Mini Bottle Production Line Automatic Glass Vial Sealing Machine Oral Vial Filling Machine

Filling Volume | 5~60ml&50~500ml&500~5000ml(Индивидуальные) |

Filling speed | 1000~8000BPH |

Cylinder | AIRTAC/Festo |

Тип управления | PLC+Touch Screen |

Hopper Volume | 20~40L |

Метод нагрева | Electric Heated(Необязательный) |

Mixing Function | Необязательный |

Приложение | HoneyWater/Syrup/Ketchup/Paste/Mayonnaise/Sauce/Ointment/Cream/Lotion/Gel/Shampoo/Detergent |

Safety Protection | Acrylic Cover&Emergency Stop Button |

Filling Volume(мл) | Productivity(b/h) | Filling Speed | Filling Precision | Air Supply |

5-50 | 1500-3500 | Adjustable | ≤±1% | 0.4-0.8МПа |

80-300 | 1500-3000 | Adjustable | ≤±1% | 0.4-0.8МПа |

100-500 | 1500-2500 | Adjustable | ≤±1% | 0.4-0.8МПа |

300-1000 | 1500-2500 | Adjustable | ≤±1% | 0.4-0.8МПа |

1000-5000 | 1000-2000 | Adjustable | ≤±1% | 0.4-0.8МПа |

Our Competitive Advantages

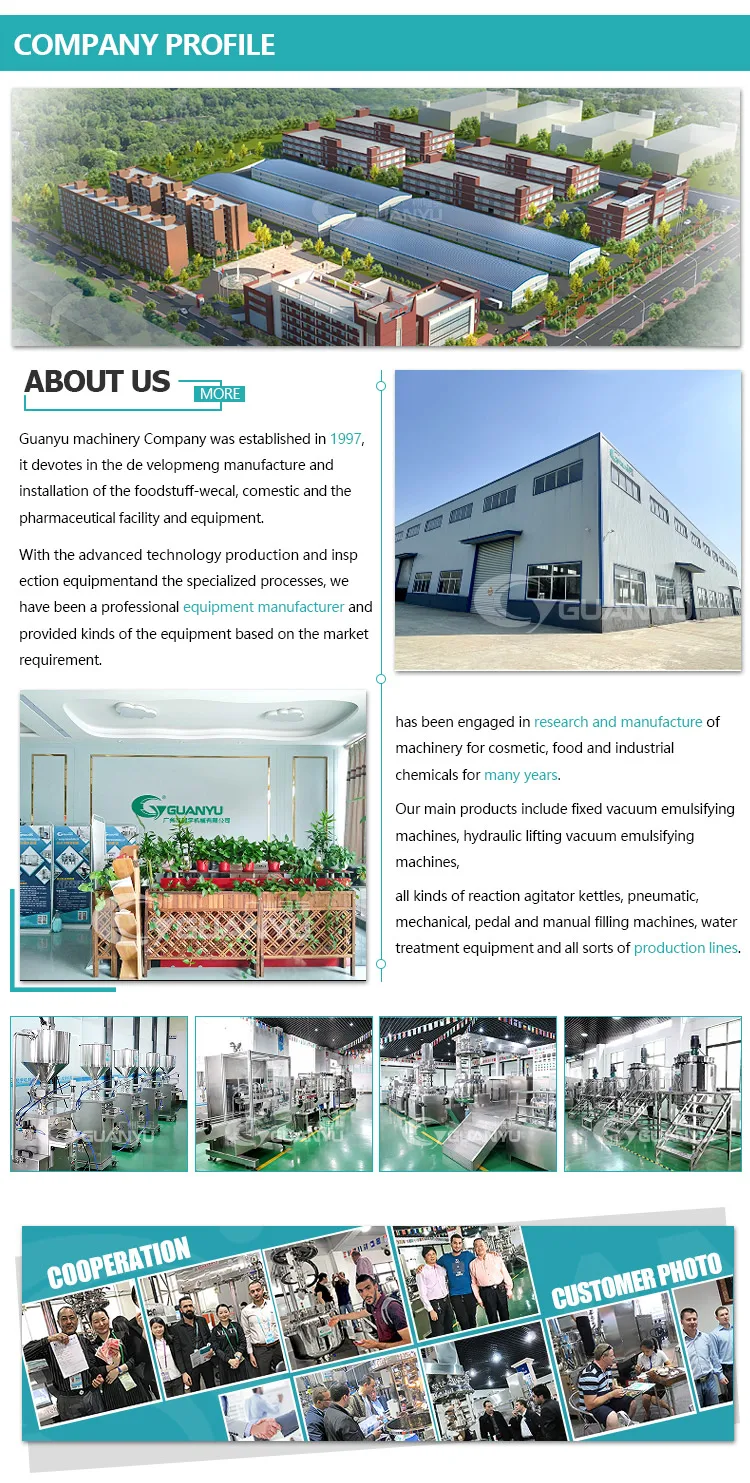

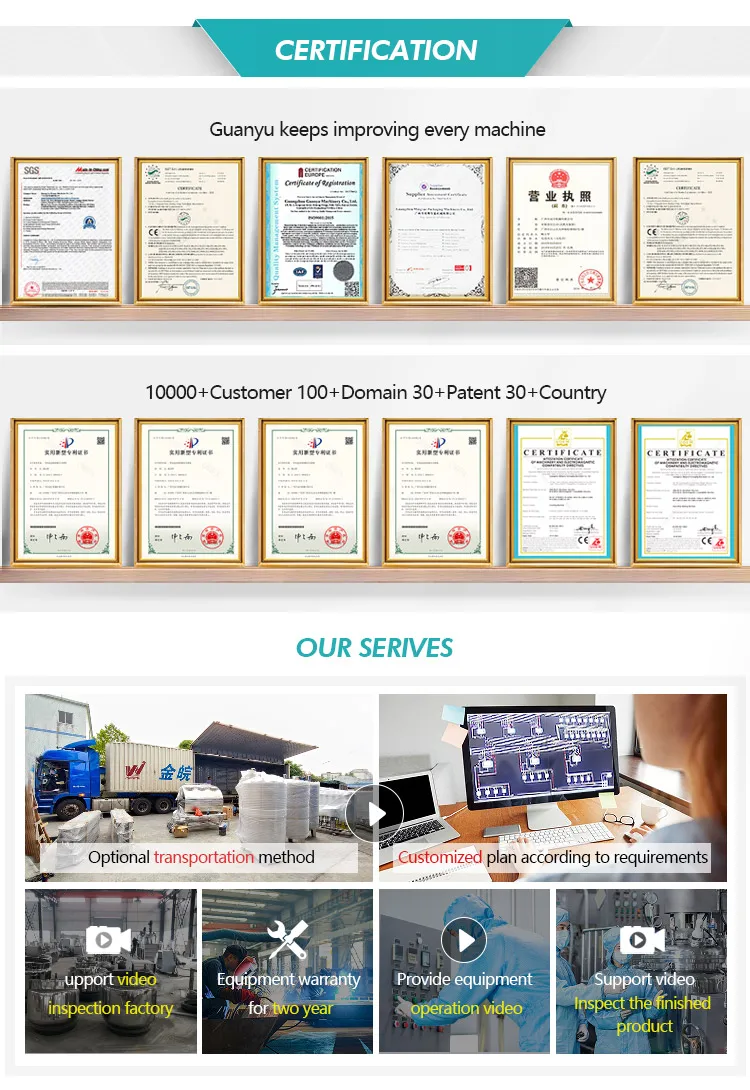

Founded in 1997, Гуанчжоуская компания Guanyu Machinery Co., ООО has amassed over 25 years of experience in the development, производство, and installation of specialized equipment for the cosmetics, еда, and pharmaceutical industries. Our company stands out due to our state-of-the-art technological production facilities, which include advanced testing and quality control systems to ensure the highest level of product performance.We utilize specialized process flows to develop and manufacture equipment that meets the highest industry standards. This dedication to innovation and quality has established us as a leader in the field, allowing us to cater to a wide range of customer needs with custom-built equipment. Our diverse range of solutions ensures that no matter how complex the production requirement, we can provide a tailored solution that delivers outstanding results.3. Customizable Machinery to Fit Every Need

At Гуанчжоуская компания Guanyu Machinery Co., ООО, we understand that each customer’s production process is unique. That’s why we offer a broad range of customizable machines designed to meet the specific needs of our clients. These include:- Vacuum Emulsifier Homogenizer Mixer: Ideal for high-precision blending and emulsifying in the cosmetics and pharmaceutical industries.

- Opened Mixing Tank Blender Stirring Machine: Flexible mixing solutions for different viscosities and materials, commonly used in food and cosmetics production.

