Mini linha de produção de garrafas Máquina automática de selagem de frascos de vidro Máquina de enchimento de frascos orais

Volume de enchimento | 5~60ml&50~500ml&500~5000ml(Personalizado) |

Velocidade de enchimento | 1000~8000BPH |

Cilindro | ARTAC/Festo |

Tipo de controlo | PLC + tela sensível ao toque |

Volume da tremonha | 20~40L |

Método de aquecimento | Aquecido Elétrico(Opcional) |

Função de mixagem | Opcional |

Aplicativo | Água com mel/xarope/ketchup/pasta/maionese/molho/pomada/creme/loção/gel/shampoo/detergente |

Proteção de segurança | Capa acrílica&Botão de parada de emergência |

Volume de enchimento(ml) | Produtividade(b/h) | Velocidade de enchimento | Precisão de enchimento | Fornecimento de ar |

5-50 | 1500-3500 | Ajustável | ≤±1% | 0.4-0.8MPa |

80-300 | 1500-3000 | Ajustável | ≤±1% | 0.4-0.8MPa |

100-500 | 1500-2500 | Ajustável | ≤±1% | 0.4-0.8MPa |

300-1000 | 1500-2500 | Ajustável | ≤±1% | 0.4-0.8MPa |

1000-5000 | 1000-2000 | Ajustável | ≤±1% | 0.4-0.8MPa |

Nossas vantagens competitivas

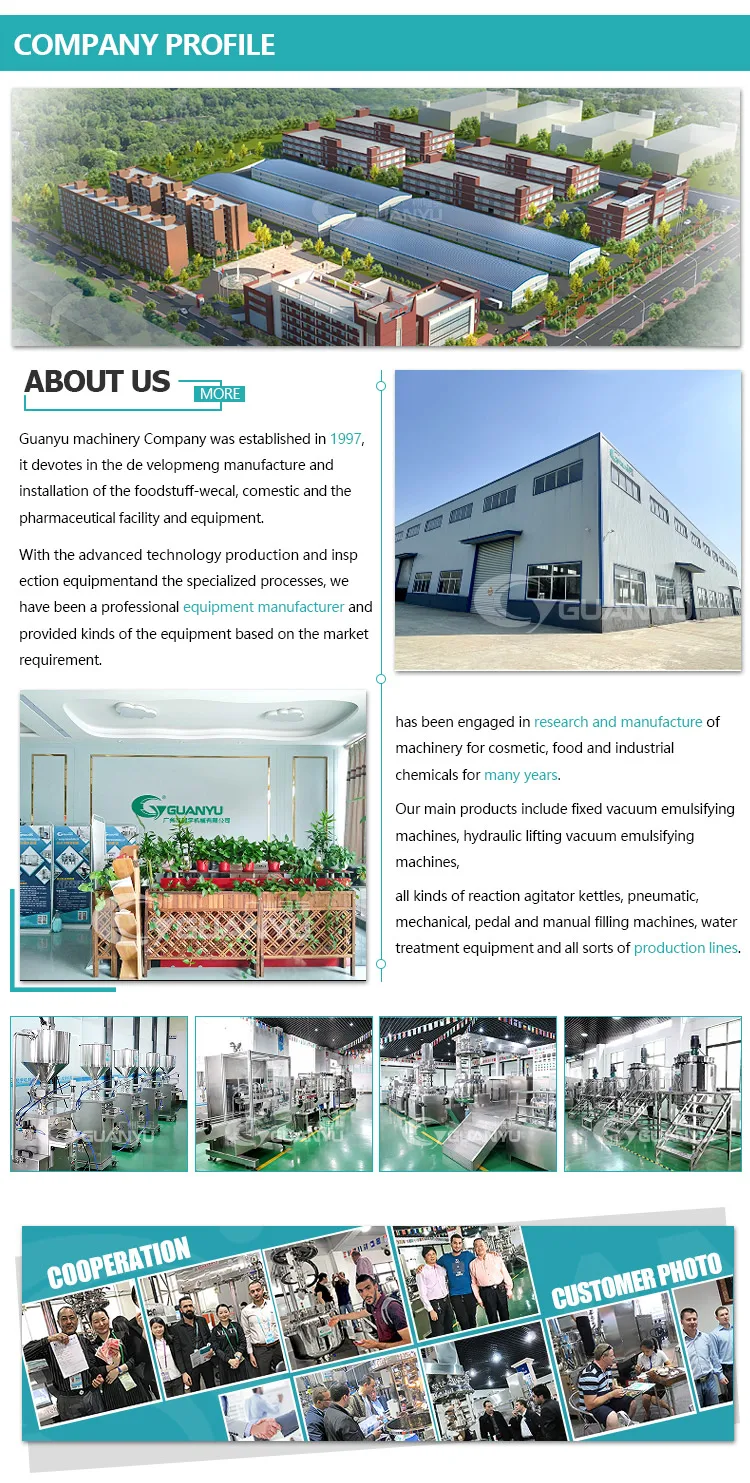

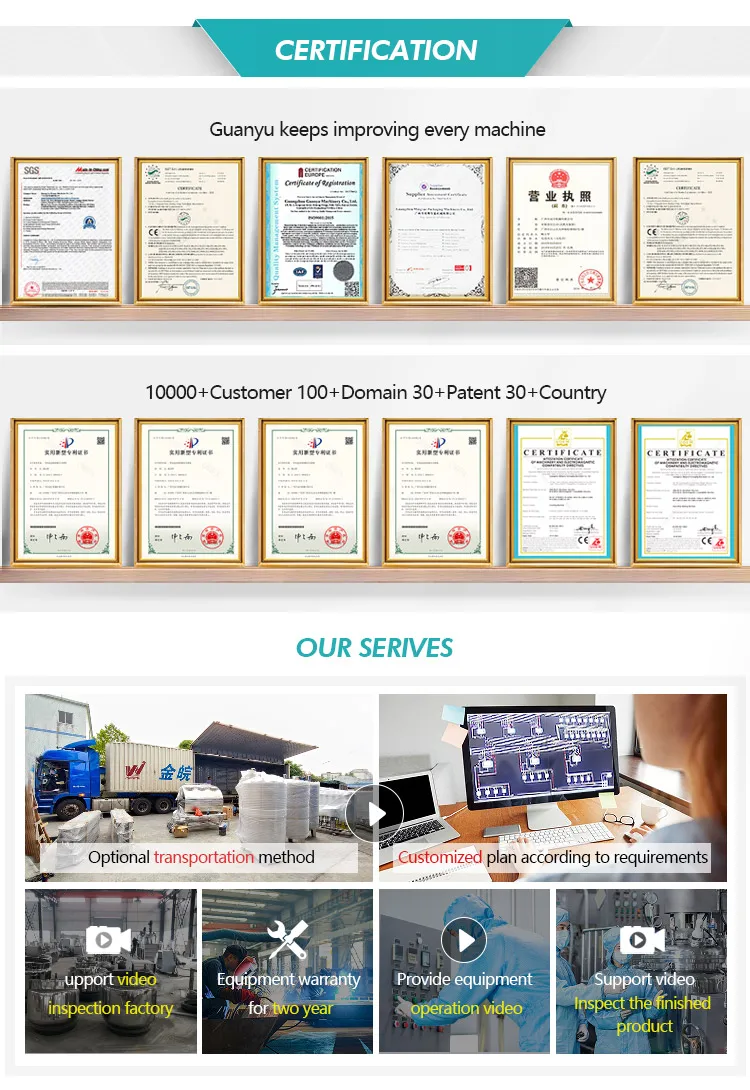

