O Guia Ultimate para o Homogenizador de Emulsificantes 50L para Produção Cosmética

Emulsifier homogenizers are essential pieces of equipment in the cosmetics industry, designed to create stable mixtures of immiscible liquids, such as oil and water. These devices facilitate the emulsification process, wherein the droplets of one liquid are dispersed within another, resulting in a homogeneous product. This technology is crucial for producing a variety of cosmetic formulations, including creams, pomadas, loções, toothpastes, and gels. The significance of emulsifier homogenizers lies in their ability to enhance product stability, textura, and appearance, which are vital attributes in cosmetic formulations.

The principles of emulsification and homogenization, while related, are distinct processes. Emulsification is the process of combining two or more liquids that typically do not mix, requiring an emulsifying agent to stabilize the blend. In contrast, homogenization is the mechanical process that reduces particle size and promotes uniform distribution within a mixture to improve overall quality and consistency. Both processes are critical for producing high-quality cosmetics that meet consumer expectations.

The 50L emulsifier homogenizer is a notable equipment choice for cosmetics manufacturers, offering a capacity that suits medium to large-scale production. Its efficient design allows for the creation of large batches while maintaining precise control over the emulsification and homogenization processes. The 50L capacity is particularly beneficial for companies looking to enhance their production efficiency without sacrificing quality. This piece of equipment further supports cosmetic producers in achieving consistent results, enabling innovative formulations that cater to evolving consumer demands.

Em essência, understanding emulsifier homogenizers and their fundamental processes is key for anyone involved in cosmetics production. The integration of the 50L emulsifier homogenizer into manufacturing workflows represents a significant step toward enhancing product quality and production efficiency in the highly competitive cosmetics market.

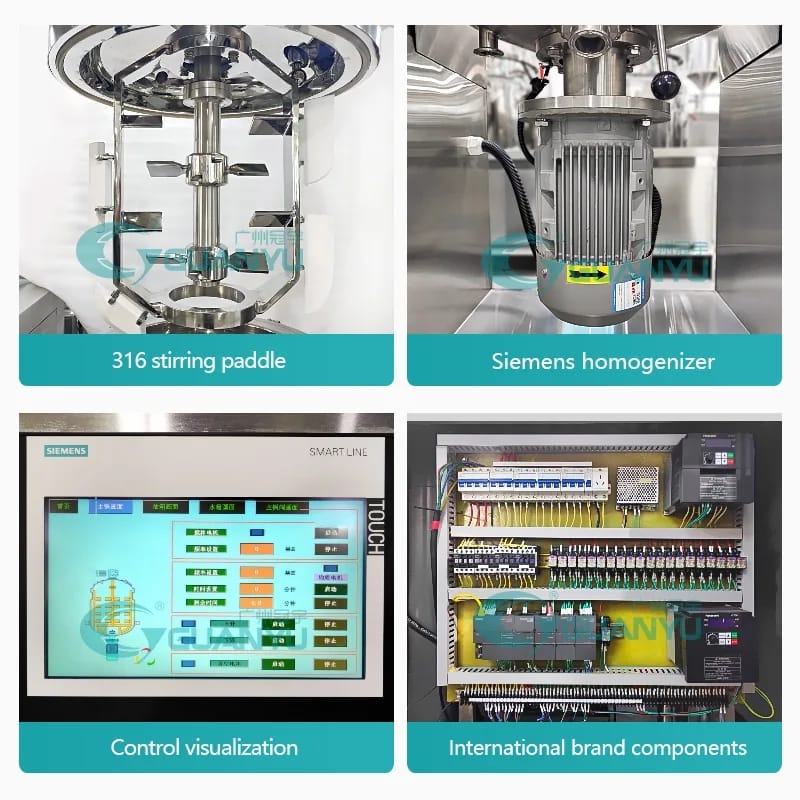

Features and Specifications of the 50L Emulsifier Homogenizer

The 50L emulsifier homogenizer represents a vital piece of equipment in cosmetics production, and its features significantly influence the quality of the final products. One of the notable construction materials used is stainless steel, which ensures durability and resistance to corrosion. This is particularly important in cosmetic manufacturing where contamination must be minimized. The design often incorporates a double jacketed vessel, allowing temperature control during the mixing process, which is essential for emulsions that require heating or cooling.

Power requirements for the 50L emulsifier homogenizer typically range from 5 para 15 HP, depending on the specific model and intended application. Adequate power facilitates efficient processing of varying viscosities, ensuring that high-quality emulsions are more readily achieved. The operating principles behind the emulsifier rely on both mechanical shear and hydraulic forces, which work together to achieve a homogeneous mixture of oil and water phases, thereby optimizing the emulsification process.

