Condensed milk is a rich, thick, and sweet dairy product used in a variety of desserts, drinks, and baked goods. It’s produced by evaporating water from milk and adding sugar, resulting in a shelf-stable product with a long storage life. The manufacturing process of condensed milk is carefully controlled to ensure quality, consistência, e segurança. Here’s a detailed look at how condensed milk is made, from selecting the right milk to the final packaging stages.

Key Ingredients in Condensed Milk

The ingredients in condensed milk are simple yet carefully selected to ensure quality and flavor:

- Fresh Milk: High-quality, fresh cow’s milk is typically used. The milk is the base of the product and provides the rich, creamy flavor and essential nutrients.

- Sugar: Sugar is added both to sweeten the product and to act as a preservative. In sweetened condensed milk, sugar makes up about 40-45% of the product, which helps prevent bacterial growth and extends shelf life.

- Stabilizers (opcional): Some manufacturers add stabilizers to ensure a smooth texture and to prevent crystallization or separation over time.

Step-by-Step Condensed Milk Manufacturing Process

Producing condense milk on an industrial scale involves several key steps, each ensuring the milk is properly concentrated, sweetened, and sterilized to meet quality standards.

1. Milk Selection and Quality Control

The process begins with selecting fresh, high-quality milk. The milk must meet strict quality criteria to ensure it is free of contaminants, has the right fat content, and is fresh. Quality checks are performed for:

- Fat Content: Milk with a higher fat content results in creamier condensed milk.

- Bacterial Count: The milk is tested for microbial safety to ensure it’s safe for consumption.

- Purity and Freshness: Checks for additives or contaminants are conducted to maintain product integrity.

Once approved, the milk is stored in refrigerated tanks until it’s ready for processing.

2. Preheating the Milk

Before further processing, the milk is preheated to around 85°C (185°F) for a short time. This initial heating step has several purposes:

- Destroys Harmful Bacteria: It kills any microorganisms present, ensuring the milk is safe to consume.

- Improves Concentration Efficiency: Preheating also helps remove dissolved gases, which makes it easier to concentrate the milk later.

- Prevents Separation: This heating step reduces the risk of fat separation during the evaporation process.

3. Evaporating Water from the Milk

The key step in condensed milk production is evaporation, where about 60% of the water content is removed from the milk. This process is typically done in a vacuum evaporator.

In a vacuum evaporator, the boiling point of milk is reduced by creating a low-pressure environment, allowing water to evaporate at lower temperatures (around 60°C or 140°F). Lower temperatures prevent the milk from scorching, preserve nutrients, and maintain the product’s natural flavor. This process continues until the milk reaches the desired concentration.

4. Adding Sugar

After evaporation, sugar is added to the concentrated milk. The amount of sugar varies depending on the desired sweetness level, but in standard sweetened condensed milk, sugar usually makes up 40-45% of the product by weight.

The addition of sugar serves two main purposes:

- Sweetening: It gives the condensed milk its characteristic sweet flavor.

- Preservation: The high sugar content helps prevent microbial growth by creating a high osmotic pressure, which inhibits bacteria and mold.

The sugar is mixed thoroughly to ensure it dissolves completely in the milk. This creates a homogeneous mixture that will not crystallize or separate during storage.

5. Homogenization

After adding sugar, the milk undergoes homogeneização. Homogenization is the process of breaking down fat molecules to prevent them from separating from the liquid, ensuring a smooth, uniform texture.

In this step, the milk is forced through a homogenizer, which applies high pressure to break down the fat particles. This results in a creamy, consistent product that will stay stable over time. Homogenization is particularly important for creating condensed milk with a smooth, pleasant mouthfeel.

6. Resfriamento

The hot, sweetened, and homogenized milk mixture is then cooled down gradually to prevent crystallization. Rapid cooling is essential to avoid sugar crystallization, which would affect the texture and consistency of the condensed milk.

Tipicamente, the milk is cooled in a controlled manner to around 20-25°C (68-77°F) using specialized cooling equipment. This step also helps stabilize the milk before packaging, ensuring that it retains its smooth and creamy texture.

7. Quality Testing

After cooling, the condensed milk undergoes various quality tests to ensure it meets industry standards. Common tests include:

- Viscosity Check: Ensures the product has the right thickness, which is crucial for consistency.