Fundado em 1997, Máquinas Co. de Guangzhou Guanyu., Ltda acumulou mais 25 anos de experiência no desenvolvimento, fabricação, e instalação de equipamentos especializados para o setor cosmético, comida, e indústrias farmacêuticas. Nossa empresa se destaca devido ao nosso instalações de produção tecnológica de última geração, que incluem testes avançados e sistemas de controle de qualidade para garantir o mais alto nível de desempenho do produto.Nós utilizamos fluxos de processos especializados desenvolver e fabricar equipamentos que atendam aos mais altos padrões da indústria. Esta dedicação à inovação e à qualidade estabeleceu-nos como uma empresa líder na área, permitindo-nos atender a uma ampla gama de necessidades dos clientes com equipamentos personalizados. Nossa diversificada gama de soluções garante que não importa quão complexo seja o requisito de produção, podemos fornecer uma solução personalizada que oferece excelentes resultados.3. Máquinas personalizáveis para atender a cada necessidade

No Máquinas Co. de Guangzhou Guanyu., Ltda, entendemos que o processo de produção de cada cliente é único. É por isso que oferecemos uma ampla gama de máquinas personalizáveis projetado para atender às necessidades específicas de nossos clientes. Estes incluem:- Misturador Homogeneizador Emulsionante a Vácuo: Ideal para mistura e emulsificação de alta precisão nas indústrias cosmética e farmacêutica.