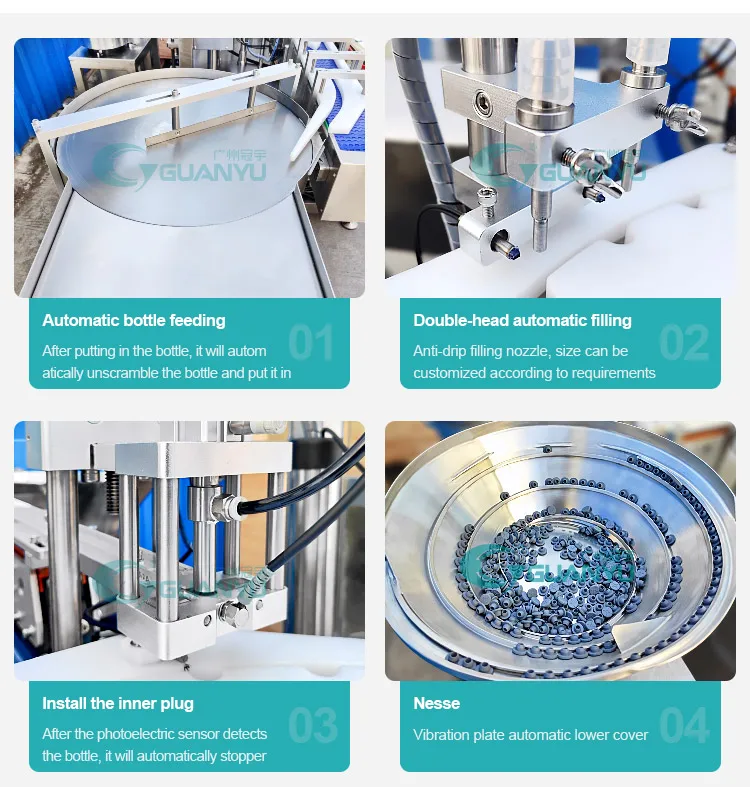

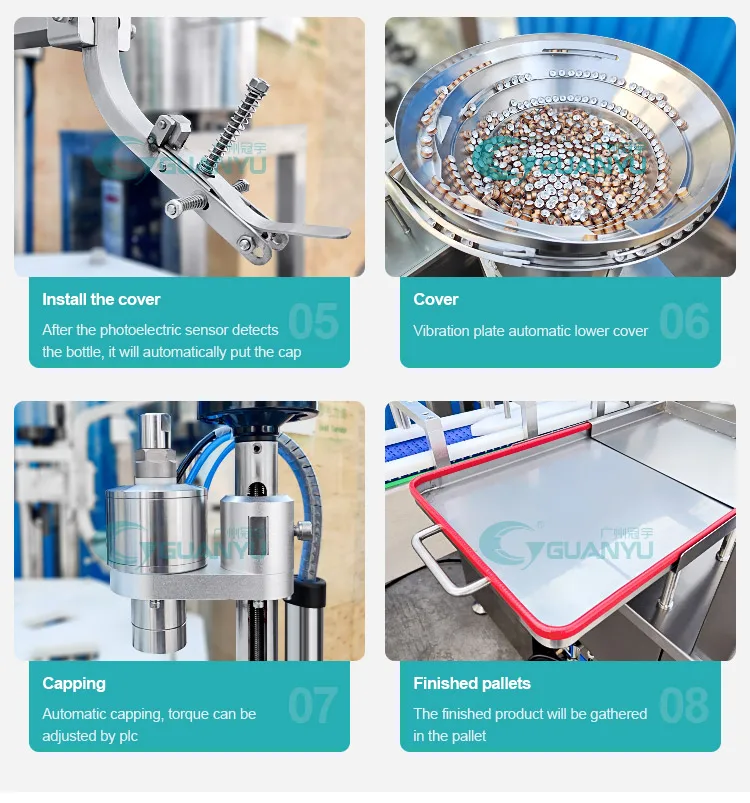

- Наполнение, Capping, Labeling, and Packaging Machines: Highly efficient automated systems designed to streamline packaging processes and increase production throughput.

- RO Reverse Osmosis Water Treatment Systems: Essential for achieving the highest purity in water used in production processes.

- Multiple Types of Storage Tanks: Offering robust storage solutions for raw materials, intermediate products, and finished goods.

Отзывы

Пока нет отзывов.