An important design specific to many 50L homogenizers is the incorporation of vacuum operations. This feature enables the removal of air from the mixture, which is crucial for maintaining product stability and extending shelf life—hallmarks of quality in cosmetic formulations. Além disso, the ease of cleaning is a design element that cannot be overlooked. The inclusion of quick-disconnect fittings and smooth surfaces makes the equipment easier to maintain, reducing downtime between batches and allowing for safe switchovers when varying product types.

Each of these features directly contributes to the overall performance of the homogenizer, ensuring that the emulsions produced meet both regulatory standards and customer expectations. These carefully engineered specifications play a pivotal role in ensuring product consistency, efficacy, e segurança, which are paramount in the competitive cosmetics industry.

Applications of the 50L Emulsifier Homogenizer in Cosmetics Production

The 50L emulsifier homogenizer plays a crucial role in the cosmetics production industry by facilitating the formulation of a wide variety of products, including creams, loções, pomadas, toothpastes, and gels. This equipment is engineered to blend, emulsionar, and stabilize mixtures of oils and water, thereby ensuring that final products have consistent texture, aparência, and performance. One notable application is in the manufacture of moisturizing creams where the emulsifier homogenizer allows for the uniform dispersion of active ingredients, enhancing the product’s effectiveness and sensory attributes.

Por exemplo, in the formulation of a high-quality facial moisturizer, the 50L emulsifier homogenizer efficiently combines water with oils and emollients. This process not only creates a stable emulsion but also contributes to a creamy texture that enhances user experience. De forma similar, when producing lotions, the machine’s capability to break down particle sizes ensures a smooth finish and prevents separation, which is essential for both aesthetic appeal and functionality.

Além disso, the use of the emulsifier homogenizer extends to the development of hair care products. In shampoos and conditioners, it assists in evenly distributing conditioners and surfactants, leading to improved performance and consumer satisfaction. The machine’s impact is evident in case studies where brands observed marked improvements in the stability and performance of their formulations post-implementation of the emulsifier homogenizer.

Regulatory considerations are vital when using emulsifiers in cosmetics. Manufacturers must adhere to guidelines set by regulatory bodies to ensure that emulsifiers comply with safety standards. This has implications for product labeling, transparency concerning ingredient sourcing, and active compliance with specified limits on specific emulsifiers. Such considerations ensure that the end product is not only effective but safe for consumer use.

Conclusão

Selecting the right emulsifier homogenizer is a critical decision for any business engaged in cosmetics production. The choice of equipment directly impacts the quality of the end product, efficiency of production processes, and ultimately, customer satisfaction. When evaluating options, businesses must consider multiple factors including production scale, budget constraints, and specific formulation requirements. Por exemplo, a 50L homogenizer can effectively cater to medium to large-scale production, ensuring consistency and stability in the cosmetic formulations.

Adicionalmente, the importance of matching the emulsifier homogenizer with the specific viscosity and texture requirements of cosmetic products cannot be overstated. Products such as creams, loções, and serums often require distinct processing techniques, which will be best supported by high-quality homogenizers designed for such applications. Investing in a reliable emulsifier not only enhances product performance but also aids in maintaining compliance with industry standards and regulations.

Além disso, while the initial investment in advanced equipment might seem substantial, the long-term benefits often outweigh these costs. By choosing a robust 50L emulsifier homogenizer, companies can achieve operational efficiency, reduce waste, and improve overall product quality, which can translate into increased customer loyalty and market competitiveness. The capacity for innovation and adaptation to changing market demands is also enhanced when equipped with state-of-the-art technology.

Em essência, businesses in the cosmetics industry are encouraged to thoughtfully assess their production needs and consider the role that quality emulsifier homogenizers can play. Taking into account factors such as production scale, budget, and product specifications will aid in making an informed investment that supports future growth and success in the increasingly competitive cosmetics market.

Obrigado pela sua partilha. Estou preocupado porque me faltam ideias criativas. É o seu artigo que me deixa cheio de esperança. Obrigado. Mas, Eu tenho uma pergunta, pode me ajudar?

Seu ponto de vista me chamou a atenção e foi muito interessante. Obrigado. Eu tenho uma pergunta para você.

Obrigado pela sua partilha. Estou preocupado porque me faltam ideias criativas. É o seu artigo que me deixa cheio de esperança. Obrigado. Mas, Eu tenho uma pergunta, pode me ajudar? https://accounts.binance.com/fr/register?ref=GJY4VW8W

Seu ponto de vista me chamou a atenção e foi muito interessante. Obrigado. Eu tenho uma pergunta para você.

