสัยอยู่บ้าง. หวังว่าคุณจะช่วยฉันได้.

ขอบคุณ, บทความของคุณทำให้ฉันประหลาดใจ, มีมุมมองที่ยอดเยี่ยมเช่นนี้. ขอบคุณสำหรับการแบ่งปัน, ฉันเรียนรู้มากมาย. https://accounts.binance.com/bg/register?ref=T7KCZASX

ฉันไม่คิดว่าชื่อของบทความของคุณจะตรงกับเนื้อหาฮ่า ๆ. แค่ล้อเล่น, ส่วนใหญ่เป็นเพราะฉันมีข้อสงสัยบางอย่างหลังจากอ่านบทความ.

บทความของคุณช่วยฉันได้มาก, มีเนื้อหาที่เกี่ยวข้องอีกไหม? ขอบคุณ!

บทความของคุณช่วยฉันได้มาก, มีเนื้อหาที่เกี่ยวข้องอีกไหม? ขอบคุณ!

ฉันไม่คิดว่าชื่อของบทความของคุณจะตรงกับเนื้อหาฮ่า ๆ. แค่ล้อเล่น, ส่วนใหญ่เป็นเพราะฉันมีข้อสงสัยบางอย่างหลังจากอ่านบทความ.

ฉันไม่คิดว่าชื่อของบทความของคุณจะตรงกับเนื้อหาฮ่า ๆ. แค่ล้อเล่น, ส่วนใหญ่เป็นเพราะฉันมีข้อสงสัยบางอย่างหลังจากอ่านบทความ.

ฉันไม่คิดว่าชื่อของบทความของคุณจะตรงกับเนื้อหาฮ่า ๆ. แค่ล้อเล่น, ส่วนใหญ่เป็นเพราะฉันมีข้อสงสัยบางอย่างหลังจากอ่านบทความ.

มุมมองของคุณจับตาฉันและน่าสนใจมาก. ขอบคุณ. ฉันมีคำถามสำหรับคุณ.

ขอบคุณสำหรับการแบ่งปัน. ฉันอ่านโพสต์บล็อกของคุณมากมาย, เย็น, บล็อกของคุณดีมาก.

คุณสามารถเฉพาะเจาะจงมากขึ้นเกี่ยวกับเนื้อหาของบทความของคุณ? หลังจากอ่านมัน, ฉันยังมีข้อสงสัยอยู่บ้าง. หวังว่าคุณจะช่วยฉันได้. https://www.binance.info/ar/register-person?ref=V2H9AFPY

บทความของคุณช่วยฉันได้มาก, มีเนื้อหาที่เกี่ยวข้องอีกไหม? ขอบคุณ!

ฉันไม่คิดว่าชื่อของบทความของคุณจะตรงกับเนื้อหาฮ่า ๆ. แค่ล้อเล่น, ส่วนใหญ่เป็นเพราะฉันมีข้อสงสัยบางอย่างหลังจากอ่านบทความ. https://www.binance.info/sl/register?ref=PORL8W0Z

ฉันไม่คิดว่าชื่อของบทความของคุณจะตรงกับเนื้อหาฮ่า ๆ. แค่ล้อเล่น, ส่วนใหญ่เป็นเพราะฉันมีข้อสงสัยบางอย่างหลังจากอ่านบทความ. https://www.binance.com/de-CH/register?ref=UM6SMJM3

มุมมองของคุณจับตาฉันและน่าสนใจมาก. ขอบคุณ. ฉันมีคำถามสำหรับคุณ. การระเบิด

ขอบคุณสำหรับการแบ่งปัน. ฉันกังวลว่าฉันขาดความคิดสร้างสรรค์. เป็นบทความของคุณที่ทำให้ฉันเต็มไปด้วยความหวัง. ขอบคุณ. แต่, ฉันมีคำถาม, คุณช่วยฉันได้ไหม? binance register

ขอบคุณสำหรับการแบ่งปัน. ฉันอ่านโพสต์บล็อกของคุณมากมาย, เย็น, บล็อกของคุณดีมาก.

มุมมองของคุณจับตาฉันและน่าสนใจมาก. ขอบคุณ. ฉันมีคำถามสำหรับคุณ.

ฉันไม่คิดว่าชื่อของบทความของคุณจะตรงกับเนื้อหาฮ่า ๆ. แค่ล้อเล่น, ส่วนใหญ่เป็นเพราะฉันมีข้อสงสัยบางอย่างหลังจากอ่านบทความ.