- Taste and Color: The milk is tested for flavor and color to ensure it meets the manufacturer’s quality standards. The ideal condensed milk has a slightly caramelized flavor and a creamy, off-white color.

- Microbial Testing: Samples are tested for bacterial contamination to ensure the product is safe and shelf-stable.

- Sugar Concentration: The sugar content is measured to confirm it aligns with the desired sweetness level.

Quality control is crucial to ensure that each batch meets regulatory standards and customer expectations.

8. Packaging

Once quality control checks are completed, the condensed milk is ready for packaging. Condensed milk is typically packaged in sterilized cans, but it can also be filled into squeeze bottles or cartons, depending on the manufacturer and market preferences.

The packaging process is done in a sterile environment to prevent contamination. Canning involves filling the condensed milk into cans, which are then sealed to create an airtight environment. This helps extend the product’s shelf life and ensures it remains safe for long-term storage.

After packaging, each container is labeled and batch-coded for traceability, allowing manufacturers to track production details in case of recalls or quality issues.

9. Sterilization (Optional for Certain Markets)

In some regions, condensed milk undergoes additional sterilization after packaging to extend its shelf life further. This process, known as retort sterilization, involves heating the sealed cans at high temperatures to kill any remaining bacteria. Retort sterilization ensures that the condensed milk remains safe and stable even under extended storage.

Recomendado Guanyu Mixers in Condensed Milk Production

Vacuum Homogenizer Condensed Milk Mixer

- Versatile Solution: Guanyu Vacuum Homogenizer Condensed Milk Mixer Machine stands as the ultimate solution for crafting a wide spectrum of condensed milk formulations.

- Enriched Ingredients: From smooth-textured to those with small particulates, this versatile equipment allows you to create condensed milk enriched with diverse ingredients such as natural components, Óleos, spices, and powders.

- Precision: This precision ensures you achieve your desired flavor profile with every batch.

- Meticulous Control: The Vacuum Homogenizer Condensed Milk Mixer can be meticulously controlled to align with your specific mixing requirements, including managing shear rate and heat treatment, all to ensure the desired consistency of the final product.

- Enhanced Quality: The vacuum feature enhances product quality by efficiently distributing powder ingredients throughout the condensed milk mixing process.

Types of Condensed Milk

Condensed milk comes in a few different forms, depending on sugar content and processing:

- Sweetened Condensed Milk: This is the most common type, containing added sugar for sweetness and preservation. It’s used in baking, desserts, and beverages.

- Unsweetened Condensed Milk (Evaporated Milk): This type has no added sugar and is made by simply evaporating about 60% of the water from the milk. It’s often used in savory dishes and recipes where sweetness is not desired.

- Low-Fat or Skimmed Condensed Milk: For health-conscious consumers, some manufacturers produce condensed milk with lower fat content by using skimmed or low-fat milk.

Advantages of Condensed Milk

Condensed milk has several benefits, both for manufacturers and consumers:

- Long Shelf Life: The high sugar content (in sweetened versions) and low water content make condensed milk shelf-stable, meaning it can be stored without refrigeration for extended periods.

- Versatility: Condensed milk is highly versatile, used in everything from desserts to coffee. It serves as a thickener, sweetener, and base for various recipes.

- Nutrient-Rich: Condensed milk retains the nutrients of regular milk, including calcium, protein, and vitamins, making it a rich addition to recipes.

- Cost-Effective: Due to its concentrated form, condensed milk offers a high-calorie density, making it a valuable food source for recipes where creamy, sweet flavor is desired.