Seu artigo me ajudou muito, existe mais algum conteúdo relacionado? Obrigado!

Seu ponto de vista me chamou a atenção e foi muito interessante. Obrigado. Eu tenho uma pergunta para você.

Você pode ser mais específico sobre o conteúdo do seu artigo? Depois de ler, ainda tenho algumas dúvidas. Espero que você possa me ajudar.

Obrigado por compartilhar. Eu li muitos dos seus posts, legal, seu blog é muito bom. https://accounts.binance.com/pt-BR/register-person?ref=IJFGOAID

Seu ponto de vista me chamou a atenção e foi muito interessante. Obrigado. Eu tenho uma pergunta para você. https://accounts.binance.com/da-DK/register-person?ref=V2H9AFPY

Obrigado pela sua partilha. Estou preocupado porque me faltam ideias criativas. É o seu artigo que me deixa cheio de esperança. Obrigado. Mas, Eu tenho uma pergunta, pode me ajudar?

Você pode ser mais específico sobre o conteúdo do seu artigo? Depois de ler, ainda tenho algumas dúvidas. Espero que você possa me ajudar.

Obrigado pela sua partilha. Estou preocupado porque me faltam ideias criativas. É o seu artigo que me deixa cheio de esperança. Obrigado. Mas, Eu tenho uma pergunta, pode me ajudar?

Obrigado pela sua partilha. Estou preocupado porque me faltam ideias criativas. É o seu artigo que me deixa cheio de esperança. Obrigado. Mas, Eu tenho uma pergunta, pode me ajudar?

Seu ponto de vista me chamou a atenção e foi muito interessante. Obrigado. Eu tenho uma pergunta para você.

Você pode ser mais específico sobre o conteúdo do seu artigo? Depois de ler, ainda tenho algumas dúvidas. Espero que você possa me ajudar.

Você pode ser mais específico sobre o conteúdo do seu artigo? Depois de ler, ainda tenho algumas dúvidas. Espero que você possa me ajudar.

Não acho que o título do seu artigo corresponda ao conteúdo haha. Estou brincando, principalmente porque tive algumas dúvidas depois de ler o artigo.

Seu ponto de vista me chamou a atenção e foi muito interessante. Obrigado. Eu tenho uma pergunta para você.

Você pode ser mais específico sobre o conteúdo do seu artigo? Depois de ler, ainda tenho algumas dúvidas. Espero que você possa me ajudar.

Não acho que o título do seu artigo corresponda ao conteúdo haha. Estou brincando, principalmente porque tive algumas dúvidas depois de ler o artigo.

Obrigado por compartilhar. Eu li muitos dos seus posts, legal, seu blog é muito bom.

Não acho que o título do seu artigo corresponda ao conteúdo haha. Estou brincando, principalmente porque tive algumas dúvidas depois de ler o artigo. https://www.binance.info/hu/register?ref=FIHEGIZ8

Seu ponto de vista me chamou a atenção e foi muito interessante. Obrigado. Eu tenho uma pergunta para você.

Obrigado por compartilhar. Eu li muitos dos seus posts, legal, seu blog é muito bom.

Obrigado pela sua partilha. Estou preocupado porque me faltam ideias criativas. É o seu artigo que me deixa cheio de esperança. Obrigado. Mas, Eu tenho uma pergunta, pode me ajudar? https://www.binance.com/en-IN/register?ref=UM6SMJM3

Você pode ser mais específico sobre o conteúdo do seu artigo? Depois de ler, ainda tenho algumas dúvidas. Espero que você possa me ajudar.

Obrigado por compartilhar. Eu li muitos dos seus posts, legal, seu blog é muito bom.

Você pode ser mais específico sobre o conteúdo do seu artigo? Depois de ler, ainda tenho algumas dúvidas. Espero que você possa me ajudar. binância

Seu ponto de vista me chamou a atenção e foi muito interessante. Obrigado. Eu tenho uma pergunta para você.

Seu ponto de vista me chamou a atenção e foi muito interessante. Obrigado. Eu tenho uma pergunta para você.

Você pode ser mais específico sobre o conteúdo do seu artigo? Depois de ler, ainda tenho algumas dúvidas. Espero que você possa me ajudar.

Não acho que o título do seu artigo corresponda ao conteúdo haha. Estou brincando, principalmente porque tive algumas dúvidas depois de ler o artigo.

I don’t think the title of your enticle matches the content lol. Estou brincando, mainly because I had some doubts after reading the enticle.