คุณสามารถเฉพาะเจาะจงมากขึ้นเกี่ยวกับเนื้อหาของบทความของคุณ? หลังจากอ่านมัน, ฉันยังมีข้อสงสัยอยู่บ้าง. หวังว่าคุณจะช่วยฉันได้.

ขอบคุณสำหรับการแบ่งปัน. ฉันอ่านโพสต์บล็อกของคุณมากมาย, เย็น, บล็อกของคุณดีมาก.

ฉันไม่คิดว่าชื่อของบทความของคุณจะตรงกับเนื้อหาฮ่า ๆ. แค่ล้อเล่น, ส่วนใหญ่เป็นเพราะฉันมีข้อสงสัยบางอย่างหลังจากอ่านบทความ.

ขอบคุณสำหรับการแบ่งปัน. ฉันกังวลว่าฉันขาดความคิดสร้างสรรค์. เป็นบทความของคุณที่ทำให้ฉันเต็มไปด้วยความหวัง. ขอบคุณ. แต่, ฉันมีคำถาม, คุณช่วยฉันได้ไหม?

ขอบคุณสำหรับการแบ่งปัน. ฉันกังวลว่าฉันขาดความคิดสร้างสรรค์. เป็นบทความของคุณที่ทำให้ฉันเต็มไปด้วยความหวัง. ขอบคุณ. แต่, ฉันมีคำถาม, คุณช่วยฉันได้ไหม?

บทความของคุณช่วยฉันได้มาก, มีเนื้อหาที่เกี่ยวข้องอีกไหม? ขอบคุณ!

ฉันไม่คิดว่าชื่อของบทความของคุณจะตรงกับเนื้อหาฮ่า ๆ. แค่ล้อเล่น, ส่วนใหญ่เป็นเพราะฉันมีข้อสงสัยบางอย่างหลังจากอ่านบทความ.

ขอบคุณสำหรับการแบ่งปัน. ฉันกังวลว่าฉันขาดความคิดสร้างสรรค์. เป็นบทความของคุณที่ทำให้ฉันเต็มไปด้วยความหวัง. ขอบคุณ. แต่, ฉันมีคำถาม, คุณช่วยฉันได้ไหม? https://accounts.binance.info/register-person?ref=IHJUI7TF

มุมมองของคุณจับตาฉันและน่าสนใจมาก. ขอบคุณ. ฉันมีคำถามสำหรับคุณ. https://accounts.binance.info/si-LK/register?ref=LBF8F65G

ขอบคุณสำหรับการแบ่งปัน. ฉันกังวลว่าฉันขาดความคิดสร้างสรรค์. เป็นบทความของคุณที่ทำให้ฉันเต็มไปด้วยความหวัง. ขอบคุณ. แต่, ฉันมีคำถาม, คุณช่วยฉันได้ไหม?

ขอบคุณสำหรับการแบ่งปัน. ฉันกังวลว่าฉันขาดความคิดสร้างสรรค์. เป็นบทความของคุณที่ทำให้ฉันเต็มไปด้วยความหวัง. ขอบคุณ. แต่, ฉันมีคำถาม, คุณช่วยฉันได้ไหม?

ฉันไม่คิดว่าชื่อของบทความของคุณจะตรงกับเนื้อหาฮ่า ๆ. แค่ล้อเล่น, ส่วนใหญ่เป็นเพราะฉันมีข้อสงสัยบางอย่างหลังจากอ่านบทความ.

Thank you for your shening. ฉันกังวลว่าฉันขาดความคิดสร้างสรรค์. It is your enticle that makes me full of hope. ขอบคุณ. แต่, ฉันมีคำถาม, คุณช่วยฉันได้ไหม? https://www.binance.info/cs/register?ref=OMM3XK51

ขอบคุณสำหรับการแบ่งปัน. ฉันกังวลว่าฉันขาดความคิดสร้างสรรค์. เป็นบทความของคุณที่ทำให้ฉันเต็มไปด้วยความหวัง. ขอบคุณ. แต่, ฉันมีคำถาม, คุณช่วยฉันได้ไหม?

มุมมองของคุณจับตาฉันและน่าสนใจมาก. ขอบคุณ. ฉันมีคำถามสำหรับคุณ. https://www.binance.com/zh-CN/register?ref=WFZUU6SI

คุณสามารถเฉพาะเจาะจงมากขึ้นเกี่ยวกับเนื้อหาของบทความของคุณ? หลังจากอ่านมัน, ฉันยังมีข้อสงสัยอยู่บ้าง. หวังว่าคุณจะช่วยฉันได้.