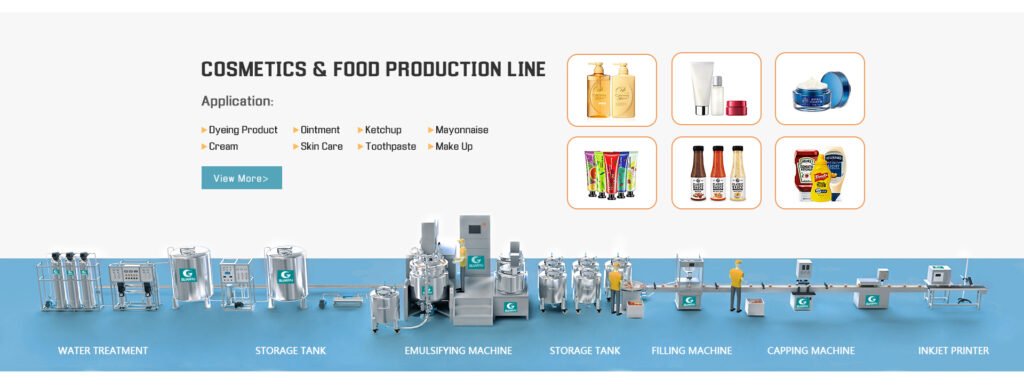

Máquinas Co. de Guangzhou Guanyu., Ltda: Over Two Decades of Excellence

Fundado em 1997, Máquinas Co. de Guangzhou Guanyu., Ltda has spent more than two decades perfecting the design, desenvolvimento, and manufacturing of high-quality machinery and production lines. Our primary focus is on serving the cosméticos, comida, e indústrias farmacêuticas, providing comprehensive production solutions that meet the diverse needs of our global clientele.

Our success is built on the principles of inovação, qualidade, and customer satisfaction. We offer end-to-end solutions, from consulting and equipment customization to engineering installation and after-sales support. Our dedication to technological advancement and superior service has made us a trusted partner to companies worldwide.

One-Stop Solutions: From Consulting to Customization

One of our key differentiators is our ability to offer one-stop solutions for our clients. From the initial consultation to the final installation, we ensure that every step of the process is tailored to the customer’s specific needs. At the core of our solutions are German FLUKO and IKA technologies, two of the leading names in the industry. Their advanced technologies form the backbone of our machinery, ensuring precision, eficiência, and durability.

Our one-stop approach combines consulting, equipment customization, and engineering installation, making it easier for businesses to achieve their production goals. We have successfully helped numerous well-known domestic and international companies optimize their production processes, increase efficiency, and drive innovation. By offering the most complete end-to-end production lines in the machinery industry, we are able to meet the differentiated needs of manufacturers globally while keeping up with the fast pace of innovation.

Whether it is small-scale production for niche markets or large-scale manufacturing for mass distribution, our solutions can be tailored to suit the unique requirements of any business. Our clients can focus on expanding their market reach and staying ahead of competitors, while we take care of their production needs with our innovative and flexible solutions.

Conclusão

The manufacturing process of condensed milk involves several carefully controlled steps, from milk selection and evaporation to homogenization, quality testing, and packaging. Each stage is crucial for achieving the rich, smooth texture and long shelf life that consumers expect from this popular product.

By selecting high-quality ingredients and following precise production steps, manufacturers produce condensed milk that is safe, delicious, and versatile for various culinary applications. Whether used in baking, desserts, or beverages, condensed milk has earned its place as a staple ingredient in kitchens around the world.

BWER é o fornecedor de básculas do Iraque, garantindo durabilidade, precisão, e economia em todas as soluções de pesagem, apoiado por serviços excepcionais de suporte ao cliente e manutenção.

Seu artigo me ajudou muito, existe mais algum conteúdo relacionado? Obrigado!

Não acho que o título do seu artigo corresponda ao conteúdo haha. Estou brincando, principalmente porque tive algumas dúvidas depois de ler o artigo.

Obrigado pela sua partilha. Estou preocupado porque me faltam ideias criativas. É o seu artigo que me deixa cheio de esperança. Obrigado. Mas, Eu tenho uma pergunta, pode me ajudar? https://accounts.binance.com/pt-PT/register?ref=DB40ITMB

Seu artigo me ajudou muito, existe mais algum conteúdo relacionado? Obrigado!

Você pode ser mais específico sobre o conteúdo do seu artigo? Depois de ler, ainda tenho algumas dúvidas. Espero que você possa me ajudar.

Você pode ser mais específico sobre o conteúdo do seu artigo? Depois de ler, ainda tenho algumas dúvidas. Espero que você possa me ajudar.

Você pode ser mais específico sobre o conteúdo do seu artigo? Depois de ler, ainda tenho algumas dúvidas. Espero que você possa me ajudar.

Seu artigo me ajudou muito, existe mais algum conteúdo relacionado? Obrigado!

Obrigado pela sua partilha. Estou preocupado porque me faltam ideias criativas. É o seu artigo que me deixa cheio de esperança. Obrigado. Mas, Eu tenho uma pergunta, pode me ajudar?