Não acho que o título do seu artigo corresponda ao conteúdo haha. Estou brincando, principalmente porque tive algumas dúvidas depois de ler o artigo.

Obrigado pela sua partilha. Estou preocupado porque me faltam ideias criativas. É o seu artigo que me deixa cheio de esperança. Obrigado. Mas, Eu tenho uma pergunta, pode me ajudar?

**cofre mental**

Mind Vault é uma fórmula premium de suporte cognitivo criada para adultos 45+. Ele foi cuidadosamente projetado para ajudar a manter um pensamento claro

**cofre mental**

cofre mental é uma fórmula premium de suporte cognitivo criada para adultos 45+. Ele foi cuidadosamente projetado para ajudar a manter um pensamento claro

**respirar**

respirar é uma tintura à base de plantas elaborada para promover o desempenho pulmonar e melhorar a qualidade da respiração.

**respirar**

respirar é uma tintura à base de plantas elaborada para promover o desempenho pulmonar e melhorar a qualidade da respiração.

Seu ponto de vista me chamou a atenção e foi muito interessante. Obrigado. Eu tenho uma pergunta para você.

Obrigado pela sua partilha. Estou preocupado porque me faltam ideias criativas. É o seu artigo que me deixa cheio de esperança. Obrigado. Mas, Eu tenho uma pergunta, pode me ajudar?

Eu aprendi muito com isso. Obrigado.

Não acho que o título do seu artigo corresponda ao conteúdo haha. Estou brincando, principalmente porque tive algumas dúvidas depois de ler o artigo.

Hi there, You have done a fantastic job. I’ll definitely digg it and in my opinion suggest to my friends. I am sure they’ll be benefited from this web site.

Obrigado por compartilhar. Eu li muitos dos seus posts, legal, seu blog é muito bom. https://accounts.binance.com/register-person?ref=IXBIAFVY

Obrigado por compartilhar. Eu li muitos dos seus posts, legal, seu blog é muito bom. https://accounts.binance.com/sk/register-person?ref=WKAGBF7Y

Obrigado pela sua partilha. Estou preocupado porque me faltam ideias criativas. É o seu artigo que me deixa cheio de esperança. Obrigado. Mas, Eu tenho uma pergunta, pode me ajudar?

Obrigado pela sua partilha. Estou preocupado porque me faltam ideias criativas. É o seu artigo que me deixa cheio de esperança. Obrigado. Mas, Eu tenho uma pergunta, pode me ajudar? https://accounts.binance.com/pt-PT/register-person?ref=KDN7HDOR

Seu ponto de vista me chamou a atenção e foi muito interessante. Obrigado. Eu tenho uma pergunta para você.

Seu ponto de vista me chamou a atenção e foi muito interessante. Obrigado. Eu tenho uma pergunta para você.

Seu artigo me ajudou muito, existe mais algum conteúdo relacionado? Obrigado!

Obrigado pela sua partilha. Estou preocupado porque me faltam ideias criativas. É o seu artigo que me deixa cheio de esperança. Obrigado. Mas, Eu tenho uma pergunta, pode me ajudar?

Obrigado por compartilhar. Eu li muitos dos seus posts, legal, seu blog é muito bom.

Downloaded the 52betapp the other day. Mobile betting is super convenient. The interface is clean and easy to use. Definitely recommend: 52betapp

Obrigado por compartilhar. Eu li muitos dos seus posts, legal, seu blog é muito bom.

Seu ponto de vista me chamou a atenção e foi muito interessante. Obrigado. Eu tenho uma pergunta para você.

**backbioma**

backbiome é um criado naturalmente, suplemento diário apoiado por pesquisas formulado para aliviar suavemente a tensão nas costas e aliviar o desconforto ciático.

**vivalis**

vivalis é uma fórmula natural premium criada para ajudar os homens a se sentirem mais fortes, mais enérgico, e mais confiante a cada dia.

**glicomute**

glicomute é uma fórmula nutricional natural cuidadosamente criada para nutrir níveis saudáveis de açúcar no sangue e apoiar o desempenho metabólico geral.

**balmorex pro**

balmorex é uma solução excepcional para indivíduos que sofrem de dores crônicas nas articulações e dores musculares.

**aquaescultura**

Aquasculpt é um suplemento revolucionário criado para ajudar no controle de peso, acelerando naturalmente o metabolismo

**calma nervosa**

nervocalm é um suplemento nutricional de alta qualidade elaborado para promover o bem-estar dos nervos, aliviar o desconforto crônico, e aumentar a vitalidade diária.