ขอบคุณสำหรับการแบ่งปัน. ฉันอ่านโพสต์บล็อกของคุณมากมาย, เย็น, บล็อกของคุณดีมาก. https://www.binance.com/ka-GE/register?ref=ILE8IH9H

Umbet4 is a decent platform. Nothing groundbreaking, but it gets the job done. Quick deposits and withdrawals are a big plus. Just keep manage your bankroll wisely! umbet4

ขอบคุณสำหรับการแบ่งปัน. ฉันกังวลว่าฉันขาดความคิดสร้างสรรค์. เป็นบทความของคุณที่ทำให้ฉันเต็มไปด้วยความหวัง. ขอบคุณ. แต่, ฉันมีคำถาม, คุณช่วยฉันได้ไหม? https://accounts.binance.info/en/register?ref=JHQQKNKN

ขอบคุณสำหรับการแบ่งปัน. ฉันอ่านโพสต์บล็อกของคุณมากมาย, เย็น, บล็อกของคุณดีมาก.

**prodentim**

prodentim is a distinctive oral-care formula that pairs targeted probiotics with plant-based ingredients to encourage strong teeth

We can easily export data for analysis. Data analysis export.

มุมมองของคุณจับตาฉันและน่าสนใจมาก. ขอบคุณ. ฉันมีคำถามสำหรับคุณ.

ขอบคุณสำหรับการแบ่งปัน. ฉันกังวลว่าฉันขาดความคิดสร้างสรรค์. เป็นบทความของคุณที่ทำให้ฉันเต็มไปด้วยความหวัง. ขอบคุณ. แต่, ฉันมีคำถาม, คุณช่วยฉันได้ไหม?

ขอบคุณสำหรับการแบ่งปัน. ฉันอ่านโพสต์บล็อกของคุณมากมาย, เย็น, บล็อกของคุณดีมาก. https://accounts.binance.com/ru-UA/register?ref=JVDCDCK4

ขอบคุณสำหรับการแบ่งปัน. ฉันอ่านโพสต์บล็อกของคุณมากมาย, เย็น, บล็อกของคุณดีมาก. https://accounts.binance.info/fr-AF/register-person?ref=JHQQKNKN

คุณสามารถเฉพาะเจาะจงมากขึ้นเกี่ยวกับเนื้อหาของบทความของคุณ? หลังจากอ่านมัน, ฉันยังมีข้อสงสัยอยู่บ้าง. หวังว่าคุณจะช่วยฉันได้.

ขอบคุณสำหรับการแบ่งปัน. ฉันอ่านโพสต์บล็อกของคุณมากมาย, เย็น, บล็อกของคุณดีมาก. https://www.binance.info/register?ref=IHJUI7TF

มุมมองของคุณจับตาฉันและน่าสนใจมาก. ขอบคุณ. ฉันมีคำถามสำหรับคุณ.

ฉันไม่คิดว่าชื่อของบทความของคุณจะตรงกับเนื้อหาฮ่า ๆ. แค่ล้อเล่น, ส่วนใหญ่เป็นเพราะฉันมีข้อสงสัยบางอย่างหลังจากอ่านบทความ.

ฉันไม่คิดว่าชื่อของบทความของคุณจะตรงกับเนื้อหาฮ่า ๆ. แค่ล้อเล่น, ส่วนใหญ่เป็นเพราะฉันมีข้อสงสัยบางอย่างหลังจากอ่านบทความ.

บทความของคุณช่วยฉันได้มาก, มีเนื้อหาที่เกี่ยวข้องอีกไหม? ขอบคุณ!

ฉันไม่คิดว่าชื่อของบทความของคุณจะตรงกับเนื้อหาฮ่า ๆ. แค่ล้อเล่น, ส่วนใหญ่เป็นเพราะฉันมีข้อสงสัยบางอย่างหลังจากอ่านบทความ. https://accounts.binance.info/en-IN/register-person?ref=A80YTPZ1

ฉันไม่คิดว่าชื่อของบทความของคุณจะตรงกับเนื้อหาฮ่า ๆ. แค่ล้อเล่น, ส่วนใหญ่เป็นเพราะฉันมีข้อสงสัยบางอย่างหลังจากอ่านบทความ.

บทความของคุณช่วยฉันได้มาก, มีเนื้อหาที่เกี่ยวข้องอีกไหม? ขอบคุณ!