- Máquina de agitação misturadora de tanque de mistura aberta: Soluções de mistura flexíveis para diferentes viscosidades e materiais, comumente usado na produção de alimentos e cosméticos.

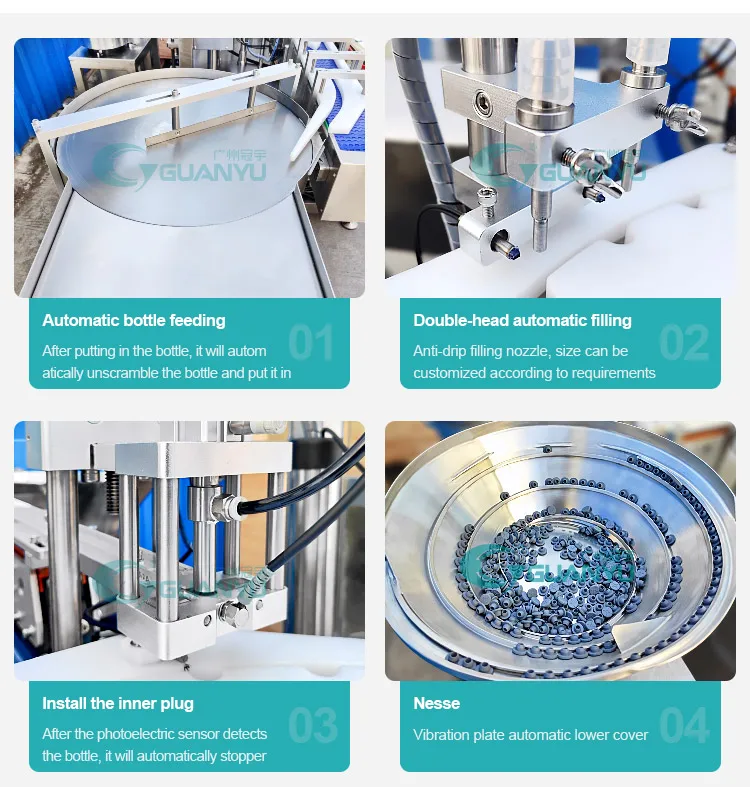

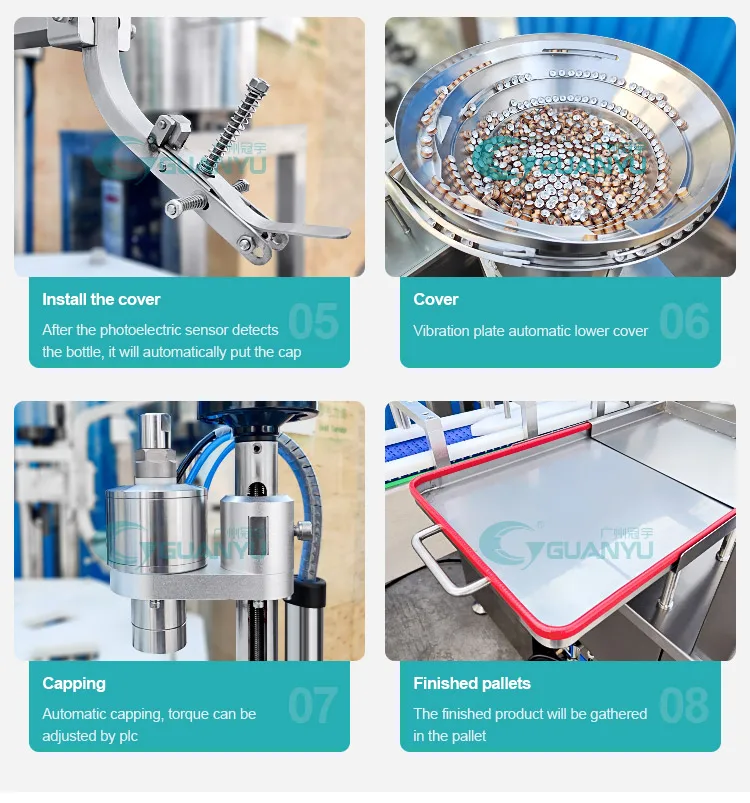

- Enchimento, Captura, Rotulagem, e máquinas de embalagem: Sistemas automatizados altamente eficientes projetados para agilizar os processos de embalagem e aumentar o rendimento da produção.

- Sistemas de tratamento de água por osmose reversa RO: Essencial para alcançar a mais alta pureza na água utilizada nos processos de produção.

- Vários tipos de tanques de armazenamento: Oferecendo soluções robustas de armazenamento para matérias-primas, produtos intermediários, e produtos acabados.

Revisões

Não há comentários ainda.