**sinadentix**

synadentix é um suplemento de saúde dentária criado para nutrir e proteger os dentes e gengivas com uma combinação direcionada de ingredientes naturais

**prostavivo**

prostavive Manter a saúde da próstata é crucial para o bem-estar geral dos homens, especialmente à medida que envelhecem.

**impulso alfa **

impulso alfa para homens, sentindo-se forte, energizado, e confiante está intimamente ligado à qualidade de vida geral. No entanto, com a idade, estresse, e demandas diárias

**você dorme**

Yusleep é gentil, mistura noturna nano-aprimorada projetada para ajudá-lo a adormecer rapidamente, ficar dormindo por mais tempo, e acorde sentindo-se claro

**glpro**

glpro é um suplemento dietético natural desenvolvido para promover níveis equilibrados de açúcar no sangue e reduzir o desejo por açúcar.

**cofre mental**

mindvault é uma fórmula premium de suporte cognitivo criada para adultos 45+.

**nitric boost ultra**

nitric boost é uma mistura diária de bem-estar formulada para elevar a vitalidade e apoiar o desempenho geral.

**femipro**

femipro é um suplemento alimentar desenvolvido como remédio natural para mulheres que enfrentam problemas de controle da bexiga e buscam melhorar sua saúde urinária.

**Vertianos **

vertiaid é um software de alta qualidade, fórmula natural criada para apoiar o equilíbrio estável, melhorar a agudeza mental, e aliviar sentimentos de tontura

**vitrafoxina**

vitrafoxina é uma fórmula premium de aprimoramento do cérebro elaborada com ingredientes naturais para promover um pensamento claro, retenção de memória, e energia mental duradoura.

**glicose**

glucore é um suplemento nutricional administrado diariamente aos pacientes para ajudar a manter o açúcar no sangue e as taxas metabólicas saudáveis.

Obrigado, I have recently been looking for info about this subject for a while and yours is the best I’ve came upon till now. Mas, what about the bottom line? Are you positive in regards to the supply?

**doce**

sugarmute é um suplemento nutricional orientado pela ciência, criado para ajudar a manter o nível de açúcar no sangue equilibrado, ao mesmo tempo que apoia a energia estável e a clareza mental

**primebioma**

O ciclo natural de renovação celular da pele desempenha um papel vital na manutenção de uma aparência saudável e jovem, eliminando células velhas e gerando novas..

**hepato burn**

hepatoburn é um produto de alta qualidade, mistura dietética baseada em plantas criada para nutrir a função hepática, encorajar um ritmo metabólico saudável, e apoiar as vias naturais de processamento de gordura do corpo.

Great information. Lucky me I discovered your website by accident (stumbleupon). I’ve saved as a favorite for later!

Wow, that’s what I was exploring for, what a material! existing here at this web site, thanks admin of this web page.

Hurrah, that’s what I was exploring for, what a information! existing here at this web site, thanks admin of this site.

Wow, that’s what I was seeking for, what a stuff! present here at this blog, thanks admin of this web page.

Hurrah, that’s what I was looking for, what a stuff! existing here at this weblog, thanks admin of this website.

Wow, that’s what I was looking for, what a information! present here at this website, thanks admin of this site.

Hurrah, that’s what I was exploring for, what a data! present here at this webpage, thanks admin of this web page.

Wow, that’s what I was searching for, what a data! existing here at this web site, thanks admin of this site.

Wow, that’s what I was seeking for, what a data! present here at this website, thanks admin of this web site.

Hurrah, that’s what I was exploring for, what a information! existing here at this webpage, thanks admin of this web page.

Hurrah, that’s what I was looking for, what a information! existing here at this webpage, thanks admin of this website.

Hurrah, that’s what I was looking for, what a material! present here at this website, thanks admin of this web site.

After I originally left a comment I appear to have clicked the -Notify me when new comments are added- checkbox and now every time a comment is added I receive four emails with the same comment. There has to be an easy method you can remove me from that service? Thanks a lot!

Hello There. I found your blog using msn. This is a really well written article.

I will be sure to bookmark it and return to read more of your useful info.

Thanks for the post. I will definitely return.

It’s going to be ending of mine day, except before ending I am reading this impressive

post to increase my experience.

When I originally left a comment I appear to have clicked the -Notify me when new comments are added- checkbox and from now on every time a comment is added I get four emails with the same comment. There has to be a way you can remove me from that service? Obrigado!

After I originally commented I seem to have clicked on the -Notify me when new comments are added- checkbox and now whenever a comment is added I recieve 4 emails with the same comment. There has to be an easy method you can remove me from that service? Many thanks!