Seu artigo me ajudou muito, existe mais algum conteúdo relacionado? Obrigado!

Seu artigo me ajudou muito, existe mais algum conteúdo relacionado? Obrigado!

Seu artigo me ajudou muito, existe mais algum conteúdo relacionado? Obrigado!

Seu ponto de vista me chamou a atenção e foi muito interessante. Obrigado. Eu tenho uma pergunta para você.

Não acho que o título do seu artigo corresponda ao conteúdo haha. Estou brincando, principalmente porque tive algumas dúvidas depois de ler o artigo.

Você pode ser mais específico sobre o conteúdo do seu artigo? Depois de ler, ainda tenho algumas dúvidas. Espero que você possa me ajudar.

Seu ponto de vista me chamou a atenção e foi muito interessante. Obrigado. Eu tenho uma pergunta para você. http://8089949.cryptostarthome.com

Obrigado, seu artigo me surpreendeu, existe um ponto de vista tão excelente. Obrigado por compartilhar, Eu aprendi muito.

Seu ponto de vista me chamou a atenção e foi muito interessante. Obrigado. Eu tenho uma pergunta para você.

Obrigado por compartilhar. Eu li muitos dos seus posts, legal, seu blog é muito bom.

Obrigado por compartilhar. Eu li muitos dos seus posts, legal, seu blog é muito bom.

Seu ponto de vista me chamou a atenção e foi muito interessante. Obrigado. Eu tenho uma pergunta para você.

Não acho que o título do seu artigo corresponda ao conteúdo haha. Estou brincando, principalmente porque tive algumas dúvidas depois de ler o artigo.

Seu artigo me ajudou muito, existe mais algum conteúdo relacionado? Obrigado!

Seu ponto de vista me chamou a atenção e foi muito interessante. Obrigado. Eu tenho uma pergunta para você.

Obrigado pela sua partilha. Estou preocupado porque me faltam ideias criativas. É o seu artigo que me deixa cheio de esperança. Obrigado. Mas, Eu tenho uma pergunta, pode me ajudar? https://www.binance.com/es/register?ref=T7KCZASX

Seu ponto de vista me chamou a atenção e foi muito interessante. Obrigado. Eu tenho uma pergunta para você.

Obrigado pela sua partilha. Estou preocupado porque me faltam ideias criativas. É o seu artigo que me deixa cheio de esperança. Obrigado. Mas, Eu tenho uma pergunta, pode me ajudar? https://www.binance.info/id/register?ref=GJY4VW8W

Você pode ser mais específico sobre o conteúdo do seu artigo? Depois de ler, ainda tenho algumas dúvidas. Espero que você possa me ajudar. https://www.binance.info/fr/register-person?ref=GJY4VW8W

Obrigado pela sua partilha. Estou preocupado porque me faltam ideias criativas. É o seu artigo que me deixa cheio de esperança. Obrigado. Mas, Eu tenho uma pergunta, pode me ajudar?

Você pode ser mais específico sobre o conteúdo do seu artigo? Depois de ler, ainda tenho algumas dúvidas. Espero que você possa me ajudar.

Não acho que o título do seu artigo corresponda ao conteúdo haha. Estou brincando, principalmente porque tive algumas dúvidas depois de ler o artigo.

Seu ponto de vista me chamou a atenção e foi muito interessante. Obrigado. Eu tenho uma pergunta para você. https://www.binance.info/ur/register?ref=WTOZ531Y

Obrigado pela sua partilha. Estou preocupado porque me faltam ideias criativas. É o seu artigo que me deixa cheio de esperança. Obrigado. Mas, Eu tenho uma pergunta, pode me ajudar?

Você pode ser mais específico sobre o conteúdo do seu artigo? Depois de ler, ainda tenho algumas dúvidas. Espero que você possa me ajudar. Рестраця на Binance

Obrigado pela sua partilha. Estou preocupado porque me faltam ideias criativas. É o seu artigo que me deixa cheio de esperança. Obrigado. Mas, Eu tenho uma pergunta, pode me ajudar?

Obrigado pela sua partilha. Estou preocupado porque me faltam ideias criativas. É o seu artigo que me deixa cheio de esperança. Obrigado. Mas, Eu tenho uma pergunta, pode me ajudar?

Não acho que o título do seu artigo corresponda ao conteúdo haha. Estou brincando, principalmente porque tive algumas dúvidas depois de ler o artigo.