When I initially commented I appear to have clicked on the -Notify me when new comments are added- checkbox and from now on whenever a comment is added I receive 4 emails with the same comment. Perhaps there is a way you can remove me from that service? Obrigado!

When I initially commented I appear to have clicked on the -Notify me when new comments are added- checkbox and now whenever a comment is added I recieve 4 emails with the exact same comment. There has to be a means you can remove me from that service? Thanks a lot!

When I initially commented I appear to have clicked the -Notify me when new comments are added- checkbox and from now on each time a comment is added I get 4 emails with the same comment. Is there a way you are able to remove me from that service? Many thanks!

When I initially left a comment I seem to have clicked on the -Notify me when new comments are added- checkbox and now whenever a comment is added I receive four emails with the exact same comment. Is there a means you can remove me from that service? Kudos!

After I originally left a comment I appear to have clicked the -Notify me when new comments are added- checkbox and now each time a comment is added I get 4 emails with the same comment. Is there a means you can remove me from that service? Appreciate it!

When I initially left a comment I appear to have clicked on the -Notify me when new comments are added- checkbox and from now on each time a comment is added I receive 4 emails with the same comment. Is there an easy method you are able to remove me from that service? Obrigado!

Hello! I could have sworn I’ve been to this website before but after browsing through some of the post I realized it’s new to me. Anyhow, I’m definitely glad I found it and I’ll be bookmarking and checking back often!

Hi there! I could have sworn I’ve been to this site before but after checking through some of the post I realized it’s new to me. Anyways, I’m definitely glad I found it and I’ll be bookmarking and checking back frequently!

Good day! I could have sworn I’ve been to this website before but after checking through some of the post I realized it’s new to me. Anyhow, I’m definitely delighted I found it and I’ll be book-marking and checking back often!

Good day! I could have sworn I’ve been to this site before but after reading through some of the post I realized it’s new to me. Anyways, I’m definitely glad I found it and I’ll be book-marking and checking back frequently!

Hi! I could have sworn I’ve been to this blog before but after reading through some of the post I realized it’s new to me. Nonetheless, I’m definitely glad I found it and I’ll be book-marking and checking back frequently!

Hey there! I could have sworn I’ve been to this website before but after reading through some of the post I realized it’s new to me. Nonetheless, I’m definitely delighted I found it and I’ll be book-marking and checking back frequently!

Obrigado por compartilhar. Eu li muitos dos seus posts, legal, seu blog é muito bom.

Hey there! I could have sworn I’ve been to this blog before but after reading through some of the post I realized it’s new to me. Nonetheless, I’m definitely glad I found it and I’ll be book-marking and checking back frequently!

Hello! I could have sworn I’ve been to this blog before but after checking through some of the post I realized it’s new to me. Nonetheless, I’m definitely happy I found it and I’ll be bookmarking and checking back frequently!

You have made some decent points there. I checked on the net to learn more about the issue and found most people will go along with your views on this site.

Ótima postagem.

Hmm is anyone else encountering problems with the images on this blog loading? I’m trying to find out if its a problem on my end or if it’s the blog. Any responses would be greatly appreciated.

Keep on writing, great job!

Hi there friends, good paragraph and fastidious arguments commented at this place, I am truly enjoying by these.

Seu ponto de vista me chamou a atenção e foi muito interessante. Obrigado. Eu tenho uma pergunta para você. https://accounts.binance.info/si-LK/register?ref=LBF8F65G

I think this is one of the most vital information for me. And i am glad reading your article. But should remark on few general things, The web site style is wonderful, the articles is really excellent : D. Good job, cheers

Excellent blog you have here.. It’s difficult to find high-quality writing like yours these days. I truly appreciate individuals like you! Take care!!

I am regular visitor, how are you everybody? This paragraph posted at this web site is truly nice.

Everyone loves what you guys are up too. This kind of clever work and coverage! Keep up the excellent works guys I’ve incorporated you guys to blogroll.

Superb site you have here but I was curious about if you knew of any message boards that cover the same topics talked about in this article? I’d really like to be a part of group where I can get comments from other experienced people that share the same interest. If you have any suggestions, please let me know. Thanks a lot!

Greate article. Keep writing such kind of information on your blog. Im really impressed by your blog

My developer is trying to convince me to move to .net from PHP. I have always disliked the idea because of the costs. But he’s tryiong none the less. I’ve been using Movable-type on a number of websites for about a year and am anxious about switching to another platform. I have heard fantastic things about blogengine.net. Is there a way I can transfer all my wordpress posts into it? Any help would be greatly appreciated!

Very soon this web site will be famous amid all blogging and site-building users, due to it’s good content

Wow, wonderful weblog layout! How long have you ever been blogging for? you made running a blog look easy. The entire glance of your site is magnificent, let alone the content material

It’s going to be ending of mine day, except before ending I am reading this impressive post to improve my knowledge.

Its like you read my mind! You appear to know a lot about this, like you wrote the book in it or something. I think that you can do with some pics to drive the message home a bit, but instead of that, this is excellent blog. An excellent read. I will certainly be back.

Thanks for any other informative blog. The place else could I am getting that type of info written in such an ideal method? I have a challenge that I am simply now running on, and I’ve been on the glance out for such information.

I loved as much as you’ll receive carried out right here. The sketch is attractive, your authored subject matter stylish. nonetheless, you command get got an shakiness over that you wish be delivering the following. unwell unquestionably come further formerly again since exactly the same nearly a lot often inside case you shield this increase.

It’s an remarkable paragraph designed for all the web viewers; they will get benefit from it I am sure.

Thanks to my father who told me regarding this website, this webpage is in fact amazing.

I always spent my half an hour to read this webpage’s content all the time along with a cup of coffee.

Great information. Lucky me I found your site by accident (stumbleupon). I have book-marked it for later!

I’m not sure where you are getting your information, but good topic. I needs to spend some time learning more or understanding more. Thanks for fantastic info I was looking for this info for my mission.

I must thank you for the efforts you have put in penning this website. I am hoping to check out the same high-grade blog posts by you later on as well. In truth, your creative writing abilities has motivated me to get my very own blog now 😉

Do you have any video of that? I’d love to find out some additional information.

Hey There. I found your blog using msn. This is a very well written article. I’ll be sure to bookmark it and return to read more of your useful info. Thanks for the post. I’ll certainly comeback.

This paragraph will assist the internet visitors for setting up new website or even a blog from start to end.

Hi! I’m at work surfing around your blog from my new iphone 3gs! Just wanted to say I love reading through your blog and look forward to all your posts! Carry on the fantastic work!

Very shortly this web site will be famous amid all blogging and site-building viewers, due to it’s nice content

I have read so many content regarding the blogger lovers however this article is genuinely a good piece of writing, keep it up.

I want to to thank you for this very good read!! I certainly enjoyed every little bit of it. I have got you saved as a favorite to look at new stuff you post…

Awesome article.

I always emailed this blog post page to all my contacts, because if like to read it next my contacts will too.

What a data of un-ambiguity and preserveness of valuable knowledge about unpredicted feelings.

Wonderful blog you have here but I was curious if you knew of any user discussion forums that cover the same topics discussed in this article? I’d really like to be a part of group where I can get opinions from other experienced individuals that share the same interest. If you have any suggestions, please let me know. Obrigado!

Spot on with this write-up, I really feel this website needs much more attention. I’ll probably be back again to read more, thanks for the info!

Hello there, You have performed an incredible job. I’ll definitely digg it and in my view suggest to my friends. I am confident they’ll be benefited from this web site.

Hello! Do you use Twitter? I’d like to follow you if that would be ok. I’m absolutely enjoying your blog and look forward to new updates.

Spot on with this write-up, I honestly believe that this web site needs far more attention. I’ll probably be back again to read through more, thanks for the information!

I will immediately clutch your rss feed as I can not find your email subscription hyperlink or newsletter service. Do you’ve any? Please allow me recognise so that I could subscribe. Obrigado.

I’m not that much of a internet reader to be honest but your blogs really nice, keep it up! I’ll go ahead and bookmark your site to come back in the future. All the best

Fabulous, what a weblog it is! This webpage gives useful data to us, keep it up.

What a information of un-ambiguity and preserveness of valuable familiarity regarding unexpected emotions.

Outstanding quest there. What occurred after? Obrigado!

It is really a great and useful piece of info. I am satisfied that you shared this useful information with us. Please stay us informed like this. Obrigado por compartilhar.

I absolutely love your blog and find many of your post’s to be exactly what I’m looking for. Do you offer guest writers to write content for yourself? I wouldn’t mind publishing a post or elaborating on some of the subjects you write regarding here. Again, awesome web log!

I really like what you guys are up too. This sort of clever work and exposure! Keep up the amazing works guys I’ve added you guys to my own blogroll.

Fine way of telling, and pleasant paragraph to take data about my presentation focus, which i am going to deliver in college.

Thanks for the good writeup. It in truth was a entertainment account it. Look advanced to far introduced agreeable from you! By the way, how can we keep in touch?

I like the helpful information you supply in your articles.

I’ll bookmark your blog and test once more here frequently.