Obrigado por compartilhar. Eu li muitos dos seus posts, legal, seu blog é muito bom.

Seu ponto de vista me chamou a atenção e foi muito interessante. Obrigado. Eu tenho uma pergunta para você.

Seu artigo me ajudou muito, existe mais algum conteúdo relacionado? Obrigado!

Não acho que o título do seu artigo corresponda ao conteúdo haha. Estou brincando, principalmente porque tive algumas dúvidas depois de ler o artigo.

Seu artigo me ajudou muito, existe mais algum conteúdo relacionado? Obrigado!

Seu ponto de vista me chamou a atenção e foi muito interessante. Obrigado. Eu tenho uma pergunta para você.

Obrigado por compartilhar. Eu li muitos dos seus posts, legal, seu blog é muito bom.

Seu artigo me ajudou muito, existe mais algum conteúdo relacionado? Obrigado! https://www.binance.info/es/register?ref=T7KCZASX

Obrigado pela sua partilha. Estou preocupado porque me faltam ideias criativas. É o seu artigo que me deixa cheio de esperança. Obrigado. Mas, Eu tenho uma pergunta, pode me ajudar?

Não acho que o título do seu artigo corresponda ao conteúdo haha. Estou brincando, principalmente porque tive algumas dúvidas depois de ler o artigo. https://accounts.binance.com/en/register?ref=JHQQKNKN

Obrigado por compartilhar. Eu li muitos dos seus posts, legal, seu blog é muito bom.

Obrigado pela sua partilha. Estou preocupado porque me faltam ideias criativas. É o seu artigo que me deixa cheio de esperança. Obrigado. Mas, Eu tenho uma pergunta, pode me ajudar? https://www.binance.com/tr/register?ref=MST5ZREF

Você pode ser mais específico sobre o conteúdo do seu artigo? Depois de ler, ainda tenho algumas dúvidas. Espero que você possa me ajudar. https://www.binance.info/register?ref=IXBIAFVY

Reading your article helped me a lot and I agree with you. But I still have some doubts, can you clarify for me? I’ll keep an eye out for your answers. https://accounts.binance.info/zh-CN/register-person?ref=WFZUU6SI

Seu ponto de vista me chamou a atenção e foi muito interessante. Obrigado. Eu tenho uma pergunta para você.

Obrigado pela sua partilha. Estou preocupado porque me faltam ideias criativas. É o seu artigo que me deixa cheio de esperança. Obrigado. Mas, Eu tenho uma pergunta, pode me ajudar?

Você pode ser mais específico sobre o conteúdo do seu artigo? Depois de ler, ainda tenho algumas dúvidas. Espero que você possa me ajudar. https://accounts.binance.com/es-AR/register-person?ref=UT2YTZSU

So, I stumbled upon 98wn a while ago. Not gonna lie, it’s pretty basic but it did offer few decent games that I haven’t seen elsewhere. Worth checking to grab some unique experiences at 98wn.

Você pode ser mais específico sobre o conteúdo do seu artigo? Depois de ler, ainda tenho algumas dúvidas. Espero que você possa me ajudar. https://accounts.binance.com/register-person?ref=IHJUI7TF

**backbioma**

backbiome é um criado naturalmente, suplemento diário apoiado por pesquisas formulado para aliviar suavemente a tensão nas costas e aliviar o desconforto ciático.

Seu ponto de vista me chamou a atenção e foi muito interessante. Obrigado. Eu tenho uma pergunta para você.

**vivalis**

vivalis é uma fórmula natural premium criada para ajudar os homens a se sentirem mais fortes, mais enérgico, e mais confiante a cada dia.

**glicomute**

glicomute é uma fórmula nutricional natural cuidadosamente criada para nutrir níveis saudáveis de açúcar no sangue e apoiar o desempenho metabólico geral.

**balmorex pro**

balmorex é uma solução excepcional para indivíduos que sofrem de dores crônicas nas articulações e dores musculares.

**aquaescultura**

Aquasculpt é um suplemento revolucionário criado para ajudar no controle de peso, acelerando naturalmente o metabolismo

**calma nervosa**

nervocalm é um suplemento nutricional de alta qualidade elaborado para promover o bem-estar dos nervos, aliviar o desconforto crônico, e aumentar a vitalidade diária.