I’m fairly sure I will be informed many new stuff proper here!

Best of luck for the following!

May I just say what a relief to discover someone who really knows

what they’re discussing on the internet. You actually understand how to bring an issue to light and make it important.

More people must check this out and understand this side of your story.

It’s surprising you’re not more popular because you certainly possess the gift.

Hi there very cool blog!! Guy .. Excellent .. Wonderful ..

I will bookmark your site and take the feeds additionally?

I am happy to seek out numerous useful info right

here in the publish, we need work out more strategies

on this regard, thank you for sharing. . . . . .

It’s remarkable in support of me to have a website, which is helpful in favor of my know-how. thanks admin

Quality posts is the important to interest the visitors to pay a quick visit the web page, that’s what this web page is providing.

日本 av – https://kanav.so

**finessa**

Finessa is a natural supplement made to support healthy digestion, improve metabolism, and help you achieve a flatter belly.

I could not refrain from commenting. Well written!

I used to be suggested this blog through my cousin. I’m not positive whether this submit is written via him as no one else realize such specified approximately my difficulty. You’re wonderful! Obrigado!

An intriguing discussion is definitely worth comment. There’s no doubt that that you ought to publish more on this topic, it may not be a taboo subject but generally folks don’t speak about these topics. To the next! Many thanks!!

This blog was… how do you say it? Relevant!! Finally I’ve found something which helped me. Many thanks!

magnificent publish, very informative. I wonder why the opposite specialists of this sector don’t realize this. You must continue your writing. I am confident, you have a huge readers’ base already!

Obrigado por compartilhar. Eu li muitos dos seus posts, legal, seu blog é muito bom.

Ei! I’m at work browsing your blog from my new iphone 3gs! Just wanted to say I love reading your blog and look forward to all your posts! Carry on the superb work!

My spouse and I stumbled over here coming from a different website and thought I may as well check things out. I like what I see so now i’m following you. Look forward to looking into your web page for a second time.

I loved as much as you’ll receive carried out right here. The sketch is tasteful, your authored material stylish. nonetheless, you command get bought an edginess over that you wish be delivering the following. unwell unquestionably come further formerly again since exactly the same nearly a lot often inside case you shield this hike.

I’m curious to find out what blog platform you are working with? I’m experiencing some small security issues with my latest website and I would like to find something more safeguarded. Do you have any suggestions?

If you are going for best contents like myself, only go to see this web page all the time for the reason that it provides feature contents, thanks

Ei! This post couldn’t be written any better! Reading through this post reminds me of my good old room mate! He always kept talking about this. I will forward this page to him. Pretty sure he will have a good read. Obrigado por compartilhar!

Awesome things here. I’m very satisfied to look your article. Thanks so much and I’m taking a look forward to touch you. Will you kindly drop me a mail?

Hello just wanted to give you a quick heads up. The words in your post seem to be running off the screen in Ie. I’m not sure if this is a formatting issue or something to do with browser compatibility but I figured I’d post to let you know. The layout look great though! Hope you get the problem solved soon. Many thanks

Incredible! This blog looks just like my old one! It’s on a completely different topic but it has pretty much the same layout and design. Outstanding choice of colors!

May I just say what a relief to discover someone who actually knows what they are talking about on the web. You certainly know how to bring a problem to light and make it important. More people really need to check this out and understand this side of your story. It’s surprising you are not more popular since you certainly have the gift.

Obrigado pela sua partilha. Estou preocupado porque me faltam ideias criativas. É o seu artigo que me deixa cheio de esperança. Obrigado. Mas, Eu tenho uma pergunta, pode me ajudar?

Você pode ser mais específico sobre o conteúdo do seu artigo? Depois de ler, ainda tenho algumas dúvidas. Espero que você possa me ajudar.

Obrigado por compartilhar. Eu li muitos dos seus posts, legal, seu blog é muito bom. https://accounts.binance.com/uk-UA/register?ref=XZNNWTW7

Seu ponto de vista me chamou a atenção e foi muito interessante. Obrigado. Eu tenho uma pergunta para você.

Seu ponto de vista me chamou a atenção e foi muito interessante. Obrigado. Eu tenho uma pergunta para você.

Aw, this was a very good post. Spending some time and actual effort to create a good article… but what can I say… I procrastinate a whole lot and never seem to get anything done.

Seu artigo me ajudou muito, existe mais algum conteúdo relacionado? Obrigado!

Seu ponto de vista me chamou a atenção e foi muito interessante. Obrigado. Eu tenho uma pergunta para você. https://accounts.binance.com/es/register-person?ref=RQUR4BEO