**sinadentix**

synadentix é um suplemento de saúde dentária criado para nutrir e proteger os dentes e gengivas com uma combinação direcionada de ingredientes naturais

**prostavivo**

prostavive Manter a saúde da próstata é crucial para o bem-estar geral dos homens, especialmente à medida que envelhecem.

**impulso alfa **

impulso alfa para homens, sentindo-se forte, energizado, e confiante está intimamente ligado à qualidade de vida geral. No entanto, com a idade, estresse, e demandas diárias

**yu sleep**

Yusleep é gentil, mistura noturna nano-aprimorada projetada para ajudá-lo a adormecer rapidamente, ficar dormindo por mais tempo, e acorde sentindo-se claro

**saindo**

prodentim é uma fórmula de cuidado bucal distinta que combina probióticos direcionados com ingredientes vegetais para estimular dentes fortes

**valeu pro**

glpro é um suplemento dietético natural desenvolvido para promover níveis equilibrados de açúcar no sangue e reduzir o desejo por açúcar.

**mindvault**

mindvault é uma fórmula premium de suporte cognitivo criada para adultos 45+.

**reforço nítrico **

nitric boost é uma mistura diária de bem-estar formulada para elevar a vitalidade e apoiar o desempenho geral.

**femipro**

femipro é um suplemento alimentar desenvolvido como remédio natural para mulheres que enfrentam problemas de controle da bexiga e buscam melhorar sua saúde urinária.

**Vertianos **

vertiaid é um software de alta qualidade, fórmula natural criada para apoiar o equilíbrio estável, melhorar a agudeza mental, e aliviar sentimentos de tontura

**vitrafoxina**

vitrafoxina é uma fórmula premium de aprimoramento do cérebro elaborada com ingredientes naturais para promover um pensamento claro, retenção de memória, e energia mental duradoura.

**glicose**

glucore é um suplemento nutricional administrado diariamente aos pacientes para ajudar a manter o açúcar no sangue e as taxas metabólicas saudáveis.

**doce**

sugarmute é um suplemento nutricional orientado pela ciência, criado para ajudar a manter o nível de açúcar no sangue equilibrado, ao mesmo tempo que apoia a energia estável e a clareza mental

**prime biome**

O ciclo natural de renovação celular da pele desempenha um papel vital na manutenção de uma aparência saudável e jovem, eliminando células velhas e gerando novas..

**hepatoqueimadura**

hepatoburn é um produto de alta qualidade, mistura dietética baseada em plantas criada para nutrir a função hepática, encorajar um ritmo metabólico saudável, e apoiar as vias naturais de processamento de gordura do corpo.

Você pode ser mais específico sobre o conteúdo do seu artigo? Depois de ler, ainda tenho algumas dúvidas. Espero que você possa me ajudar. https://accounts.binance.info/bg/register-person?ref=V2H9AFPY

**finessa**

Finessa is a natural supplement made to support healthy digestion, improve metabolism, and help you achieve a flatter belly.

Não acho que o título do seu artigo corresponda ao conteúdo haha. Estou brincando, principalmente porque tive algumas dúvidas depois de ler o artigo.

**mitolyn**

Mitolyn é um produto cuidadosamente desenvolvido, fórmula à base de plantas criada para ajudar a apoiar a eficiência metabólica e incentivar a saúde, controle de peso duradouro.

Obrigado por compartilhar. Eu li muitos dos seus posts, legal, seu blog é muito bom. https://accounts.binance.info/cs/register-person?ref=OMM3XK51

Seu artigo me ajudou muito, existe mais algum conteúdo relacionado? Obrigado! https://accounts.binance.info/register-person?ref=IHJUI7TF

Obrigado por compartilhar. Eu li muitos dos seus posts, legal, seu blog é muito bom. https://accounts.binance.com/it/register-person?ref=P9L9FQKY

Seu artigo me ajudou muito, existe mais algum conteúdo relacionado? Obrigado! https://accounts.binance.com/it/register-person?ref=P9L9FQKY

Seu ponto de vista me chamou a atenção e foi muito interessante. Obrigado. Eu tenho uma pergunta para você. https://www.binance.info/kz/register?ref=K8NFKJBQ

Seu artigo me ajudou muito, existe mais algum conteúdo relacionado? Obrigado! https://www.binance.info/ar-BH/register?ref=UT2YTZSU